Professional Documents

Culture Documents

8217 2

Uploaded by

Yang WuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8217 2

Uploaded by

Yang WuCopyright:

Available Formats

Hanging pipe support, side movable, for pipes with heat

insulation, surrounding pipe support, slide

bearing, ferritic steel

temperature 20 C to 300 C; nominal diameter 25 to 200

Werknorm

8217-2

August 2001

Replaces Standards 8217

version 08.99

Dimensions in mm

Contents

1

2

3

4

Page

Layout, pipe configuration.......................................................................................................... 1

Pipe supports, dimensions......................................................................................................... 2

Pipe support parts list ................................................................................................................ 5

Pipeline thermal expansion........................................................................................................ 6

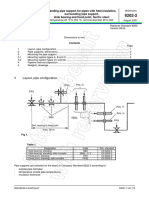

Layout, pipe configuration

Pos. U

FPH

Pos. V

Pos U

SBH

SBHL

FPH

Dist. from bearing to fixed point

max. 30 m

Fig. 1. Layout, pipe configuration

Table 1.

Designation

Slide bearing, hanging

Slide bearing, hanging, side movable

Fixed point, hanging

Standards Leverkusen

Code

Dim standard

SBH

CS 8214-2

SBHL, U, V

CS 8217-2

FPH

CS 8214-2

Page 1 of 7

Werknorm 8217-2 August 2001

Pipe supports are selected on the basis of Company Standard 8217-2 according to:

-

outside pipe diameter

temperature (inside pipe temperature)

insulation thickness

Slide bearings specified in this standard are designed for a maximum distance from the fixed point of 30 m.

For longer distances, slide bearing length l1 must be checked and corrected as needed. The diagram in Fig.

3 on page 6 showing thermal expansion, fixed-point distances and temperature differences is intended as an

aid.

The specific pipe support type is determined with reference to the required insulation thickness s1 and the

base dimension h1.

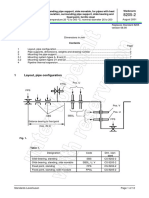

Pipe supports, dimensions

SBHL-type supports for mounting system types A, B and C

l1

w2

l1

l2

25

w1

10

7s1

h5

h2

d1

0,

a=

l3

h1

10

R

Kante gebrochen

h3

b1

Edge brocken

d3H11

h11

b2

w3

10

s1

Pipe clamp form A

Rohrschelle Form A

Mounting system A

Mounting system B

Befestigung A

Befestigung B

Hex bolt

Sechskantschraube

M16 x 40 Mu

IPB100

IPB120

18

Mounting system C

Befestigung C

Lock washer

Klemmscheibe 18

Hex bolt

Sechskantschraube

M16 x 90 Mu

Washer

Scheibe 16

L 60 x 8

Washer

Scheibe 16

L 50 x 7

L 60 x 8

Hex bolt

Sechskantschraube

M16 x 40 Mu

Square washer

Vierkantscheibe 18

60

100

SBHL: Inside pipe temperature

20 C to 200 C l1 = 200 mm

over 200 C to 300 C l1 = 300 mm

100

Splint 5 x 50

d 3=20, 25 und 30 mm

Splint 8 x 56

d 3=40 und 45 mm

100

Insulation thickness s1 is selected with

reference to inside pipe temperature

in accordance with CS 81011.

Fig. 2. SBHL-type pipe supports

Standards Leverkusen

Page 2 of 7

Werknorm 8217-2 August 2001

Table 2. Dimension h1 for SBHL pipe supports

Pipe

h1

Nominal

d1

diameter

25

33.7

32

42.4

40

48.3

50

60.3

65

76.1

80

88.9

100

114.3

125

139.7

150

168.3

200

219.1

Pipe support type

40

Insulation thickness s1

60

80

100

120

122

126

129

135

164

170

185

198

232

258

1

142

146

149

156

184

190

205

218

252

278

2

202

206

209

216

244

250

265

278

312

338

5

162

166

169

176

204

210

225

238

272

298

3

182

186

189

196

224

230

245

258

292

318

4

Nomenclature for a pipe support for a ND 50 pipe, Slide bearing, hanging, side movable, temperature to 200

C, insulation thickness s1 = 60 mm, prepared for mounting system type A1:

Pipe support CS 8217-1-50 SBHL 200-60 A1

Table 3. Dimensions h2 and h3 for SBHL pipe supports

Pipe

Nominal

diameter

h2 + h3

Insulation thickness s1

d1

40

25

33.7

32

42.4

40

48.3

50

60.3

65

76.1

80

88.9

100

114.3

125

139.7

150

168.3

200

219.1

Rohrhalterungstyp

60

80

100

120

100

100+20 100+40

100+60

100+80

120

120+20 120+40

120+60

120+80

140

140+20 140+40

140+60

140+80

Table 4. Dimensions for bolts and long-bore hole for l1 = 200 mm

Nom.

diam.

25

32

40

50

65

80

100

125

150

200

Pipe

Standards Leverkusen

Bolt

d1

33.7

42.4

48.3

60.3

76.1

88.9

114.3

139.7

168.3

219.1

Long-bore hole

d3

l3

l2

20

250

21

25

25

290

26

40

290

41

Angle brace

DIN EN 10056-1

w2

w3

100

70 x

50 x

30

37

32,5

100

75 x

50 x

30

39

40

100

100x 65 x

35

47

Page 3 of 7

Werknorm 8217-2 August 2001

Table 5. Dimensions t2 and l2 for fixed point distance 30 m

Insulation

thickness

s1

40

60

80

100

120

Standards Leverkusen

Nominal

diameter

ND

25

32

40

50

65

80

100

125

150

200

25

32

40

50

65

80

100

125

150

200

25

32

40

50

65

80

100

125

150

200

50

65

80

100

125

150

200

100

125

150

200

Pipe temp.

20 C to

200 C

Inside pipe temp.

over 200 C to 300C

SBHL

SBHL

t1

l3

t1

l3

UV

UV

280

260

280

310

260

290

280

260

280

310

260

290

280

260

280

310

260

290

280

260

280

310

260

290

280

260

280

310

260

290

Page 4 of 7

Werknorm 8217-2 August 2001

Pipe support parts list

Table 6. Parts list for mounting system, slide bearing, hanging, side movable, as shown in Fig. 2

Quantity

for

mounting

A

B

C

1

Nomenclature

Pipe support

DIN no.

CS no.

Part no.

Material

Pos.

no.

USt 37-2

Remarks

RSt 37-2

1

Bolt 20

1.4541

DIN 436

Splint 5 x 50

1.4541

DIN EN ISO 1234

splint hole 5

L 70 x 50 x 6

St 37 - 2

DIN EN 10056-1

Washer 16

St

DIN EN ISO 7091

1 345 035

-

Lock washer C 18-F

Washer 18

Hex bolt M 16 x 40 MU

St 37 - 2

St

DIN 436

1 345 115

5.6/5-2

DIN EN ISO 4016

galvanized

CS 8399

1 290 752

)

DIN EN ISO 4034

-

Hex bolt M 16 x 90 MU

5.6/5-2

Hex bolt M 16 x 40 MU

5.6/5-2

DIN EN ISO 4108

galvanized

DIN EN ISO 4034

DIN EN ISO 4016

galvanized

DIN EN ISO 4034

2

Pipe clamp, half

St 37-2

CS 8250

) See Table 4 for individual part drawings.

) Dimension l2 from Table 5.

3

) Anti-corrosion treatment as specified in CS 8110-F, hot-galvanized. Other types of anti-corrosion treatment required are to be indicated in the order.

2

Standards Leverkusen

Page 5 of 7

Werknorm 8217-2 August 2001

Pipeline thermal expansion

Dist. from fixed point

Fig. 3. Thermal expansion: ferritic steel

Standards Leverkusen

Page 6 of 7

Werknorm 8217-2 August 2001

List of standards cited

DIN 436

Square washers for use in timber constructions

DIN 1014-1

Steel bars; Hot rolled squares for general purpose; Dimensions, permissible deviations

on dimension and form

DIN 1017-1

Steel bars; Hot rolled flat steel for general purpose; Dimensions, weights,

permissible variations

DIN 1025-2

Hot rolled I-beams; Part 2: Wide flange I-beams, IPB-series; Dimensions, masses,

sectional properties

DIN EN 10055

Hot-rolled, equal-legged T steel with rounded edges and ends; dimensions, dimensional limits and shape tolerances; German version EN 10055: 1995

DIN EN 10056-1

Structural steel equal and unequal leg angles; Part 1: Dimensions; german version

EN 10056-1:1998

DIN EN ISO 1234

Split pins (ISO 1234:1997) German version EN ISO 1234:1997

DIN EN ISO 4016

Hexagon head bolts; Product grades A and B (ISO 4014:1999); German version

EN ISO 4014:2000

DIN EN ISO 4018

Hexagon head screws; Product grade C (ISO 4018_1999); German version

EN ISO 4018:2000

DIN EN ISO 4034

Hexagon nuts; Product grade C (ISO 4034: 1999); German version EN ISO 4034:2000

DIN EN ISO 7091

Plain washers; Normal series; Product grade C; (ISO 7091:2000); German version

EN ISO 7091:2000

CS 8101-1

Heat insulation; insulation layer thickness, definitions, terms

CS 8110

Pipe supports; anti-corrosion treatment; specifications

CS 8214-2

Hanging pipe supports for pipes with heat insulation, surrounding pipe support, slide

bearing and fixed point; temperature 20 C to 300 C; nominal diameter 25 to 200

CS 8250

Pipe supports; pipe clamps for nominal diameters 15 to 1000

CS 8252

Pipe supports; pipe clamps for nominal diameter 25 to 500

CS 8399

Pipes; Lock washers for double-angle bridges

Previous versions

CS 8217: 12.70; 05.76; 04.98; 08.99

Changes

The following changes were made to the version of August 1999:

a) Company Standard 8217 was revised and issued separately as CS 8217-2 for ferritic steel

Standards Leverkusen

Page 7 of 7

You might also like

- 19A Time Collection Device Integration Activity Guide PDFDocument78 pages19A Time Collection Device Integration Activity Guide PDFAliya AmarNo ratings yet

- DIN 1626-84 WELDED CIRCULAR TUBES OF NON ALLOY STEELS WITH SPECIAL USt 37.0 - ST 37.0 - ST 44.0 - ST 52.0 - DIN1.0253 - 1.0254 1.0256 1.0256 1.0421 DIN1626-84Document2 pagesDIN 1626-84 WELDED CIRCULAR TUBES OF NON ALLOY STEELS WITH SPECIAL USt 37.0 - ST 37.0 - ST 44.0 - ST 52.0 - DIN1.0253 - 1.0254 1.0256 1.0256 1.0421 DIN1626-84nunosobralNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Equivalent ASTM MaterialDocument34 pagesEquivalent ASTM Materialgolf0910251891% (45)

- Wns Type Energy-Saving BoilerDocument14 pagesWns Type Energy-Saving BoilerYang WuNo ratings yet

- Wns Type Energy-Saving BoilerDocument14 pagesWns Type Energy-Saving BoilerYang WuNo ratings yet

- MagnetostictiveDocument17 pagesMagnetostictivekanikasharma22No ratings yet

- Ricardo R4105ZD-61kW Genset Spec SheetDocument2 pagesRicardo R4105ZD-61kW Genset Spec SheetRonald Booc100% (3)

- 8202 2Document10 pages8202 2Yang WuNo ratings yet

- Werknorm: Layout Diagram, Pipe RoutingDocument6 pagesWerknorm: Layout Diagram, Pipe RoutingYang WuNo ratings yet

- 1 Layout, Pipe ConfigurationDocument12 pages1 Layout, Pipe ConfigurationYang WuNo ratings yet

- Bimetal Thermometers Model 52, Industrial Series: ApplicationsDocument4 pagesBimetal Thermometers Model 52, Industrial Series: ApplicationsAhrian BenaNo ratings yet

- PL 008748Document10 pagesPL 008748ronaldxmenNo ratings yet

- Tip 3241-7 PozicionatorDocument8 pagesTip 3241-7 PozicionatorEmir DelicNo ratings yet

- BS 4504 FlangeDocument11 pagesBS 4504 FlangeAlon BalonNo ratings yet

- Swagwlok Lap Flange PDFDocument6 pagesSwagwlok Lap Flange PDFPraveen KumarNo ratings yet

- UchwytyDocument42 pagesUchwytyharlyganNo ratings yet

- Diaphragm Valve, Metal: ConstructionDocument6 pagesDiaphragm Valve, Metal: ConstructionDenial BasanovicNo ratings yet

- Bayer: Pipes With Low-Temperature Insulation, SuspendedDocument5 pagesBayer: Pipes With Low-Temperature Insulation, SuspendedYang WuNo ratings yet

- Swagelok Flange AdaptersDocument6 pagesSwagelok Flange AdapterstotcsabNo ratings yet

- Sec1.2 Iso LF FlangesDocument17 pagesSec1.2 Iso LF FlangesMauricio MelloNo ratings yet

- Tubular Products From Special MetalsDocument26 pagesTubular Products From Special Metalskaveh-bahiraeeNo ratings yet

- Piping Specifications - Sn10 1 Pipe: Doc No: JKPM/DOC/M/001 Page 1 of 44 R0Document44 pagesPiping Specifications - Sn10 1 Pipe: Doc No: JKPM/DOC/M/001 Page 1 of 44 R0josphinvalarNo ratings yet

- AAP S6 High Pressure Fittings E2 SDocument23 pagesAAP S6 High Pressure Fittings E2 SJusthyTaquiri0% (1)

- Sec1 1 1Document2 pagesSec1 1 1rajfmc100% (1)

- EN10255 Pipe SizeDocument3 pagesEN10255 Pipe SizeStefan CristescuNo ratings yet

- Block & Bleed Valve: High Technology Valve & Fitting SeriesDocument20 pagesBlock & Bleed Valve: High Technology Valve & Fitting SeriesMayur PatelNo ratings yet

- MGH PTF CatalogDocument16 pagesMGH PTF CatalogWawanW36No ratings yet

- Catalog Tevi Arcelor MittalDocument4 pagesCatalog Tevi Arcelor MittalPaul FlorianNo ratings yet

- Accessories For Pipes: FlangesDocument7 pagesAccessories For Pipes: FlangesJbr IrvingNo ratings yet

- DIN 2093 2006-03 eDocument18 pagesDIN 2093 2006-03 eLuis Testa100% (1)

- ValvulaDocument8 pagesValvulaJosé Gasset Del ValleNo ratings yet

- SAE Flanges PDFDocument55 pagesSAE Flanges PDFG.SWAMI100% (2)

- Techical Delivery Conditions PDFDocument31 pagesTechical Delivery Conditions PDFGoran DjuricNo ratings yet

- DS Din 11864-3 Iso 1127Document7 pagesDS Din 11864-3 Iso 1127dinamitero_1985No ratings yet

- S 55 WikaDocument2 pagesS 55 WikaAliArababadiNo ratings yet

- DS DIN 11864-1 11850 Aseptic Unions PDFDocument7 pagesDS DIN 11864-1 11850 Aseptic Unions PDFChandhu Kurian ThampiNo ratings yet

- PB TW10 GBDocument6 pagesPB TW10 GBfebri_bontangNo ratings yet

- Anchor SupportsDocument7 pagesAnchor Supportstejasp8388No ratings yet

- List of DIN StandardsDocument84 pagesList of DIN StandardsAntonio FrescoNo ratings yet

- NUTRON Models T3 and B3 Ball Valves: Forged Steel Floating Ball Valves For Heavy-Duty, Reduced Maintenance PerformanceDocument32 pagesNUTRON Models T3 and B3 Ball Valves: Forged Steel Floating Ball Valves For Heavy-Duty, Reduced Maintenance PerformanceDanny PuchaNo ratings yet

- Flanges enDocument18 pagesFlanges enPablo José López FernándezNo ratings yet

- PDFDocument110 pagesPDFbaczaicarolzoltanNo ratings yet

- Din 8074 Pehd PipesDocument20 pagesDin 8074 Pehd PipesAli MkawarNo ratings yet

- General CatalogueDocument144 pagesGeneral CataloguePhilipMDMNo ratings yet

- ErmetoDocument14 pagesErmetoJavier VespaNo ratings yet

- 8249Document13 pages8249Yang WuNo ratings yet

- Tube SupportsDocument8 pagesTube SupportsSyahirul AlimNo ratings yet

- Chapter1 TriClamp Connection CS003EDocument0 pagesChapter1 TriClamp Connection CS003Ekingathur26681No ratings yet

- Tube Pitch HEDocument29 pagesTube Pitch HEDitha TiyaraNo ratings yet

- T 80120 CaDocument16 pagesT 80120 CaVinod KumarNo ratings yet

- Catalago Swagelok Suportes PDFDocument8 pagesCatalago Swagelok Suportes PDFvitorpoNo ratings yet

- DB 650 GBDocument6 pagesDB 650 GBDenial BasanovicNo ratings yet

- CS PipingDocument15 pagesCS PipingJavierSeimanNo ratings yet

- 61502YDocument9 pages61502YbalajivangaruNo ratings yet

- Valvulas de Bola - JAMESBURYDocument4 pagesValvulas de Bola - JAMESBURYcasv9No ratings yet

- Att 2 - EdsDocument30 pagesAtt 2 - Eds정동현No ratings yet

- PG 43-44 Butterfly Valve PDFDocument2 pagesPG 43-44 Butterfly Valve PDFChamitha MadushanNo ratings yet

- Marcegaglia Stainless-Steel en Ott12Document37 pagesMarcegaglia Stainless-Steel en Ott12lucidbaseNo ratings yet

- Abicor Binzel - MB GRIP 36 KDDocument6 pagesAbicor Binzel - MB GRIP 36 KDJessi JohnsonNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- NHC NHU NH60Hz IA144-CDocument9 pagesNHC NHU NH60Hz IA144-CYang WuNo ratings yet

- Astm, Ks-Jis-Din Material Comparison Tables (Part 1)Document5 pagesAstm, Ks-Jis-Din Material Comparison Tables (Part 1)Yang WuNo ratings yet

- B 45-75kW IA102-BDocument7 pagesB 45-75kW IA102-BYang WuNo ratings yet

- B Ia110-LDocument9 pagesB Ia110-LYang WuNo ratings yet

- B 45-75kW IA102-BDocument7 pagesB 45-75kW IA102-BYang WuNo ratings yet

- Astm Mto ListDocument4 pagesAstm Mto ListYang WuNo ratings yet

- NHC NHU NH60Hz IA144-CDocument9 pagesNHC NHU NH60Hz IA144-CYang WuNo ratings yet

- Bechtek Piping Material ClassDocument34 pagesBechtek Piping Material ClassBari Ipung GunturNo ratings yet

- Bayer AGDocument5 pagesBayer AGYang WuNo ratings yet

- 60hz Cast Iron Pump ChineseDocument2 pages60hz Cast Iron Pump ChineseYang WuNo ratings yet

- Bechtek Piping Material ClassDocument34 pagesBechtek Piping Material ClassBari Ipung GunturNo ratings yet

- Explant-I User GuideDocument28 pagesExplant-I User GuideXinggrage NihNo ratings yet

- HsaDocument11 pagesHsaYang WuNo ratings yet

- ch29 733 744Document12 pagesch29 733 744Yang WuNo ratings yet

- Betco ScaffoldDocument52 pagesBetco ScaffoldezzularabNo ratings yet

- Catalogue Dorpa enDocument12 pagesCatalogue Dorpa enYang WuNo ratings yet

- Getting Started With Final DesignerDocument50 pagesGetting Started With Final DesignerManny MendozaNo ratings yet

- Bayer: Pipes With Low-Temperature Insulation, SuspendedDocument5 pagesBayer: Pipes With Low-Temperature Insulation, SuspendedYang WuNo ratings yet

- Explant-A User GuideDocument14 pagesExplant-A User GuideFaizal SattuNo ratings yet

- Bayer AGDocument5 pagesBayer AGYang WuNo ratings yet

- 8249Document13 pages8249Yang WuNo ratings yet

- 8214 2Document11 pages8214 2Yang WuNo ratings yet

- SCDL - PGDBA - Finance - Sem 2 - Strategic ManagementDocument20 pagesSCDL - PGDBA - Finance - Sem 2 - Strategic Managementapi-3762419100% (2)

- Negative Skin Friction Aaron Budge Minnesota State UniversityDocument46 pagesNegative Skin Friction Aaron Budge Minnesota State UniversityNguyễn Thành NhânNo ratings yet

- Frequency Analysis Vibration Spectrum Analysis Steve GoldmanDocument9 pagesFrequency Analysis Vibration Spectrum Analysis Steve GoldmantylerdurdaneNo ratings yet

- Etic HackDocument31 pagesEtic HackJOrdi CrespoNo ratings yet

- 3 Africacert Project PublicDocument15 pages3 Africacert Project PublicLaïcana CoulibalyNo ratings yet

- Lab 11&12Document9 pagesLab 11&12Divyashini MohanNo ratings yet

- BHTM445 Syllabus MW - Spring 2015-2016Document6 pagesBHTM445 Syllabus MW - Spring 2015-2016dangerousbabyNo ratings yet

- Assessing The Impact of Premier Information Systems Research OverDocument20 pagesAssessing The Impact of Premier Information Systems Research OvergasibuteaNo ratings yet

- PanavisionSVI ELIS 1024A Datasheet PDS0004RevJDocument13 pagesPanavisionSVI ELIS 1024A Datasheet PDS0004RevJAmarnath M DamodaranNo ratings yet

- Qs Iar MB PT Mega Pratama UnggulDocument7 pagesQs Iar MB PT Mega Pratama UnggulNaufal MuljonoNo ratings yet

- Pressure Sensors - Nautilus: For Control Circuits, Type XML-F PresentationDocument11 pagesPressure Sensors - Nautilus: For Control Circuits, Type XML-F PresentationxzxNo ratings yet

- SAP ABAP ResumeDocument3 pagesSAP ABAP Resumeshakti1392821No ratings yet

- Growth of Escherichia Coli in A 5 Litre Batch Fermentation VesselDocument15 pagesGrowth of Escherichia Coli in A 5 Litre Batch Fermentation VesselAs'ad Mughal100% (2)

- Grade 2 SasmoDocument8 pagesGrade 2 SasmoThích Toán HọcNo ratings yet

- Installation Manual - BM-BE - 1212Document2 pagesInstallation Manual - BM-BE - 1212Lit Phen TuNo ratings yet

- Checklists 4yrDocument2 pagesChecklists 4yrKarla TreviñoNo ratings yet

- Giving Constructive Feedback Training Course OutlineDocument3 pagesGiving Constructive Feedback Training Course OutlineJeeNo ratings yet

- Correctos Calculos en Blow DownDocument4 pagesCorrectos Calculos en Blow Downroberdani12100% (2)

- Patrick Bernard Resume 2018 ExecutiveDocument3 pagesPatrick Bernard Resume 2018 ExecutivePatrick BernardNo ratings yet

- Grant Guidelines: Background InformationDocument10 pagesGrant Guidelines: Background Informationmth29No ratings yet

- Ti 59 - A Note On Battery CorrosionDocument3 pagesTi 59 - A Note On Battery CorrosionLeon ZieglerNo ratings yet

- 06 NetNumen U31 System DescriptionDocument39 pages06 NetNumen U31 System Descriptionمحيي الدين الكميشى100% (1)

- Government Polytechnic Muzaffarpur: Name of The Lab: Power Electronics & DrivesDocument18 pagesGovernment Polytechnic Muzaffarpur: Name of The Lab: Power Electronics & DrivesVK DNo ratings yet

- DTC 5618Document20 pagesDTC 5618Gajaram SutharNo ratings yet

- 08 - Relief System Adequacy - A Step Towards SAFER Operations - Deepak - IngeneroDocument40 pages08 - Relief System Adequacy - A Step Towards SAFER Operations - Deepak - IngeneroCalNo ratings yet

- Position PaperDocument3 pagesPosition Paperapi-178099475100% (1)

- Tank Specification - Fiberglass Tanks 0408Document13 pagesTank Specification - Fiberglass Tanks 0408shankarkl100% (2)