Professional Documents

Culture Documents

Emulsion - Phase Inversion Composition - 2013 PDF

Uploaded by

onynhoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Emulsion - Phase Inversion Composition - 2013 PDF

Uploaded by

onynhoCopyright:

Available Formats

Article

pubs.acs.org/Langmuir

Highly Stable Concentrated Nanoemulsions by the Phase Inversion

Composition Method at Elevated Temperature

Lijie Yu, Chao Li, Jian Xu, Jingcheng Hao, and Dejun Sun*

Key Laboratory of Colloid and Interface Chemistry, Shandong University, Ministry of Education, Jinan, Shandong, 250100, P. R.

China

ABSTRACT: Oil-in-water nanoemulsions were produced in

the system water/Span 80Tween 80/paran oil via the

phase inversion composition (PIC) method at elevated

temperature. With the increase of preparation temperature

from 20 to 70 C, we found that the emulsion droplet

diameter decreases from 10.3 m to 51 nm, proving the

formation of nanoemulsions. The viscosity of nanoemulsions

clearly increases with droplet volume fraction, , but the

droplet size changes less. Signicantly, at 0.5, the size

distribution of nanoemulsions can be kept unchangeable more

than 5 months. These results proved that the highly viscous paran oil can hardly be dispersed by the PIC method at 25 C, but

the increase in preparation temperature makes it possible for producing monodisperse nanoemulsions. Once the nanoemulsion is

produced, the stability against Ostwald ripening is outstanding due to the extremely low solubility of the paran oil in the

continuous phase. The highly stable nanoemulsions are of great importance in practical applications.

INTRODUCTION

Emulsions with droplet diameter in the nanometer scale are

often referred to as nanoemulsions.1 Since emulsions are

thermodynamically unstable systems, energy input is required

for the formation of emulsions. Two main approaches are

currently used for the preparation of nanoemulsions: high

energy and low energy. For the high-energy method, intense

mechanical energy input is carried out by extreme shear stirring,

high-pressure homogenizers, or ultrasounds.25 One important

advantage of these methods is the emulsication of the highly

viscous oil phase such as silicon oil and long-chain

triglycerides.6,7 The size distribution of these nanoemulsions

has not changed over months due to the insolubility of the oil

phase in water.8 In addition, concentrated nanoemulsions could

be produced by the combination of high-pressure homogenization and repeated ultracentrifugal fractionation. The

disadvantage of the these methods is the high energy intensity

required to generate nanoemulsions with small droplets,

making this approach unfavorable for industrial applications.8

For the low-energy method, the chemical energy stored in

the components is used by changing the spontaneous curvature

of the surfactants. For nonionic surfactant systems, this can be

achieved by changing the temperature at constant composition,

i.e., phase inversion temperature, PIT method, or changing the

composition at constant temperature, i.e., phase inversion

composition, PIC method.9,10 The PIC method has a great

potential for scale-up applications because of the ease of

formation and relatively low energy costs. A phase transition is

produced by stepwise addition of water to a mixture of the

surfactant and oil for the formation of oil-in-water (O/W)

nanoemulsions. 11 This process is well-known for the

emulsication of short-chain alkanes prepared at 25 C.12

2012 American Chemical Society

However, the Ostwald ripening, i.e., the oil diusion in the

aqueous phase, causes nanoemulsions to break down in

relatively short time periods, which is the main limitation for

developing practical applications.13

Generally speaking, the production of monodisperse nanoemulsions with small droplet size and high kinetic stability is

attractive for both a theoretical and practical point of view. In

our previous work, the liquid paran-in-water nanoemulsions

were prepared via the PIC method at low temperature.14 The

emulsion droplet diameter grows slowly and remains less than

300 nm after 5 months of storage at room temperature.

Afterward, nanoemulsions were prepared via the PIT method

using a more viscous paran oil. The size distribution has not

changed more than 6 months.15,16 In this report we present a

complete study on the formation and stability of nanoemulsions made via the PIC method using the viscous paran

oil. This study explored the inuence of emulsication

temperature, HLB value, and droplet volume fraction. These

results demonstrate that the PIC method at elevated temperature is of great signicance in nanoemulsion formation and

long-term stability.

EXPERIMENTAL SECTION

Materials. The paran oil (d25 = 0.86, chemically pure grade),

Sorbitan monooleate (Span 80, chemically pure grade), and

polyoxyethylene (20) sorbitan monooleate (Tween 80, chemically

pure grade) were obtained from Sinopharm Chemical Reagent Co.,

Ltd. The components of this paran oil are mainly isoalkenes with

Received: July 24, 2012

Revised: September 14, 2012

Published: September 18, 2012

14547

dx.doi.org/10.1021/la302995a | Langmuir 2012, 28, 1454714552

Langmuir

Article

2033 carbon atoms, as measured with an Agilent 7890 GC (Agilent

Co.). All reagents were used as received without further purication.

Water used in this work was deionized water.

Preparation of Nanoemulsions. Before emulsication, the

surfactants (Span 80 and Tween 80) were dissolved into the oil

phase under magnetic stirring. The surfactantoil mixture and water

were placed separately in a water bath at the desired temperature.

Then the water phase was added dropwise to the oil solution. After the

emulsication, the samples were immediately poured into colorimetric

cylinders and cooled at ambient temperature (20 C). The inuence

of composition parameters, including the oil-to-surfactant weight ratio

(O/S) and the droplet volume fraction (), was investigated

systematically. Moreover, the formation of nanoemulsions depends

not only on composition variations but also on preparation

conditions.17,18 So the experimental parameters were maintained

constant at a stirring rate of 600 rpm and an addition rate of 2 mL/

min.

Droplet Size Determination. Nanoemulsion droplet size and

distribution were determined by dynamic light scattering (DLS,

using a Brookhaven BI-200SM instrument). A 200 mW green laser (

= 532 nm) with variable intensity was used, and measurements were

carried out at room temperature with a scattering angle of 90. The

emulsion was diluted about 1000 times with deionized water just

before the measurements. The average radius and polydispersity index

were calculated from the intensity autocorrelation data with the

cumulants method. The intensityintensity time correlation functions

were analyzed by the CONTIN method.19

The morphology of macroemulsion droplets was observed with an

Axioskop 40 optical microscope (ZEISS, Germany). The size

distribution was obtained by processing the picture using the

microscopic image analysis software.

Long-Term Stability Test. The long-term stability of nanoemulsions

was assessed by measuring the change of droplet size with time of

storage. The samples were kept sealed at room temperature.

Interfacial Tension Measurements. The interfacial tension

between water and surfactant-in-oil solution was measured by the

spinning drop interfacial tension meter of Model TX500C, which can

be used in a wide range of measurements, 105102 mN m1.

Experiments were carried out with special care to avoid water

evaporation.

Rheological Measurements. Rheological measurements were

carried out on a HAAKE RS 6000 rheometer with a coneplate

geometry at 25 C. The diameter and the cone angle of the cone

plate were 35 mm and 1, respectively. In a steady shear experiments,

the shear rate was typically increased form 1 to 1000 s1 within 5 min.

Electrical Conductivity. Appropriate amounts of oil, surfactants,

and water (0.01 mol/L NaCl was added for the conductivity

determinations) were mixed at room temperature using a magnetic

stirrer. The specic conductivity of samples was measured as a

function of temperature by means of a DDS-307 conductometer with a

Pt/platinized electrode.

Figure 1. Eect of emulsication temperature on emulsion droplet

diameter and interfacial tension for samples with O/S = 1:1 and =

0.1. The dashed lines are used as a guide to the eye.

preparation temperature, the interfacial tension decreases and

the amount of surfactant molecules adsorbed at the O/W

interface increases gradually. At elevated temperatures (70

C), the surfactant adsorption reaches saturation.

Eect of Composition at Elevated Temperature. As

stated above, the droplet size distributions remain unchanged

when the emulsions are prepared at 70, 80, and 90 C. The

temperature of preparation is xed at 70 C for further

investigations. In this section, we examined the inuence of

HLB value and O/S on nanoemulsion formation.

When the emulsion is stabilized by a mixture of nonionic

surfactants, the mixed HLB value is considered to be the

algebraic average of the HLB value of the individual surfactants.

In other words, the variation in the mixed HLB values was

calculated according to the relationship

HLBmix = HLBA A% + HLBB B%

(1)

where HLBmix is the HLB value of the mixed surfactants,

HLBA/B is the HLB value of surfactant A or B, and A% and B%

are the weight percentages of A and B, respectively. All the

HLB values used are obtained at 25 C.

The HLBmix has little eect on the size distributions of

nanoemulsions obtained by the PIT method.20,21 In contrast,

the droplet diameter prepared by the PIC method depends on

both the surfactant mixing ratio and the preparation temperature.22,23 Figure 2 shows the inuence of HLB value on

emulsion droplet size. Corresponding to the minimum droplet

size, there is an optimum HLB region around 10 to 11. In the

following work the eect of O/S was investigated and the

HLBmix of Span 80 and Tween 80 was xed at 10.3 for

simplication. Furthermore, when the emulsions are produced

RESULTS AND DISCUSSION

Eect of Emulsication Temperatures at Fixed

Composition. The droplet diameter of the nanoemulsions

as a function of the preparation temperature is shown in Figure

1. Droplet diameter decreases from 10.3 m to 51 nm with the

increase of emulsication temperature at a constant composition (O/S = 1:1, = 0.1). Macroemulsions with high

polydispersities were obtained when the emulsions were

prepared at 20 or 30 C. The droplet size and polydispersity

decrease dramatically with the increase of emulsication

temperature from 20 to 70 C and remain unchanged with a

further increase in the temperature. Figure 1 also shows the

curve of interfacial tension, which is similar to that of droplet

size. This means that nanoemulsions cannot be obtained at low

temperature due to the relatively high interfacial tension and

the high viscous resistance of the oil phase. With the increase of

Figure 2. Droplet size as a function of the HLB value for samples with

O/S = 1:1 and = 0.1. The dashed lines are used as a guide to the eye.

14548

dx.doi.org/10.1021/la302995a | Langmuir 2012, 28, 1454714552

Langmuir

Article

dispersed phase (0 < 0.25). The eect of on the droplet

size distribution has been studied less frequently because of the

disadvantage on storage stability especially when the droplets

are concentrated.

In this system, the concentrated nanoemulsions were

produced by simply reducing the amount of water addition

during the emulsication process. The droplet volume fraction,

given by the oil volume fraction plus the surfactant volume

fraction, was varied from 0.1 to 0.62 (Figure 4). The droplet

below 30 C macroemulsions are obtained, yet at 70 C the

droplet diameter remains less than 150 nm over the entire HLB

range investigated. These results prove that the PIC method at

elevated temperature is a meaningful way to produce

nanoemulsions.

We examined the inuence of O/S on emulsion diameter

and polydispersity index of nanoemulsions, as presented in

Figure 3. The droplet diameter increases from 51 to 191 nm as

Figure 3. Evolution of the droplet diameter () and polydispersity

index () of nanoemulsions as a function of oil/surfactant weight

ratio. The dashed lines are used as a guide to the eye.

Figure 4. Variations of droplet diameter () and polydispersity index

() of emulsions as a function of . The dashed lines are used as a

guide to the eye. The solid line indicates the maximally random

jammed volume (MRJ) for monodisperse spheres.

the O/S increases from 1:1 to 4:1. This variation tendency

agrees with those reported earlier by the PIC method prepared

at 25 C.10,18,22 At low O/S the polydispersity index is less than

0.2, which reects a good monodispersity of the nanoemulsions.

Studies on nanoemulsion preparation by low-energy

methods have shown that the key to nanoemulsion formation

could be attributed to the phase transitions occurred during the

emulsication process.11,24,25 The droplet size is governed by

the surfactant phase structure (bicontinuous microemulsion or

liquid crystal phase) at the inversion point induced by either

temperature or composition.1,26,27 However, as is shown in

many literatures,9,28 the purity of all the components is

extremely important in the phase behavior investigation. The

response to temperature in systems with technical grade

surfactants could be completely dierent from that of the pure

system because the partition of surfactant homologues between

water and oil is distinct from each other. The technical grade

surfactants and oil phase used in this system makes it less

meaningful to investigate the phase behavior at dierent

temperatures. So we observed the appearance change with

water addition at 20 and 70 C. When the samples are

equilibrated at 70 C within the experimental O/S region, an

inverse microemulsion phase gradually transforms to an

isotropic bluish bicontinuous microemulsion as water concentration increases. In contrast, when the samples are kept at 20

C, the isotropic microemulsion gradually transforms to a white

gel phase. The change in the natural curvature of the surfactants

during the emulsication process is responsible for the uniform

nanoemulsion formation at elevated temperatures.

Formation of Concentrated Nanoemulsions. In highenergy methods, monodisperse nanoemulsions can be formed

over a wide range of droplet volume fraction (0 < 0.6) by

the combination of high-pressure homogenization and repeated

ultracentrifugal fractionation at 18 000 rpm for 3 h.3,4 The size

distribution of these emulsions has not changed over months.

However, using low-energy methods,10,28,29 most nanoemulsions are prepared at relatively low volume fractions of the

diameter remains less than 58 nm when O/S is xed at 1:1. In

addition, similar patterns were obtained at other O/S ratios.

For instance, the droplet size remains less than 197 nm when

O/S is xed at 4:1. These results demonstrate that the

individual oil droplets do not depend on the dilution of water

once they have been formed. The droplet size is mainly

governed by the structure of the bicontinuous phase during the

phase inversion. Excess water acts only as a dilution medium.

This is in agreement with the literature data28 showing that for

emulsions produced by the PIT method. The slight increase of

the polydispersity index might be attributed to the weak

interactions between oil droplets.

The droplet diameter of the emulsion with = 0.62 is

slightly larger than those of emulsions with lower internal phase

volume fractions. The solid line in Figure 4 marks the

maximally random jammed (MRJ) state for monodisperse

spheres with a packing fraction of MRJ 0.64.30 Mason et al.7

proposed that at high the deform droplets are packed into

foam-like structures. Wilking et al. 8 demonstrated the

disruption of droplet aggregates of concentrated nanoemulsions

into individual droplets by high shear ows using rheological

small-angle neutron scattering. In this case, the increase in

droplet size of the emulsion with = 0.62 might be due to the

droplet deformation and/or the formation of tumbling clusters.

When 0.7, a white gel instead of the translucent

nanoemulsion was observed, which was an indication of

phase inversion.

Figure 5 shows the shear rate dependence of the viscosities of

nanoemulsions with dierent droplet volume fractions.

Emulsions with 0.4 exhibit strong shear-thinning behavior.

With the increase of shear rate, the structure of the

nanoemulsions (i.e., the arrangement of droplets) is gradually

destroyed and locally dense clusters are disrupted into

individual droplets.8 Samples with 0.3 behave like the

Newtonian ows. This result indicates that the cluster

14549

dx.doi.org/10.1021/la302995a | Langmuir 2012, 28, 1454714552

Langmuir

Article

advantages of the PIC method are as follows: (i) Nanoemulsions could be obtained over a wide range of preparation

temperature. The droplet diameter is below 100 nm when the

temperature is above 50 C in the PIC method, as shown in

Figure 1. But the emulsication in the PIT method should be

xed to a temperature close to THLB. (ii) The temperature

quench after preparation is not necessary in the PIC method.

As stated above, nanoemulsions were poured into colorimetric

cylinders and cooled at ambient temperature. In contrast, using

the PIT method, the samples should be quickly transferred to

an ice bath, and a constant stirring is necessary in many

systems.15,16,32,33 (iii) The eciency of emulsication is

improved by the PIC method. When the emulsion with a

volume of 20 mL was prepared by the PIC method at elevated

temperature, the total emulsication process was carried out

within less than 10 min, whereas the same sample should be

equilibrated at THLB for more than 30 min before the

temperature quench in this system using the PIT method.

High Stability. Ostwald ripening is usually considered to be

the major destabilization mechanism of nanoemulsions. It arises

from the fact that oil solubility increases with decreasing droplet

size. Large droplets grow at the expense of small ones in

polydisperse emulsions due to molecular diusion of the oil

through the continuous phase. The rate of Ostwald ripening

can be obtained by LSW (LifshitzSlezovWagner) theory:34

Figure 5. Shear viscosity as a function of shear rate for emulsions with

dierent dispersed phase volume fractions.

aggregations and interdroplet attractions are weak in the highly

diluted nanoemulsions.

Figure 6 shows the variation of conductivity with temperature for samples with O/S of 1:1 and dierent droplet volume

dr 3

8 CVmD

=

dt

9 RT

(2)

where r is the average droplet radius, t is the storage time, C is

the bulk phase solubility, is the interfacial tension, Vm is the

molar volume of the oil, D is the diusion coecient of the oil

phase in the continuous phase, R is the gas constant, and T is

the absolute temperature. Equation 2 predicts a linear

relationship between the cube of the radius and time.

The main limitation for developing nanoemulsion applications is the relatively low stability. When the emulsication was

produced by high-energy methods, the stability of nanoemulsions could be improved by increasing the oil viscosity,

corresponding to the decrease in C. The size distributions of

these nanoemulsions have not changed over months.6,8 But the

disadvantages of these methods are the high energy cost and

viscous heating.35 For instance, the high-pressure homogenizers

generally work in the pressure range between 50 and 100 MPa.1

When nanoemulsions were prepared using low-energy

methods, the eect of carbon number of various n-alkanes on

nanoemulsion formation and stability has been investigated.31,36,37 The Ostwald ripening is suppressed by the

increase in carbon chain length owing to the decrease of oil

solubility in water.37 Nevertheless, the initial droplet size

increases with the increase in hydrocarbon alkyl chain length

due to the increase in the interfacial tension and oil viscosity. In

brief, it is dicult to obtain highly kinetically stable

nanoemulsions with remarkably small droplet sizes by lowenergy methods.

In our previous work,14 nanoemulsions could be obtained by

the PIC method below 50 C because the liquid paran is

mainly constituted of short-chain isoalkanes (C15 to C26). In

this paper the paran oil is mainly constituted of long-chain

isoalkanes (C20 to C33), which makes the dispersed phase hard

to be emulsied by the PIC method at low temperatures

(Figure 1). Further increase in preparation temperature makes

it possible to produce monodisperse nanoemulsions. The

stability of these nanoemulsions was assessed by following the

Figure 6. Conductivity as a function of temperature for samples with

dierent droplet volume fractions. The dashed lines are used as a guide

to the eye.

fractions. Independent of , with the increase of temperature

the conductivity initially increases slightly and after a certain

point decreases suddenly, reaching very low values. This

indicates that the inversion from an O/W to a W/O emulsion

takes place. The HLB temperature, THLB, was taken as the

average value between the maximum and the minimum values

of conductivity. The reduction of THLB with may be

attributed to the impurity of the surfactants.11,12,21

In nonionic surfactant systems, when nanoemulsions are

prepared by the PIC method at 25 C, the THLB of the systems

is usually lower than 50 C.9,12,20 It is well-known that near the

THLB the interfacial tension reaches a minimum.31 In this way

the PIC process can make use of the low interfacial tension.

However, coalescence rate is extremely fast around the THLB. So

the droplet size of these emulsions grows fast and the

nanoemulsions break down in days. In our system nanoemulsions cannot be obtained at 25 C because the interfacial

tension is relatively high and the THLB is above 70 C. The

emulsication at elevated temperatures takes advantage of the

minimum interfacial tension and makes it possible to produce

nanoemulsions. Moreover, the storage stability of emulsions at

room temperature is improved by avoiding coalescence around

the THLB. In brief, the THLB can be used to guide the

emulsication temperature of the PIC method.

Although the droplet diameters prepared by this method are

similar to those obtained using the PIT method,15,16 the

14550

dx.doi.org/10.1021/la302995a | Langmuir 2012, 28, 1454714552

Langmuir

Article

applications. It is noteworthy that although the stability of our

nanoemulsions is similar to that of microemulsions, there is a

distinct dierence between them. Because the structure of these

nanoemulsions is highly dependent on the method used to

prepare them,38 consequently the PIC method at elevated

temperature is an excellent alternative for the formation of

stable nanoemulsions. Further eort is required to investigate

the emulsication of other highly viscous oil phases and the

application of these concentrated nanoemulsions.

change in droplet diameters with time of storage at room

temperature (20 C), as summarized in Figure 7. The size

CONCLUSIONS

AUTHOR INFORMATION

Paran oil-in-water nanoemulsions have been obtained by the

PIC method at elevated temperatures. The increase in

preparation temperature enhances the surfactant adsorption at

the O/W interface and reduces the viscous resistance of the oil

phase. As a result, the droplet diameter decreases dramatically

with the increase in emulsication temperature. The droplet

diameter is mainly governed by the structure of microemulsion

during the emulsication process, and excess water acts only as

a dilution medium. In brief, nanoemulsions could be obtained

over a wide range of temperature and droplet volume fractions.

Once formed, the size distributions of nanoemulsions have not

changed over 5 months. The insolubility of the oil phase in the

continuous phase prevented the Ostwald ripening process. The

PIC method at elevated temperature is an attractive alternative

for preparation of nanoemulsions since this method leads to

formation of concentrated nanoemulsions with long-term

stability.

Figure 7. Droplet size as a function of time for samples prepared at

dierent emulsication temperatures and stored at 20 C (O/S = 1:1

and = 0.1).

distributions of nanoemulsions prepared at elevated temperatures have not changed over 5 months. In addition,

nanoemulsions prepared within the experimental O/S region

(Figure 3) also remained stable during the same storage time

(data not shown). In recent literature it has been presented that

the Ostwald ripening rate could be reduced by the addition of a

second, less soluble, component to the dispersed phase.6,34 It is

deduced that the components with long-chain hydrocarbons

could help enhance the stability against Ostwald ripening.

Figure 8 shows the eect of droplet volume fraction on the

stability of nanoemulsions stored at ambient temperature. The

Corresponding Author

*E-mail djsun@sdu.edu.cn; Tel +86-531-88364749; Fax +86531-88364750.

Notes

The authors declare no competing nancial interest.

ACKNOWLEDGMENTS

This work was nancially supported by the Key Project of

Chinese National Programs for Fundamental Research and

Development (973 Program, No. 2009CB930103).

Figure 8. Droplet size as a function of time for samples with dierent

droplet volume fractions.

REFERENCES

(1) Solans, C.; Izquierdo, P.; Nolla, J.; Azemar, N.; Garcia-Celma, M.

J. Nano-emulsions. Curr. Opin. Colloid Interface Sci. 2005, 10, 102

110.

(2) Nakabayashi, K.; Amemiya, F.; Fuchigami, T.; Machida, K.;

Takeda, S.; Tamamitsu, K.; Atobe, M. Highly Clear and Transparent

Nanoemulsion Preparation under Surfactant-Free Conditions using

Tandem Acoustic Emulsification. Chem. Commun. 2011, 47, 5765

5767.

(3) Meleson, K.; Graves, S.; Mason, T. G. Formation of

Concentrated Nanoemulsions by Extreme Shear. Soft Mater. 2004,

2, 109123.

(4) Graves, S.; Meleson, K.; Wilking, J.; Lin, M. Y.; Mason, T. G.

Structure of Concentrated Nanoemulsions. J. Chem. Phys. 2005, 122,

134703.

(5) Mason, T. G.; Graves, S. M.; Wilking, J. N.; Lin, M. Y. Effective

Structure Factor of Osmotically Deformed Nanoemulsions. J. Phys.

Chem. B 2006, 110, 2209722102.

(6) Wooster, T. J.; Golding, M.; Sanguansri, P. Impact of Oil Type

on Nanoemulsion Formation and Ostwald Ripening Stability.

Langmuir 2008, 24, 1275812765.

size of the sample with = 0.62 increases with storage and the

appearance of the emulsion gradually changed from translucent

to opaque white. A free oil phase was present above the

emulsion surface after 50 days. It may be due to the close

packing of droplets, the formation of tumbling clusters, and the

subsequent phase separation.

To the best of our knowledge, few reports have been

published on the stable concentrated nanoemulsions obtained

by low-energy methods. In this system, the droplet diameters of

nanoemulsions with in the range between 0.1 and 0.5 have

not changed over 5 months. The Ostwald ripening process is

almost prevented taking the advantage of long-chain hydrocarbon oil. This is of great signicance from an applied point of

view. The stability of these concentrated nanoemulsions could

essentially satisfy the stability requirements in most practical

14551

dx.doi.org/10.1021/la302995a | Langmuir 2012, 28, 1454714552

Langmuir

Article

(7) Mason, T. G.; Wilking, J. N.; Meleson, K.; Chang, C. B.; Graves,

S. M. Nanoemulsions: Formation, Structure, and Physical Properties. J.

Phys.: Condens. Matter 2006, 18, 635666.

(8) Wilking, J. N.; Chang, C. B.; Fryd, M. M.; Porcar, L.; Mason, T.

G. Shear-Induced Disruption of Dense Nanoemulsion Gels. Langmuir

2011, 27, 52045210.

(9) Roger, K.; Cabane, B.; Olsson, U. Emulsification through

Surfactant Hydration: The PIC Process Revisited. Langmuir 2011, 27,

604611.

(10) Maestro, A.; Sole, I.; Gonzalez, C.; Solans, C.; Gutierrez, J. M.

Influence of the Phase Behavior on the Properties of Ionic

Nanoemulsions Prepared by the Phase Inversion Composition

Method. J. Colloid Interface Sci. 2008, 327, 433439.

(11) Forgiarini, A.; Esquena, J.; Gonzalez, C.; Solans, C. Studies of

the Relation between Phase Behavior and Emulsification Methods

with Nanoemulsion Formation. Prog. Colloid Polym. Sci. 2000, 115,

3639.

(12) Forgiarini, A.; Esquena, J.; Gonzalez, C.; Solans, C. Formation

of Nano-emulsions by Low-energy Emulsification Methods at

Constant Temperature. Langmuir 2001, 17, 20762083.

(13) Gutierrez, J. M.; Gonzalez, C.; Maestro, A.; Sole, I.; Pey, C. M.;

Nolla, J. Nano-emulsions: New Applications and Optimization of

Their Preparation. Curr. Opin. Colloid Interface Sci. 2008, 13, 245251.

(14) Liu, W.; Sun, D.; Li, C.; Liu, Q.; Xu, H. Formation and Stability

of Paraffin Oil-in-water Nano-emulsions Prepared by the Emulsion

Inversion Point Method. J. Colloid Interface Sci. 2006, 303, 557563.

(15) Mei, Z.; Xu, J.; Sun, D. O/W Nano-emulsions with Tunable PIT

Induced by Inorganic Salts. Colloids Surf., A 2011, 375, 102108.

(16) Mei, Z.; Liu, S.; Wang, L.; Jiang, J.; Xu, J.; Sun, D. Preparation of

Positively Charged Oil/water Nano-emulsions with a Sub-PIT

Method. J. Colloid Interface Sci. 2011, 361, 565572.

(17) Sole, I.; Pey, C. M.; Maestro, A.; Gonzalez, C.; Porras, M.;

Solans, C.; Gutierrez, J. M. Nano-emulsions Prepared by the Phase

Inversion Composition Method: Preparation Variables and Scale Up. J.

Colloid Interface Sci. 2010, 344, 417423.

(18) Sole, I.; Maestro, A.; Gonzalez, C.; Solans, C.; Gutierrez, J. M.

Optimization of Nano-emulsion Preparation by Low-energy Methods

in an Ionic Surfactant System. Langmuir 2006, 22, 83268332.

(19) Ju, R. T. C.; Frank, C. W.; Gast, A. P. CONTIN Analysis of

Colloidal Aggregates. Langmuir 1992, 8, 21652171.

(20) Forgiarini, A.; Esquena, J.; Gonzalez, C.; Solans, C. Formation

and Stability of Nano-emulsions in Mixed Nonionic Surfactant

Systems. Prog. Colloid Polym. Sci. 2001, 118, 184189.

(21) Izquierdo, P.; Feng, J.; Esquena, J.; Tadros, T. F.; Dederen, J. C.;

Garcia, M. J.; Azemar, N.; Solans, C. The Influence of Surfactant

Mixing Ratio on Nano-emulsion Formation by the PIT Method. J.

Colloid Interface Sci. 2005, 285, 388394.

(22) Pey, C. M.; Maestro, A.; Sole, I.; Gonzalez, C.; Solans, C.;

Gutierrez, J. M. Optimization of Nano-emulsions Prepared by Lowenergy Emulsification Methods at Constant Temperature Using a

Factorial Design Study. Colloids Surf., A 2006, 288, 144150.

(23) Hessien, M.; Singh, N.; Kim, C.; Prouzet, E. Stability and

Tunability of O/W Nanoemulsions Prepared by Phase Inversion

Composition. Langmuir 2011, 27, 22992307.

(24) Izquierdo, P.; Esquena, J.; Tadros, T. F.; Dederen, J. C.; Feng, J.;

Garcia-Celma, M. J.; Azemar, N.; Solans, C. Phase Behavior and Nanoemulsion Formation By the Phase Inversion Temperature Method.

Langmuir 2004, 20, 65946598.

(25) Morales, D.; Solans, C.; Gutierrez, J. M.; Garcia-Celma, M. J.;

Olsson, U. Oil/water Droplet Formation by Temperature Change in

the Water/C16E6/Mineral Oil System. Langmuir 2006, 22, 3014

3020.

(26) Fernandez, P.; Andre, V.; Rieger, J.; Kuhnle, A. Nano-emulsion

Formation by Emulsion Phase Inversion. Colloids Surf., A 2004, 251,

5358.

(27) Wang, L.; Li, X.; Zhang, G.; Dong, J.; Eastoe, J. Oil-in-water

Nanoemulsions for Pesticide Formulations. J. Colloid Interface Sci.

2007, 314, 230235.

(28) Morales, D.; Gutierrez, J. M.; Garcia-Celma, M. J.; Solans, Y. C.

A Study of the Relation Between Bicontinuous Microemulsions and

Oil/water Nano-emulsion Formation. Langmuir 2003, 19, 71967200.

(29) Wang, L.; Mutch, K. J.; Eastoe, J.; Heenan, R. K.; Dong, J.

Nanoemulsions Prepared by a Two-Step Low-Energy Process.

Langmuir 2008, 24, 60926099.

(30) Donev, A.; Cisse, I.; Sachs, D.; Variano, E.; Stillinger, F. H.;

Connelly, R.; Torquato, S.; Chaikin, P. M. Improving the Density of

Jammed Disordered Packings Using Ellipsoids. Science 2004, 303,

990993.

(31) Tadros, T.; Izquierdo, R.; Esquena, J.; Solans, C. Formation and

Stability of Nano-emulsions. Adv. Colloid Interface Sci. 2004, 108, 303

318.

(32) Roger, K.; Cabane, B.; Olsson, U. Formation of 10100 nm

Size-Controlled Emulsions through a Sub-PIT Cycle. Langmuir 2009,

26, 38603867.

(33) Rao, J.; McClements, D. J. Stabilization of Phase Inversion

Temperature Nanoemulsions by Surfactant Displacement. J. Agric.

Food Chem. 2010, 58, 70597066.

(34) Taylor, P. Ostwald Ripening in Emulsions. Adv. Colloid Interface

Sci. 1998, 75, 107163.

(35) Fryd, M. M.; Mason, T. G. Advanced Nanoemulsions. Annu.

Rev. Phys. Chem. 2012, 63, 493518.

(36) Izquierdo, P.; Esquena, J.; Tadros, T. F.; Dederen, C.; Garcia,

M. J.; Azemar, N.; Solans, C. Formation and Stability of Nanoemulsions Prepared Using the Phase Inversion Temperature Method.

Langmuir 2002, 18, 2630.

(37) Taylor, P. Ostwald Ripening in Emulsions: Estimation of

Solution Thermodynamics of the Disperse Phase. Adv. Colloid Interface

Sci. 2003, 106, 261285.

(38) McClements, D. J. Nanoemulsions versus Microemulsions:

Terminology, Differences, and Similarities. Soft Matter 2012, 8, 1719

1729.

14552

dx.doi.org/10.1021/la302995a | Langmuir 2012, 28, 1454714552

You might also like

- Stăniloae, Dumitru Theology and The ChurchDocument240 pagesStăniloae, Dumitru Theology and The Churchonynho100% (2)

- Ozone Depletion, Ultraviolet Radiation, Climate Change and Prospects For A Sustainable FutureDocument11 pagesOzone Depletion, Ultraviolet Radiation, Climate Change and Prospects For A Sustainable FutureonynhoNo ratings yet

- Ozone Depletion, Ultraviolet Radiation, Climate Change and Prospects For A Sustainable FutureDocument11 pagesOzone Depletion, Ultraviolet Radiation, Climate Change and Prospects For A Sustainable FutureonynhoNo ratings yet

- CV TT Brad-FachDocument2 pagesCV TT Brad-FachonynhoNo ratings yet

- Magnetite Coprecipitation MechanimDocument8 pagesMagnetite Coprecipitation MechanimonynhoNo ratings yet

- CV - Christoph - Pittius - CV - 2011 PDFDocument3 pagesCV - Christoph - Pittius - CV - 2011 PDFonynhoNo ratings yet

- Magnetite Coprecipitation 8Document8 pagesMagnetite Coprecipitation 8onynhoNo ratings yet

- Biocompatibility+Distribution of NanoparticlesDocument12 pagesBiocompatibility+Distribution of NanoparticlesonynhoNo ratings yet

- Magnetite Coprecipitation 8Document8 pagesMagnetite Coprecipitation 8onynhoNo ratings yet

- Synthesis and Magnetic Properties of Cobalt Ferrite (Cofe O) Nanoparticles Prepared by Wet Chemical RouteDocument18 pagesSynthesis and Magnetic Properties of Cobalt Ferrite (Cofe O) Nanoparticles Prepared by Wet Chemical Routeprabhjot100No ratings yet

- Biosensors Electrochemical 2008Document7 pagesBiosensors Electrochemical 2008onynhoNo ratings yet

- Drug Delivery Magnetic Nanoparticle 2013Document12 pagesDrug Delivery Magnetic Nanoparticle 2013onynhoNo ratings yet

- Emulsion Phase Inversion Temperature Shinoda 1964Document6 pagesEmulsion Phase Inversion Temperature Shinoda 1964onynhoNo ratings yet

- Drug Delivery Magnetic Nanoparticle Review 2009Document8 pagesDrug Delivery Magnetic Nanoparticle Review 2009onynhoNo ratings yet

- Atherosclerosis Detection Methods Biochemical Markers 2006Document12 pagesAtherosclerosis Detection Methods Biochemical Markers 2006onynhoNo ratings yet

- Magnetite Coprecipitation MechanimDocument8 pagesMagnetite Coprecipitation MechanimonynhoNo ratings yet

- Magnetite Coprecipitation 9 PDFDocument7 pagesMagnetite Coprecipitation 9 PDFonynhoNo ratings yet

- Synthesis and Surface Engineering of Iron Oxide Nano ParticlesDocument27 pagesSynthesis and Surface Engineering of Iron Oxide Nano Particlesnik-dimNo ratings yet

- Magnetite Coprecipitation 8Document8 pagesMagnetite Coprecipitation 8onynhoNo ratings yet

- 2064-2110 - Magnetic Iron Oxide Nanoparticles - Synthesis, Stabilization, VectorizationDocument47 pages2064-2110 - Magnetic Iron Oxide Nanoparticles - Synthesis, Stabilization, Vectorizationehagar60No ratings yet

- Drug Delivery Magnetic Nanoparticle Bookchapter 2012Document36 pagesDrug Delivery Magnetic Nanoparticle Bookchapter 2012onynhoNo ratings yet

- Ferrite 2015Document9 pagesFerrite 2015onynhoNo ratings yet

- Biosensors Electrochemical 2011Document20 pagesBiosensors Electrochemical 2011onynhoNo ratings yet

- Drug Delivery Magnetic Nanoparticle Review 2013Document12 pagesDrug Delivery Magnetic Nanoparticle Review 2013onynhoNo ratings yet

- Magnetite Preparation 2004Document9 pagesMagnetite Preparation 2004onynhoNo ratings yet

- Magnetic Nanoparticles Synthesis, Protection, Functionalization, and ApplicationDocument23 pagesMagnetic Nanoparticles Synthesis, Protection, Functionalization, and Applicationl0ngfellowNo ratings yet

- Cell Isolation PHDDocument129 pagesCell Isolation PHDonynhoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chapter 12: Partial Differential EquationsDocument11 pagesChapter 12: Partial Differential EquationsDark bOYNo ratings yet

- CS TheoryDocument403 pagesCS TheoryAnonymous scnl9rHNo ratings yet

- Catalogo Generale Marston PDFDocument40 pagesCatalogo Generale Marston PDFANo ratings yet

- Sanyo Alarm Codes PDFDocument6 pagesSanyo Alarm Codes PDFomarNo ratings yet

- Masterspec Copper SpecificationDocument10 pagesMasterspec Copper SpecificationNabil RamehNo ratings yet

- History of Photo Volatic CellDocument12 pagesHistory of Photo Volatic CellKarthick ThiyaguNo ratings yet

- Transpiration ResourceDocument33 pagesTranspiration ResourceGgdhdgsg KdhahshhNo ratings yet

- Tech Memo - y FactorDocument4 pagesTech Memo - y FactorsumitrochakrabortiNo ratings yet

- Tutorial 17 Rapid DrawdownDocument17 pagesTutorial 17 Rapid DrawdownJustoArteagaHuacchaNo ratings yet

- Mullarney Sweeteners Used in Chewable TabletsDocument10 pagesMullarney Sweeteners Used in Chewable TabletsKatherine PosadaNo ratings yet

- Biochemistry of Connective Tissue DentistrykopptxDocument97 pagesBiochemistry of Connective Tissue DentistrykopptxAbdullah Khalid VirkNo ratings yet

- AbrasionDocument18 pagesAbrasionNiño Bryan Talibong AceroNo ratings yet

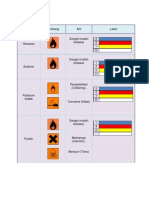

- Manufacture of LithoponeDocument10 pagesManufacture of LithoponeSharon K Thomas50% (2)

- Installation Dresser MeterDocument32 pagesInstallation Dresser MeterCoco GalindoNo ratings yet

- Venair - Tubo Vena (En)Document2 pagesVenair - Tubo Vena (En)TelxinaNo ratings yet

- New Piping Flexibility Rules in ASME B31.3 AppendixP - Becht & Diehl - ASME - 2006Document5 pagesNew Piping Flexibility Rules in ASME B31.3 AppendixP - Becht & Diehl - ASME - 2006Alvin SmithNo ratings yet

- Estimation of Glucose Concentration PDFDocument3 pagesEstimation of Glucose Concentration PDFAmiel DionisioNo ratings yet

- CE 308 - Lec 8 - Admixtures - 2Document22 pagesCE 308 - Lec 8 - Admixtures - 2umair4362No ratings yet

- Journal Type (Thesis)Document12 pagesJournal Type (Thesis)api-19649313No ratings yet

- Combustion Chemstry1Document6 pagesCombustion Chemstry1Dr Mohammad AlzoubyNo ratings yet

- Renolit So-Gfb: Description AdvantagesDocument3 pagesRenolit So-Gfb: Description AdvantagesAhmed El TayebNo ratings yet

- 5070 s04 QP 4Document16 pages5070 s04 QP 4mstudy123456No ratings yet

- AISI1040Document2 pagesAISI1040Anonymous qRbPsLpuNNo ratings yet

- Tube Repair and Protection For DamageDocument112 pagesTube Repair and Protection For Damagesandipwarbhe1234100% (1)

- Landing GearDocument6 pagesLanding GearMureithi SamNo ratings yet

- Mean Activity Coefficients of Electrolytes As A Function of ConcentrationDocument4 pagesMean Activity Coefficients of Electrolytes As A Function of ConcentrationLuis CarlosNo ratings yet

- Nutrition of The Tamandua I. Nutrient Composition of Termites and Stomach Contents From Wild TAMANDUA BANDEIRA PDFDocument16 pagesNutrition of The Tamandua I. Nutrient Composition of Termites and Stomach Contents From Wild TAMANDUA BANDEIRA PDFgabrielwerneckNo ratings yet

- Organic Chemistry I - Simple Book PublishingDocument9 pagesOrganic Chemistry I - Simple Book PublishingMandyNo ratings yet

- Lec1 PDFDocument3 pagesLec1 PDFusmanNo ratings yet

- K3Document5 pagesK3Dani SetiawanNo ratings yet