Professional Documents

Culture Documents

Stainless Steel Handbook 2015

Uploaded by

Claudio Flores0 ratings0% found this document useful (0 votes)

8 views6 pagesfittting

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentfittting

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views6 pagesStainless Steel Handbook 2015

Uploaded by

Claudio Floresfittting

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

I) 7A)

CAST IRON Y STRAINER FLANGED PN 10/16

Size:

Ends :

Min Temperature :

Max Temperature :

Max Pressure :

Specifications :

Materials :

Date 09717

DN 15 to DN 400

Flanges GN10/16

- 10°C

+ 120°C

16 Bars up to DN 200 ( 10 bars over )

Removable stainless steel filter

Bolted bonnet with draining cap

Cast iron body

uniVtrade.nl

Reval

Page | sur6

Tnfomanion provided a» an indisation and wuljoct to pooble modification

REF. 220

CAST IRON Y STRAINER FLANGED PN 10/16

SPECIFICATIONS

Use

Removable stainless steel fiter

REF. flanges GN16 up to ON200, GN10 over ( GN1 possible from DN 250 to 300 )

Horizontal or vertical position with descendant fuid (respect the fow direction indicated by the arrow )

Mesh 1,mm up to DN 128, 1.5 mm from DN 150 to DN 800 , 8 mm for ON 360 and DN 400

Bolted bonnet with draining cap threaded BSP

For common fluids

Min Temperature Ts :- 10°C

Max Temperature Ts :+ 120°C

Max Pressure Ps: 16 bars up to DN200 , 10 bars over

HEAD LOSS GRAPH

Head loss

(Bar)

o7

08s

oat

028

oa

007

0.06.

0.04.

003.

oo.

DN 40 50 65 80 100 125 150 200 250300 350 400

22 4s 9 3 8 2 45 90 126181 227 454908 130218162271 4542 (MB/H)

FLOW

uniVtrade.nl

Dave: 09711

Revol

Page 2 sur

Tnformation provided ss on Indication and subject wo pomibic modification

REF. 220

CAST IRON Y STRAINER FLANGED PN 10/16

REF. flanges GN10/16 from DN 15 to 180, GN16 for DN200, GN10 from DN250 to 400 ( GN16 possible for DN260 and 300 )

MATERIALS :

tem Materials

1 Body ast iron EN GJL-250

2 Fitter $88 308

3 Bonnet Gast iron EN GJL-250

4 Bonnet gasket Graphite

5 Draining cap Brass

6 Bonnet screw Stoel Ret 372

uniVtrade.nl

Date 0977 Revi

Page 3 sur6

Tnformation provided ss on Ealication and subject > pomible modification

CAST IRON Y STRAINER FLANGED PN 10/16

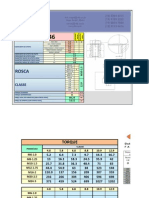

Filter size

DN

H1 B&B

a a) O Ce) 250 300 350

L 130 | 150 | 160 290 | 310 | 350 | 400 | 4a0 | 600 | 730 | as0 | 980 | 1400

Ref. 4 85 | 78 | 84 | 120 | 131 | 135 | 165 | 185 | 226 | 267 | 305 | 368 | 616 | ses | cas | 759

drain) | ser | aves | aves | aim | ava | sas | aos | sas | ava | siae | aie | a | ts [oem | ares | a2

220 oD 16 | 22 | 2 | 35 | a1 | st | 67 | 79 129 | 156 | 209 | 250 | 300 | 353 | 403

Ht as | 60 | 72 | 86 | 101 | 115 | 147 | 160 | 195 | 234 | 230 | 325 | ase | 484 | 500 | 650

mosh [14 | ta | aa faa faa [aa [at] ta [ta [aa [as [as | 1s | ts] 3 | 3

Weight inka) | 22 | 3 | 37 | 58 | 74 | 928 |13.11|1687|2447| 398 | 57 | 97 | 163.5] 2335] 312 | 422

uniVtrade.nl

Dawe0971 Revol

Page 4 sur

Tfommmion provided w an indication and sijelo posible modification

REF. 220

CAST IRON Y STRAINER FLANGED PN 10/16

‘STANDARDS :

+ Fabrication according to ISO 9001 : 2008

* DIRECTIVE 97/23/CE : Concemed by article 3, § 3

* Length according to DIN 3202 - NF 29354 , EN 558-1 serie 1

* RF. flanges according to EN 1092-1 PN10/16

INSTALLATION POSITIONS

Vertical position ( descondand fluid ) Horizontal position

ADVICE : Our opinion and our advice are not guaranteed and manufact. shall nt be liable for the consequences of damages.

‘The customer must check the right choice ofthe products withthe real service conditions.

uniVtrade.nl

Date: 09711 Revol

Page § sur

Information provided es on Indication and subject to pomible modification

REF. 220

CAST IRON Y STRAINER FLANGED PN 10/16

INSTALLATION INSTRUCTIONS

GENERAL GUIDELINES :

‘+ Ensure that the strainers to be used are appropriate for the conditions of the installation (type of

fluid, pressure and temperature),

‘+ Be sure to have enough valves to be able to isolate the sections of piping as well as the appropriate

equipment for maintenance and repair.

‘+ Ensure that the strainers to be installed are of correct strenght to be able to support the capacity of their

usage.

‘+ Installation of all circuits should ensure that their function can be automatically tested on a regular

basis (at least two times a year

INSTALLATION INSTRUCTIONS :

‘+ Before installing the strainers, clean and remove any objects from the pipes (in particular bits of

sealing and metal) which could obstruct and block the strainers.

«Ensure that both connecting pipes either side of the strainer (upstream and downstream) are

aligned (if they're not, the strainer may not work correctly).

‘+ Make sure that the two sections of the pipe (upstream and downstream) match, the strainer unit will

not absorb any gaps. Any distortions in the pipes may affect the thightness of the connection, the

working of the strainer and can even cause a rupture. To be sure, place the kit in position to ensure the

assembling will work.

‘+ Make sure flanges are cleaned.

* If sections of piping do not have their final support in place, they should be temporarily fixed. This

is to avoid unnecessary strain on the strainer.

© Tighten the bolts in cross.

‘© The pressurisation must be increased gradually.

* So that the maintenance operations could be easily done, place a stop valve before and after the

strainer Thereby, the strainer could be isolated. During this operation, ensure to have a new bonnet gasket to avoid

a leakage during the restarting,

* Fluids in the strainer must not contain solid objects ( it could damaged the seat ).

uniVtrade.nl

Dave: 09717 Revor

Page 6 sur

Tnformation provided as on indication and aubject to posable madification

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Scope of Work-Fabrication of Heat ExchangersDocument3 pagesScope of Work-Fabrication of Heat ExchangersAsad KhanNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- API 6A Spec Flange Bolt+ Ring Chart PDFDocument1 pageAPI 6A Spec Flange Bolt+ Ring Chart PDFAlan JuanNo ratings yet

- Powell Gate ValvesDocument3 pagesPowell Gate Valveszguy360No ratings yet

- CameronDocument4 pagesCameronhermon_agustio0% (1)

- Torque and clamp load calculation for M10 boltsDocument4 pagesTorque and clamp load calculation for M10 boltsmajonas77No ratings yet

- STL Sand Trap LouverDocument3 pagesSTL Sand Trap LouverImran HussainNo ratings yet

- Duplex Stainless SteelsDocument19 pagesDuplex Stainless SteelsdinaksNo ratings yet

- Is 5561 1970Document17 pagesIs 5561 1970Palani JayaramanNo ratings yet

- Field Welding ManualDocument30 pagesField Welding Manualshakirhamid6687No ratings yet

- AntiSegregation HopperDocument5 pagesAntiSegregation Hoppermecaunidos7771No ratings yet

- Technical Specification of ABC Cable - Ergon EnergyDocument61 pagesTechnical Specification of ABC Cable - Ergon EnergySatyaNo ratings yet

- Internal Lining Repairs PDFDocument2 pagesInternal Lining Repairs PDFClaudio FloresNo ratings yet

- Coastal F: Ansi B16.5 Class 900 Welding Neck FlangesDocument1 pageCoastal F: Ansi B16.5 Class 900 Welding Neck FlangesClaudio FloresNo ratings yet

- Cromacore 2209T1Document1 pageCromacore 2209T1Claudio FloresNo ratings yet

- Praxair Shielding Gas ManualDocument70 pagesPraxair Shielding Gas ManualjanedrunkerNo ratings yet

- Paranormal Experiences That Lie Outside The Range of Normal Experience or Scientific ExplanationDocument73 pagesParanormal Experiences That Lie Outside The Range of Normal Experience or Scientific ExplanationClaudio Flores0% (1)

- Assembly Model 1Document1 pageAssembly Model 1Claudio FloresNo ratings yet

- Assembly Model 1Document1 pageAssembly Model 1Claudio FloresNo ratings yet

- 223Document10 pages223Claudio FloresNo ratings yet

- 223Document10 pages223Claudio FloresNo ratings yet

- 6 Medidor de Espesor de Recubrimiento TT211Document1 page6 Medidor de Espesor de Recubrimiento TT211Claudio FloresNo ratings yet

- Classifications of Magnetic MaterialsDocument3 pagesClassifications of Magnetic MaterialsNasha Agarwal100% (1)

- VEC Question Bank on Manufacturing Technology 1Document13 pagesVEC Question Bank on Manufacturing Technology 1rgopi_83No ratings yet

- Asme Sa-562-Sa-562M Specification For Pressure Vessel Plates, Carbon Steel, Manganese-Titanium Forglass or Diffused Metallic Coatings PDFDocument4 pagesAsme Sa-562-Sa-562M Specification For Pressure Vessel Plates, Carbon Steel, Manganese-Titanium Forglass or Diffused Metallic Coatings PDFElkin Dario Aguirre MesaNo ratings yet

- Magnets for Industry: Powerful Solutions for All ApplicationsDocument50 pagesMagnets for Industry: Powerful Solutions for All Applicationssalty.mothNo ratings yet

- " Analysis of Parameters For Casting Ductile Iron Pipe: A Dissertation Phase-I Presentation OnDocument34 pages" Analysis of Parameters For Casting Ductile Iron Pipe: A Dissertation Phase-I Presentation OnAnonymous l5PQDDkNo ratings yet

- TriMarkCatalog Filler MaterialDocument50 pagesTriMarkCatalog Filler MaterialSuphi YükselNo ratings yet

- Access Fitting Weld ProcedureDocument2 pagesAccess Fitting Weld Procedurewhah11No ratings yet

- Analyze A Sample of Brass QualitativelyDocument4 pagesAnalyze A Sample of Brass QualitativelyMEGHNA MATHURNo ratings yet

- ASTM A131 Steel grade EH36 mechanical propertiesDocument1 pageASTM A131 Steel grade EH36 mechanical propertiesI-SignNo ratings yet

- b51 Gabions 403Document6 pagesb51 Gabions 403Bachtiar Ali AfandiNo ratings yet

- Powerpoint Templates: Metallic Materials Constraints for SpacecraftDocument71 pagesPowerpoint Templates: Metallic Materials Constraints for Spacecraftleila hanjani hanantoNo ratings yet

- Pedrollo Submersible Vortex Pump - VXDocument2 pagesPedrollo Submersible Vortex Pump - VXGeorge CobraNo ratings yet

- Spi Plate Flange Guide 2009Document20 pagesSpi Plate Flange Guide 2009Iebe SeventynineNo ratings yet

- ABREX NSSMC Abrasion Resistance Plate Catalogue PDFDocument8 pagesABREX NSSMC Abrasion Resistance Plate Catalogue PDFomni_partsNo ratings yet

- Welding ErrorsDocument42 pagesWelding ErrorsNDTInstructorNo ratings yet

- ATLAS 7R DatasheetDocument5 pagesATLAS 7R DatasheetiorrusNo ratings yet

- MD Reviewer 1Document1 pageMD Reviewer 1Dave Vendivil SambranoNo ratings yet

- Shape Memory AlloysDocument16 pagesShape Memory AlloysIvan HernandezNo ratings yet

- Lightweight Metal Foam Heat ExchangersDocument7 pagesLightweight Metal Foam Heat ExchangersPat RNo ratings yet

- Ecoreco E-Waste Recovery-By Mr. T R Rao 2Document10 pagesEcoreco E-Waste Recovery-By Mr. T R Rao 2bksoni100% (1)