Professional Documents

Culture Documents

Saic-W-2xxx-15 Pre Welding & Joint Fit-Up Inspection

Uploaded by

Ansuman KalidasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic-W-2xxx-15 Pre Welding & Joint Fit-Up Inspection

Uploaded by

Ansuman KalidasCopyright:

Available Formats

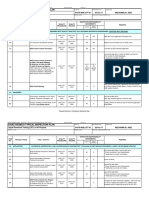

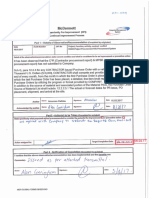

SAUDI ARAMCO ID/PID - 6/29/15 - REV A (Standards Cutoff - September 2013)

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Welding & Weld Joint Fit-up Inspection

PROJECT TITLE

DATE APPROVED

SAICW-2XXX-15

WBS / BI / JO NUMBER

QR NUMBER

WELDCONTRACTOR / SUBCONTRACTOR

McDERMOTT

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED INSPECTION DATE & TIME

ACTUAL INSPECTION DATE & TIME

EQPT CODE

SYSTEM ID.

PURCHASE ORDER NUMBER

PLANT NO.

EC / PMCC / MCC NO.

QUANTITY INSP.

MH's SPENT

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER

SAUDI ARAMCO ACTIVITY NUMBER

WORK PERMIT REQUIRED?

CONTRACTOR INSPECTION LEVEL

NO

SATIP-M-005-01 / SATIP-W-013-01

SAUDI ARAMCO INSPECTION LEVEL

ITEM

No.

ACCEPTANCE CRITERIA

WELDING ENVIROMENT

A1

Wind shields or tents shall be required when the wind is strong enough

to affect arc stability or shielding gas coverage or when deemed

necessary by Saudi Aramco Inspection. GTAW, GMAW, and gasshielded FCAW shall not be used for field or yard fabrication unless

adequate windshields are used. The wind velocity in the weld area for

GTAW, GMAW, or gas shielded FCAW shall not exceed 8 kph (2.2 m/s).

SAES-W-013

Para. 10.2.1

A2

Welding shall not be done when surfaces are wet or damp or exposed to

rain or snow or when the welders are exposed to inclement conditions.

Any wet or damp surfaces must be dried by heating for a distance of 100

mm from the weld joint and shall be warm to the hand before welding.

SAES-W-013

Para. 10.2.2

A3

Contamination from the environment, such as wind-blown sand, shall be

prevented by the use of adequate shielding.

SAES-W-013

Para. 10.2.3

JOINT PREPARATION

B1

Oil, moisture, rust, scale, sand, paint (except weldable primers for

approved applications - refer to paragraph 7.4.4 for restrictions), metallic

coatings (e.g., zinc), or other foreign matter shall be removed from the

weld surface and at least 25 mm of adjacent base metal prior to welding,

including any such coatings on temporary attachments or supports.

B2

REFERENCE

Flame cutting and arc-air gouging

10.3.2.1 Ragged and irregular edges shall be ground or machined to

bright metal.

10.3.2.2 Thermally cut or gouged surfaces for all materials, including

carbon steels, shall be power brushed or ground prior to welding.

10.3.2.3 Thermal cut surfaces of stainless steel and non-ferrous

materials shall be ground to bright (unoxidized) material prior to welding.

Page 1 of 4

SAES-W-013

Para. 10.3.1

SAES-W-013

Para. 10.3.2

PASS

FAIL

N/A

RE-INSP DATE

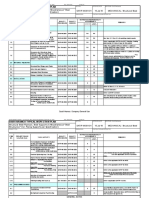

SAUDI ARAMCO ID/PID - 6/29/15 - REV 0 (Standards Cutoff - September 2013)

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Welding & Weld Joint Fit-up Inspection

PROJECT TITLE

SAIC NUMBER

SAICW-2XXX-15

WBS / BI / JO NUMBER

ITEM

No.

ACCEPTANCE CRITERIA

REFERENCE

B3

All full penetration joints requiring double sided welding shall be ground

or gouged to sound metal and inspected by penetrant testing (PT) or

magnetic particle testing (MT) prior to welding the reverse side. The

automatic SAW process is exempt from this requirement if procedure

qualification and production results demonstrate that acceptable

penetration can be reliably achieved (see 7.4.7).

SAES-W-013

Para 10.3.3

B4

Permanent backing rings or strips shall not be used unless specified in

the design and approved by CSD.

SAES-W-013,

Para. 9.3

B5

Temporary backup strips in weld joints may be used providing the

backing material is of a composition similar to the base metal or weld

metal. Under no circumstances shall rebar or galvanized steel be used.

Temporary backup shoes made of non-metallic, non-fusing material may

be used.

SAES-W-013,

Para. 9.4

B6

Full penetration groove joint included angles less than 30 degrees

(except for portions of compound bevels) shall not be used without

approval. The approval shall be obtained through the welding procedure

review process.

SAES-W-013,

Para. 9.6

B7

Buttering or weld build-up on joints

SAES-W-013,

Para. 10.3.4

B8

Radial offset of butt joints, including field deck-to-pile or deck column-todeck column joints, shall not exceed 3 mm for joints welded from one

side, with or without a backing strip (including stabbing guides). The

contractor shall either trial fit or make detailed measurements for each

member, including out-of-roundness, as part of the fabrication

dimensional checks for each component in order to insure the radial

offset limit will not be exceeded.

SAES-W-013

Para 10.4

B9

Edge preparation for intersecting tubular joints shall conform to the

Contract Drawings, SAES-M-005, and API RP 2A-WSD.

DE-119893

Para.5.1.3

B10

Edge preparation for beams and shapes shall be in accordance with

AWS D1.1 and the Contract Drawings

DE-119893

Para.5.1.4

B11

Saudi Aramco Inspection shall witness and approve all TKY joint fit-ups

on Category A or B materials.

SAES-W-013

Para 15.1.11

PRE-HEAT

C1

Preheat shall be in accordance with the AWS D1.1 and SAES-W-013

For materials not covered by the Code or SAES-W-013, the preheat and

postweld heat treatment shall be as specified in the approved welding

procedure.

SAES-W-013

Para 11.1

C2

The minimum preheat shall not be less than the greater of the following

(Note: The listed preheats are minimum requirements. The actual

preheat temperature selected and used by the fabricator must be

sufficient to prevent cracking):

a) 10C.

b) The required or recommended preheat listed in AWS D1.1.

c) For field fabrication or repair of P-No. 1 carbon steel materials, the

preheat listed in Standard Drawing AE-036451.

SAES-W-013

Para 11.2

C3

For steels with specified minimum yield strengths above 60 ksi, the

preheat shall be as specified in the approved welding procedure.

Special applications may require special weldability tests to evaluate the

preheat.

SAES-W-013

Para 11.3

C4

If a weld joint is wet or has surface moisture or condensation, it shall be

dried by heating for a distance of 100 mm from the weld joint and shall

be warm to the hand before welding.

SAES-W-013

Para 11.4

C5

Temperature-indicating crayons, thermocouples, or contact pyrometers

shall be used to measure preheat and interpass temperatures.

SAES-W-013

Para 11.5

Page 2+1 of 3

DATE APPROVED

QR NUMBER

WELDCONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

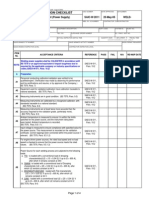

SAUDI ARAMCO ID/PID - 6/29/15 - REV 0 (Standards Cutoff - September 2013)

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

DATE APPROVED

SAICW-2XXX-15

Pre-Welding & Weld Joint Fit-up Inspection

PROJECT TITLE

WBS / BI / JO NUMBER

ITEM

No.

ACCEPTANCE CRITERIA

REFERENCE

C6

The preheat temperature shall be established over a minimum distance

of 75 mm on each side of the weld.

SAES-W-013

Para 11.6

C7

If the wall thickness exceeds 25 mm and preheating is to be done from

the same side as the welding, then the heat source shall be removed for

1 minute to allow for temperature equalization prior to measuring the

temperature.

SAES-W-013

Para 11.7

TACK WELDS

D1

All tack welds shall be made by qualified welders.

SAES-W-013

Para 10.6.1

D2

All tacks or temporary welds shall be performed with the same care,

materials, electrodes, minimum preheat, and procedures that are used

for permanent welds.

SAES-W-013

Para 10.6.2

D3

Tack welds shall be of sufficient size to maintain joint alignment. The

recommended tack size is 3.2-4.8mm and length is 12.525.4mm. The

minimum number of tack welds are:

Pipe diameter of 101.6m or less: three equally spaced tacks.

Pipe diameter above 101.6m: minimum of four equally spaced tacks.

The designated inspector should determine if more tacks are needed.

QR NUMBER

WELDCONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAES-W-013

Para 10.6.3

D4

Tack welds that are to be incorporated into the final weld shall be

thoroughly cleaned, prepared at each end, and inspected for cracks.

Any cracked tacks shall be removed before welding the joint.

SAES-W-013

Para 10.6.4

D5

If the tack welds are to be incorporated into the final weld and are made

with a different process or electrode than the root pass, then the tack

weld process or electrode shall have been used as the root pass for an

appropriate procedure qualification.

SAES-W-013

Para 10.6.5

D6

Bridge tacks (located above the root area) are acceptable but such tacks

must be made completely within the weld groove and shall be

completely removed prior to completion of the weld.

SAES-W-013

Para 10.6.6

GENERAL REQUIREMENTS

E1

Any temporary welded attachments or temporary tack welds shall be

ground off. Attachments may be thermally cut off no closer than 3 mm to

the base metal surface, prior to the required grinding

SAES-W-013

Para 10.8

E2

When temporary welding is deemed necessary, the welding shall be

performed with the same care, materials electrodes, minimum preheat

and procedures as permanent welding.

DE-119893

Para.5.3.1

E3

If any grinding reduces the base metal to less than the design minimum,

the ground area shall be rewelded and ground flush with the original

base metal surface or the component shall be replaced. Rewelding shall

be done only with the prior approval of Saudi Aramco Inspection.

SAES-W-013

Para 10.9

E4

Coated and clad or overlaid surfaces shall be protected from the welding

arc, associated weld spatter, and damage from ground clamps or other

associated equipment.

SAES-W-013

Para 10.12

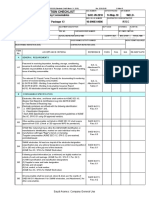

REMARKS:

REFERENCE DOCUMENTS:

1. SAES-W-013, Welding Requirements for Offshore Structures, 15 December 2009

2. DE-119893 Specification for Structural Fabrication, Load-Out & Tie-Down of Offshore Structures, April 2014, Rev.08

Contractor / Third-Party

Saudi Aramco

Construction Representative*

PMT Representative

Work is Complete and Ready for Inspection:

Name, Initials and Date:

QC Inspector

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

PID Representative

Performed Inspection

Work / Rework May Proceed

Name, Initials and Date:

Name, Initials and Date:

QC Supervisor

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

T&I Witnessed

Name, Initials and Date:

Name, Organization,

Initials and Date:

Page 3+1 of 3

SAUDI ARAMCO ID/PID - 6/29/15 - REV 0 (Standards Cutoff - September 2013)

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

SAICW-2XXX-15

Pre-Welding & Weld Joint Fit-up Inspection

PROJECT TITLE

ITEM

No.

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

Quality Record Approved:

Name, Sign and Date:

DATE APPROVED

REFERENCE

QR NUMBER

WELDCONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

Y = YES

N = NO F = FAILED

Name, Organization,

Initials and Date:

*Person Responsible for Completion of Quality Work / Test

Page 4+1 of 3

You might also like

- Ad 036821 001Document1 pageAd 036821 001AmolNo ratings yet

- Aramco Questionnaire Latest One 08062020Document29 pagesAramco Questionnaire Latest One 08062020brparekh100% (1)

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- Nail Arts DesignsDocument30 pagesNail Arts DesignsYam MuhiNo ratings yet

- Saudi Aramco Welding Consumables ChecklistDocument5 pagesSaudi Aramco Welding Consumables ChecklistAnsuman KalidasNo ratings yet

- L2V4bGlicmlzL2R0bC9kM18xL2FwYWNoZV9tZWRpYS8yMjMwNzY3 PDFDocument84 pagesL2V4bGlicmlzL2R0bC9kM18xL2FwYWNoZV9tZWRpYS8yMjMwNzY3 PDFfruitfuckNo ratings yet

- SAUDI ARAMCO LPT INSPECTION PLANDocument3 pagesSAUDI ARAMCO LPT INSPECTION PLANDurga Jagan PuppalaNo ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- SATR-L-2001 Flange Joint Tightening Test ReportDocument6 pagesSATR-L-2001 Flange Joint Tightening Test ReportAnonymous S9qBDVkyNo ratings yet

- Smmi 2017-04 PDFDocument100 pagesSmmi 2017-04 PDFMarceloLarrosaNo ratings yet

- Saudi Aramco PMI checklist ensures alloy purityDocument5 pagesSaudi Aramco PMI checklist ensures alloy puritykarioke mohaNo ratings yet

- SAEP-352 - Welding Procedures Review and Approval PDFDocument14 pagesSAEP-352 - Welding Procedures Review and Approval PDFsilvrsurfr637No ratings yet

- Saudi Aramco welding inspection checklistDocument3 pagesSaudi Aramco welding inspection checklistManoj KumarNo ratings yet

- SAIC-L-2014 Flange Joint Insp PDFDocument7 pagesSAIC-L-2014 Flange Joint Insp PDFAnonymous S9qBDVkyNo ratings yet

- Dark Winter Color Palette GuideDocument3 pagesDark Winter Color Palette Guidesunayhernandez1No ratings yet

- Saep 321Document28 pagesSaep 321brecht1980No ratings yet

- Lesson Plan 1 Art-Color WheelDocument4 pagesLesson Plan 1 Art-Color Wheelapi-284315223No ratings yet

- Saep 1146Document8 pagesSaep 1146Ronanki RaviNo ratings yet

- CV for Mechanical Inspector and Welding InspectorDocument28 pagesCV for Mechanical Inspector and Welding InspectorAJMAL KAREEMNo ratings yet

- SAUDIPIPINGMATTRACEDocument9 pagesSAUDIPIPINGMATTRACEMAZHARULNo ratings yet

- Saep 324Document8 pagesSaep 324brecht1980100% (3)

- ASME IX QW (Welding General Requirements)Document12 pagesASME IX QW (Welding General Requirements)Ariq Fauzan100% (1)

- Saudi Aramco Typical Inspection PlanDocument11 pagesSaudi Aramco Typical Inspection PlanAhdal NoushadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- IKEA Showroom Project DefinitionDocument9 pagesIKEA Showroom Project Definitionsabuz4No ratings yet

- Dragon Feng Shui Audit Reveals Ways to Improve Home's EnergyDocument7 pagesDragon Feng Shui Audit Reveals Ways to Improve Home's EnergyParag Shetty100% (1)

- 0.hydro Test Package Index - 1Document13 pages0.hydro Test Package Index - 1VISHNUPRASAD ARAKKAL MOHANDASNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldDocument32 pagesSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldIrshad Iqbal100% (2)

- Validate Welding Power SuppliesDocument4 pagesValidate Welding Power Suppliesfariboy123No ratings yet

- AWS D1.1 (2020) - Essential Variable For WPS & WeldersDocument7 pagesAWS D1.1 (2020) - Essential Variable For WPS & WeldersFouad OudinaNo ratings yet

- SAIC-L-2035 Rev 6Document2 pagesSAIC-L-2035 Rev 6biplabpal2009No ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistJoni Carino SuniNo ratings yet

- SAUDI ARAMCO SHOP FABRICATION INSPECTION PLANDocument2 pagesSAUDI ARAMCO SHOP FABRICATION INSPECTION PLANskychurch100% (1)

- Saudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 Weldm4metz100% (1)

- PIPELINE WELD NUMBERING SYSTEMDocument9 pagesPIPELINE WELD NUMBERING SYSTEMgst ajah100% (2)

- 1 SATIP-L-350-01 On-Plot Piping - Rev 01Document4 pages1 SATIP-L-350-01 On-Plot Piping - Rev 01zooplado75% (4)

- SAIC W 2069 in Process Welding InspectionDocument8 pagesSAIC W 2069 in Process Welding InspectionAbdul Gafoor ShaikhNo ratings yet

- Saudi Aramco Inspection Checklist: Review of WPS & Process Control Procedure (Pipelines) SAIC-W-2038 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Review of WPS & Process Control Procedure (Pipelines) SAIC-W-2038 Weldhamidjoyia100% (1)

- SAIC-M-2012 Rev 7supportsDocument33 pagesSAIC-M-2012 Rev 7supportsvijayachiduNo ratings yet

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldDocument19 pagesSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldIrshad IqbalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument23 pagesSaudi Aramco Inspection ChecklistjahaanNo ratings yet

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechJagdishNo ratings yet

- The Doom Seeker 1Document32 pagesThe Doom Seeker 1drachenfels6669117100% (1)

- Saudi Aramco Inspection Checklist: SAIC-W-2032 24-Jul-18 Weld-Upgrade Aramco JNGLFP Propane System BI-21-00087 MacoDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-W-2032 24-Jul-18 Weld-Upgrade Aramco JNGLFP Propane System BI-21-00087 MacojahaanNo ratings yet

- ASME BPVC.IX performance thickness limitsDocument1 pageASME BPVC.IX performance thickness limitskumar100% (2)

- Sfa-5 01 PDFDocument10 pagesSfa-5 01 PDFMahesh DeshmukhNo ratings yet

- A Tibetan FurnitureDocument5 pagesA Tibetan FurnitureEma StrnadNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalpravinNo ratings yet

- SAIC-W-2006 Rev 0Document4 pagesSAIC-W-2006 Rev 0philipyap100% (2)

- Aramco Pwht-QandA PDFDocument2 pagesAramco Pwht-QandA PDFAnasNo ratings yet

- Saep 321Document25 pagesSaep 321AbdullahNo ratings yet

- Saudi Aramco Test ReportDocument4 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019Document2 pagesSaudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019David RodriguesNo ratings yet

- 175 060100Document1 page175 060100Abu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Inspection Checklist: Selection of Welds For NDE (On-Plot Piping & Structures) SAIC-W-2015 WeldDocument23 pagesSaudi Aramco Inspection Checklist: Selection of Welds For NDE (On-Plot Piping & Structures) SAIC-W-2015 WeldIrshad IqbalNo ratings yet

- Saudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 WeldDocument1 pageSaudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 Weldkartik_harwani4387No ratings yet

- SAUDICHECK - WELD TRACKING DATABASEDocument5 pagesSAUDICHECK - WELD TRACKING DATABASEManoj KumarNo ratings yet

- Weekly Welder ReportDocument2 pagesWeekly Welder Reportkarthi51289No ratings yet

- QA/QC Engineer-Mechanical (Aramco approvedDocument4 pagesQA/QC Engineer-Mechanical (Aramco approvedshahzad siddiqui0% (1)

- SAIC-LT-2007 LeaK Testing-Vacuum BoxDocument3 pagesSAIC-LT-2007 LeaK Testing-Vacuum BoxKirubhakarPooranamNo ratings yet

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDocument3 pagesSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidNo ratings yet

- BPV IX-16-3 QW-283 - ButteringDocument1 pageBPV IX-16-3 QW-283 - ButteringyutweldingNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- Weld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020Document3 pagesWeld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020bishalNo ratings yet

- Saudi Aramco Inspection Checklist: Fireproofing Concrete Application Inspection SAIC-B-1002 1-Nov-09 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Fireproofing Concrete Application Inspection SAIC-B-1002 1-Nov-09 CivilWaleed MedhatNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistaamirapi100% (1)

- First Article InspectionDocument1 pageFirst Article InspectionAnsuman KalidasNo ratings yet

- 5L E45 Purch Guidelines R0 201306Document1 page5L E45 Purch Guidelines R0 201306Ansuman KalidasNo ratings yet

- 5L E45 Purch Guidelines R0 201306 PDFDocument4 pages5L E45 Purch Guidelines R0 201306 PDFAnsuman KalidasNo ratings yet

- Risk Based Thinking and The Digital Transformation of QualityDocument32 pagesRisk Based Thinking and The Digital Transformation of QualityAnsuman KalidasNo ratings yet

- Data Sheet Width Flange BeamDocument32 pagesData Sheet Width Flange BeamIrvan IskandarNo ratings yet

- TBT - Key Changes To Material Receiving Inspection ProcedureDocument1 pageTBT - Key Changes To Material Receiving Inspection ProcedureAnsuman KalidasNo ratings yet

- Acb enDocument48 pagesAcb enM Refaat FathNo ratings yet

- The Effect of Multiple Postweld Heat Treatment Cycles On The Weldability of Waspaloy®Document6 pagesThe Effect of Multiple Postweld Heat Treatment Cycles On The Weldability of Waspaloy®Aliakbar GhaderiNo ratings yet

- PDFDocument2 pagesPDFAnsuman KalidasNo ratings yet

- PSL 2 Pipe for sour serviceDocument6 pagesPSL 2 Pipe for sour serviceAnsuman KalidasNo ratings yet

- LL in The Sichuan Museum & Ba-Shu CultureDocument15 pagesLL in The Sichuan Museum & Ba-Shu CultureEdo ĐạtNo ratings yet

- Dome of The RockDocument24 pagesDome of The Rockriz2010No ratings yet

- M F HusainDocument3 pagesM F Husainajith0% (1)

- Commission Lesson Plan in Art DLSJBCDocument11 pagesCommission Lesson Plan in Art DLSJBCLovely Grace CajegasNo ratings yet

- Famous ArtistsDocument3 pagesFamous ArtistsddinennaNo ratings yet

- EAA 384 – Construction Technology of Civil Engineering BuildingDocument65 pagesEAA 384 – Construction Technology of Civil Engineering BuildingArvinthran Raja KumaranNo ratings yet

- Kindergarten Daily ScheduleDocument2 pagesKindergarten Daily ScheduleEstiErnawatiNo ratings yet

- IntachDocument11 pagesIntachAbhishek JaniNo ratings yet

- Arts and Crafts HandoutsDocument5 pagesArts and Crafts HandoutsFreyssinet LynNo ratings yet

- Jean-Luc Godard's: Pierrot Le FouDocument23 pagesJean-Luc Godard's: Pierrot Le FouFelix Perez CoduriNo ratings yet

- PraxiarDocument8 pagesPraxiara_roy003No ratings yet

- Brochure Beadcrete Int Designer-BeadcreteDocument9 pagesBrochure Beadcrete Int Designer-BeadcreteKaneNo ratings yet

- The Politics of Friendship Modern Art inDocument30 pagesThe Politics of Friendship Modern Art inArham SyahlalaNo ratings yet

- Eng 103 Midterm ReviewerDocument11 pagesEng 103 Midterm ReviewerBeyoncé GalvezNo ratings yet

- Heinrich Schütz EditionDocument124 pagesHeinrich Schütz EditionJoão SassacamiNo ratings yet

- Color WheelDocument19 pagesColor WheelZenia Fe Llausas McVeyNo ratings yet

- Subjective and Objective Perspectives Intended Learning OutcomesDocument9 pagesSubjective and Objective Perspectives Intended Learning OutcomesShai GuiamlaNo ratings yet

- History of Visual ArtsDocument2 pagesHistory of Visual ArtsEricka DanielNo ratings yet

- Close-Up B1 Workbook Unit 8Document7 pagesClose-Up B1 Workbook Unit 8Ignacio Santaeufemia100% (2)

- Dissociation + RadioheadDocument15 pagesDissociation + RadioheadFennelstratocasterNo ratings yet

- Paul SietsemaDocument3 pagesPaul SietsemaPaolo ViscogliosiNo ratings yet