Professional Documents

Culture Documents

Agitator Sizing

Uploaded by

sj_scribdCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Agitator Sizing

Uploaded by

sj_scribdCopyright:

Available Formats

Today I am presenting the gist of my technical paper on "Motor rating calculations

for slurry mixing agitators in Alumina refinery" which has been published recently

in aluminium issue of the magazine "Minerals & Metals Review" (page 30

and 31 in MMR, August 2011 issue).

In various technical forums, process experts as well as equipment manufacturers

have opined that the design of agitators for mixing bauxite, residue and hydrate

in Alumina refinery is complicated and tricky issue. In this paper, we will discuss

the subject with brief description of involved terminology, associated design

parameters and methodology with sample motor rating calculations for the slurry

mixing agitator of a Pre-desilication tank of Alumina refinery.

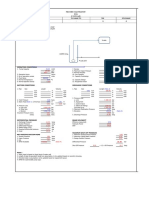

Method to arrive at motor rating:

Impeller power for slurry mixing agitator is calculated using following

mathematical relationsImpeller Power, P = N * *N3 * D5/(16*104) h.p.

Where D = Diameter of impeller in meters,

N = Revolution per minute for impeller,

N = Power number for impeller and

= Specific gravity of slurry.

Sample calculations:

Simplified calculations to arrive at the motor rating for the agitator of Predesilication tank of around 3000 m3gross capacity with realistic assumptions

have been presented belowFluid Height in Tank , H = 16 m and Diameter of tank, D = 14 m

Slurry volume in tank = *D2*H/4 = * (14)2*16 /4 = 2463 m3

Solid consistency in Slurry = 50 % (w/w), Specific gravity of slurry, = 1.602,

Viscosity of slurry, = 550 cp

Agitator Impeller Diameter, D= 33 % of tank diameter = 14 * 33% m = 4.62 m

Tip speed of Impeller = 290 m/minute,

Drive motor RPM = 1500 rpm.

Gear Box Reduction Ratio = 75

∴ Agitator RPM, N = Drive Motor RPM/Gear Box Reduction Ratio = 1500/75

= 20 rpm

Flow Number N = 0.56 and Power Number,

N = 0.51 (assumed figures)

∴ Pumping Capacity = N * N * D3 m3/minute

= 0.56 * 20 * (4.62)3 = 1104.44 m3/min. = 18.41 m3/sec.

Area of Tank

= * D2 = *(14)2 / 4 = 153.94 m2

Bulk fluid Velocity

= pumping capacity/area of tank

= 1104.44 / 153.94= 7.18 m/min.= 23.55 ft./min.

Degree of Agitation = bulk fluid velocity / 6

(For 6 ft/min., degree of agitation =1 and Degree of agitation varies from 0 to 10)

= 23.55 / 6 = 3.93 ~ 4

Annular Area = * (D2- D2 ) /4

Where D = Diameter of tank

and

D= Diameter of impeller in meters.

= 3.14 * (142 (4.622) / 4 = 137.18 m2

Rising velocity of particles = pumping capacity / annular area

= 1104.44 / 137.18 = 8.051 m/min. = 0.1342 m/sec.

Tank Turnover rate = Pumping capacity / tank capacity

= 1104.44 / 2463 = 0.45 times / min.

Power Number N

Shaft Power,

= 0.51

= N* *(D)5 * N3 /(16 *104)

Where N = Impeller power no.,

Shaft RPM,

D = Diameter of impeller in meters,

N = revolutions per minute

∴ Shaft Power, P = 0.51 * 1.602 * (4.402)5 * 203 / (16 *104) = 85.98 h.p.

Taking Gear Box Efficiency = 80% and Drive Motor Efficiency = 95%,

Design margin

= 1.15

∴ Drive Motor Rating = 1.15 * 85.98/(0.80 * 0.95) =130 h.p. = 97.0 kW.

Thus the drive motor of about 100 kW shall be adequate for successful

operation of agitator of 3000 m3 capacity Pre-desilication tank in

Alumina refinery.

Rajendra Kunwar

You might also like

- Agitator CalculationDocument4 pagesAgitator CalculationAnkur Koul100% (4)

- Design Calculations For Slurry AgitatorsDocument19 pagesDesign Calculations For Slurry Agitatorsmshah222100% (4)

- Agitator Power Requirement and Mixing Intensity CalculationDocument27 pagesAgitator Power Requirement and Mixing Intensity Calculation황종서100% (1)

- Dense Phase PR Drop & Pipe SizingDocument32 pagesDense Phase PR Drop & Pipe SizingyoyoNo ratings yet

- Separator Design Guide PDFDocument36 pagesSeparator Design Guide PDFAdam RizkyNo ratings yet

- Eductor Design - JacobyDocument14 pagesEductor Design - Jacobyvkumaran100% (4)

- Existing:-Pitch Blade Turbine AgitatorDocument5 pagesExisting:-Pitch Blade Turbine AgitatorPrathmesh Gujarati100% (1)

- Pump CalculationDocument8 pagesPump CalculationankitNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument27 pagesAgitator Power Requirement and Mixing Intensity CalculationElizabeth Allende CéspedesNo ratings yet

- Closed vs Open Impeller Design AdvantagesDocument3 pagesClosed vs Open Impeller Design Advantagesucb2_ntpcNo ratings yet

- Agitator Design PrinciplesDocument130 pagesAgitator Design PrinciplesHamlet GhookasianNo ratings yet

- NaOH Practicality StudyDocument51 pagesNaOH Practicality StudyPeterWangNo ratings yet

- Agitator SelectionDocument20 pagesAgitator SelectionRamakrishna Koushik100% (2)

- Cyclone Design and AnalysisDocument21 pagesCyclone Design and Analysisjorge FranciscpNo ratings yet

- Sugar Factory Insulation Training MaterialDocument29 pagesSugar Factory Insulation Training MaterialZerihun Negash100% (1)

- Slurry Piping DesignDocument11 pagesSlurry Piping DesignDipanjan ChakrabartiNo ratings yet

- Dust Control at Conveyor Transfer PointsDocument15 pagesDust Control at Conveyor Transfer PointsHaulian Siregar100% (2)

- Agitator Power Calculation FormatDocument2 pagesAgitator Power Calculation FormatSandeep GosaviNo ratings yet

- T7111-DAS-1053-A-IFA-Baghouse Datasheet - 20170930 PDFDocument4 pagesT7111-DAS-1053-A-IFA-Baghouse Datasheet - 20170930 PDFtiantaufikNo ratings yet

- Agitator DesignDocument8 pagesAgitator Designsandesh_honraoNo ratings yet

- Agitator Guide for Mixing and Stirring Tank ProductsDocument10 pagesAgitator Guide for Mixing and Stirring Tank Productsagrocel_bhv5591No ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument27 pagesAgitator Power Requirement and Mixing Intensity Calculationmpshah29860% (5)

- Design Two-Phase Separators Within The Right LimitsDocument8 pagesDesign Two-Phase Separators Within The Right Limitschipiloo100% (1)

- Slurry Viscocity CalculationDocument3 pagesSlurry Viscocity CalculationVijay PatelNo ratings yet

- HCL Scrubber DesignDocument5 pagesHCL Scrubber DesignManish0301198375% (4)

- (How To) Select A Motor Capacity For Agitator - Pharma EngineeringDocument9 pages(How To) Select A Motor Capacity For Agitator - Pharma EngineeringpratikNo ratings yet

- Machine Chest Mixing DesignDocument4 pagesMachine Chest Mixing DesignMark Vicson100% (1)

- Agitator SizingDocument4 pagesAgitator SizingArbee AquinoNo ratings yet

- Agitator DesignDocument7 pagesAgitator DesignTint Tiger100% (4)

- Pump Sizing SpreadsheetDocument2 pagesPump Sizing Spreadsheetandrew rachmanNo ratings yet

- Agitator Calculation. - SPLDocument2 pagesAgitator Calculation. - SPLAbarajithan RajendranNo ratings yet

- Sparger Design GuideDocument11 pagesSparger Design GuideHarshavardhan D. GorakhNo ratings yet

- Modeling Cyclone PerformanceDocument4 pagesModeling Cyclone PerformancesergioNo ratings yet

- Agitator CalDocument2 pagesAgitator Calvazzoleralex6884No ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument26 pagesAgitator Power Requirement and Mixing Intensity CalculationWael Abdel-Mageed100% (1)

- HydroCyclone Design Equations and Sizing Parameters For CalculationsDocument4 pagesHydroCyclone Design Equations and Sizing Parameters For Calculationsbfyg0% (1)

- The Hydrocyclone: International Series of Monographs in Chemical EngineeringFrom EverandThe Hydrocyclone: International Series of Monographs in Chemical EngineeringRating: 5 out of 5 stars5/5 (3)

- Design Calculations For Slurry Agitators in Alumina RefineryDocument3 pagesDesign Calculations For Slurry Agitators in Alumina RefineryChristopher LloydNo ratings yet

- Method To Arrive at Motor RatingDocument5 pagesMethod To Arrive at Motor RatingkiranNo ratings yet

- Agitator Design CalcDocument5 pagesAgitator Design Calcranjit34380% (5)

- Design Calculations For Slurry Agitators: Method To Arrive at Motor RatingDocument21 pagesDesign Calculations For Slurry Agitators: Method To Arrive at Motor RatingSachin5586No ratings yet

- New Microsoft Word Document PDFDocument17 pagesNew Microsoft Word Document PDFtusharNo ratings yet

- Design of AgitatorDocument3 pagesDesign of Agitatorkaps12No ratings yet

- Combustion Air Consumption and Volumetric Efficiency: 1.1 ObjectiveDocument3 pagesCombustion Air Consumption and Volumetric Efficiency: 1.1 ObjectiveHammam Abu ShoshehNo ratings yet

- Car crushing hydraulic circuit analysisDocument22 pagesCar crushing hydraulic circuit analysisphankhoa83100% (1)

- Pelton Wheel Quiz Solutions - SanjeetDocument8 pagesPelton Wheel Quiz Solutions - SanjeetSanjeet Kumar100% (1)

- Exp 2 Performance Parameter of Diesel EngineDocument7 pagesExp 2 Performance Parameter of Diesel EngineShashwat JainNo ratings yet

- Rig Maths Presentation on Hydrostatic Pressure, Pump Discharge, Capacity FormulasDocument10 pagesRig Maths Presentation on Hydrostatic Pressure, Pump Discharge, Capacity FormulassubhashNo ratings yet

- Reciprocating Pump Experiment No: 6Document6 pagesReciprocating Pump Experiment No: 6anil kumarNo ratings yet

- Axial Pump Impeller DesignDocument8 pagesAxial Pump Impeller DesignRioEstikaNo ratings yet

- Chemical Engineering Design of The Spray DryerDocument6 pagesChemical Engineering Design of The Spray Dryervictor100% (1)

- Gear Pump Project ReportDocument13 pagesGear Pump Project ReportBekan NegesaNo ratings yet

- Research Inventy: Gear Pump Design AnalysisDocument7 pagesResearch Inventy: Gear Pump Design AnalysisMorteza ShakerienNo ratings yet

- Machinery in Road ConstructionDocument20 pagesMachinery in Road ConstructionErik Bonilla AlbertoNo ratings yet

- EXP 7 To Determine The Volumetric Efficiency of A Four Stroke Petrol Engine at Variable LoadDocument2 pagesEXP 7 To Determine The Volumetric Efficiency of A Four Stroke Petrol Engine at Variable Load70130046No ratings yet

- Design of AgitatorDocument3 pagesDesign of AgitatorManish PatelNo ratings yet

- Engine Design and Operating ParametersDocument26 pagesEngine Design and Operating Parametersishanv_1430% (1)

- Design center crank shaft dimensionsDocument8 pagesDesign center crank shaft dimensionsSagarias AlbusNo ratings yet

- Chapter 4Document9 pagesChapter 4Aung KhantNo ratings yet

- Galgotias College of Engineering and TechnologyDocument19 pagesGalgotias College of Engineering and TechnologyJv100% (1)

- 50-Article Text-81-3-10-20171207Document12 pages50-Article Text-81-3-10-20171207sj_scribdNo ratings yet

- Treatment of Distillery Spent Wash-880Document5 pagesTreatment of Distillery Spent Wash-880sj_scribdNo ratings yet

- 2Document1 page2sj_scribdNo ratings yet

- The Selected Sprinkler Is Tree Type System and Is Usually Designed To Cover The Whole Tank Including The RoofDocument1 pageThe Selected Sprinkler Is Tree Type System and Is Usually Designed To Cover The Whole Tank Including The Roofsj_scribdNo ratings yet

- Knife Gate Valve - For Reference OnlyDocument16 pagesKnife Gate Valve - For Reference Onlysj_scribdNo ratings yet

- IEI AM Application FormDocument9 pagesIEI AM Application Formjpr220022No ratings yet

- Tanques PVSVDocument13 pagesTanques PVSVwfjerrNo ratings yet

- 4Document1 page4sj_scribdNo ratings yet

- 2Document1 page2sj_scribdNo ratings yet

- Column QueriesDocument1 pageColumn Queriessj_scribdNo ratings yet

- Write Plant Manual GuideDocument3 pagesWrite Plant Manual Guidesj_scribd100% (1)

- ElementDocument1 pageElementsj_scribdNo ratings yet

- Codeware COMPRESS engineering software for pressure vessel and heat exchanger designDocument14 pagesCodeware COMPRESS engineering software for pressure vessel and heat exchanger designAnonymous gfR3btyU0% (1)

- 'Line SizeDocument2 pages'Line Sizesj_scribdNo ratings yet

- Status Vendor RegistrationDocument19 pagesStatus Vendor Registrationsj_scribdNo ratings yet

- Leakage ReductionDocument1 pageLeakage Reductionsj_scribdNo ratings yet

- Reducing Steam Header PressureDocument1 pageReducing Steam Header Pressuresj_scribdNo ratings yet

- Nozzle ProDocument1 pageNozzle Prosj_scribdNo ratings yet

- Reducing Steam Header PressureDocument1 pageReducing Steam Header Pressuresj_scribdNo ratings yet

- Allocation of Streams in A Shell and Tube ExchangerDocument1 pageAllocation of Streams in A Shell and Tube Exchangersj_scribdNo ratings yet

- Fouling Resistances For Typical Proceass ApplicationsDocument1 pageFouling Resistances For Typical Proceass Applicationssj_scribdNo ratings yet

- Insulation Material: Table 6-3: Thermal Conductivity of Hot InsulationDocument1 pageInsulation Material: Table 6-3: Thermal Conductivity of Hot Insulationsj_scribdNo ratings yet

- Location of Nozzle at U-BendDocument1 pageLocation of Nozzle at U-Bendsj_scribdNo ratings yet

- Line SizeDocument1 pageLine Sizesj_scribdNo ratings yet

- Lecture 9Document1 pageLecture 9sj_scribdNo ratings yet

- Block Bypass Streams in Heat Exchanger SimulationsDocument1 pageBlock Bypass Streams in Heat Exchanger Simulationssj_scribdNo ratings yet

- Thermal ConductivityDocument1 pageThermal Conductivitysj_scribdNo ratings yet

- Tube MaterialDocument1 pageTube Materialsj_scribdNo ratings yet

- Separation of Benzene and Toluene by DistillationDocument1 pageSeparation of Benzene and Toluene by Distillationsj_scribdNo ratings yet

- Refresher Module 01 (M14) - Quantity SurveyingDocument2 pagesRefresher Module 01 (M14) - Quantity SurveyingFely Joy RelatoresNo ratings yet

- Wet BenchDocument29 pagesWet BenchAnurag KiroriwalNo ratings yet

- Excavation Removal-PlanDocument34 pagesExcavation Removal-PlanABDELKADER BENABDALLAHNo ratings yet

- Chap: Wood and Wood ProductsDocument2 pagesChap: Wood and Wood ProductsT N Roland BourgeNo ratings yet

- 2DXL Super Loader BrochureDocument8 pages2DXL Super Loader BrochureJayant Kushwaha0% (1)

- HEAT TRANSFER AND SHELL & TUBE EXCHANGERSDocument30 pagesHEAT TRANSFER AND SHELL & TUBE EXCHANGERSHernan CobaNo ratings yet

- Reactivod de FlotacionDocument4 pagesReactivod de FlotacionHector RamosNo ratings yet

- JOWA STP 2010-40 DAEHAN H.1037 Final Dwgs Rev0 PDFDocument118 pagesJOWA STP 2010-40 DAEHAN H.1037 Final Dwgs Rev0 PDFmishaNo ratings yet

- Mobil Delvac Hydraulic 10w Delvac Hydraulic 10w Delivers Excellent PerformanceDocument2 pagesMobil Delvac Hydraulic 10w Delvac Hydraulic 10w Delivers Excellent PerformanceYordan YupanquiNo ratings yet

- Refrigeration and Liquefaction Processes ExplainedDocument26 pagesRefrigeration and Liquefaction Processes ExplainedJolaloreNo ratings yet

- 1.2 Structure and PropertiesDocument15 pages1.2 Structure and PropertiesLuisa Fernanda Sanchez ZambranoNo ratings yet

- 01 - DS - P293 Data Sheet Issue 5Document3 pages01 - DS - P293 Data Sheet Issue 5Parul MehtaNo ratings yet

- The Complete Guide To Plastic Rotational MoldingDocument17 pagesThe Complete Guide To Plastic Rotational MoldingAiltaoSoaresNo ratings yet

- Uniclass2015 PR v1 18Document229 pagesUniclass2015 PR v1 18abdullah sahibNo ratings yet

- Properties Are Used To Identify Substances.: How Can Properties Help You Identify A Substance?Document5 pagesProperties Are Used To Identify Substances.: How Can Properties Help You Identify A Substance?Pothik OchenaNo ratings yet

- Minolta Ep1050 ServiceDocument266 pagesMinolta Ep1050 ServiceSunny SinghNo ratings yet

- Technical Data Sheet Permatex Copper Anti-Seize LubricantDocument1 pageTechnical Data Sheet Permatex Copper Anti-Seize Lubricant최승원No ratings yet

- Mechanical equipment schedule and legendDocument2 pagesMechanical equipment schedule and legendarief bahtiarNo ratings yet

- Technical Bulletin: Three Bond 2217HDocument3 pagesTechnical Bulletin: Three Bond 2217HbehzadNo ratings yet

- 813 02e Oil-GasDocument20 pages813 02e Oil-GasLuong AnhNo ratings yet

- Catalog Web SlingsDocument39 pagesCatalog Web SlingsMichel NdiayeNo ratings yet

- Analysis and Design of Axial Flow Fans with Varying Blade Numbers and MaterialsDocument7 pagesAnalysis and Design of Axial Flow Fans with Varying Blade Numbers and MaterialshonghieutrNo ratings yet

- Design of Square Footing F2Document18 pagesDesign of Square Footing F2Mohammed Sumer100% (1)

- Effective Thermal Design of Cooling TowersDocument6 pagesEffective Thermal Design of Cooling TowersandrshoNo ratings yet

- Teknokroma Capillary Columns: Trb-WaxDocument1 pageTeknokroma Capillary Columns: Trb-WaxchiralicNo ratings yet

- Design of ReboilersDocument24 pagesDesign of ReboilersKrishanu SahaNo ratings yet

- Petronas Details RAPID Project Contract AwardsDocument9 pagesPetronas Details RAPID Project Contract AwardsIzzadAfif1990100% (1)

- 1st Summative 1st QuarterDocument3 pages1st Summative 1st QuarterGuia Marie Diaz BriginoNo ratings yet

- Paper Vault: Cryptex TypeDocument11 pagesPaper Vault: Cryptex TypeTariq HalawaNo ratings yet

- AZ LicensesDocument29 pagesAZ LicensessivaNo ratings yet