Professional Documents

Culture Documents

Vertical Surge Tank

Uploaded by

ihllhmCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vertical Surge Tank

Uploaded by

ihllhmCopyright:

Available Formats

Vertical Surge Tank

Store liquid hydrocarbons after separation

APPLICATIONS

Onshore and offshore exploration and

development oil and gas well testing

Production wells

ADVANTAGES

Liquid flow rate, shrinkage factor,

and meter factor measurement

Large-volume dead oil sampling

Constant backpressure maintenance

when used as a second-stage separator

Single or double compartment

Sight glasses or magnetic

level indicators

High- and low-level alarm system

on each compartment

Automatic pressure controlled valve

that is open on gas outlet

Diverter, vortex breaker,

and stiffening rings

Bypass manifold that allows isolating

the surge tank from the flow process

Sampling points and pressure

and temperature ports

Overpressure protection by relief valves

Shock-protection frame

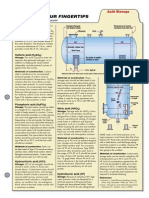

The vertical surge tank (VST) is an H2S service

vessel designed to store liquid hydrocarbons

after separation. The VST is used to measure

liquid flow rates and the combined shrinkage

and meter factor. It can also be used as a

second-stage separator and can hold a

constant backpressure by using its automatic

pressure control valve on the gas outlet.

The VST usually consists of either a singleor a double-compartment vessel and a

level-measuring system with sight glasses

or magnetic levels. Dual-compartment VSTs

provide a way to empty one tank compartment

while filling another. To prevent overpressure

and overfilling, the VST is fitted with a pressurerelief valve and a high- and low-level alarm

system. The VST is designed with a diverter,

a vortex breaker, and stiffening rings capable

of withstanding a vacuum in the vessel. It

is also fitted with sampling, pressure, and

temperature ports, and a bypass manifold

is included.

All VSTs are shock protected by a frame,

and the latest models are designed to the

Det Norske Veritas (DNV) 2.7-1 standard.

VSTs operate in the vertical position, but

they are transported in a horizontal position.

All surge tanks are manufactured under Type

Approval or Design Verification Review and

are provided with a Certificate of Conformity

and full quality file.

Vertical surge tank.

Vertical Surge Tank

Specifications

Model

Vessel

Capacity,

bbl [m3]

Oil

Capacity,

bbl [m3]

Working

Pressure,

psi [kPa]

Temperature

Range,

degF [degC]

Maximum Gas

Flow Rate,

Mcf/d [m3/d]

Level

Measurement

System

Safety

Valves

DNV

Rating

2.7-1

VST-A

1 80

[1 12.7]

1 80

[1 12.7]

2 50

[2 7.95]

1 80

[1 12.7]

2 50

[2 7.95]

2 50

[2 7.95]

2 50

[2 7.95]

2 50

[2 7.95]

2 50

[2 7.95]

46.5

[7.4]

46.5

[7.4]

58

[9.2]

46.5

[7.4]

58

[9.2]

58

[9.2]

58

[9.2]

58

[9.2]

58

[9.2]

50

[345]

50

[345]

150

[1,034]

50

[345]

150

[1,034]

150

[1,034]

150

[1,034]

150

[1,034]

150

[1,034]

32 to 212

[0 to 100]

4 to 212

[20 to 100]

32 to 212

[0 to 100]

32 to 212

[0 to 100]

4 to 212

[20 to 100]

4 to 212

[20 to 100]

32 to 212

[0 to 100]

32 to 212

[0 to 100]

4 to 212

[20 to 100]

4,500

[127,425]

4,500

[127,425]

10,000

[283,168]

4,500

[127,425]

10,000

[283,168]

10,000

[283,168]

10,000

[283,168]

10,000

[283,168]

10,000

[283,168]

Sight glass

No

Sight glass

No

Magnetic level

No

Magnetic level

Yes

Magnetic level

Yes

Magnetic level

Yes

Magnetic level

Yes

Sight glass and

magnetic level

Magnetic level

Yes

Yes

VST-B

VST-D

VST-BB

VST-FA

VST-FAC

VST-FB

VST-FC

VST-FW

(winterized)

Specifications and Codes

Model

VST-A

VST-B

VST-D

VST-BB

VST-FA

VST-FAC

VST-FB

VST-FC

VST-FW

(winterized)

Connections

Oil

Inlet

Gas

Outlet

Oil

Outlet

Water

Outlet

Pressure

Safety

Valve

3-in

Fig 602

Female

3-in

Fig 602

Female

3-in

Fig 602

Female

3-in

Fig 602

Female

3-in

Fig 602

Female

3-in

Fig 1,502

Female

3-in

Fig 602

Female

3-in

Fig 602

Female

3-in

Fig 602

Female

4-in

Fig 602

Male

4-in

Fig 602

Male

4-in

Fig 602

Male

4-in

Fig 602

Male

4-in

Fig 602

Male

4-in

Fig 602

Male

4-in

Fig 602

Male

4-in

Fig 602

Male

4-in

Fig 602

Male

3-in

Fig 602

Male

3-in

Fig 602

Male

3-in

Fig 602

Male

3-in

Fig 602

Male

3-in

Fig 602

Male

3-in

Fig 602

Male

3-in

Fig 602

Male

3-in

Fig 602

Male

3-in

Fig 602

Male

3-in

Fig 602

Male

3-in

Fig 602

Male

3-in

Fig 602

Male

3-in

Fig 602

Male

3-in

Fig 602

Male

3-in

Fig 602

Male

3-in

Fig 602

Male

3-in

Fig 602

Male

3-in

Fig 602

Male

4-in

Fig 602

Male

4-in

Fig 602

Male

4-in

Fig 602

Male

4-in

Fig 602

Male

4-in

Fig 602

Male

4-in

Fig 602

Male

4-in

Fig 602

Male

4-in

Fig 602

Male

4-in

Fig 602

Male

Dimensions

(L W H), ft [m]

Weight,

lbm [kg]

Applied Codes

8.04 7.87 20.0

[2.45 2.4 6.1]

13,420

[6,100]

ASME VIII Div. 1, ASME/ANSI

B31.3, H2S (NACE MR0175)

8.04 7.87 20.0

[2.45 2.4 6.1]

13,420

[6,100]

ASME VIII Div. 1, ASME/ANSI

B31.3, H2S (NACE MR0175)

8.53 7.87 24.27

[2.6 2.4 7.4]

24,765

[11,400]

ASME VIII Div. 1, ASME/ANSI

B31.3, H2S (NACE MR0175)

8.04 7.87 20.0

[2.45 2.4 6.1]

13,420

[6,100]

ASME VIII Div. 1, ASME/ANSI

B31.3, H2S (NACE MR0175)

8.53 7.87 24.27

[2.6 2.4 7.4]

27,000

[12,000]

ASME VIII Div. 1, ASME/ANSI

B31.3, H2S (NACE MR0175)

8.53 7.87 24.27

[2.6 2.4 7.4]

28,660

[13,000]

ASME VIII Div. 1, ASME/ANSI

B31.3, H2S (NACE MR0175)

8.53 7.87 24.27

[2.6 2.4 7.4]

27,000

[12,000]

ASME VIII Div. 1, ASME/ANSI

B31.3, H2S (NACE MR0175)

8.53 7.87 24.27

[2.6 2.4 7.4]

29,762

[13,500]

8.53 7.87 24.27

[2.6 2.4 7.4]

29,762

[13,500]

ASME VIII Div. 1 (U-Stamp),

ASME/ANSI B31.3, H2S (NACE

MR0175), DNV 2.7-1

ASME VIII Div. 1 (U-Stamp),

ASME/ANSI B31.3, H2S (NACE

MR0175), DNV 2.7-1

For

reference only and should be confirmed using ArchiTest* well test design and methodology software

bypass manifoldoil inlet rated to 1,440 psi

American Society of Mechanical Engineers

American National Standards Institute

No

*Mark of Schlumberger

Other company, product, and service names

are the properties of their respective owners.

Copyright 2016 Schlumberger. All rights reserved. 16-TS-155105

slb.com/welltesting

You might also like

- H07127 ThreePhaseHorzSepDocument2 pagesH07127 ThreePhaseHorzSepGuillermo Manuel SchödlNo ratings yet

- Den Con CatalogDocument36 pagesDen Con Catalogbaskaran vNo ratings yet

- 500 BBL Mobile Frac Tank Brochure1Document2 pages500 BBL Mobile Frac Tank Brochure1enggmohanNo ratings yet

- MODELS 4, 6, 8 High-Capacity Strainers and FiltersDocument6 pagesMODELS 4, 6, 8 High-Capacity Strainers and Filterspeter2mNo ratings yet

- 3.0 Systems Division-FiltersDocument8 pages3.0 Systems Division-Filtersmatteo2009No ratings yet

- Bi-Di PigDocument1 pageBi-Di PigrobyharyudhaNo ratings yet

- Sedifilt Oil & Gas Brochure PDFDocument8 pagesSedifilt Oil & Gas Brochure PDFAalap DerasaryNo ratings yet

- WelChem BubbleCapTray 2020-2Document6 pagesWelChem BubbleCapTray 2020-2Joel OkohNo ratings yet

- Seprasol Plus: Liquid/Gas CoalescersDocument4 pagesSeprasol Plus: Liquid/Gas CoalescersSiavash YarahmadiNo ratings yet

- Principles of Separation: Production and Test SeparatorsDocument28 pagesPrinciples of Separation: Production and Test SeparatorsهانيزايدNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V9: Tema SheetDocument7 pagesAspen Exchanger Design and Rating Shell & Tube V9: Tema SheetTuấn VũNo ratings yet

- Vane Separator (Brochure PEERLESSMFG)Document6 pagesVane Separator (Brochure PEERLESSMFG)Julio OrtegaNo ratings yet

- Presentationlu 180126221936 PDFDocument20 pagesPresentationlu 180126221936 PDFhaptoorNo ratings yet

- Separador BifásicoDocument42 pagesSeparador BifásicoAldoDeLaCerda100% (1)

- Hytorc Pressure/Torque Conversion Chart For MXT Hydraulic Torque Wrenches Hytorc Pressure/Torque Conversion Chart For MXT Hydraulic Torque WrenchesDocument2 pagesHytorc Pressure/Torque Conversion Chart For MXT Hydraulic Torque Wrenches Hytorc Pressure/Torque Conversion Chart For MXT Hydraulic Torque WrenchesMarcello LaraNo ratings yet

- Comparing CoalescersDocument12 pagesComparing Coalescersmohamed_sahnoun_enisNo ratings yet

- Liquid SealDocument2 pagesLiquid SealAkshat RoyNo ratings yet

- Da and Dhda Datasheet Master - XLSM - Hpu-Dhda118-4.1 Rev1Document3 pagesDa and Dhda Datasheet Master - XLSM - Hpu-Dhda118-4.1 Rev1jujuroyaleNo ratings yet

- Quick Opening ClosuresDocument4 pagesQuick Opening ClosureseduinNo ratings yet

- Acid StorageDocument1 pageAcid StorageChelsea SkinnerNo ratings yet

- 48" X 15' Three Phase Test SeparatorDocument2 pages48" X 15' Three Phase Test Separatorpraash bhattNo ratings yet

- Three Phase Well Test SeparatorDocument3 pagesThree Phase Well Test SeparatorPraveen VelathNo ratings yet

- General Requirements For Flares and Flare StacksDocument9 pagesGeneral Requirements For Flares and Flare StacksReza100% (1)

- Three Phase Separator - Liquid InternalsDocument7 pagesThree Phase Separator - Liquid Internalsmehul10941No ratings yet

- Peco Filter CaseDocument11 pagesPeco Filter CaseLuis MaureraNo ratings yet

- KIRK KVME Mist EliminatorsDocument2 pagesKIRK KVME Mist EliminatorsSHINo ratings yet

- Nozzle CriteriaDocument2 pagesNozzle CriteriaKhalil LasferNo ratings yet

- Three-Phase Horizontal Test SeparatorDocument2 pagesThree-Phase Horizontal Test SeparatorsyazwanNo ratings yet

- Heater TreaterDocument5 pagesHeater TreaterImmanuel100% (1)

- Separator Vessel: Ms. Shreya SahajpalDocument6 pagesSeparator Vessel: Ms. Shreya SahajpalShreya Sahajpal KaushalNo ratings yet

- Water SoftenersDocument11 pagesWater Softenersadel rihanaNo ratings yet

- Trays in RefineryDocument22 pagesTrays in RefineryHammad HashmiNo ratings yet

- Pressure Temperature Chart According To ASME B16.34 ASME B PV CodeDocument5 pagesPressure Temperature Chart According To ASME B16.34 ASME B PV CodeDwayne YiiNo ratings yet

- Well Stimulation VesselsDocument2 pagesWell Stimulation VesselsOscar RamirezNo ratings yet

- Horizontal and Vertical Heater Treaters GuideDocument4 pagesHorizontal and Vertical Heater Treaters GuideJatin RamboNo ratings yet

- US9260541 Methods of Catalyst ActivationDocument22 pagesUS9260541 Methods of Catalyst ActivationyamakunNo ratings yet

- Crude Oil Heater Dimensioning ProcedureDocument2 pagesCrude Oil Heater Dimensioning ProcedureMubarik AliNo ratings yet

- VGS Vane Separators Are Recommended ForDocument1 pageVGS Vane Separators Are Recommended ForSanthu PeelaNo ratings yet

- Dual-Pot Sand Filter Type B (DSF-B)Document2 pagesDual-Pot Sand Filter Type B (DSF-B)kanchanabalajiNo ratings yet

- Filtration in HydrotreatingDocument2 pagesFiltration in Hydrotreatingck196548400% (1)

- Vortex BreakerDocument2 pagesVortex Breakernaruto256No ratings yet

- Steam Tracing StudyDocument4 pagesSteam Tracing StudypalluraviNo ratings yet

- NGL1 V1 Sec 4Document218 pagesNGL1 V1 Sec 4varatharajan g rNo ratings yet

- Specify Three-Phase SeparatorsDocument12 pagesSpecify Three-Phase SeparatorsRobert MontoyaNo ratings yet

- Gas Absorption Theory and Equipment SelectionDocument15 pagesGas Absorption Theory and Equipment SelectionAndreea IoanaNo ratings yet

- Catelogue - Internals For Packed ColumnDocument20 pagesCatelogue - Internals For Packed ColumnvaidyakunjalNo ratings yet

- Strata RCDDocument2 pagesStrata RCDDavid VilchesNo ratings yet

- UBM 85 FT BoomDocument2 pagesUBM 85 FT Boomwahid_100No ratings yet

- Crude Distillation UnitDocument1 pageCrude Distillation Unitnew styleNo ratings yet

- Hot High Pressure SeparatorDocument2 pagesHot High Pressure SeparatorKhai NguyenNo ratings yet

- Separator NadobyDocument15 pagesSeparator NadobyVidyasenNo ratings yet

- QMT Energy Surface Well Testing (SWT) - Fourth Generation Green Emission Oil Burner Head PDFDocument2 pagesQMT Energy Surface Well Testing (SWT) - Fourth Generation Green Emission Oil Burner Head PDFTg TarroNo ratings yet

- Condensate Flash Vessel HandbookDocument3 pagesCondensate Flash Vessel HandbookHari Gunawan NugrahaNo ratings yet

- Ambient Crude Oil StorageDocument11 pagesAmbient Crude Oil Storagesatish1637No ratings yet

- Separator & Production FacilitiesDocument11 pagesSeparator & Production FacilitiestumiNo ratings yet

- 1290 RegulatorsDocument3 pages1290 RegulatorsPitichai PakornrersiriNo ratings yet

- Filters FbaDocument1 pageFilters FbaSpoonful BurnsideNo ratings yet

- Vertical Surge Tank PsDocument2 pagesVertical Surge Tank PsliganozonaruNo ratings yet

- Features/Benefits: Production Testing Solutions Three-Phase Test SeparatorDocument1 pageFeatures/Benefits: Production Testing Solutions Three-Phase Test SeparatorJayesh SanganiNo ratings yet

- Gufmc 0138 UsDocument8 pagesGufmc 0138 Usmusaismail8863No ratings yet

- AmmoniaDocument4 pagesAmmoniaYutt WattNo ratings yet

- Aalborg OmDocument4 pagesAalborg OmihllhmNo ratings yet

- Applying NPSH To Metering PumpsDocument3 pagesApplying NPSH To Metering PumpsJoce88888100% (1)

- Cleaning-In-Place in The Dairy IndustryDocument11 pagesCleaning-In-Place in The Dairy IndustryihllhmNo ratings yet

- Guide To The Selection of Rotodynamic Pumps FinalDocument35 pagesGuide To The Selection of Rotodynamic Pumps FinalAmeer BashaNo ratings yet

- Ammonia Handling Manual PDFDocument14 pagesAmmonia Handling Manual PDFEdenson Flores TrujilloNo ratings yet

- Tank InstrumentsDocument10 pagesTank InstrumentsihllhmNo ratings yet

- Sulphide Scavengers in Oil and Gas Industry - A ReviewDocument8 pagesSulphide Scavengers in Oil and Gas Industry - A ReviewMartín Diego MastandreaNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Composite Boiler Aalborg PDFDocument2 pagesComposite Boiler Aalborg PDFihllhmNo ratings yet

- Vapour Pressure HCL Water PDFDocument1 pageVapour Pressure HCL Water PDFihllhmNo ratings yet

- Chemical EquationsDocument6 pagesChemical EquationsihllhmNo ratings yet

- Implementing Off Page ConnectorsDocument9 pagesImplementing Off Page ConnectorsihllhmNo ratings yet

- 10 Reasons To Move From AutoCAD To AutoCAD P&IDDocument2 pages10 Reasons To Move From AutoCAD To AutoCAD P&IDihllhmNo ratings yet

- Boiling Liquid Expanding Vapor Explosion - Simulation and RiskDocument1 pageBoiling Liquid Expanding Vapor Explosion - Simulation and RiskihllhmNo ratings yet

- AutoCAD PID 2011 Features and BenefitsDocument2 pagesAutoCAD PID 2011 Features and BenefitsPaula ErazoNo ratings yet

- Boiler Efficiency Guide PDFDocument24 pagesBoiler Efficiency Guide PDFAsnfiasnfd FenfeNo ratings yet

- Stemming The TideDocument48 pagesStemming The TideDevika Hemalatha DeviNo ratings yet

- Implementing Off Page ConnectorsDocument9 pagesImplementing Off Page ConnectorsihllhmNo ratings yet

- Offshore Platform WBS TemplateDocument4 pagesOffshore Platform WBS TemplateihllhmNo ratings yet

- 10 Reasons To Move From AutoCAD To AutoCAD P&IDDocument2 pages10 Reasons To Move From AutoCAD To AutoCAD P&IDihllhmNo ratings yet

- PFD&PID With AUtoCAD P&ID PDFDocument7 pagesPFD&PID With AUtoCAD P&ID PDFihllhmNo ratings yet

- Work Breakdown Structures: White PaperDocument6 pagesWork Breakdown Structures: White PaperjmpbarrosNo ratings yet

- Ballast Water Management MethodsDocument2 pagesBallast Water Management MethodsRajesh Kumar ChaubeyNo ratings yet

- Project Control SetupDocument2 pagesProject Control SetupihllhmNo ratings yet

- DOE Guidance WBS PDFDocument18 pagesDOE Guidance WBS PDFEl KhanNo ratings yet

- Navgathi-New Shipbuilding Project Management PDFDocument16 pagesNavgathi-New Shipbuilding Project Management PDFihllhm100% (1)

- Ge Oil &gas Turbocompressor Trains On First Floating LNG PlantDocument12 pagesGe Oil &gas Turbocompressor Trains On First Floating LNG PlantihllhmNo ratings yet

- Ge Oil &gas Turbocompressor Trains On First Floating LNG Plant PDFDocument12 pagesGe Oil &gas Turbocompressor Trains On First Floating LNG Plant PDFihllhmNo ratings yet

- Quatitative Microscopy Cog PDFDocument6 pagesQuatitative Microscopy Cog PDFNiyati GuptaNo ratings yet

- FTTH Accessories PDFDocument10 pagesFTTH Accessories PDFdannyalcivarNo ratings yet

- EPA 1668 A, Ag-2003Document129 pagesEPA 1668 A, Ag-2003Karina Rondon RivadeneyraNo ratings yet

- Problems On Beams PDFDocument16 pagesProblems On Beams PDFC j50% (6)

- Review: Modeling Damping in Mechanical Engineering StructuresDocument10 pagesReview: Modeling Damping in Mechanical Engineering Structuresuamiranda3518No ratings yet

- Atomic absorption spectroscopy analysis of metalsDocument3 pagesAtomic absorption spectroscopy analysis of metalsVishnu VichuZNo ratings yet

- PAP NAV Energie Savings in Twin Propellers DesignDocument14 pagesPAP NAV Energie Savings in Twin Propellers Designyannickjan2005No ratings yet

- The Statistical Imagination: Chapter 7. Using Probability Theory To Produce Sampling DistributionsDocument18 pagesThe Statistical Imagination: Chapter 7. Using Probability Theory To Produce Sampling DistributionsVictoria LiendoNo ratings yet

- CBR Lab Report: Soil Subgrade TestingDocument4 pagesCBR Lab Report: Soil Subgrade Testingsdcsdcdcw33% (3)

- Basic ChemistryDocument14 pagesBasic ChemistryPitherNo ratings yet

- Weather in Kuttiadi - Google SearchDocument1 pageWeather in Kuttiadi - Google Searchsorry Its My StyleNo ratings yet

- GX200 AdjDocument1 pageGX200 AdjAngelescuONo ratings yet

- Saikat SaraniDocument11 pagesSaikat SaraniPartha GangopadhyayNo ratings yet

- Determining Dielectric Constants Using A Parallel Plate CapacitorDocument5 pagesDetermining Dielectric Constants Using A Parallel Plate CapacitorAhmAd GhAziNo ratings yet

- Magnetism Workhsheet Siap EditDocument10 pagesMagnetism Workhsheet Siap EditMamberamo ClassNo ratings yet

- BHEL Haridwar Block 2 Heavy Fabrication, Training ReportDocument53 pagesBHEL Haridwar Block 2 Heavy Fabrication, Training ReportUdit Soni100% (5)

- Open Stent Design: Craig Bonsignore NDC 47533 Westinghouse Drive Fremont, CA, 94566Document93 pagesOpen Stent Design: Craig Bonsignore NDC 47533 Westinghouse Drive Fremont, CA, 94566akire_aicragNo ratings yet

- GEC 104 Week 1 Lesson 1 Math Modern WorldDocument4 pagesGEC 104 Week 1 Lesson 1 Math Modern WorldJahnna Marie PomaresNo ratings yet

- Lab 3 - Intro To DynamicDocument36 pagesLab 3 - Intro To DynamicRacheal KirbyNo ratings yet

- HW2 Solutions FinalDocument5 pagesHW2 Solutions Finalpande_100No ratings yet

- Design of Masonry StructuresDocument10 pagesDesign of Masonry StructuresmuhammedNo ratings yet

- Trư NG Thcs : Question IV. Find and Correct The Mistake in Each Sentence. (1p)Document2 pagesTrư NG Thcs : Question IV. Find and Correct The Mistake in Each Sentence. (1p)Anh ThưNo ratings yet

- A Study of Manufacturing of Steam TurbinesDocument40 pagesA Study of Manufacturing of Steam TurbinesSaketh Varma MudunuriNo ratings yet

- P 211enDocument26 pagesP 211enRadhakrishnan BalasubramanianNo ratings yet

- Newton's Laws of Motion Worksheet.Document2 pagesNewton's Laws of Motion Worksheet.Llama jennerNo ratings yet

- Design and Manufacturing of Automatic Gear Shifter For BicycleDocument10 pagesDesign and Manufacturing of Automatic Gear Shifter For BicycleMannam RujendraNo ratings yet

- Formulae and Design Rules To Ec2Document45 pagesFormulae and Design Rules To Ec2moodoo100% (4)

- Microwave Engineering - CLO - Fall - 2020Document2 pagesMicrowave Engineering - CLO - Fall - 2020Usama FaizNo ratings yet

- Chapter 14 Modern SpectrosDocument24 pagesChapter 14 Modern SpectrosChicken ChickenNo ratings yet

- E1213-14 Práctica Estándar para La Diferencia Mínima de Temperatura Resoluble para Sistemas de Imágenes TérmicasDocument3 pagesE1213-14 Práctica Estándar para La Diferencia Mínima de Temperatura Resoluble para Sistemas de Imágenes Térmicasfredy lopezNo ratings yet