Professional Documents

Culture Documents

Pigment Grinding and Spray Gun Research

Uploaded by

AstonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pigment Grinding and Spray Gun Research

Uploaded by

AstonCopyright:

Available Formats

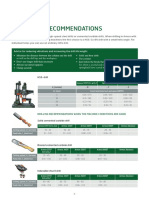

Pigment Grinding Options

1. Small size high speed disperser/attritor with grinding beads

inside

a. Pros

i. This is classically what is used for amounts 0-10L,

Lab amount.

ii. Black pigments possibly taking 10+ hours of max

speed dispersion + grinding media to complete.

Attritors are quicker

iii. Likely a cheap alternative for the process and

amounts we will be working with while still giving us

the flexibility for mixing and changing constituents of

the paint.

b. Cons

i. Not very scalable and is the most time consuming

process

c. Costs

i. Small Lab High speed disperser 3HP: $700-1200used,

1500-2000new

1. http://www.mixerdirect.com/high-sheardispersers/bench-scale-dispersers.html?

dp_motor_type=578&explosion_proof=540

a. Local, Kentucky

2. https://www.alibaba.com/showroom/lab-high-speed-disperser.html

a. International China

3. http://www.ebay.com/sch/i.html?

_from=R40&_trksid=p2374313.m570.l1313.TR

0.TRC0.H0.Xhigh+speed+disperser.TRS0&_nkw

=high+speed+disperser&_sacat=26235

a. Local, used

4. http://www.phxequip.com/subcategory.179.0/mi

lls-attritors.aspx

a. local, attritor, 0-1Gal

ii. 4-6 kg Y-TZP 2mm Grinding Media - $100

1. https://www.americanelements.com/yttriastabilized-zirconia-grinding-beads-308076-80-4

2. expected $20/kg

iii. Disperser blade head 4in diameter - $100

1. http://www.mixerdirect.com/impellers/highshear/dispersion-blade.html?

impeller_diameter=525

d. Description of process

i. Raw materials to be loaded then grinding media to

be loaded at 0.75kg Ce-TZP beads/1kg material.

Grinded for 5-8 hours with periodic fineness checks.

2. Small grinding mill

a. Pros

i. Large scale up possibility

ii. Grind large amounts between 40-250L

b. Cons

i. Unable to grind for small amounts used in lab testing

c. Costs

3. Ask any paints manufacturing company to grind.

a. Pros

i. No capital cost.

ii. Good option for if only a few batches

iii. Local: Vista Paints, Dunn Edwards Paints

b. Cons

i. Cannot alter formula and other parts as easily during

process

c. Costs

i. TBD

Spray gun Options

1. Spray gun (HVLP, LVLP)

a. Specifications

i. Full cone

ii.

iii. Full cone head creates better spread Im more

familiar with these conventional spray guns so if I

would be the one operating I would want to go with

this one.

iv. High Volume Low Pressure (HVLP) Siphon (pictured

on left)

1. Working at 26-29psi, 10-14 cfm

v. Low Volume Low Pressure (LVLP) Gravity (pictured on

right)

1. Working at 10-15psi, 5-7cfm

vi. Transfer efficiency 40-50%

vii. Comparing the two, it all depends on volume. The

siphon gun works at a higher pressure and can take

higher volumes of paint while the gravity one works

at a lower pressure and lower volumes of paint.

b. Cost

i. Gravity: DeVilbiss Finishline 4 FLG-670 HVLP Spray

Paint Gun - $200

ii. Siphon: - $230

https://www.zoro.com/binks-hvlp-spray-gun-pressure7041-6931-1/i/G2061595/?

gclid=Cj0KEQjw7Ne_BRDRmP2ojKfzv98BEiQAPuqPyX

uWo_CkgXvfJUaZdcxwdQxncI_JthhPfp43PW1DuzUaAh

8w8P8HAQ&gclsrc=aw.ds

iii. Air pressurizer - $170 -200

http://www.searsoutlet.com/d/product_details.jsp?

pid=108623&mode=seeAll&&sid=IDx20110411x000

008&scid=scplpU991108623&sc_intid=U991108623

&gclid=Cj0KEQjw7Ne_BRDRmP2ojKfzv98BEiQAPuqPy

YtAbY8pW8l9ul88g0eDt8p0jzfQFCCOnuXXuIMpCIaAsL38P8HAQ&beta=true

http://www.homedepot.com/p/Husky-20-Gal-175-psiQuiet-Portable-Air-Compressor-C201H/206189626?

cm_mmc=Shopping%7cTHD%7cG%7c0%7cG-BASEPLA-D25H-AirCompressors

%7c&gclid=Cj0KEQjw7Ne_BRDRmP2ojKfzv98BEiQAP

uqPya3C2T_bTsmECCDucW8QnbYeKM5qoNycnGDhSV

lfRTMaAlzy8P8HAQ&gclsrc=aw.ds

2. Micro Bell (Rotary)

a. Specifications

i.

ii. Commonly used when part of automation in high

volume paint locations that require cost savings and

high transfer efficiency. Ex Automotive coats.

iii. Typically quite a bit more expensive, but will create

the best finishes. This is the case because of the

micro sized particles it will create from the paint that

will settle more evenly on the surface of the

substrate.

iv. Transfer efficiency 80-85%

You might also like

- Powder Coating GuideDocument35 pagesPowder Coating Guidegcldesign100% (1)

- Using An Airless Paint Sprayer - tcm96-1128824Document6 pagesUsing An Airless Paint Sprayer - tcm96-1128824ravi00098No ratings yet

- Construction Safety and Health Narrative MethodsDocument46 pagesConstruction Safety and Health Narrative MethodsEldreen Ann Jebulan Vargas100% (1)

- Machine Guarding PDFDocument133 pagesMachine Guarding PDFbrsharmaNo ratings yet

- Mihir's Handbook of Chemical Process Engineering (Excerpts)Document74 pagesMihir's Handbook of Chemical Process Engineering (Excerpts)Mihir Patel100% (4)

- The Unexpected Rewards of Testing A MixerDocument4 pagesThe Unexpected Rewards of Testing A MixerJoshua JohnsonNo ratings yet

- Tech TipsDocument7 pagesTech TipsPetchi MuthuNo ratings yet

- NIg 4th Trip PT GeneralDocument8 pagesNIg 4th Trip PT GeneralkingstonNo ratings yet

- Steel Grade: General InformationDocument2 pagesSteel Grade: General InformationMina MagdyNo ratings yet

- Random Question For InterviewDocument5 pagesRandom Question For InterviewMohamed HashemNo ratings yet

- D2784Document7 pagesD2784rimi7alNo ratings yet

- Dyeing of Polyester and Cotton BlendDocument50 pagesDyeing of Polyester and Cotton BlendarafathosainNo ratings yet

- Plant Commissioning & Start Up ProcedureDocument18 pagesPlant Commissioning & Start Up Procedureaamirapi100% (7)

- 1-3 Production Possibilities WorksheetDocument2 pages1-3 Production Possibilities WorksheetJNo ratings yet

- Q & A 3 BgasDocument8 pagesQ & A 3 BgasAbdulRahman Mohamed Hanifa100% (2)

- Coating Application and TestingDocument22 pagesCoating Application and Testingsri ramadhaniNo ratings yet

- Como Pintar Modelos A Escala Con AerografoDocument44 pagesComo Pintar Modelos A Escala Con AerografoLeslie Royal100% (1)

- Slurry Pump The KproDocument11 pagesSlurry Pump The Kpro4lk0nNo ratings yet

- Gas Pipeline Hydraulic CourseDocument49 pagesGas Pipeline Hydraulic Coursekarisnda100% (1)

- Stone Blower 1Document22 pagesStone Blower 1kbaker001No ratings yet

- NVC Flexographic EguideDocument21 pagesNVC Flexographic EguideBernard Andre Palacios Gomez100% (1)

- Learn How to Airbrush Aquatic Animals for the BeginnerFrom EverandLearn How to Airbrush Aquatic Animals for the BeginnerRating: 4.5 out of 5 stars4.5/5 (2)

- Astm D473. SedimentosDocument6 pagesAstm D473. SedimentosgeralNo ratings yet

- Methods of Paint Application PDFDocument2 pagesMethods of Paint Application PDFNerinel CoronadoNo ratings yet

- High Viscosity MixingDocument6 pagesHigh Viscosity MixingRaheel SultanNo ratings yet

- Ppg Pmc: Khoá Huҩn Luyӌn Công Nghӌ Sơn Cơ Bҧn Phҫn 3 Thi Công SơnDocument50 pagesPpg Pmc: Khoá Huҩn Luyӌn Công Nghӌ Sơn Cơ Bҧn Phҫn 3 Thi Công SơnTrần Thái AnNo ratings yet

- Project Report: Sleek Powder Paints Address:-Plot No: - 83, MIDC Area, Satpur NashikDocument5 pagesProject Report: Sleek Powder Paints Address:-Plot No: - 83, MIDC Area, Satpur NashikRahul JadhavNo ratings yet

- ASSIGNMENT 1 Without Kill SheetDocument20 pagesASSIGNMENT 1 Without Kill SheetPrateekNo ratings yet

- Spray PaintDocument7 pagesSpray PaintErvin EvangelistaNo ratings yet

- Bgas Painting-Q A-2Document46 pagesBgas Painting-Q A-2Arif AliNo ratings yet

- Paint Products and Finish ProductsDocument17 pagesPaint Products and Finish ProductsSheree LabeNo ratings yet

- Dye House ManagementDocument6 pagesDye House ManagementMd.oaliur RahamanNo ratings yet

- Low Liquor Package Dyeing MachineDocument6 pagesLow Liquor Package Dyeing MachineMehmet KacmazNo ratings yet

- 7 Tank ProcessDocument4 pages7 Tank ProcessJalagandeeswaran Kalimuthu100% (1)

- Evolution of Coating Applications Methods & Technology For Eastern NACE ConferenceDocument46 pagesEvolution of Coating Applications Methods & Technology For Eastern NACE ConferenceBAKRNo ratings yet

- Training Assessment Day 5Document2 pagesTraining Assessment Day 5CERTSNo ratings yet

- Airless vs. Conven. Adv. Dis.Document1 pageAirless vs. Conven. Adv. Dis.joeneerzidiNo ratings yet

- Cost-Proposal NDT GreenlandDocument1 pageCost-Proposal NDT GreenlandDang-dang Siggaoat-CopiacoNo ratings yet

- TDS MD en 5402C Epicon Finish HBDocument1 pageTDS MD en 5402C Epicon Finish HBcelescopitoNo ratings yet

- Lith Printing Technique - Lesson 1: The BasicsDocument6 pagesLith Printing Technique - Lesson 1: The Basicschicco pitecoNo ratings yet

- Lith Printing Technique - Lesson 1: The BasicsDocument6 pagesLith Printing Technique - Lesson 1: The Basicschicco pitecoNo ratings yet

- PDS Hempaprime Multi 500 Summer en-GBDocument2 pagesPDS Hempaprime Multi 500 Summer en-GBFreddyNo ratings yet

- Rusayl Institute Liquid Penetrant Testing - Level Ii General QuestionaireDocument8 pagesRusayl Institute Liquid Penetrant Testing - Level Ii General QuestionairekingstonNo ratings yet

- Fabric Dyeing MachineDocument8 pagesFabric Dyeing MachineSI ShakilNo ratings yet

- Equipment Feature - Finding The Right Mixer For Processing Paints and CoatingsDocument3 pagesEquipment Feature - Finding The Right Mixer For Processing Paints and CoatingsMajd M. KhalilNo ratings yet

- TVE-FCM10 Q2M3Weeks56 OKDocument20 pagesTVE-FCM10 Q2M3Weeks56 OKjooshmarkhenNo ratings yet

- TroubleshootingDocument4 pagesTroubleshootingvinaysagarNo ratings yet

- MAAC402 - Test 1 - 2022 - ReviewDocument5 pagesMAAC402 - Test 1 - 2022 - ReviewBandile MhlongoNo ratings yet

- Pu Sole Develop Formula ProcessDocument2 pagesPu Sole Develop Formula ProcessMax TranNo ratings yet

- PT2 Specific - MasterDocument4 pagesPT2 Specific - MasterYousef Adel HassanenNo ratings yet

- Loading Considerations For Nozzleless Black Powder RocketsDocument10 pagesLoading Considerations For Nozzleless Black Powder RocketsBruno GonçalvesNo ratings yet

- Heatseal H520: Product Data SheetDocument1 pageHeatseal H520: Product Data SheetdjokanomcaNo ratings yet

- Experiment For Rube GoldbergDocument11 pagesExperiment For Rube Goldbergapi-366504107No ratings yet

- PDS Hempaprime Multi 500 Winter en-GBDocument2 pagesPDS Hempaprime Multi 500 Winter en-GBFreddyNo ratings yet

- SP 300Document242 pagesSP 300michael calvoNo ratings yet

- Materials Engineer PreDocument23 pagesMaterials Engineer PremjfprgcNo ratings yet

- From The Lab: Tto o TTH He e R Re Eaall W Wo Orrlld DDocument4 pagesFrom The Lab: Tto o TTH He e R Re Eaall W Wo Orrlld Dmohan804100% (1)

- BA 211 Exercise 2: Machine Component Shaper GrinderDocument2 pagesBA 211 Exercise 2: Machine Component Shaper GrinderEden Mae DeGuzmanNo ratings yet

- Chapter 5 Strategic Capacity Planning For ProductsDocument3 pagesChapter 5 Strategic Capacity Planning For ProductsqeessamNo ratings yet

- Castrol Engine Oil2Document3 pagesCastrol Engine Oil2Boopathi KalaiNo ratings yet

- Training Assessment Day 2Document2 pagesTraining Assessment Day 2CERTSNo ratings yet

- Foot Pedal SprayDocument22 pagesFoot Pedal Sprayvisputenilesh175No ratings yet

- 3D Model Fixing SOPDocument4 pages3D Model Fixing SOPHan BinNo ratings yet

- HVLP Versus Airless Paint Sprayer A GuideDocument6 pagesHVLP Versus Airless Paint Sprayer A GuideCemalOlgunÇağlayanNo ratings yet

- BGAS Level 2Document3 pagesBGAS Level 2asiqna0% (1)

- Topcoat HS 420Document4 pagesTopcoat HS 420junot880% (1)

- Polyvinyl Silioxane Impression MaterialDocument13 pagesPolyvinyl Silioxane Impression MaterialEshan VermaNo ratings yet

- Design (II) 2Document49 pagesDesign (II) 2khudhayer1970No ratings yet

- Lava Heat Italia - Lava Lite KD Patio Heater - Owners ManualDocument23 pagesLava Heat Italia - Lava Lite KD Patio Heater - Owners ManuallavaheatitaliaNo ratings yet

- Designing An Efficient Compressed Air Distribution NetworkDocument12 pagesDesigning An Efficient Compressed Air Distribution Networkosama alabsiNo ratings yet

- InsulatorDocument6 pagesInsulatorMuhammad AftabuzzamanNo ratings yet

- FilmTec ManualDocument205 pagesFilmTec ManualSarmad HameedNo ratings yet

- E 9018 Sika Permac 2330Document4 pagesE 9018 Sika Permac 2330Mark InnesNo ratings yet

- Waves Group - Marketing Catalouge - 400MEDocument26 pagesWaves Group - Marketing Catalouge - 400MEfrostysidNo ratings yet

- Catalog Aer Condiționat Split Inverter SAMSUNG-2014Document17 pagesCatalog Aer Condiționat Split Inverter SAMSUNG-2014georgianconstantinNo ratings yet

- Visit ReportDocument13 pagesVisit ReportAlankrutha DevuNo ratings yet

- Fibers - Honeywell Advanced Fibers and CompositesDocument2 pagesFibers - Honeywell Advanced Fibers and CompositesnitzeebbNo ratings yet

- Spargers - For Reaction Vessels: New From ACE..Document2 pagesSpargers - For Reaction Vessels: New From ACE..parykoochakNo ratings yet

- Electrical Checklist FNLDocument5 pagesElectrical Checklist FNLArnulfo LavaresNo ratings yet

- Machining Recommendations: Advice For Reducing Vibrations and Increasing The Drill Life LengthDocument3 pagesMachining Recommendations: Advice For Reducing Vibrations and Increasing The Drill Life LengthbasaricaNo ratings yet

- K SpanDocument36 pagesK SpanMerve MerveNo ratings yet

- DielectricResonatortype A4Document2 pagesDielectricResonatortype A4denivaldo2009No ratings yet

- Impact of Plastic Formwork Over Conventional FormworkDocument6 pagesImpact of Plastic Formwork Over Conventional FormworkAchmad Zaki Zulkarnain100% (1)

- Aerated LagoonDocument8 pagesAerated LagoonAmmu JoeNo ratings yet

- Ssnde14 Final LDocument72 pagesSsnde14 Final LmiamarchNo ratings yet

- MSMBM Oct 2022 - 2Document2 pagesMSMBM Oct 2022 - 2battuarunNo ratings yet

- Nuova Fima MGS18 - 63mmDocument2 pagesNuova Fima MGS18 - 63mmPaweł HejmowskiNo ratings yet

- Experimental Investigation On Concrete-Filled Corrugated Steel Tubular Column Under Constant Axial Load and Cyclic Load PDFDocument23 pagesExperimental Investigation On Concrete-Filled Corrugated Steel Tubular Column Under Constant Axial Load and Cyclic Load PDFTamir EnkhNo ratings yet

- C592 13Document9 pagesC592 13Ichwan Ciptadi100% (1)