Professional Documents

Culture Documents

Il 03900006 e

Uploaded by

Jonathan Parra MondacaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Il 03900006 e

Uploaded by

Jonathan Parra MondacaCopyright:

Available Formats

Installation Leaflet IL03900006E

Effective May 2012

Superseded April 2012

Instructions for S811+ Soft Starter, S811+T..., S811+U..., and S811+V...

9.

DANGER HIGH VOLTAGE

MAKE SURE ALL POWER IS OFF BEFORE WIRING. FAILURE TO DO SO WILL RESULT IN

PERSONAL INJURY, DEATH OR SUBSTANTIAL PROPERTY DAMAGE.

The Soft Starter features an electronic motor overload protection feature. This

protects the motor and power wiring against overheating caused by excessive

current for extended periods of time.

Note: Short circuit protection must be applied on the line side of the soft starter.

Entering the motor full load current rating, using the Mtr Nameplate FLA parameter programs trip current. It is programmable in amps from 32% - 100% of the

units rated current.

Table 1. Overload - Adjustment Settings

Catalog No.

Current Range

Catalog No.

Current Range

S811+T18...

S811+T24...

S811+T30...

56 - 180

75 - 240

95 - 304

S811+U36...

S811+U42...

S811+U50...

112 - 360

131 - 420

156 - 500

S811+V36...

S811+V42...

S811+V50...

S811+V65...

S811+V72...

S811+V85...

S811+V10...

112 - 360

131 - 420

156 - 500

203 - 650

250 - 720

265 - 850

320 - 1000

Note: Mtr Nameplate FLA parameter is settable to any point within its range.

The thermal overload is designed to protect the motor from heating caused by

drawing too much current. If the motor is overloaded, the current drawn rises and

heats the motor. The Mtr Nameplate FLA sets the trip threshold and the trip class

(5 to 30) is set with the Overload Trip Class parameter.

IMPORTANT: Note the following items before you begin

1.

2.

3.

4.

5.

6.

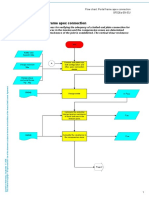

P and Hand inputs must be energized (24V DC) to enable starting of the

soft starter from the terminal block.

To Start: Apply 24V DC to Input 1 while the P input is energized.

To initiate a Stop, remove the P input.

For 2-wire control, jumper P and Input 1 together.

After an Overload Trip, the S811+ Soft Starter cannot be restarted until

the prescribed cool-down time has elapsed. Cycling power does not reset

the timers. If 24V DC power is removed, the soft starter will remember the

remaining time and will resume the cool-down timing when power is again reapplied.

When the S811+ goes into bypass, a sound similar to contactor chatter can

be heard. This sound is the result of multiple contactors closing one after the

other in a very short period. It is normal operation intended to reduce the

surge current requirements of your power supply.

Initial Configuration

1.

2.

3.

4.

5.

6.

7.

8.

The S811+ should now function properly for most applications. Adjust other

parameters as necessary to meet your application needs.

Table 2. Line and Load Power Wiring

(Qty.)Lug

Kit

Number of

Conductors

Wire Sizes Cu

75C Only

Torque

Req.

4 - 1/0 MCM

(21.2 - 53.5 mm2)

250 Lb-in

(28.3 Nm)

4/0 - 500 MCM

(107 - 240 mm2)

250 Lb-in

(28.3 Nm)

2/0 - 300 MCM

(70 - 150 mm2)

225 Lb-in

(25.5 Nm)

S811+T..., S811+U...

(2) EML22

(2) EML23

(2) EML24

1

2

(2) EML25

(2) EML26

1

2

S811+V...

(2) EML28

4/0 - 500 MCM

(107 - 240 mm2)

250 Lb-in

(28.3 Nm)

(2) EML30

(2) EML32

4

6

2

1 2

4/0 - 500 MCM

(107 - 240 mm2)

250 Lb-in

(28.3 Nm)

(2) EML33

2/0 - 300 MCM

(70 - 150 mm2)

225 Lb-in

(25.5 Nm)

Requires special lug cover. Check with Eaton for availability.

CSA approved 350 MCM - 500 MCM.

Table 3. Control Wiring

1

2

Wire Size

Number of Conductor

Torque Req.

22 - 14 AWG (0.33 - 2.5 mm2)

12 AWG (4.0 mm2)

3.5 Lb-in

(0.4 Nm)

Table 4. Short Circuit Rating

Soft Starter

Catalog Number

Three-Phase Short Circuit Rating

240V

480V

600V

S811+T...

S811+U...

S811+V...

18 kA

30 kA

42 kA

18 kA

30 kA

42 kA

18 kA

30 kA

42 kA

690V

1

1

Contact Eaton.

Suitable for use in a circuit capable of delivering not more than 30,000 rms symmetrical amperes, 600 volts maximum when protected by Class L fuses or inverse

time circuit breaker rated 600V, 1500 amperes, maximum.

Table 5. MOV Kit Options

1

Before applying the Line voltage, apply 24V DC to the + and - connections of

the S811+s terminal block. Eaton will be displayed by the DIM while the

S811+ is powering up. When power-up is complete the DIM should be displaying 3 Line Currents.

Using the DIM, review the parameter settings in the Soft Start

Config and Protections menus. The following setup procedures will use

the factory default settings unless changed by you.

In the Soft Start Config menu, set the Mtr Nameplate FLA parameter to the

motors nameplate rated current. This setting assumes the motor has a 1.15

Service Factor.

Set Overload Trip Class parameter for the desired overload trip characteristic

(curve).

In the Protections menu set the Motor Rated Volt parameter to the motor s

operating voltage.

If auto fault reset is required, set the Reset Mode parameter to Auto (and Start

Control to Level - default). Note: Auto Reset is intended for unattended installations where there is no danger to personnel or other equipment when the

motor starts without warning. If Auto Reset is enabled, CAUTION must be

exercised to assure that any restart occurs in a safe manner.

Apply the Mains voltage and verify that no fault is present. If a fault is indicated, display the Motor Control menus Active Faults parameter to determine

the source of the fault.

A Phase Reversal Fault can be remedied by either changing the Phase

Sequence parameter from ABC to ACB or removing Mains power and

switching the incoming line connections at L1 and L2 of the S811+.

Using the S811+ Jog Input, jog the motor just enough to verify that the direction of rotation is correct.

Eaton Corporation

Electrical Sector

1111 Superior Ave.

Cleveland, OH 44114

United States

877-ETN-CARE (877-386-2273)

Eaton.com

2012 Eaton Corporation

All Rights Reserved

Publication No. IL03900006E / 001

April 2012

Catalog Number

Description

EMS39

EMS41

600V (max) MOV for S811+... Soft Starters

690V (max) MOV for S811+... Soft Starters

Note: LOAD WIRES MUST BE 75o C STRANDED COPPER CONDUCTORS ONLY

WHEN USING THE PROTECTIVE MODULE [EMS39]

Table 6. 24V Power Supply Kits

Catalog

Number

Steady State

Wattage

Inrush

Wattage

Input Voltage

PSG240E

PSG240F

240W

240W

360W

360W

85 - 264 VAC

320 - 575 VAC

Table 7. Control Circuit Fuseholder Kit

Catalog Number

Fuse Type

C320FBR

Class CC

Note: The ground-fault protection system shall be performance tested when first

installed on site. The test shall be conducted in accordance with instructions that

shall be provided with the equipment. A written record of this test shall be made

and shall be available to the authority having jurisdiction.

Eaton is a registered trademark of Eaton

Corporation.

All other trademarks are property of their

respective owners.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Grillage Analogy C.S.surana R.agrawal - For WordDocument283 pagesGrillage Analogy C.S.surana R.agrawal - For WordMohak Nagrani100% (1)

- JHA For Tie-In at PCR14-02Document7 pagesJHA For Tie-In at PCR14-02Francis Enriquez TanNo ratings yet

- C Rollway PDFDocument16 pagesC Rollway PDFoxonoerNo ratings yet

- 2sc-Pco - Dual Solenoid Control ValveDocument3 pages2sc-Pco - Dual Solenoid Control Valveshan07011984No ratings yet

- Available in Capacities From 35 To 2,637 Ammonia Tons!: Bulletin 153BDocument32 pagesAvailable in Capacities From 35 To 2,637 Ammonia Tons!: Bulletin 153BHarikrishnanNo ratings yet

- Allison - Technical Documents 157 - Cooling Test - UpdateDocument29 pagesAllison - Technical Documents 157 - Cooling Test - Updateangie michell paccini rodriguezNo ratings yet

- 17-03 Overpressure Blowdown PDFDocument9 pages17-03 Overpressure Blowdown PDFJoyNo ratings yet

- Atchdog: Remote Monitoring System W/interruptionDocument2 pagesAtchdog: Remote Monitoring System W/interruptionSamuel RomeroNo ratings yet

- Ravi Sir DLC PresentationDocument13 pagesRavi Sir DLC Presentationসৌগত রায় ঘটকNo ratings yet

- HammerDocument128 pagesHammerIulian MihaiNo ratings yet

- 1 AdDocument39 pages1 AdPratik PradhanNo ratings yet

- PET Resin Production and UsesDocument13 pagesPET Resin Production and UsesA MahmoodNo ratings yet

- SF026a-Flow Chart Portal Frame Apex ConnectionDocument3 pagesSF026a-Flow Chart Portal Frame Apex ConnectiondvelchevNo ratings yet

- Gold AlloysDocument16 pagesGold AlloyscoldmailhotmailNo ratings yet

- Gantry Crane WheelsDocument3 pagesGantry Crane WheelsflasnicugNo ratings yet

- Correction of Service Manual Si-18 M-11011Document18 pagesCorrection of Service Manual Si-18 M-11011Ahmed AzadNo ratings yet

- XDB102 3Document3 pagesXDB102 3Young WuNo ratings yet

- GFRC Glass Fibre Reinforced ConcreteDocument9 pagesGFRC Glass Fibre Reinforced ConcreteMohd ShahrizanNo ratings yet

- High Cost of Quick Turnarounds and Erroneous Procedures: Petr LenfeldDocument11 pagesHigh Cost of Quick Turnarounds and Erroneous Procedures: Petr Lenfeldkirandevi1981No ratings yet

- Lean Manufacturing A1Document14 pagesLean Manufacturing A1Ankita SinhaNo ratings yet

- CCCC - Direct Buried 1200 mm2 132 KV Double Circuits (Filling 1.5 K.M-W)Document10 pagesCCCC - Direct Buried 1200 mm2 132 KV Double Circuits (Filling 1.5 K.M-W)ManafNo ratings yet

- DLF Linear Slot DiffuserDocument15 pagesDLF Linear Slot DiffuserintequabNo ratings yet

- VRS VRRM maximum values for continuous operation SEMIPACK 5 thyristor modulesDocument4 pagesVRS VRRM maximum values for continuous operation SEMIPACK 5 thyristor modulesEdgar Allan OlescoNo ratings yet

- Dlab Ms-H280-ProDocument3 pagesDlab Ms-H280-ProAntoNo ratings yet

- All Makes Filters Cross Reference GuidesDocument5 pagesAll Makes Filters Cross Reference GuidesJafet Israel RojasNo ratings yet

- Spe 0413 0012 OgfDocument6 pagesSpe 0413 0012 OgfZenga Harsya PrakarsaNo ratings yet

- Pellets TechnologyDocument8 pagesPellets TechnologyRajesh Chaudary ANo ratings yet

- 9103796-105CN - Techn Descr SC 45Document139 pages9103796-105CN - Techn Descr SC 45happyNo ratings yet

- Phase Transitions: Lectures in Physical Chemistry 4Document8 pagesPhase Transitions: Lectures in Physical Chemistry 4Farah AnjumNo ratings yet

- Klip Lok 700 Brochure 2015Document6 pagesKlip Lok 700 Brochure 2015Andreas KamwankaNo ratings yet