Professional Documents

Culture Documents

F-Hse-12 - Rev 00 Absorbant Loading

Uploaded by

vishal bailurOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F-Hse-12 - Rev 00 Absorbant Loading

Uploaded by

vishal bailurCopyright:

Available Formats

1

of

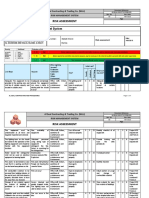

JOB SAFETY ANALYSIS

Area/Zone :

Task Description :

RIL JERP

Unit :

JERP

Product/Possible

Swapnil Patil

Developed by :

Equipment No :

Absorbant Loading by Sock method.

Reviewed by (crew) :

Absorbant Dust

Reviewed by Client :

contaminants

PPE (Standard) :

Extra PPE Required :

Task Step

Potential Hazard

Falling from height

Hand injury

Loading preparation ( Scaffolding Erection, install Chute may dislodge under it own weight

hopper , loding pipe,chute, shock inside the reactor)

scaffolding collaps

Use body harness all the

During toolbox talk,CR s

use proper PPE

Use metal pipe ( which i

scaffolding erection as p

Tripping Hazard

Ensure no pipes or hose

Drop objective and fall from height

Barrication the liftin

PPE's must be worne

CR to ensure no perso

Crane may topple due to poor set -up

CR lifting supervisor to

Use of Crane for lifting activities (Catalyst Drum

Lifting by lifting basket,Grid Lifting)

F-HSE-12 Rev.00

Issue Date : 9 January 2008

of

JOB SAFETY ANALYSIS

Area/Zone :

Task Description :

RIL JERP

Unit :

JERP

Swapnil Patil

Developed by :

Equipment No :

Absorbant Loading by Sock method.

Reviewed by (crew) :

Product/Possible

Absorbant Dust

Reviewed by Client :

contaminants

PPE (Standard) :

Extra PPE Required :

Task Step

Use of Crane for lifting activities (Catalyst Drum

Lifting by lifting basket,Grid Lifting)

3

Ventilate reactor for normal entry

Gas testing after installation of air eductor for

ventilation

F-HSE-12 Rev.00

Potential Hazard

Hand Injury/Pinch points

During toolbox talk, CR

Falling from height

Use body harness all the

Weather High Wind

Manufactures recomme

speed of 20knots.

Uncontrolled load during hoisting/slewing

CR Asia rigger shall at

the boom at allowabl

Wrong installation of eductor causing poor ventilation

CR to ventilate accordin

condition

Hand Injury

During toolbox talk,CR s

Noise

CR to ensure all working

Personal may overcome to gases or low O2 level

Gas test to be conducte

Issue Date : 9 January 2008

of

JOB SAFETY ANALYSIS

Area/Zone :

Task Description :

RIL JERP

Unit :

JERP

Swapnil Patil

Developed by :

Equipment No :

Absorbant Loading by Sock method.

Reviewed by (crew) :

Product/Possible

Absorbant Dust

Reviewed by Client :

contaminants

PPE (Standard) :

Extra PPE Required :

Task Step

Confined space entry for loading

Potential Hazard

Slip trip fall

Ensure adequate lightin

clamps at one site to av

Pinch point

Mind your hand and fing

Electrocution

Poor illumination

Inspection of cables for

Proper lying of cable to

Dont keep scaffolding m

CR supervisor to ensure

Oxygen Deficiency

Adequate Ventilation, co

Strain due to limited access or limited work space

Personal injury

Authorised Entry, Work

Minimum personal allow

CR signal man to ensure

F-HSE-12 Rev.00

Pinch point / person may hit by swinging the load

Issue Date : 9 January 2008

of

JOB SAFETY ANALYSIS

Area/Zone :

Task Description :

RIL JERP

Unit :

JERP

Equipment No :

Product/Possible

Absorbant Loading by Sock method.

Swapnil Patil

Developed by :

Reviewed by (crew) :

Absorbant Dust

Reviewed by Client :

contaminants

PPE (Standard) :

Extra PPE Required :

Task Step

Potential Hazard

CR to use tag line contro

Pinch point / person may hit by swinging the load

All lifting gear to be certi

segirate and tag not to u

Use all tools and tackles

6

Loading of Absorbant

F-HSE-12 Rev.00

Dislodge of loading pipe/sock

Use loading pipe (which

canvas sock

Exposure to catalyst dust

CR to ensure workers ar

Oxygen deficiency

CR safety watch to ensu

Poor lighting condition in the reactor

Ensure minimum lighting

Issue Date : 9 January 2008

of

Date work performed :

Page :

Do you have :

Access to a fire

extinguisher

Access to a safety shower/eyewash

Access to an Emergency Alarm

Completed Permits for the job

Control Measures

ody harness all the time and anchor to anchorage point

g toolbox talk,CR supervisor to remind workers to keep fingers away from pinch points /

oper PPE

etal pipe ( which is rigged by chain block and slings) for all of chute except th canvas sock

ding erection as per specification and certificate as fit for use

e no pipes or hoses are lying around on platform

arrication the lifting zone area,( Hard Barrication)

E's must be worned (Full body safety harness ) Use of proper material lifting procedure

o ensure no personnel is directly underneath the load

ifting supervisor to ensure proper setup of the crane

Crane load chart verification

Rigging plan to follow while crane using

F-HSE-12 Rev.00

Issue Date : 9 January 2008

6 of

Date work performed :

Page :

Do you have :

Access to a fire

extinguisher

Access to a safety shower/eyewash

Access to an Emergency Alarm

Completed Permits for the job

Control Measures

g toolbox talk, CR supervisor to remind workers to keep fingers away from pinch points.

ody harness all the time and anchor to anchorage point

actures recommendations to be adhered for high wind conditions or a maximum wind

of 20knots.

Asia rigger shall attach tag lines to control load

oom at allowable speed.

Crane operator will move

ventilate according to ventilation plan ; all ventilation eductors must be in working

on

g toolbox talk,CR supervisor to remind workers to keep fingers away from pinch points

ensure all working personnel at the reactor to wear proper hearing protection

est to be conducted by AGT through the gas meter by client and ensure by Cr Asia

F-HSE-12 Rev.00

Issue Date : 9 January 2008

of

Date work performed :

Page :

Do you have :

Access to a fire

extinguisher

Access to a safety shower/eyewash

Access to an Emergency Alarm

Completed Permits for the job

Control Measures

e adequate lighting inside the Colum 24v lighting only , keep the scaffolding pipe &

s at one site to avoid slip trip and fall

your hand and finger from trapping , Use hand proper hand gloves

ction of cables for any worn or damage condition, Use of ELCB/ECB, Proper grounding,

r lying of cable to protect them from damage,

keep scaffolding material on the cable

pervisor to ensure proper illumination inside the column (24V hand lamp)

ate Ventilation, continuous gas monitoring , ensure O2 level 19.5% to 23.5%

rised Entry, Work break, job rotation,

um personal allow to work inside the reactor

gnal man to ensure that nobody is under the suspended load

F-HSE-12 Rev.00

Issue Date : 9 January 2008

of

Date work performed :

Page :

Do you have :

Access to a fire

extinguisher

Access to a safety shower/eyewash

Access to an Emergency Alarm

Completed Permits for the job

Control Measures

use tag line control load from swinging

ng gear to be certified , check the equiptment before take to site damage tools to be

te and tag not to use

l tools and tackles are certified

ading pipe (which are rigged by chain-blocks and slings)for all of the chute except the

s sock

ensure workers are wearing dust mask during cleaning.

fety watch to ensure that theO2 level should be in between 19.5% and 23.5%

e minimum lighting at working area

F-HSE-12 Rev.00

Issue Date : 9 January 2008

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Risk Assessment Template For Fit-OutDocument5 pagesRisk Assessment Template For Fit-OutJedz Gumapas79% (14)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HSEDocument5 pagesHSETany2008No ratings yet

- Vaibhav Arun BailurDocument3 pagesVaibhav Arun Bailurvishal bailurNo ratings yet

- API 570, Piping Inspection Code (June 2006) .: (DAY 2 - Sections 1 To 6)Document5 pagesAPI 570, Piping Inspection Code (June 2006) .: (DAY 2 - Sections 1 To 6)vishal bailur100% (1)

- 2.3 Hot WorkDocument9 pages2.3 Hot Workvishal bailurNo ratings yet

- Closed Book PortionDocument5 pagesClosed Book Portionvishal bailurNo ratings yet

- Open Book PortionDocument6 pagesOpen Book Portionvishal bailurNo ratings yet

- Code Calculations: Api 570 - Piping Inspector Certification Preparatory CourseDocument8 pagesCode Calculations: Api 570 - Piping Inspector Certification Preparatory Coursevishal bailurNo ratings yet

- Code Calculations: (Pressure Testing Requirements) Exercise-5Document5 pagesCode Calculations: (Pressure Testing Requirements) Exercise-5vishal bailurNo ratings yet

- Walkie Talkie With BatteryDocument4 pagesWalkie Talkie With Batteryvishal bailurNo ratings yet

- Punch Points ASME Sec. V - Non Destructive ExaminationsDocument6 pagesPunch Points ASME Sec. V - Non Destructive Examinationsvishal bailurNo ratings yet

- Punch Points API RP 578 Material Verification Program (DAY 5)Document7 pagesPunch Points API RP 578 Material Verification Program (DAY 5)vishal bailurNo ratings yet

- Catalyst Loading by Dense Method Multi Bed Reactor Inert AtmosphereDocument7 pagesCatalyst Loading by Dense Method Multi Bed Reactor Inert Atmospherevishal bailurNo ratings yet

- Catalyst Loading by Dense Method (SingleBed) in Inert AtmosphereDocument5 pagesCatalyst Loading by Dense Method (SingleBed) in Inert Atmospherevishal bailurNo ratings yet

- Cat Loading by Sock Method in Inert AtmosphereDocument5 pagesCat Loading by Sock Method in Inert Atmospherevishal bailurNo ratings yet

- F-Sp-Hse06-01 Rev 03 Hira NewDocument14 pagesF-Sp-Hse06-01 Rev 03 Hira Newvishal bailurNo ratings yet

- PVC MSDSDocument9 pagesPVC MSDSSandry KesumaNo ratings yet

- Safety Plan ProgramDocument68 pagesSafety Plan ProgramdanielcabasaNo ratings yet

- Nalco Tri Act 1820Document13 pagesNalco Tri Act 1820anon_336536469No ratings yet

- Accident Prevention Plan ElementsDocument60 pagesAccident Prevention Plan ElementssimoniaNo ratings yet

- GBG 8 ManualDocument168 pagesGBG 8 Manualkaiser55No ratings yet

- Material Safety Data Sheet: Grauer & Weil (India) LimitedDocument4 pagesMaterial Safety Data Sheet: Grauer & Weil (India) LimitedPhan Trang0% (2)

- Presentation Total Productive Maintenance (TPM)Document14 pagesPresentation Total Productive Maintenance (TPM)jaanus143No ratings yet

- ISP Formulation GuideDocument48 pagesISP Formulation Guidesotitobahal92% (24)

- Guidance On The Application of Fee For Intervention (FFI) : HSE BooksDocument37 pagesGuidance On The Application of Fee For Intervention (FFI) : HSE BooksrockapeNo ratings yet

- RR 446Document82 pagesRR 446Andres Lucero LeivaNo ratings yet

- Useful Document - OHS - Asbestos GuidelinesDocument15 pagesUseful Document - OHS - Asbestos GuidelinesvictorNo ratings yet

- Ototoxin FS 51-002-0713 PDFDocument2 pagesOtotoxin FS 51-002-0713 PDFDaniel FarcasNo ratings yet

- Sample Diploma Unit A Examination PaperDocument4 pagesSample Diploma Unit A Examination PaperKm MehboobNo ratings yet

- RA 023 Risk Assessment - FireDocument4 pagesRA 023 Risk Assessment - Firethomson100% (4)

- SOPs of Oakdale TandooriDocument4 pagesSOPs of Oakdale TandooriSalman M. AhmedNo ratings yet

- Jha Tank Erection NDTDocument3 pagesJha Tank Erection NDTrosevelvet100% (1)

- Delfresh Mushroom Farm Inspection ReportsDocument33 pagesDelfresh Mushroom Farm Inspection ReportsTyler OlsenNo ratings yet

- Fall ProtectionDocument34 pagesFall Protectionneo_chemistNo ratings yet

- WSH Healthcare GuidelinesDocument75 pagesWSH Healthcare GuidelinesJohn KurongNo ratings yet

- Safety and Health Management Program PDFDocument113 pagesSafety and Health Management Program PDFCarl WilliamsNo ratings yet

- Machinery Safe Use An IntroductionDocument32 pagesMachinery Safe Use An IntroductionKyaw Kyaw AungNo ratings yet

- 40haz - 06 Caught in Between HazardsDocument1 page40haz - 06 Caught in Between HazardsochableNo ratings yet

- Confused by NFPA70EDocument4 pagesConfused by NFPA70Ecperalta_4No ratings yet

- Chapter 4 HealthDocument96 pagesChapter 4 HealthiffahNo ratings yet

- Sainsburys Road SafetyDocument8 pagesSainsburys Road SafetymynameiszooNo ratings yet

- Revised DMLC I Template - January 2017Document10 pagesRevised DMLC I Template - January 2017waleed yehiaNo ratings yet

- Safety Systems For CO2 PlantsDocument16 pagesSafety Systems For CO2 PlantsJimmie PerezNo ratings yet

- TTL Safety PoliciesDocument60 pagesTTL Safety PoliciesCory WalkerNo ratings yet