Professional Documents

Culture Documents

Pms

Uploaded by

Bilal KazmiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pms

Uploaded by

Bilal KazmiCopyright:

Available Formats

PRACTICAL NO.

8

OBJECT:

To simulate a gas processing unit using Aspen hysys software

PROCEDURE:

From the file menu select New and then Case

Click the New case icon in the toolbar

For this case we are selecting components(methane, ethane,

propane, i-butane, n-butane, CO, N) and fluid package for this

case will be (Peng-Robinson)

Now we will enter into the simulation environment and place a material

stream from the object pallet and specify the following properties:

a) Stream name: feed1

b) Temperature: 60F

c) Pressure: 600psia

d) Molar flow: 6 MMSCFD

Now we will specify the composition of the material stream

Now we will place another material stream and specify the conditions

and composition of the stream as:

a) Stream name: feed2

b) Temperature: 60F

c) Pressure: 600 psia

d) Molar flow: 4 MMSCFD

Now we will place the mixer from the object pallet

Now we will specify the connections as follows:

Now we will install a separator from the object pallet and specify the

following connections:

Now we will install a heat exchanger from the object pallet

And specify the connections of the heat exchanger as follows:

Click the parameter option and specify the delta p of 10psi for both

the shell side and the tube side respectively

Click the Rating tab and select the sizing page. In the configuration

column click on the tube passes per shell and change the value to 1

Since the heat exchanger is still under specified. Now we will install

chiller from the object pallet

And specify the following connections to the chiller as follows:

Enter the parameter page and specify the delta p of 10psi

For the COOLED GAS stream coming out of the chiller we will specify

the temperature of 0F

Now we will install a separator from the object pallet and specify the

connections as:

Now we will again go back to the heat exchanger by double clicking on

it and click on the Spec option and add an specification to the heat

exchanger

a) Stream(+): sep vap

b) Stream(-): sales gas

c) Temperature: 10F

Now we will place a balance from the the object pallet

And specify the conditions as follows:

Now we will click the parameter option and select the balance type to

be Mole

Now we will enter into the sales DP material stream by double clicking

on it and specify the vapor as 1 and pressure of 800psia

Now we will again install a second mixer and specify the connections

as:

After this we will install a column from the object pallet

And specify the connections of the column as;

Now after specifying all the connections of the column we will proceed

to the pressure page and specify the condenser pressure of

200psia and Reboiler pressure of 205psia

We will further advances to the optional estimate page by clicking next

and specify the condenser temperature of 40F and

temperature estimate of 200F

Reboiler

By clicking next we will proceed to the last page of input expert and

specify vapor rate of 2 MMSCFD and Reflux ratio 1

Now we will click the done button but the red bar at the bottom of the

screen indicates that column has no converged and we will need to

specify additional specs

Now we will specify the column specs by clicking the Monitor option

and on the monitor page we will add the spec of Column component

fraction and specify the coumn specs as follows:

Now the degree of freedom has turned to zero and column is now ready

to be run by clicking the run option at the bottom of the page

Now we will place adjust from the object pallet

By double clicking on the adjusting icon we will enter into the connection

page here we will specify the adjusted variable object (COOLED GAS)

and variable(temperature).similarly we will specify the targeted

variable object(sales DP) and variable(temperature) and specified

targeted value of 10F

Now we will go to the parameter page and enter 0.1F in the tolerance

cell and step size of 5F

Click the start button and The Adjust converges on the target value within

the

Specified tolerance in five iterations.

HYSYS has a Spreadsheet operation that allows you to import streams or

operation variables, performance calculations, and export calculated

results.

Now we will click the add import button and select the object to be

sales gas and variable master comp mole fraction and specify

variables of (c1,c2,c3,i-c4,n-c4)

Now we will click the spread sheet option at the bottom of the screen

and specify the headings and calculate the values of different mole

fractions.

In the end our simulation can be represented as:

RESULTS OF THE STUDY

By clicking on the workbook icon

we can access the results for

the entire flow sheet. The material stream and the compositions tabs appear

below:

You might also like

- Sintesis of Co2Document10 pagesSintesis of Co2Gary Kiel Palacios EspinozaNo ratings yet

- General TyreDocument28 pagesGeneral TyreBilal KazmiNo ratings yet

- A. Galvagno Et Al.Document11 pagesA. Galvagno Et Al.Bilal KazmiNo ratings yet

- Molino 2016Document16 pagesMolino 2016vitor_alberto_7No ratings yet

- 1 s2.0 S0032591014010018 MainDocument6 pages1 s2.0 S0032591014010018 MainIlham Alfian FirdanaNo ratings yet

- A. AlNouss Et Al.Document15 pagesA. AlNouss Et Al.Bilal KazmiNo ratings yet

- A D D Diallo Et Al.Document8 pagesA D D Diallo Et Al.Bilal KazmiNo ratings yet

- Rauch Et Al.Document20 pagesRauch Et Al.Bilal KazmiNo ratings yet

- Rudra 2019Document12 pagesRudra 2019SofíaNo ratings yet

- An Overview of Economic Analysis and Environmental Impacts of Natural Gas Conversion TechnologiesDocument18 pagesAn Overview of Economic Analysis and Environmental Impacts of Natural Gas Conversion TechnologiesBilal KazmiNo ratings yet

- Y.cao, y Bai and J. DuDocument10 pagesY.cao, y Bai and J. DuBilal KazmiNo ratings yet

- Naphthacracking 120907055612 Phpapp02Document22 pagesNaphthacracking 120907055612 Phpapp02regina pramuditaNo ratings yet

- M. Singh Et AlDocument9 pagesM. Singh Et AlBilal KazmiNo ratings yet

- D.A Ali Et Al.Document12 pagesD.A Ali Et Al.Bilal KazmiNo ratings yet

- Novel Natural Gas To Liquids Processes - Process Synthesis and Global Optimization StrategiesDocument27 pagesNovel Natural Gas To Liquids Processes - Process Synthesis and Global Optimization StrategiesBilal KazmiNo ratings yet

- Biological Conversion of Methane To Liquid Fuels - Status and OpportunitiesDocument16 pagesBiological Conversion of Methane To Liquid Fuels - Status and OpportunitiesBilal KazmiNo ratings yet

- Molecules: Eco-Friendly Synthesis of A New Class of Pyridinium-Based Ionic Liquids With Attractive Antimicrobial ActivityDocument14 pagesMolecules: Eco-Friendly Synthesis of A New Class of Pyridinium-Based Ionic Liquids With Attractive Antimicrobial ActivityBilal KazmiNo ratings yet

- Biotechnological Conversion of Methane To Methanol - Evaluation of Progress and PotentialDocument39 pagesBiotechnological Conversion of Methane To Methanol - Evaluation of Progress and PotentialBilal KazmiNo ratings yet

- Research PaperDocument27 pagesResearch PaperBilal KazmiNo ratings yet

- Simulation Co2 Removal Unit of Natural Gas by Aspen-Hysys: January 2012Document6 pagesSimulation Co2 Removal Unit of Natural Gas by Aspen-Hysys: January 2012Bilal KazmiNo ratings yet

- 2018 BPP Index ServiceLife DepreciationDocument40 pages2018 BPP Index ServiceLife DepreciationIsaac CastilloNo ratings yet

- Aspen Plus v8.0 - Getting Started Customizing ModelsDocument70 pagesAspen Plus v8.0 - Getting Started Customizing ModelsLucas WalkerNo ratings yet

- Liquid-Liquid Extraction in Systems Containing Butanol and Ionic Liquids A ReviewDocument14 pagesLiquid-Liquid Extraction in Systems Containing Butanol and Ionic Liquids A ReviewBilal KazmiNo ratings yet

- 11 7677 WP Depg 1215 PDFDocument18 pages11 7677 WP Depg 1215 PDFTaniadi SuriaNo ratings yet

- Naphthacracking 120907055612 Phpapp02Document22 pagesNaphthacracking 120907055612 Phpapp02regina pramuditaNo ratings yet

- Acssuschemeng 9b05132 PDFDocument12 pagesAcssuschemeng 9b05132 PDFBilal KazmiNo ratings yet

- CrackingDocument20 pagesCrackingNiaz Ali KhanNo ratings yet

- TAWARRUQDocument3 pagesTAWARRUQBilal KazmiNo ratings yet

- Ie7b04477 Si 001Document6 pagesIe7b04477 Si 001Bilal KazmiNo ratings yet

- Drilling MethodsDocument50 pagesDrilling MethodsKhairul AshrafNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Commonlit Bloody KansasDocument8 pagesCommonlit Bloody Kansasapi-506044294No ratings yet

- Problems of Education in The 21st Century, Vol. 78, No. 4, 2020Document199 pagesProblems of Education in The 21st Century, Vol. 78, No. 4, 2020Scientia Socialis, Ltd.No ratings yet

- Identifying States of Matter LessonDocument2 pagesIdentifying States of Matter LessonRaul OrcigaNo ratings yet

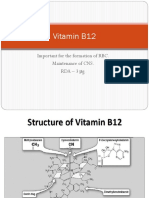

- Vitamin B12: Essential for RBC Formation and CNS MaintenanceDocument19 pagesVitamin B12: Essential for RBC Formation and CNS MaintenanceHari PrasathNo ratings yet

- My Testament On The Fabiana Arejola M...Document17 pagesMy Testament On The Fabiana Arejola M...Jaime G. Arejola100% (1)

- Multiple Choice Test - 66253Document2 pagesMultiple Choice Test - 66253mvjNo ratings yet

- Photojournale - Connections Across A Human PlanetDocument75 pagesPhotojournale - Connections Across A Human PlanetjohnhorniblowNo ratings yet

- Academic Transcript Of:: Issued To StudentDocument3 pagesAcademic Transcript Of:: Issued To Studentjrex209No ratings yet

- Exodus Post Apocalyptic PDF 10Document2 pagesExodus Post Apocalyptic PDF 10RushabhNo ratings yet

- Mpeg-1 11172-1Document46 pagesMpeg-1 11172-1Hana HoubaNo ratings yet

- All Projects Should Be Typed On A4 SheetsDocument3 pagesAll Projects Should Be Typed On A4 SheetsNikita AgrawalNo ratings yet

- 1402 2046Document11 pages1402 2046Luca PilottiNo ratings yet

- Social Case Study Report on Rape VictimDocument4 pagesSocial Case Study Report on Rape VictimJulius Harvey Prieto Balbas87% (76)

- Cultural Practices and Academic Performance of Blaan Pupils in Sinapulan Elementary SchoolDocument15 pagesCultural Practices and Academic Performance of Blaan Pupils in Sinapulan Elementary SchoolLorNo ratings yet

- Newtons First LawDocument14 pagesNewtons First LawcaitlyntreacyNo ratings yet

- So Neither or NorDocument2 pagesSo Neither or NorMita KusniasariNo ratings yet

- DNS Mapping and Name ResolutionDocument5 pagesDNS Mapping and Name ResolutionAmit Rashmi SharmaNo ratings yet

- Basic Statistical Tools for Data Analysis and Quality EvaluationDocument45 pagesBasic Statistical Tools for Data Analysis and Quality EvaluationfarjanaNo ratings yet

- Research Paper Is at DominosDocument6 pagesResearch Paper Is at Dominosssharma83No ratings yet

- Revolute-Input Delta Robot DescriptionDocument43 pagesRevolute-Input Delta Robot DescriptionIbrahim EssamNo ratings yet

- Lesson 6. TNCTDocument32 pagesLesson 6. TNCTEsther EdaniolNo ratings yet

- Ujpited ?tate of Americal: PresidentsDocument53 pagesUjpited ?tate of Americal: PresidentsTino Acebal100% (1)

- Cartha Worth SharingDocument27 pagesCartha Worth SharingtereAC85No ratings yet

- Detect Organic Elements with Sodium FusionDocument10 pagesDetect Organic Elements with Sodium FusionMukundNo ratings yet

- Ductile Brittle TransitionDocument7 pagesDuctile Brittle TransitionAndrea CalderaNo ratings yet

- University Students' Listening Behaviour of FM Radio Programmes in NigeriaDocument13 pagesUniversity Students' Listening Behaviour of FM Radio Programmes in NigeriaDE-CHOICE COMPUTER VENTURENo ratings yet

- 202002Document32 pages202002Shyam SundarNo ratings yet

- Thelen Reid Brown Raysman & Steiner LLP - Document No. 7Document1 pageThelen Reid Brown Raysman & Steiner LLP - Document No. 7Justia.comNo ratings yet

- Engb546 NP RevisedDocument5 pagesEngb546 NP RevisedRafaelaNo ratings yet

- Evidence Law PDFDocument15 pagesEvidence Law PDFwanborNo ratings yet