Professional Documents

Culture Documents

2012 Mfe 3207

Uploaded by

Bernice JohnsonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2012 Mfe 3207

Uploaded by

Bernice JohnsonCopyright:

Available Formats

UNIVERSITY OF MALTA

FACULTY OF ENGINEERING

B.ENG.(HONS.) IN MECHANICAL ENGINEERING

Year IV SEMESTER II

JUNE 2012 SESSION OF EXAMINATIONS

MFE3207 Quality Management and Control

31st May 2012

9.15-11.15 hours

Stationary: Control Chart for Variable Data

Use of Calculators Allowed

List of Equations

This paper contains FOUR questions. You are to attempt THREE questions.

1. Statistical Process Control (SPC) is an important aspect of quality management and control.

(a)

What is meant by the term control in Statistical Process Control?

(5 marks)

(b)

What is the difference between SPC for variables and SPC for attributes?

(4 marks)

(c)

Explain the difference between special and common causes of variation. Give

examples in your explanation.

(6 marks)

(d)

Why is variation in processes important in quality management and control?

(5 marks)

(e)

How can variation be provided for in the design of products?

(5 marks)

(f)

Why is the use of sampling important when inspecting large quantities of material?

Use diagrams, and give examples where appropriate.

(8 marks)

Page 1 of 3

2. The ISO9001:2008 standard for Quality Management Systems is of increasing importance to

the food and drink industry. A food manufacturing company is looking towards implementing

a quality management system. As the quality engineer responsible for business processes in

this company you are being asked to investigate the details of ISO9001:2008.

(a)

What advantages would be brought to this food manufacturing company by achieving

ISO9001:2008 certification?

(5 marks)

(b)

Describe in detail the management responsibilities in setting up and maintaining a

Quality Management System.

(10 marks)

(c)

What clause of the Quality Management System would the data collection process be

a part of? Give reasons for your answer.

(5 marks)

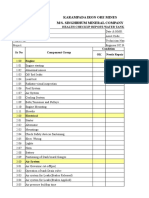

(d)

This company is also carrying out a Cost of Quality exercise. Manufacturing costs per

year are 500,000. Prevention, Appraisal and Failure costs are listed in Table 1. The

costs of implementing the Quality Management System are of 15,000. Run a

comparative Cost of Quality analysis of this data, before and after introducing the

Quality Management System. Comment on the results.

(13 marks)

Table 1 - Prevention, Appraisal and Failure costs

Prevention

Appraisal

Failure

5,000

75,000

5,000

3. A Bio-Medical manufacturing company is a supplier to some of the industrys leading

companies. This company is having problems with maintaining the high production rates at

the same quality levels. The management team are considering the implementation of Quality

Circles on the shop floor to solve this problem.

(a)

What is the principle philosophy behind Quality Circles and why in your opinion

have the management team made the decision of introducing this quality method?

(6 marks)

(b)

List the New Quality Tools and describe in detail how each of these tools would

help the Quality Circles to achieve their goals?

(14 marks)

(c)

What does the Kaizen philosophy promote and how?

(7 marks)

(d)

Describe two methodologies that can help the company to further implement the

Kaizen philosophy.

(6 marks)

Page 2 of 3

4.

A supplier and manufacturer of stainless steel components has been receiving many

complaints and returns from its customers due to defective products. For this reason the

company has decided to monitor the situation by carrying out Statistical Process Control

(SPC) at the end of the production line. Table 2 shows the SPC Data collected during an 8

hour shift. The specification for this product dimension is 15.5mm1.5mm

Table 2 SPC Data

Time

8.00

8.30

9.00

9.30

10.00

10.30

11.00

11.30

12.00

12.30

13.00

13.30

14.00

14.30

15.00

15.30

16.00

1

15.20

15.40

15.30

14.90

14.90

15.00

14.90

15.70

15.50

15.40

14.60

15.40

14.50

15.50

15.10

16.40

16.40

2

15.60

15.20

15.00

15.40

15.20

14.60

14.90

15.30

15.20

15.00

15.00

15.50

15.30

15.00

14.80

16.80

16.80

3

15.50

15.40

14.80

15.50

14.70

14.60

15.50

14.90

14.90

14.80

15.70

15.00

14.90

14.60

15.30

17.20

17.20

(a)

Describe the steps that should be followed by the process engineers to collect the data

required.

(10 marks)

(b)

What benefits does the use of SPC bring to the company?

(5 marks)

(c)

What type of SPC chart should be used for this study?

(3 marks)

(d)

Plot the relevant SPC Charts using the graph paper provided.

(10 marks)

(e)

Analyse the data and SPC chart plotted, and state your observations.

(5 marks)

Page 3 of 3

You might also like

- 2014 Mfe 3207Document4 pages2014 Mfe 3207Bernice Johnson100% (1)

- Control Charts: Nov 2020 Nitin Is Making Use of Control Charts To Monitor The Thickness andDocument5 pagesControl Charts: Nov 2020 Nitin Is Making Use of Control Charts To Monitor The Thickness andYajish Budia0% (2)

- TQM Model Question PaperDocument1 pageTQM Model Question PaperpecmbaNo ratings yet

- This Paper Contains Four Questions. You Are To Attempt Any ThreeDocument4 pagesThis Paper Contains Four Questions. You Are To Attempt Any ThreekwejkbaNo ratings yet

- GE 2022 Model Question PapersDocument3 pagesGE 2022 Model Question PapersDeepa DhilipNo ratings yet

- Anna University Question Papers and AnswersDocument107 pagesAnna University Question Papers and AnswersSengottuvelu SundaramNo ratings yet

- 058 - GE8077, GE6757 Total Quality Management TQM - Question Bank 2Document19 pages058 - GE8077, GE6757 Total Quality Management TQM - Question Bank 2heba aburayyanNo ratings yet

- Production & Operation ManagementDocument13 pagesProduction & Operation Managementmadhvendra99No ratings yet

- GHJKLDocument2 pagesGHJKLAnonymous lt2LFZHNo ratings yet

- 05 Allowed: Questions: 0G: Ffit"#J"Rflff'TmanagementDocument2 pages05 Allowed: Questions: 0G: Ffit"#J"Rflff'TmanagementRaman KumarNo ratings yet

- Mtech. Total Quality ManagementDocument5 pagesMtech. Total Quality ManagementsimalaraviNo ratings yet

- OmDocument7 pagesOmBishnu Ram GhimireNo ratings yet

- GE8077 Total Quality Management 3Document3 pagesGE8077 Total Quality Management 3Atharsh SNo ratings yet

- Retake Exam MOT9564 2010-11Document2 pagesRetake Exam MOT9564 2010-11mrslayerdudeNo ratings yet

- Soalan Quality ControlDocument5 pagesSoalan Quality ControlIskandar Ibrahim100% (1)

- Om 01Document4 pagesOm 01Gurcharan Rajal SinghNo ratings yet

- Analysis of Product Quality Improvement Through Kaizen and DMAIC Method in Rubber Sole ManufacturingDocument7 pagesAnalysis of Product Quality Improvement Through Kaizen and DMAIC Method in Rubber Sole ManufacturingEditor IjasreNo ratings yet

- Business Statistics L3 Past Paper Series 2 2011Document7 pagesBusiness Statistics L3 Past Paper Series 2 2011Haznetta HowellNo ratings yet

- MG 1301 - TQM - QB - 5 UnitsDocument7 pagesMG 1301 - TQM - QB - 5 UnitsSenthil KumarNo ratings yet

- GE2022 TQM Question BankDocument21 pagesGE2022 TQM Question BankVadivel AeroNo ratings yet

- IMS IA - Exam PaperDocument15 pagesIMS IA - Exam PaperujuabhiNo ratings yet

- OM01Document4 pagesOM01Gurcharan Rajal SinghNo ratings yet

- CMA SrilankaDocument7 pagesCMA SrilankaFerry SihalohoNo ratings yet

- 2007 GoodDocument155 pages2007 Goodpooyeh_rNo ratings yet

- 2nd Year Assignment Question Papers 2011 2012Document12 pages2nd Year Assignment Question Papers 2011 2012Shraveen RajNo ratings yet

- To Analyze The Use of Statistical Tool/S For Cost Effectiveness and Quality of ProductsDocument11 pagesTo Analyze The Use of Statistical Tool/S For Cost Effectiveness and Quality of ProductsInternational Organization of Scientific Research (IOSR)No ratings yet

- Reduce The Failure Rate of The Screwing Process With Six Sigma ApproachDocument8 pagesReduce The Failure Rate of The Screwing Process With Six Sigma ApproachLe ProfesseurNo ratings yet

- Basic LevelDocument12 pagesBasic Levelmohan yadavNo ratings yet

- Tota Lquality Management MB016 QuestionDocument21 pagesTota Lquality Management MB016 QuestionAiDLo0% (2)

- AssignmentDocument3 pagesAssignmentNIRALINo ratings yet

- Improving Quality With Basic Statistical Process Control (SPC) Tools: A Case StudyDocument13 pagesImproving Quality With Basic Statistical Process Control (SPC) Tools: A Case Studymarine2006No ratings yet

- HBC 2402 HPS 2209 Production and Operations ManagementDocument2 pagesHBC 2402 HPS 2209 Production and Operations Managementkagunyalewis00No ratings yet

- Chapter - 4, 6, 10 QuizDocument22 pagesChapter - 4, 6, 10 QuizMd Al Alif Hossain 2121155630No ratings yet

- Case StudyDocument13 pagesCase Studybia palmaNo ratings yet

- Quality Management System in Automatic Machine ConDocument5 pagesQuality Management System in Automatic Machine Conrthik123No ratings yet

- TQM Am06Document2 pagesTQM Am06Somasundaram RamuNo ratings yet

- ISO 9001correlation MatricesDocument7 pagesISO 9001correlation MatricesSyv Consultores AsociadosNo ratings yet

- 305EMM Total Quality Management 2020/2021 Statistical Process Control Improvement Program and Quality Costing Submission Date 14 June 2021Document4 pages305EMM Total Quality Management 2020/2021 Statistical Process Control Improvement Program and Quality Costing Submission Date 14 June 2021Muhammad Hussain0% (1)

- TEST1 Om AnswerDocument12 pagesTEST1 Om AnswerSyahidan AyobNo ratings yet

- TQM Model PaperDocument5 pagesTQM Model PaperEricka ClementsNo ratings yet

- Waste Elimination Using VSM and VALSATDocument9 pagesWaste Elimination Using VSM and VALSATkokoblukNo ratings yet

- Production Planning and Control Question BankDocument12 pagesProduction Planning and Control Question Bankelavarasansiva100% (1)

- ISO 9000 Solutions, Inc.: Free Download - 2000Document11 pagesISO 9000 Solutions, Inc.: Free Download - 2000tlidiaNo ratings yet

- ExamDocument6 pagesExamBWQ67% (3)

- Total Quality Management07ADocument4 pagesTotal Quality Management07ASafia LamraniNo ratings yet

- Six Sigma Yellow Belt-Part 1Document15 pagesSix Sigma Yellow Belt-Part 1Eduardo Expósito EspinosaNo ratings yet

- TQM-important QuestionsDocument5 pagesTQM-important QuestionsSridhar Atla100% (1)

- Standard Iso 9001:2015, Most Important Changes and Their Impact On Supplier Complaints ManagementDocument7 pagesStandard Iso 9001:2015, Most Important Changes and Their Impact On Supplier Complaints ManagementJuan Pablo Castellanos MuñozNo ratings yet

- CMA Srilanka PDFDocument7 pagesCMA Srilanka PDFFerry SihalohoNo ratings yet

- Workshop D - Req of STNDDocument3 pagesWorkshop D - Req of STNDKranti Yadav100% (1)

- BA7104 TotalQualityManagementquestionbankDocument10 pagesBA7104 TotalQualityManagementquestionbankAnonymous uHT7dDNo ratings yet

- Checklist+ISO9001 1t2009Document48 pagesChecklist+ISO9001 1t2009leiasaan2100% (1)

- Production and Operation Mgt.Document2 pagesProduction and Operation Mgt.Princesrk786No ratings yet

- TQM QBDocument11 pagesTQM QBsrichandranidNo ratings yet

- Smu 4th Sem Operation Management AssignmentsDocument11 pagesSmu 4th Sem Operation Management AssignmentsProjectHelpForuNo ratings yet

- SCM Test 2Document4 pagesSCM Test 2hmichaelkimNo ratings yet

- Departmentof Mechanicalengineering Question Bank Viiisemester - Ie6605Productionplanning Andcontrol Question Bank U N I T I I N T R O D U C T IO NDocument12 pagesDepartmentof Mechanicalengineering Question Bank Viiisemester - Ie6605Productionplanning Andcontrol Question Bank U N I T I I N T R O D U C T IO NSanthanakumar MNo ratings yet

- Cqe Q&aDocument51 pagesCqe Q&aGaren Chen 凯仁100% (1)

- ASTM A686 T72301 W1A 9.5 Steel Plate, ASTM T72301 W1A 9.5 Tool SteelDocument2 pagesASTM A686 T72301 W1A 9.5 Steel Plate, ASTM T72301 W1A 9.5 Tool SteelBernice JohnsonNo ratings yet

- Fig - F: March 30, 1954 M. J. Stu'RzmanDocument6 pagesFig - F: March 30, 1954 M. J. Stu'RzmanBernice JohnsonNo ratings yet

- Effect of Hardness, Residual Stress and Grain Size On The Fatigue Life of Ultra-Clean Bainitically Hardened Bearing SteelDocument69 pagesEffect of Hardness, Residual Stress and Grain Size On The Fatigue Life of Ultra-Clean Bainitically Hardened Bearing SteelBernice JohnsonNo ratings yet

- Sin Cos Cos Sin Cos Sin Cos Sin 2 Cos Sin Cos Sin 2 Sin Cos) (TDocument6 pagesSin Cos Cos Sin Cos Sin Cos Sin 2 Cos Sin Cos Sin 2 Sin Cos) (TBernice JohnsonNo ratings yet

- Saben Silver Steel 1.2210: C Si MN CR Mo W V CoDocument1 pageSaben Silver Steel 1.2210: C Si MN CR Mo W V CoBernice JohnsonNo ratings yet

- Mme3210 Sem 2 2015 PCDocument3 pagesMme3210 Sem 2 2015 PCBernice JohnsonNo ratings yet

- 2013 Mfe 3207Document3 pages2013 Mfe 3207Bernice JohnsonNo ratings yet

- Wild HorsesDocument4 pagesWild HorsesBernice Johnson0% (2)

- Stationery: Use of Calculators Is AllowedDocument3 pagesStationery: Use of Calculators Is AllowedBernice JohnsonNo ratings yet

- Im Not Giving UP YET!!!!!!!!!!!!!!! !! U Should Never Let Go ofDocument2 pagesIm Not Giving UP YET!!!!!!!!!!!!!!! !! U Should Never Let Go ofBernice JohnsonNo ratings yet

- Values in Science and TechnologyDocument19 pagesValues in Science and TechnologyBernice JohnsonNo ratings yet

- What've I Gotta Say To Change Your Mind What've I Gotta Do To Make You Mine This Feeling I Get Keeps Me Wishing We'd Never MetDocument1 pageWhat've I Gotta Say To Change Your Mind What've I Gotta Do To Make You Mine This Feeling I Get Keeps Me Wishing We'd Never MetBernice JohnsonNo ratings yet

- End of Year Test 2008Document4 pagesEnd of Year Test 2008Bernice JohnsonNo ratings yet

- Data Sheet PhysicsDocument4 pagesData Sheet PhysicsBernice JohnsonNo ratings yet

- Mark Scheme: University of Malta Matriculation Certificate Examination Intermediate Level MAY 2010Document17 pagesMark Scheme: University of Malta Matriculation Certificate Examination Intermediate Level MAY 2010Bernice JohnsonNo ratings yet

- End of Year Test 2009Document4 pagesEnd of Year Test 2009Bernice JohnsonNo ratings yet

- Module 4 - Sustainable Development and The EnvironmentDocument21 pagesModule 4 - Sustainable Development and The EnvironmentBernice Johnson0% (1)

- Physics AM 26: SyllabusDocument20 pagesPhysics AM 26: SyllabusBernice JohnsonNo ratings yet

- The OlympiansDocument12 pagesThe OlympiansmhayellaNo ratings yet

- Pierre Grimal - A Concise Dictionary of Classical MythologyDocument476 pagesPierre Grimal - A Concise Dictionary of Classical MythologyIsrael Reyna90% (10)

- SOK Module 1: Democratic Values and Citizenship: Types of DemocracyDocument12 pagesSOK Module 1: Democratic Values and Citizenship: Types of DemocracyBernice Johnson100% (3)

- INDEX NUMBER: - : Biology III 2008-2010 1 HR 30 MinsDocument6 pagesINDEX NUMBER: - : Biology III 2008-2010 1 HR 30 MinsBernice JohnsonNo ratings yet

- Spec 2Document5 pagesSpec 2Bernice JohnsonNo ratings yet

- Chemistry AM 06: SyllabusDocument14 pagesChemistry AM 06: SyllabusBernice JohnsonNo ratings yet

- Eng21 (Story of Hamguchi Gohei)Document9 pagesEng21 (Story of Hamguchi Gohei)Alapan NandaNo ratings yet

- Geotechnical Aspects of Open Stope Design at BHP Cannington: G C StreetonDocument7 pagesGeotechnical Aspects of Open Stope Design at BHP Cannington: G C StreetonJuan PerezNo ratings yet

- Conveyor Control Using Programmable Logic ControllerDocument7 pagesConveyor Control Using Programmable Logic ControllerWann RexroNo ratings yet

- 3rd Page 5Document1 page3rd Page 5api-282737728No ratings yet

- Q4 Music 6 Module 2Document15 pagesQ4 Music 6 Module 2Dan Paolo AlbintoNo ratings yet

- Rubric For Aet570 BenchmarkDocument4 pagesRubric For Aet570 Benchmarkapi-255765082No ratings yet

- Neelima A Kulkarni ResumeDocument3 pagesNeelima A Kulkarni ResumeAcademics LecturenotesNo ratings yet

- A SURVEY OF ENVIRONMENTAL REQUIREMENTS FOR THE MIDGE (Diptera: Tendipedidae)Document15 pagesA SURVEY OF ENVIRONMENTAL REQUIREMENTS FOR THE MIDGE (Diptera: Tendipedidae)Batuhan ElçinNo ratings yet

- Buss40004 - Balance of PowerDocument3 pagesBuss40004 - Balance of PowerVishwa NirmalaNo ratings yet

- International Patient Referral - Part 2 - Revised - 29-04-2010 - 2Document2 pagesInternational Patient Referral - Part 2 - Revised - 29-04-2010 - 2Fatah AssadNo ratings yet

- Zygosaccharomyces James2011Document11 pagesZygosaccharomyces James2011edson escamillaNo ratings yet

- The Minimum Means of Reprisal - China's S - Jeffrey G. LewisDocument283 pagesThe Minimum Means of Reprisal - China's S - Jeffrey G. LewisrondfauxNo ratings yet

- Toi Su20 Sat Epep ProposalDocument7 pagesToi Su20 Sat Epep ProposalTalha SiddiquiNo ratings yet

- Water Tanker Check ListDocument8 pagesWater Tanker Check ListHariyanto oknesNo ratings yet

- A Review of Stories Untold in Modular Distance Learning: A PhenomenologyDocument8 pagesA Review of Stories Untold in Modular Distance Learning: A PhenomenologyPsychology and Education: A Multidisciplinary JournalNo ratings yet

- Standard nfx15-211Document2 pagesStandard nfx15-211Luis Enrique Cóndor PorrasNo ratings yet

- Topic Group Present (Week 8) Chapter 1:sociology and Learning ManagementDocument2 pagesTopic Group Present (Week 8) Chapter 1:sociology and Learning ManagementLEE LEE LAUNo ratings yet

- Paramount Healthcare Management Private Limited: First Reminder Letter Without PrejudiceDocument1 pageParamount Healthcare Management Private Limited: First Reminder Letter Without PrejudiceSwapnil TiwariNo ratings yet

- Model TB-16Document20 pagesModel TB-16xuanphuong2710No ratings yet

- A - PAGE 1 - MergedDocument73 pagesA - PAGE 1 - MergedGenalyn DomantayNo ratings yet

- BRAND AWARENESS Proposal DocumentDocument11 pagesBRAND AWARENESS Proposal DocumentBuchi MadukaNo ratings yet

- Technion - Computer Science Department - Technical Report CS0055 - 1975Document25 pagesTechnion - Computer Science Department - Technical Report CS0055 - 1975MoltKeeNo ratings yet

- Audi R8 Advert Analysis by Masum Ahmed 10PDocument2 pagesAudi R8 Advert Analysis by Masum Ahmed 10PMasum95No ratings yet

- CDR Writing: Components of The CDRDocument5 pagesCDR Writing: Components of The CDRindikuma100% (3)

- How Can Literary Spaces Support Neurodivergent Readers and WritersDocument2 pagesHow Can Literary Spaces Support Neurodivergent Readers and WritersRenato Jr Bernadas Nasilo-anNo ratings yet

- Broiler ProductionDocument13 pagesBroiler ProductionAlexa Khrystal Eve Gorgod100% (1)

- Lec. 2Document22 pagesLec. 2محمدNo ratings yet

- Hetal Patel: Team Leader - SalesDocument2 pagesHetal Patel: Team Leader - SalesPrashant kumarNo ratings yet

- The Grass Rink Summer Final 2019Document9 pagesThe Grass Rink Summer Final 2019api-241553699No ratings yet

- Vernacular ArchitectureDocument4 pagesVernacular ArchitectureSakthiPriya NacchinarkiniyanNo ratings yet