Professional Documents

Culture Documents

Standard Test Method For Determination of Bulk Density (Unit Weight) and Voids in Aggregates.

Uploaded by

MazharYasinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard Test Method For Determination of Bulk Density (Unit Weight) and Voids in Aggregates.

Uploaded by

MazharYasinCopyright:

Available Formats

Plain and Reinforced Concrete -1 (Lab Manual)

JOB NO.5

Standard test method for determination of bulk density (unit

weight) and voids in aggregates.

(ASTM C 29)

Scope and significance:

To determine the unit weight and bulk density of coarse and fine aggregates. Determine

%age of voids present in aggregates materials.

Apparatus:

Weighing balance (0.005kg)

Tempering rod, diameter of rod=16mm, L=600mm

Cylindrical measure

(Table 1 ASTM C 29)

Agg. Max. size

capacity

12.5mm

2.8L (0.0028m)

1 25mm

9.3L (0.0093m)

1 37.5mm

14.0L (0.0014m)

MAZHAR YASIN (BSCE01133122)

23

Plain and Reinforced Concrete -1 (Lab Manual)

Related theory:

Density:

It is the ratio of mass of substance by the volume of solid.

Density =

Bulk density:

It is the mass of the unit volume of bulk aggregate material.

The term volume includes the volume of the individual particles and the volume of the

voids between the particles.

Bulk density =

Voids:

Space between the particles not occupied by solid content. (Voids within particles are not

included)

Roding Procedure: (for compacted density)

Fill the cylinder one third full and level the surface with finger.

Rod the layer of aggregates with 25 strokes of tamping rod evenly distributed over

the surface.

Fill the measure two third full and again level and rod as above.

Fill the measure completely so that the aggregate overflow and rod again in the

previous minor.

Level the surface and make sure that the projections of larger pieces of coarse

aggregate above the measure balance approximately the voids in the surface

below the top of measure.

Precautions:

When temping the first layer do not allow to rod to strike the bottom of the cylinder.

While Roding the 2nd layer use biggest effort but not more force then to cause the

temping rod to move to previous layer.

Procedure: (for loose density)

Fill the measures to over flowing by mean of a scope or shower discharging the

aggregates from a height of not more 50mm (2in) above the top of measure.

Level the surface and make sure that the projections of larger pieces of coarse

aggregate above the measure balance approximately the voids in the surface

below the top of measure.

MAZHAR YASIN (BSCE01133122)

24

Plain and Reinforced Concrete -1 (Lab Manual)

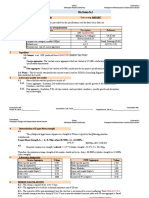

Observations and Calculations

Sample

State

Wt. of

cylinder

Wt. of

cylinder +

aggregate

Wt. of

aggregate

Vol. of

cylinder

Bulk

density

(kg)

(kg)

(kg)

m3

kg/m3

Coarse

Compacted

Aggregates

Loose

5.90

13.998

8.098

0.00530

1527.92

5.90

13.386

7.486

0.00530

1412.45

Fine

Compacted

Aggregates

Loose

0.874

2.508

1.634

0.000942

1734.60

0.874

2.372

1.498

0.000942

1589.42

Comments

In this experiment

we determined bulk density of coarse and fine aggregates.

During the concrete mix design, when the aggregate is to be batched by volume

or by weight, then it becomes necessary to know the mass of the aggregates that

will fill the container of unit volume.

If we know the bulk density of the aggregate material, then we can easily determine

the mass required to fill a unit volume container.

Bulk density also indicates the percentage of voids present in the aggregate

material. This percentage of voids affects the grading of the aggregates which is

important in high strength concrete. Bulk density depends upon how densely the

aggregate is packed.

It also depends upon the size, distribution and shape of the particles. If the particles

are of the same size, then it can be packed to a limited extent but when the smaller

particles are added, the voids get filled with them and thus the bulk density

increases.

MAZHAR YASIN (BSCE01133122)

25

You might also like

- Standard Test Method For The Determination of The Normal Consistency of Hydraulic Cement PDFDocument3 pagesStandard Test Method For The Determination of The Normal Consistency of Hydraulic Cement PDFKamran AliNo ratings yet

- Bulkage & Silt Content of Fine Aggregate.Document1 pageBulkage & Silt Content of Fine Aggregate.XOXOXOXO XOXOXOXONo ratings yet

- Homework 4Document12 pagesHomework 4UsmanNo ratings yet

- ASTM C 136 Sieve Analysis of Fine and Coarse Aggregates (D)Document5 pagesASTM C 136 Sieve Analysis of Fine and Coarse Aggregates (D)Yasir DharejoNo ratings yet

- HW I Chapter 5 - Highway DrainageDocument43 pagesHW I Chapter 5 - Highway DrainageSolomon DesalegnNo ratings yet

- Solved A 3-m High Sandy Fill Material Was Placed Loosely at A ...Document1 pageSolved A 3-m High Sandy Fill Material Was Placed Loosely at A ...Cristian A. GarridoNo ratings yet

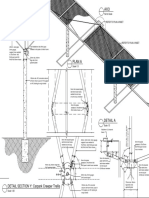

- Pavement Design - (Rigid Flexible) DPWHDocument25 pagesPavement Design - (Rigid Flexible) DPWHrekcah ehtNo ratings yet

- Detailed Syllabus of Soil MechanicsDocument9 pagesDetailed Syllabus of Soil MechanicsRajesh KhadkaNo ratings yet

- ACI 211.1 Method Final 2Document21 pagesACI 211.1 Method Final 2Yemane KebedeNo ratings yet

- Ce353-Ch6 Compaction PDFDocument31 pagesCe353-Ch6 Compaction PDFShamoyal KhanNo ratings yet

- Solved - Three Groups of Students From The Geotechnical EngineerDocument5 pagesSolved - Three Groups of Students From The Geotechnical Engineerabdullahiomar2020100% (1)

- Solved Refer To Figure 10.47. A Flexible Rectangular Area Is S...Document1 pageSolved Refer To Figure 10.47. A Flexible Rectangular Area Is S...Cristian A. GarridoNo ratings yet

- COMPACTION OF SOILS (Loiza)Document2 pagesCOMPACTION OF SOILS (Loiza)Loiza Joi MulanoNo ratings yet

- Lecture2 - Vertical StressDocument123 pagesLecture2 - Vertical StressJoseph BaruhiyeNo ratings yet

- Solved Results of A Standard Proctor Compaction Test On A Silt...Document1 pageSolved Results of A Standard Proctor Compaction Test On A Silt...Cristian A. GarridoNo ratings yet

- LEC 3. Fire DemandDocument17 pagesLEC 3. Fire DemandUsama EjazNo ratings yet

- Solved A Layered Soil Is Shown in Figure 7.33. Given - H1 1....Document1 pageSolved A Layered Soil Is Shown in Figure 7.33. Given - H1 1....Cristian A. GarridoNo ratings yet

- Soil Classification: A. AASHTO Classification SystemDocument4 pagesSoil Classification: A. AASHTO Classification SystemSheenaNo ratings yet

- 3) Bearing CapacityDocument19 pages3) Bearing CapacityhaftamuTekle100% (1)

- Traffic Flow PrinciplesDocument46 pagesTraffic Flow PrinciplessaketNo ratings yet

- Analysis of Truss-InteriorDocument4 pagesAnalysis of Truss-InteriorJune JavierNo ratings yet

- Application of Multilinear Regression Analysis in Modeling of Soil Properties For Geotechnical Civil Engineering Works in Calabar SouthDocument7 pagesApplication of Multilinear Regression Analysis in Modeling of Soil Properties For Geotechnical Civil Engineering Works in Calabar SouthMasood AhmedNo ratings yet

- CIVL 3210 - Assignment 2 - 2023 - SolutionDocument8 pagesCIVL 3210 - Assignment 2 - 2023 - Solutiondemar holnessNo ratings yet

- WorkedExamplestoBS8110 MinDocument49 pagesWorkedExamplestoBS8110 MinRwagatare civilcontractorsNo ratings yet

- Masonry Estimates ComputationDocument7 pagesMasonry Estimates ComputationSean Franz VilardoNo ratings yet

- D - Horizontal Alignment and Super ElevationDocument22 pagesD - Horizontal Alignment and Super ElevationAva CastilloNo ratings yet

- Capacity and Level of ServiceDocument16 pagesCapacity and Level of ServiceBismilNo ratings yet

- Practice Problems Geotechnical EngineeringDocument18 pagesPractice Problems Geotechnical EngineeringJeslyn MonteNo ratings yet

- Department of Agriculture Engineering: Question BankDocument23 pagesDepartment of Agriculture Engineering: Question BankSeetharam P.GNo ratings yet

- 12 One Way Ribbed Slab-SlightDocument18 pages12 One Way Ribbed Slab-Slightريام الموسوي100% (1)

- Question BankDocument72 pagesQuestion BankPreethi Abinaya100% (1)

- Lecture 6Document73 pagesLecture 6yeshi janexoNo ratings yet

- Exercise Chapter 3Document22 pagesExercise Chapter 3NurAtieqahNo ratings yet

- Example1 3Document7 pagesExample1 3MERIHUn100% (1)

- Hatanaka, M., and A. Uchida, 1996, Internal Friction Angle of Sandy Soil.Document9 pagesHatanaka, M., and A. Uchida, 1996, Internal Friction Angle of Sandy Soil.Yutong LuNo ratings yet

- Aggregate Blending Absorption Specific GravityDocument44 pagesAggregate Blending Absorption Specific Gravityyusuf alhowaidi100% (1)

- Foundation Engineering I CE-325: Chapter 3: Bearing Capacity of Shallow FoundationsDocument17 pagesFoundation Engineering I CE-325: Chapter 3: Bearing Capacity of Shallow FoundationsRobert Prince100% (1)

- Consolidation & SettlementDocument86 pagesConsolidation & SettlementARUNNo ratings yet

- 13 Density and Specific Gravity of Hydraulic CementDocument5 pages13 Density and Specific Gravity of Hydraulic CementJoshua NavalloNo ratings yet

- Standard Test Method For The Determination of The Normal Consistency of Hydraulic Cement. (ASTM C 187-04)Document3 pagesStandard Test Method For The Determination of The Normal Consistency of Hydraulic Cement. (ASTM C 187-04)MazharYasin100% (1)

- Determination of Consistency of Standard Cement PasteDocument3 pagesDetermination of Consistency of Standard Cement PasteAfifah FauziNo ratings yet

- Flexible Pavement Overlay DesignDocument28 pagesFlexible Pavement Overlay Designgyan100% (1)

- Geot. Report Basha Wolde Site 8.18.2017Document32 pagesGeot. Report Basha Wolde Site 8.18.2017Minilik Tikur SewNo ratings yet

- CHP - V Sight DistancerDocument26 pagesCHP - V Sight Distancerሽታ ዓለሜ0% (1)

- Lab 2Document8 pagesLab 2Flonja ShytiNo ratings yet

- 1 Geological Formation of Soils and TypesDocument48 pages1 Geological Formation of Soils and TypesMuaz HararNo ratings yet

- Traffic Loading and Volume 903191978Document65 pagesTraffic Loading and Volume 903191978Kevin Hernandez100% (1)

- Problem 1 1Document21 pagesProblem 1 1Jingwei ZhongNo ratings yet

- PS !@Document14 pagesPS !@Jared RoseNo ratings yet

- Astm C29Document4 pagesAstm C29Amit GabaniNo ratings yet

- 04 - Pavement Design Flexible SNDocument67 pages04 - Pavement Design Flexible SNkleinNo ratings yet

- Soil Mechanics Problem SetDocument7 pagesSoil Mechanics Problem SetChristine YasaNo ratings yet

- Soil Mechanics Is A Branch of Engineering Mechanics ThatDocument20 pagesSoil Mechanics Is A Branch of Engineering Mechanics ThatNico GeotinaNo ratings yet

- Problem:: X X X X F X XDocument22 pagesProblem:: X X X X F X Xnik arif100% (3)

- Density of Aggregates: ObjectivesDocument4 pagesDensity of Aggregates: ObjectivesKit Gerald EliasNo ratings yet

- CE 222 Lab Exercise 4Document3 pagesCE 222 Lab Exercise 4Reyy ArbolerasNo ratings yet

- Standard Test Procedures ReportDocument8 pagesStandard Test Procedures ReportSyed JamalNo ratings yet

- T 19-09 (Bulk Density (Unit Weight) and Voids in Aggregate)Document8 pagesT 19-09 (Bulk Density (Unit Weight) and Voids in Aggregate)tran_lamNo ratings yet

- Bulk Density and Voids in Aggregate (Highlight)Document5 pagesBulk Density and Voids in Aggregate (Highlight)samiNo ratings yet

- Construction and Building MaterialsDocument9 pagesConstruction and Building MaterialsMazharYasinNo ratings yet

- Lecture 1 & 2: Construction ProjectsDocument19 pagesLecture 1 & 2: Construction ProjectsMazharYasinNo ratings yet

- SBR LatexDocument2 pagesSBR LatexMazharYasinNo ratings yet

- CementDocument12 pagesCementMazharYasinNo ratings yet

- Hot Weather ConcretingDocument6 pagesHot Weather ConcretingMazharYasinNo ratings yet

- Drawing Lecture-1Document28 pagesDrawing Lecture-1MazharYasinNo ratings yet

- Uol HRD EdifDocument1 pageUol HRD EdifMazharYasinNo ratings yet

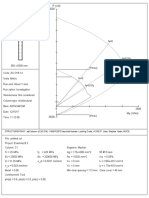

- Structurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceDocument1 pageStructurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceMazharYasinNo ratings yet

- Experiment No. 10: To Determine The Effect of Rate of Loading On The Compressive Strength of P.C.C Cube and CylinderDocument3 pagesExperiment No. 10: To Determine The Effect of Rate of Loading On The Compressive Strength of P.C.C Cube and CylinderMazharYasinNo ratings yet

- Table: Assembled Joint Masses Joint Masssource U1 U2 U3 R1 R2 R3 CenterxDocument80 pagesTable: Assembled Joint Masses Joint Masssource U1 U2 U3 R1 R2 R3 CenterxMazharYasinNo ratings yet

- Structurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceDocument1 pageStructurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceMazharYasinNo ratings yet

- Brick BondsDocument4 pagesBrick BondsMazharYasinNo ratings yet

- SP ColumnDocument2 pagesSP ColumnMazharYasinNo ratings yet

- GRE+GAT WORD LIST (Edited)Document442 pagesGRE+GAT WORD LIST (Edited)MazharYasinNo ratings yet

- SDOF Damped Forced Vibration - NewmarkDocument5 pagesSDOF Damped Forced Vibration - NewmarkMazharYasinNo ratings yet

- Hetal Patel: Team Leader - SalesDocument2 pagesHetal Patel: Team Leader - SalesPrashant kumarNo ratings yet

- 3M 309 MSDSDocument6 pages3M 309 MSDSLe Tan HoaNo ratings yet

- Baxter - Heraeus Megafuge 1,2 - User ManualDocument13 pagesBaxter - Heraeus Megafuge 1,2 - User ManualMarcos ZanelliNo ratings yet

- Lesson: The Averys Have Been Living in New York Since The Late NinetiesDocument1 pageLesson: The Averys Have Been Living in New York Since The Late NinetiesLinea SKDNo ratings yet

- Holiday AssignmentDocument18 pagesHoliday AssignmentAadhitya PranavNo ratings yet

- Invoices For UEG IstanbulDocument7 pagesInvoices For UEG IstanbulIesaw IesawNo ratings yet

- Ymrtc LogDocument26 pagesYmrtc LogVinicius Silveira0% (1)

- Metalcor - 1.4507 - Alloy - F255 - Uranus 52N - S32520Document1 pageMetalcor - 1.4507 - Alloy - F255 - Uranus 52N - S32520NitinNo ratings yet

- Building For The Environment 1Document3 pagesBuilding For The Environment 1api-133774200No ratings yet

- Eu Schengen Catalogue enDocument54 pagesEu Schengen Catalogue enSorin din ConstanțaNo ratings yet

- HandsoutDocument3 pagesHandsoutloraine mandapNo ratings yet

- A - PAGE 1 - MergedDocument73 pagesA - PAGE 1 - MergedGenalyn DomantayNo ratings yet

- MV Lec PDFDocument102 pagesMV Lec PDFJonas Datu100% (1)

- Standard nfx15-211Document2 pagesStandard nfx15-211Luis Enrique Cóndor PorrasNo ratings yet

- Using The Monopoly Board GameDocument6 pagesUsing The Monopoly Board Gamefrieda20093835No ratings yet

- Toi Su20 Sat Epep ProposalDocument7 pagesToi Su20 Sat Epep ProposalTalha SiddiquiNo ratings yet

- Will Smith BiographyDocument11 pagesWill Smith Biographyjhonatan100% (1)

- Specification Sheet: Case I Case Ii Operating ConditionsDocument1 pageSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarNo ratings yet

- PH of Soils: Standard Test Method ForDocument3 pagesPH of Soils: Standard Test Method ForYizel CastañedaNo ratings yet

- Catálogo MK 2011/2013Document243 pagesCatálogo MK 2011/2013Grupo PriluxNo ratings yet

- 2a Unani Medicine in India - An OverviewDocument123 pages2a Unani Medicine in India - An OverviewGautam NatrajanNo ratings yet

- NHM Thane Recruitment 2022 For 280 PostsDocument9 pagesNHM Thane Recruitment 2022 For 280 PostsDr.kailas Gaikwad , MO UPHC Turbhe NMMCNo ratings yet

- Ae - Centuries Before 1400 Are Listed As Browsable DirectoriesDocument3 pagesAe - Centuries Before 1400 Are Listed As Browsable DirectoriesPolNeimanNo ratings yet

- Vocations The New Midheaven Extension ProcessDocument266 pagesVocations The New Midheaven Extension ProcessMiss M.100% (24)

- WinCC Control CenterDocument300 pagesWinCC Control Centerwww.otomasyonegitimi.comNo ratings yet

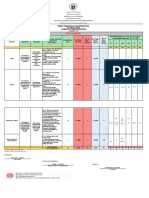

- Revised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10Document6 pagesRevised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10May Ann GuintoNo ratings yet

- Lec. 2Document22 pagesLec. 2محمدNo ratings yet

- Internship ReportDocument36 pagesInternship ReportM.IMRAN0% (1)

- M.Plan SYLLABUS 2022-24Document54 pagesM.Plan SYLLABUS 2022-24Mili DawsonNo ratings yet

- TrellisDocument1 pageTrellisCayenne LightenNo ratings yet