Professional Documents

Culture Documents

Burst Disc

Uploaded by

Indrajit BorikarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Burst Disc

Uploaded by

Indrajit BorikarCopyright:

Available Formats

DOC.

NO

PIPE STRESS ANALYSIS

RELIEF VALVE REACTION FORCE

(Vapour Discharge)

PROJECT

PREPARED

LOCATION

CHECKED

PROJ. NO

APPROVED

CLIENT

DATE

REV. NO

STATUS

REVISION

REV.

GENERAL

UNITS

Stress calculation note

PSV no.

Ref. P&ID

CN 208

T71-PSV-202A/B

4

5

INPUT DATA

Discharge System

Dynamic load factor DAF

Area of outlet at point of discharge, A

Inlet design temperature, T

11

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

2

mm2

32282.6

175

449.15

Static pressure within outlet at point of

discharge, P

barg

10

Gas/Vapour flowrate, W g

kg/s

74.76

1.432

18.23

73465.10

10

12

13

14

15

16

17

18

19

20

21

22

23

Closed

Specific heat ratio, k

Gas molecular weigt, M

REACTION FORCE

Relief Valve Reaction Force, F

F =DAF{(129.Wg.(k.T)/((k+1).M)) + 0.1(AP)}

REMARKS

Reaction forces from relief valves is considered as occasional loads. It is calculated with reference to API AP 520 Part II and

a dynamic amplification foctor (DAF) of 2.

F

=

Reaction force

A

=

Area of the outlet at the point of discharge, mm2

Wg

=

Gas Flow Rate, kg/s

Specific Heat Ratio, Cp/Cv

k

=

T

M

P

=

=

=

Inlet Design Temperature, oK

Molecular Weight

Static pressure within the outlet at the point of discharge, barg

NOTE :

1. For closed system, 0.1(AP) is neglected.

DOC. NO

PIPE STRESS ANALYSIS

RELIEF VALVE REACTION FORCE

(Vapour Discharge)

PROJECT

PREPARED

LOCATION

CHECKED

PROJ. NO

APPROVED

CLIENT

DATE

REV. NO

STATUS

REVISION

REV.

GENERAL

UNITS

Stress calculation note

PSV no.

Ref. P&ID

CN 208

T73-PSV-201

4

5

INPUT DATA

Discharge System

Dynamic load factor DAF

Area of outlet at point of discharge, A

Inlet design temperature, T

11

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

2

mm2

1902.7

80

354.15

Static pressure within outlet at point of

discharge, P

barg

10

Gas/Vapour flowrate, W g

kg/s

1.42

1.322

18.17

1220.42

10

12

13

14

15

16

17

18

19

20

21

22

23

Closed

Specific heat ratio, k

Gas molecular weigt, M

REACTION FORCE

Relief Valve Reaction Force, F

F =DAF{(129.Wg.(k.T)/((k+1).M)) + 0.1(AP)}

REMARKS

Reaction forces from relief valves is considered as occasional loads. It is calculated with reference to API AP 520 Part II and

a dynamic amplification foctor (DAF) of 2.

F

=

Reaction force

A

=

Area of the outlet at the point of discharge, mm2

Wg

=

Gas Flow Rate, kg/s

Specific Heat Ratio, Cp/Cv

k

=

T

M

P

=

=

=

Inlet Design Temperature, oK

Molecular Weight

Static pressure within the outlet at the point of discharge, barg

NOTE :

1. For closed system, 0.1(AP) is neglected.

DOC. NO

PIPE STRESS ANALYSIS

RELIEF VALVE REACTION FORCE

(Two-Phase/Liquid Discharge)

REV. NO

STATUS

PROJECT

PREPARED

LOCATION

CHECKED

PROJ. NO

APPROVED

CLIENT

DATE

REVISION

REV.

GENERAL

UNITS

Stress calculation note

PSV no.

Ref. P&ID

4

5

INPUT DATA

Discharge System

Dynamic load factor, DAF

Inlet design temperature, T

Liquid flowrate, W

kg/hr

196000

10

Area of the outlet at point of discharge, A

Vapour density at exit consitions, g

Liquid density at exit conditions, l

Weight fraction vapour at exit conditions, x

Absolute pressure at pipe exit, Pe

Absolute ambient pressure, Pa

mm2

19606.7

kg/m3

kg/m3

kPa

kPa

12

1000

0.5

10

2

302.37

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Liquid, Closed

2

oC

REACTION FORCE

Relief Valve Reaction Force, F

F= DAF

REMARKS

[(

W2

12 . 96 A

)(

(1x )

x

A

+

+

P Pa )

g

l

1000 ( e

110

Reaction forces from relief valves is considered as occasional loads. It is calculated with reference to API AP 520 Part II and

a dynamic amplification foctor (DAF) of 2

F

=

Reaction force

A

=

Area of the outlet at the point of discharge, mm2

W

=

Flow Rate, kg/hr

T

=

Inlet Design Temperature, oC

l

=

Liquid density at exit conditions, kg/m3

g

=

Vapour density at exit conditions, kg/m3

x

Pe

Pa

=

=

=

Weight fraction vapour at exit conditions

Absolute pressure at pipe exit, kPa

Absolute ambient pressure, kPa

NOTE :

1. For closed system,

A

Pe Pa

1000

is neglected.

DOC. NO

PIPE STRESS ANALYSIS

BURSTING DISC REACTION FORCE

REV. NO

STATUS

PROJECT

PREPARED

LOCATION

CHECKED

PROJ. NO

APPROVED

CLIENT

DATE

REVISION

REV.

GENERAL

UNITS

Stress calculation note

PSV no.

Ref. P&ID

4

5

INPUT DATA

Inlet pressure, P

Inlet design temperature, T

Orifice area of disc, A

Specific heat ratio, k

bar

10

100

mm2

19606.6797510539

1.1

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

REACTION FORCE

Bursting Disc Reaction Force, F

15563.78

F=0 .378 ( k+ 1 ) AP

REMARKS

Reaction forces from relief valves is considered as occasional loads. It is calculated with reference to API AP 520 Part II

F

P

T

A

k

=

=

=

=

=

Reaction force

Inlet Pressure, bar

Inlet Design Temperature, oC

Orifice area of disc, mm2

Specific Heat Ratio, Cp/Cv

API RP 520 Part I - Table 7

Properties of Gases

Gas

Methane

Ethane

Ethylene

Propane

Propylene

Isobutane

n-Butane

l-Butene

Isopentane

n-Pentane

I-Pentene

n-Hexane

Benzene

n-Heptane

Toluene

n-Octane

n-Nonane

n-Decane

Air

Ammonia

Carbon Dioxide

Hydrogen

Hydrogen Sulfide

Sulfer Dioxide

Steam

Molecular

Weight

16.04

30.07

28.03

44.09

47.08

58.12

58.12

56.10

72.15

72.15

70.13

86.18

78.11

100.20

92.13

114.22

128.23

142.28

29.96

17.03

44.01

2.02

34.08

64.04

18.01

Specific Heat

Ratio

(k = Cp/Cv)

at 60oF and

1 Atm

1.31

1.19

1.24

1.13

1.15

1.18

1.19

1.11

1.08

1.08

1.08

1.06

1.12

1.05

1.09

1.05

1.04

1.03

1.40

1.30

1.29

1.41

1.32

1.27

1.33

Critical Flow

Pressure Ratio

at 60oF and

1 Atm

Specific

Gravity

at 60oF and

1 Atm

0.54

0.57

0.57a

0.58

0.58a

0.59a

0.59

0.59a

0.59a

0.59a

0.59a

0.59a

0.58

0.60a

0.59

0.60a

0.60a

0.60a

0.53

0.53

0.55

0.52

0.53

0.55

0.54

0.554

1.058

0.969

1.522

1.453

2.007

2.007

1.937

2.491

2.491

2.421

2.973

2.697

3.459

3.181

3.944

4.428

4.912

1.000

0.588

1.519

0.0696

1.176

2.212

0.622

Critical Constants

Pressure

Temperature

(psia)

(oF)

673

718

742

617

667

529

551

543

483

490

586

437

714

397

590

362

552

304

547

1636

1071

188

1306

1143

3206

-116

90

50

206

197

273

304

276

369

386

377

454

552

513

604

564

610

632

-221

270

88

-400

213

316

706

Condensation

Temperature

1 Atm

(oF)

-259

-128

-155

-44

-54

11

31

21

82

97

86

156

176

209

231

258

303

345

-313

-28

-109

-423

-77

14

212

Flammability

Limits

(volume

percent in air

mixture)

5.0 - 15.0

2.9 - 13.8

2.7 - 34.8

2.1 - 9.5

2.8 - 10.8

1.8 - 8.4

1.9 - 8.4

1.4 - 9.3

1.4 - 8.3

1.4 - 7.8

1.4 - 8.7

1.2 - 7.7

1.3 - 7.9

1.0 - 7.0

1.2 - 7.1

0.96

0.87 - 2.7

0.78 - 2.6

-15.5 - 27.0

-4.0 - 74.2

4.3 - 45.5

---

References

1

1

1

1

2, 3

1

1

2, 3

1

1

1

1

2, 3

1

2, 3

1

1

1

2, 3

2, 3

2, 3

2, 3

2, 3

2, 3

2, 3

Estimated

References

1. Physical Constants of Hydrocarbons C1 to C10, ASTM Special Technical Publication No. 109A, Philadelphia, Pennsylvania, 1963.

2. International-Critical Tables, McGraw-Hill Book Co., Inc., New York, New York.

3. Engineering Data Book, Gas Processors Suppliers Association, Tulsa, Oklahoma, 1977.

You might also like

- Burst DiscDocument6 pagesBurst DiscMa AlNo ratings yet

- PSV - Folha de CalculosDocument4 pagesPSV - Folha de CalculosInspetor SoldagemNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Memorial PSVDocument1 pageMemorial PSVRicardo TsuyamaNo ratings yet

- Understanding Process Equipment for Operators and EngineersFrom EverandUnderstanding Process Equipment for Operators and EngineersRating: 4.5 out of 5 stars4.5/5 (3)

- PSV Force Rev0bDocument1 pagePSV Force Rev0bdumbledoreaaaaNo ratings yet

- Pressure Safety Valve Sizing Calculation Rev.01 APUDocument10 pagesPressure Safety Valve Sizing Calculation Rev.01 APUAlvin SmithNo ratings yet

- Warm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationFrom EverandWarm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationNo ratings yet

- Pressure Safety Valve Sizing CalculationDocument11 pagesPressure Safety Valve Sizing CalculationDonni AzharNo ratings yet

- PSV 0600B Well Test Separator - L03Document6 pagesPSV 0600B Well Test Separator - L03Ebby OnyekweNo ratings yet

- Process Heat Transfer: Principles, Applications and Rules of ThumbFrom EverandProcess Heat Transfer: Principles, Applications and Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (11)

- Pressure Safety Valve Sizing Calculation Rev.01Document3 pagesPressure Safety Valve Sizing Calculation Rev.01Alvin Smith100% (10)

- Analog Circuit Design Volume 2: Immersion in the Black Art of Analog DesignFrom EverandAnalog Circuit Design Volume 2: Immersion in the Black Art of Analog DesignNo ratings yet

- Pressure Safety Valve Sizing Calculations Vapour or Gas ReliefDocument3 pagesPressure Safety Valve Sizing Calculations Vapour or Gas ReliefDhananjay NilkuteNo ratings yet

- PSVDocument3 pagesPSVswapnavattemNo ratings yet

- PSV Sizing CalculationsDocument53 pagesPSV Sizing CalculationsAMITH OK93% (28)

- PSV Sizing Psv-414 UpdateDocument7 pagesPSV Sizing Psv-414 UpdateBui Khoi NguyenNo ratings yet

- Pressure Safety Valve Sizing CalculationDocument4 pagesPressure Safety Valve Sizing Calculationphavlo3No ratings yet

- Orifice Sizing CalculationDocument24 pagesOrifice Sizing Calculationjamestpp67% (3)

- PSVDocument1 pagePSVmumNo ratings yet

- PSV Sizing Psv-402 Update PsetDocument7 pagesPSV Sizing Psv-402 Update PsetBui Khoi NguyenNo ratings yet

- Section 5Document100 pagesSection 5Brayan Dali Nattez VargasNo ratings yet

- PSV 0764 CD Vent KO Drum Liquid Pump - L03Document3 pagesPSV 0764 CD Vent KO Drum Liquid Pump - L03Ebby OnyekweNo ratings yet

- InstruCalc Relief Device Sizing PDFDocument1 pageInstruCalc Relief Device Sizing PDFEkundayo JohnNo ratings yet

- Valve SizingDocument38 pagesValve SizingEmmanuel JohnsonNo ratings yet

- Re Seng CoversDocument19 pagesRe Seng CoversweldsvNo ratings yet

- H H. W W W 358.9628.D - .H 6.31533.W D.: AGA Flow Orifice Calculation RoutinesDocument24 pagesH H. W W W 358.9628.D - .H 6.31533.W D.: AGA Flow Orifice Calculation RoutinescincaohijauNo ratings yet

- PVRV Sizing For Atmospheric Storage TanksDocument2 pagesPVRV Sizing For Atmospheric Storage TanksSaeid Rahimi Mofrad50% (4)

- Reciprocating CompressorDocument6 pagesReciprocating CompressorEDUARDONo ratings yet

- Assessment of Heat ExchangersDocument14 pagesAssessment of Heat ExchangersranveerNo ratings yet

- API520 RVsizingDocument7 pagesAPI520 RVsizingdemem09100% (3)

- Section 5Document135 pagesSection 5tizeskiNo ratings yet

- 4b - IPO GL DesignDocument53 pages4b - IPO GL Designmrjohnston37No ratings yet

- Blowdown Orifice Sizing CalculationDocument1 pageBlowdown Orifice Sizing Calculationlutfi awnNo ratings yet

- Appendix A: Gantt ChartDocument30 pagesAppendix A: Gantt ChartSaifuddin NordinNo ratings yet

- Ognition PSV Sizing Calculation SpreadsheetDocument2 pagesOgnition PSV Sizing Calculation Spreadsheetger80No ratings yet

- AC Tutor1Document4 pagesAC Tutor1Jady chess24No ratings yet

- Thermodynamic Lab Experiment 8Document6 pagesThermodynamic Lab Experiment 8Ronaldo UlisiNo ratings yet

- Unit - 1 16 Marks Questions and Answers PDFDocument24 pagesUnit - 1 16 Marks Questions and Answers PDFGopi RaguNo ratings yet

- Fluid Handling Engineers: U S Agency - Taco DivDocument5 pagesFluid Handling Engineers: U S Agency - Taco DivsitehabNo ratings yet

- Roll No: 184110033 Name: Dhiren MakwanaDocument4 pagesRoll No: 184110033 Name: Dhiren Makwanapoonam rathodNo ratings yet

- PSV Sizing - API-520 PDFDocument8 pagesPSV Sizing - API-520 PDFAnonymous da6X60VpII100% (1)

- To Determine The Coefficient of Performance of Heat Pump and Production of Heat Pump Performance Curves Over A Range of Source and Delivery TemperaturesDocument11 pagesTo Determine The Coefficient of Performance of Heat Pump and Production of Heat Pump Performance Curves Over A Range of Source and Delivery TemperaturesMuhammad Sohail Tariq0% (1)

- Performance Test On Two-Stage Reciprocating Air CompressorDocument6 pagesPerformance Test On Two-Stage Reciprocating Air CompressorAji V s100% (2)

- Pressure Safety Valve Process Calculation NoteDocument14 pagesPressure Safety Valve Process Calculation NoteKhanh PhamNo ratings yet

- 2phase Separator Size 2010 VerAADocument22 pages2phase Separator Size 2010 VerAAAnonymous a4Jwz14WNo ratings yet

- Spirax Sarco-The Steam and Condensate Loop - Pressure Relief Valve Sizing - Hot Water LineDocument6 pagesSpirax Sarco-The Steam and Condensate Loop - Pressure Relief Valve Sizing - Hot Water Linedongpc1100% (1)

- Boiling Film ExperimentDocument12 pagesBoiling Film ExperimentsquionkNo ratings yet

- Final Presentation - Melanie RondotDocument22 pagesFinal Presentation - Melanie RondotSyed Haider AliNo ratings yet

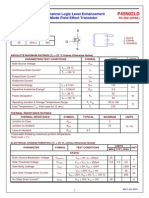

- P45N02LD Niko-Sem: N-Channel Logic Level Enhancement Mode Field Effect TransistorDocument3 pagesP45N02LD Niko-Sem: N-Channel Logic Level Enhancement Mode Field Effect TransistorAnonymous qrSsYuxyoYNo ratings yet

- PSV1 4112Document1 pagePSV1 4112QuangThai1988100% (1)

- Ap09n70p A MosfetDocument9 pagesAp09n70p A MosfetRomar BulaonNo ratings yet

- Well Head NodalDocument7 pagesWell Head Nodalmath62210No ratings yet

- Lab Report Air ConditioningDocument5 pagesLab Report Air ConditioningAzira Misman38% (8)

- Experiment No.4: 2. Keep The Status of Air Damper Positions and Expansion Device Selection AsDocument34 pagesExperiment No.4: 2. Keep The Status of Air Damper Positions and Expansion Device Selection AsRam DudiNo ratings yet

- Compressibility Factor Z CalcDocument3 pagesCompressibility Factor Z Calclutfi awnNo ratings yet

- Upload - Piping Stress Analysis - Contact and Saddle Support Stress 1.10Document6 pagesUpload - Piping Stress Analysis - Contact and Saddle Support Stress 1.10Anonymous qhVGVpNo ratings yet

- Liquid Nitrogen VolumeDocument2 pagesLiquid Nitrogen VolumeIndrajit BorikarNo ratings yet

- LN2 Capacity CalculationDocument2 pagesLN2 Capacity CalculationIndrajit BorikarNo ratings yet

- Emission Harp / Ceidars Form Year Liquid Storage Tanks Tank Instructions InstrDocument9 pagesEmission Harp / Ceidars Form Year Liquid Storage Tanks Tank Instructions InstrvikramNo ratings yet

- Flow CalculatorDocument45 pagesFlow CalculatorIndrajit BorikarNo ratings yet

- LN2 Capacity CalculationDocument2 pagesLN2 Capacity CalculationIndrajit BorikarNo ratings yet

- Rockwell-Slc500 Modbus Address Calculation SheetDocument7 pagesRockwell-Slc500 Modbus Address Calculation SheetIndrajit BorikarNo ratings yet

- Equivalent LengthDocument2 pagesEquivalent LengthIndrajit BorikarNo ratings yet

- Tecnicas para Cartas de Amor U OdioDocument4 pagesTecnicas para Cartas de Amor U OdioChristian Gabriel Stampacchio100% (16)

- Cascade Control - Handle Processes That Challenge Regular PID ControlDocument3 pagesCascade Control - Handle Processes That Challenge Regular PID ControlHayden Lovett100% (2)

- Coeffiecient of Thermal Expansion Oil Volume at NTP NTP TempDocument1 pageCoeffiecient of Thermal Expansion Oil Volume at NTP NTP TempIndrajit BorikarNo ratings yet

- Project OverviewDocument11 pagesProject OverviewIndrajit BorikarNo ratings yet

- Viscocity For GasesDocument5 pagesViscocity For GasesIndrajit BorikarNo ratings yet

- Blower AjstmentDocument4 pagesBlower AjstmentIndrajit BorikarNo ratings yet

- Laminate PropertiesDocument2 pagesLaminate PropertiesIndrajit BorikarNo ratings yet

- Laminate PropertiesDocument2 pagesLaminate PropertiesIndrajit BorikarNo ratings yet

- Lesson 06 Potential Flow and Elementary FlowsDocument23 pagesLesson 06 Potential Flow and Elementary FlowsAlmukhtar AlkinanyNo ratings yet

- Beam Deflection FormulaeDocument2 pagesBeam Deflection Formulae7575757575100% (6)

- E 1211 - 97 - RteymtetukveDocument6 pagesE 1211 - 97 - RteymtetukveLENDNo ratings yet

- Air Conditioning LiebheerDocument298 pagesAir Conditioning Liebheerdiasfm100% (2)

- Flow Control ValvesDocument7 pagesFlow Control ValvesSasko DimitrovNo ratings yet

- XXXX Evacuation Area ESDocument45 pagesXXXX Evacuation Area ESRifatAlAhmedNo ratings yet

- SWOP BrochureDocument16 pagesSWOP BrochurePurwanto ritzaNo ratings yet

- General Service Type Vertical Inline PumpsDocument22 pagesGeneral Service Type Vertical Inline Pumpssas999333No ratings yet

- Eco CompactDocument48 pagesEco CompactRoberto FreymannNo ratings yet

- 2015 Nissan GTRDocument2 pages2015 Nissan GTRSheral AidaNo ratings yet

- SOLARIS Product Ordering System PurchasesDocument24 pagesSOLARIS Product Ordering System PurchasesNina BuenNo ratings yet

- Commercial Wet Dry Vacuum Cleaner User ManualDocument8 pagesCommercial Wet Dry Vacuum Cleaner User ManualmurNo ratings yet

- Rules of Thumb For Process EngineerDocument105 pagesRules of Thumb For Process EngineerHary100% (6)

- Dwyer Rma 32 SSV Flow Meter DatasheetDocument2 pagesDwyer Rma 32 SSV Flow Meter DatasheetPedro PeñaNo ratings yet

- Ammonia Ref CycleDocument11 pagesAmmonia Ref CycleJom BonhayagNo ratings yet

- 1 Homework 1Document7 pages1 Homework 1Alexis DelgadoNo ratings yet

- Resolvers HaroweDocument8 pagesResolvers Harowemcantraks17No ratings yet

- Testing and AdjustingDocument20 pagesTesting and AdjustingAlexandra Yupanqui sarmiento100% (2)

- Briggs and Stratton 294442Document29 pagesBriggs and Stratton 294442FRNo ratings yet

- Engine DeratingDocument4 pagesEngine Deratingiuliiulian100% (1)

- Daftar Pustaka Ship MotionDocument6 pagesDaftar Pustaka Ship MotionAris MunandarNo ratings yet

- Mechanics Prob 2Document3 pagesMechanics Prob 2Paul Angelou CiriacoNo ratings yet

- محاضرات داينمك 20082009Document16 pagesمحاضرات داينمك 20082009subhyNo ratings yet

- R-30iB PMC Manual (B-83254EN 01)Document520 pagesR-30iB PMC Manual (B-83254EN 01)Sem FadeyNo ratings yet

- S04 FIP FIPD En-BDocument16 pagesS04 FIP FIPD En-BzuccoloNo ratings yet

- Airy Stress FunctionDocument2 pagesAiry Stress FunctionNaga Manikanta TatikondaNo ratings yet

- Peru Herramientas Weldy Extrusora Booster Ex2-Ex3 MDocument6 pagesPeru Herramientas Weldy Extrusora Booster Ex2-Ex3 MandersNo ratings yet

- Ressure Test Procedure For Piping SystemDocument5 pagesRessure Test Procedure For Piping SystemKyaw Kyaw AungNo ratings yet

- Fundamentlsof Rotor and Power Train Maintenance Techniques and ProceduresDocument68 pagesFundamentlsof Rotor and Power Train Maintenance Techniques and ProceduresrfriosEPNo ratings yet

- CSWIP 3.0 - Visual Welding Inspector - 1-90Document90 pagesCSWIP 3.0 - Visual Welding Inspector - 1-90Attalh Djaafar AttalhNo ratings yet