Professional Documents

Culture Documents

Appendix A - Torque Specs Torque Charts: Standard Bolt Torque Metric Bolt Torque

Uploaded by

jlfyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appendix A - Torque Specs Torque Charts: Standard Bolt Torque Metric Bolt Torque

Uploaded by

jlfyCopyright:

Available Formats

Operation & Maintenance Manual

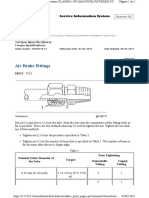

Torque Charts

Appendix A - Torque Specs

maximum torque values are based on 75% of the

specified minimum proof strength of the bolt steel

in order to provide a safety factor. The term "lube"

applies to cadmium plating and/or application of

thread lubricants. Hardened washers should

always be used, regardless of whether standard

nuts or lock nuts are employed.

Torque Charts

The following pages contain charts for use as

guides when tightening bolts and nuts. These

specifications should be followed unless specific

torques are given elsewhere in this manual.

Metric Bolt Torque

Standard Bolt Torque

Table A - 2 is a list of torque values recommended

for metric bolts. The maximum torque values are

based on 75% of the specified minimum proof

strength. The term "lube" includes the application

of thread lubricants, cadmium plating and the use

of hardened washers regardless of whether

standard or lock nuts are used.

Table A - 1 is a list of recommended torque values

for standard bolts. Use this torque chart to avoid

overstressing standard nuts and bolts used on

equipment. These specifications should be

followed unless specific torques are given. Trio

uses various bolts Grades 2, 5, and 8. The

CRSH-OM-0003ENG(OCT-2014)

A-1

Model CT-Series Jaw Crushers

Operation & Maintenance Manual

Torque Charts

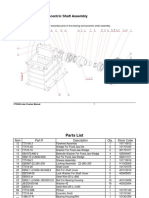

Standard Bolt Torque Chart

S.A.E Grade 2

dia.

(in.)

Dry

pitch

(thd/in.) (ft-lbs) N-M

S.A.E Grade 5

Lube

Dry

S.A.E Grade 8

Lube

Dry

Lube

(ft-lbs)

N-M

(ft-lbs)

N-M

(ft-lbs)

N-M

(ft-lbs)

N-M

(ft-lbs)

N-M

1/4

20

11

12

16

12

1/4

28

10

14

14

19

11

15

5/16

18

11

15

12

17

23

13

18

25

34

19

26

5/16

24

12

16

10

14

19

26

15

20

27

37

21

28

3/8

16

20

27

15

20

31

42

24

33

44

60

34

46

3/8

24

23

31

17

23

35

47

27

37

49

66

38

52

7/16

14

32

43

25

34

49

66

38

52

70

95

54

73

7/16

20

36

49

27

37

55

75

42

57

78

106

60

81

1/2

13

49

66

38

52

75

102

58

79

106

144

82

111

1/2

20

55

75

42

57

85

115

65

88

120

163

92

125

9/16

12

70

95

54

73

109

148

84

114

154

209

118

160

9/16

18

79

107

60

81

121

164

93

126

171

232

132

179

5/8

11

97

132

75

102

150

203

115

156

212

287

163

221

5/8

18

110

149

85

115

170

231

131

178

240

325

185

251

3/4

10

157

213

121

164

266

361

205

278

376

510

289

392

3/4

16

180

244

133

180

297

403

229

311

420

570

323

438

7/8

210

285

160

217

430

583

330

447

606

822

466

632

7/8

14

230

312

177

240

473

641

364

494

668

906

514

697

320

434

240

325

644

873

495

671

909

1233

699

948

14

340

461

255

346

704

955

542

735

995

1349

765

1037

1-1/8

350

475

270

366

794

1077

611

829

1288

1747

990

1342

1-1/8

12

395

536

305

414

891

1208

685

929

1445

1959

1111

1507

1-1/4

495

671

380

515

1120

1519

862

1169

1817

2464

1398

1896

1-1/4

12

550

746

425

576

1241

1683

954

1294

2012

2728

1548

2099

1-3/8

655

888

500

678

1469

1992

1130

1532

2382

3230

1832

2484

1-3/8

12

745

1010

570

773

1673

2269

1287

1745

2712

3677

2086

2829

1-1/2

865

1173

665

902

1949

2643

1500

2034

3161

4286

2432

3298

1-1/2

12

975

1322

750

1017

2194

2975

1687

2288

3557

4823

2736

3710

1-3/4

1370

1857

1055

1430

2286

3100

1758

2384

4988

6764

3837

5203

4.5

2060

2793

1585

2149

3438

4662

2644

3585

7500

10170

5769

7823

2-1/4

4.5

3015

4088

2320

3146

5027

6817

3867

5244

10969 14874

8438

11442

2-1/2

4125

5593

3170

4298

6875

9323

5288

7171

15000 20340 11538 15646

2-3/4

5590

7579

4300

5830

9321

12639

7170

9723

17794 24129 13688 18561

7385

10013

5680

7701

12313 16696

9472

12844 23507 31875 18082 24519

Table A - 1: Torque Values for Standard Hardware

CRSH-OM-0003ENG(OCT-2014)

A-2

Model CT-Series Jaw Crushers

Operation & Maintenance Manual

Torque Charts

Metric Bolt Torque Chart

Property Class = 8.8

Dry

dia pitch

(mm) (mm) (ft-lbs) N-M

Property Class = 10.9

Lube

Dry

Property Class = 12.9

Lube

Dry

Lube

(ft-lbs)

N-M

(ft-lbs)

N-M

(ft-lbs)

N-M

(ft-lbs)

N-M

(ft-lbs)

N-M

6.9

9.3

5.2

9.7

13.2

7.3

9.9

11.6

15.7

8.7

11.8

17.7

23.9

13.3

18

24.9

33.8

18.7

25.4

29.8

40.4

22.4

30.4

10

1.5

30

41

24

32

44

60

34

46

52

71

40

54

10

1.25

32

43

24

33

46

63

36

49

55

74

42

57

12

1.75

53

72

41

55

77

105

60

81

91

123

70

95

12

1.25

58

78

44

60

85

115

65

88

99

134

76

103

14

85

115

65

88

124

168

95

129

145

196

111

151

14

1.5

91

124

70

95

134

181

103

139

156

212

120

163

16

131

178

101

137

192

260

148

200

225

305

173

234

16

1.5

140

190

108

146

204

277

157

213

240

325

184

250

18

2.50

181

246

139

189

265

359

204

276

311

421

239

324

18

1.5

204

276

156

212

297

403

229

310

349

473

268

364

20

2.5

256

347

197

267

374

507

288

390

439

595

338

458

20

1.5

284

385

218

296

415

563

319

433

487

660

375

508

22

2.5

349

473

268

364

510

692

392

532

599

812

460

624

22

1.5

383

519

294

399

560

759

431

584

657

891

505

685

24

443

600

340

461

647

877

497

674

759

1029

583

791

24

482

654

371

503

705

956

543

736

828

1122

637

863

27

648

879

499

676

949

1286

729

989

1112

1508

856

1160

27

700

949

538

730

1023

1387

787

1067

1200

1627

923

1252

30

985

1335

741

1004

1389

1883

1044

1416

1665

2257

1252

1697

36

1716

2326

1290

1749

2419

3280

1819

2466

2900

3931

2180

2956

42

2753

3732

2070

2806

3882

5263

2919

3957

4652

6307

3498

4742

48

4156

5634

3124

4236

5860

7944

4406

5973

7023

9521

5280

7159

56

6662

9032

5009

6791

9393

12735

7063

9575

11259 15264

8465

11477

64

9954

13496

7484

10147 14035 19028 10553 14307 16822 22807 12648 17148

72

14410 19536 10835 14689 20319 27547 15277 20712 24353 33016 18310 24824

Table A - 2: Torque Values for Metric Hardware

CRSH-OM-0003ENG(OCT-2014)

A-3

Model CT-Series Jaw Crushers

Operation & Maintenance Manual

Belt Drive Troubleshooting

8) If a drive uses multiple belts, use only

matched belts. A matched set of belts last

longer and loading is evenly divided among

all the belts. Belts from different

manufacturers should not be mixed in a set

because material differences could reduce belt

life. Always replace belts in full sets.

7) Keep belts straight. Dont allow v-belts to run

out of alignment. To run properly, sheaves

must be parallel and grooves must be in line.

See (Figure B - 3)

9) Dont overload belts. If the drive has 10

sheave grooves, use 10 belts. Using less than

the designed number puts stress on the

remaining ones. This can cause premature

failure.

Belt Drive Troubleshooting

Good maintenance practices should help you

experience minimal trouble with belts and

sheaves, however there may be times when

troubles are experienced. The following table can

be used as a troubleshooting tool.

Figure B - 3 Sheave Alignment

CRSH-OM-0003ENG(OCT-2014)

B-2

Model CT-Series Jaw Crushers

Operation & Maintenance Manual

General Belt Care

Appendix B - V-Belt Drive

Information

5) Do not overtighten belts. Overtightening

shortens the useful life of belts and sheaves.

This can also cause premature bearing

failures. Ideal belt tension is the lowest at

which belts wont slip under peak loads.

General Belt Care

V-belts achieve more service life if kept clean and

dry. Rock dust and rust from metals are abrasive.

Oils and acids deteriorate belt material. Dust and

moisture on belts can cause slippage. Dust buildup

in sheaves can cause harmful vibration.

6) Periodically inspect v-belt drives for wear on

belts or sheaves. See (Figure B - 1) and

(Figure B - 2) Replace worn sheaves.

Worn

Sheave

Belt dressing compounds are available and are

sometimes used for various reasons. While they

may be used, belt dressing may actually shorten

belt life. Clean, well cared for belts are the best

way to care for belt problems. Daily cleaning of

belts and sheaves by blowing them off with

compressed air can increase their useful life.

Worn Belt

or Sheave

Normal

Store un-used belts in a cool and dry environment

with no direct sunlight. Store on shelves or in

original containers. Do not allow belts to be bent

to diameters smaller that what is recommended for

the belt cross section.

Figure B - 1 Typical Belt & Sheave Wear

General Belt Recommendations

1) Keep belts and sheaves clean.

2) Avoid belt or sheave rubbing. Dont let belts

or sheaves rub against a guard (or anything

else) while they are running.

3) Drive belts with motors mounted on

adjustable bases. This allows convenient and

proper installation of belts without prying on

belts.

4) Keep belts properly tightened. Most belt

stretch occurs in the first 30-40 hours of

operation. Check belt tension frequently

during this period.

CRSH-OM-0003ENG(OCT-2014)

Figure B - 2 Sheave Gauge Shows Wear

B-1

Model CT-Series Jaw Crushers

Operation & Maintenance Manual

Torque Charts

This Page Intentionally Left Blank

CRSH-OM-0003ENG(OCT-2014)

A-4

Model CT-Series Jaw Crushers

You might also like

- Assembly TECHLOK 3 Fold English v3 2013Document2 pagesAssembly TECHLOK 3 Fold English v3 2013Chup AlaNo ratings yet

- Kawasaki ZX9R 98-99Document307 pagesKawasaki ZX9R 98-99motomech100% (3)

- Lubrication Specifications Universal JointsDocument6 pagesLubrication Specifications Universal Jointsmohammed barghothiNo ratings yet

- AV Industrial Products LTD Catalogue Anti Vibration MountsDocument52 pagesAV Industrial Products LTD Catalogue Anti Vibration MountsAV Industrial Products LtdNo ratings yet

- SEBF8301 ADocument9 pagesSEBF8301 AnopainmadafakaNo ratings yet

- Hydraulic Cylinder Parker 3lDocument48 pagesHydraulic Cylinder Parker 3lDian Pramadi100% (2)

- Ringspann ClampDocument5 pagesRingspann ClamphamishjbadamsonNo ratings yet

- Torque SpecificationDocument20 pagesTorque SpecificationSyed Mohammad Naveed100% (1)

- 03-Senr3130!08!01-All Torque SpecificationsDocument16 pages03-Senr3130!08!01-All Torque Specificationsgustavoespinosam100% (1)

- SJ Repacking Longsweep STDDocument2 pagesSJ Repacking Longsweep STDVipul Shah100% (1)

- Tables Rope DriveDocument7 pagesTables Rope DriveSatyajit RoyNo ratings yet

- Number: 08 Ddec Vi-40 S.M. REF.: 13.2 Engine: Dd15 DATE: August 2008Document4 pagesNumber: 08 Ddec Vi-40 S.M. REF.: 13.2 Engine: Dd15 DATE: August 2008Hamilton mirandaNo ratings yet

- Jost CatalogueDocument227 pagesJost CatalogueLechien LeNo ratings yet

- Smooth9.17HRO Manual 112805Document32 pagesSmooth9.17HRO Manual 112805dfjklasdfrvNo ratings yet

- Elastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsDocument6 pagesElastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsAdhie_ginthinkNo ratings yet

- PIX Belts Product CatalogueDocument66 pagesPIX Belts Product Cataloguevideo1233% (3)

- Bridon Oil and GasDocument48 pagesBridon Oil and GasmkccmNo ratings yet

- Metric Bolt and Cap Screw Torque ValuesDocument3 pagesMetric Bolt and Cap Screw Torque Valuesalecandro_90No ratings yet

- Web Slings Lift All CatalogDocument26 pagesWeb Slings Lift All CatalogAnonymous MxwCc4No ratings yet

- BlueSky BlueLock ProcedureDocument2 pagesBlueSky BlueLock ProcedurealtexsteveNo ratings yet

- Compounding Guide StruktolDocument154 pagesCompounding Guide Struktoldusik007100% (6)

- Specifications TorqueDocument20 pagesSpecifications Torquethoma111s100% (2)

- SB 295 355 297 RR 052 001Document6 pagesSB 295 355 297 RR 052 001EDDIN1960100% (1)

- 99924-2094-01 FS600V FS541V FS481V English-EbookDocument167 pages99924-2094-01 FS600V FS541V FS481V English-EbookJeff Comfort100% (1)

- Pulleys TechDocument8 pagesPulleys TechashkansoheylNo ratings yet

- John Deere 450CLC Excavator Service Repair Technical Manual (TM1925)Document14 pagesJohn Deere 450CLC Excavator Service Repair Technical Manual (TM1925)laopaodunNo ratings yet

- ChaindriveDocument40 pagesChaindriverana__singhNo ratings yet

- KZ1000 KZ1100Document370 pagesKZ1000 KZ1100motomech100% (12)

- Caterpillar 3208 Diesel Engine SM Manual Copy OneDocument350 pagesCaterpillar 3208 Diesel Engine SM Manual Copy Oneswoods71588% (25)

- Installation Manual Ra r3Document17 pagesInstallation Manual Ra r3Carlos EscalonaNo ratings yet

- Roller Chain Coupling: Features 1. Simple Structure 1. Advantages of HousingDocument5 pagesRoller Chain Coupling: Features 1. Simple Structure 1. Advantages of Housingsyaifularifin33No ratings yet

- English Teekay BrochureDocument48 pagesEnglish Teekay BrochuresalicurriNo ratings yet

- Catalog CureleDocument0 pagesCatalog CureleCristi CryyNo ratings yet

- Omega Elastomeric Couplings - Installation ManualDocument2 pagesOmega Elastomeric Couplings - Installation ManualmmkattaNo ratings yet

- Ball ScrewDocument4 pagesBall ScrewJohn BlackburnNo ratings yet

- Hidráulica Sello Cilíndrico de Análisis de FallasDocument22 pagesHidráulica Sello Cilíndrico de Análisis de FallasPedro Cerna DiazNo ratings yet

- Pulley Alignment ProceduDocument9 pagesPulley Alignment ProceduJosh Watts100% (2)

- Collar EyeBolt To BS4278 Table 1Document9 pagesCollar EyeBolt To BS4278 Table 1Rajesh N Priya GopinathanNo ratings yet

- Geith - Acople Ec460bDocument25 pagesGeith - Acople Ec460bjrincon26No ratings yet

- ActuatorDocument12 pagesActuatorDeepu RockzzNo ratings yet

- Quick Couplers Mechanical Hydraulic 068700 PDFDocument26 pagesQuick Couplers Mechanical Hydraulic 068700 PDFSTEVHEN MARTHINNo ratings yet

- Seals: V-Ring PackingsDocument6 pagesSeals: V-Ring PackingsRtfjrjgr Xefwwxebge XsjlkzxzlsjxsjNo ratings yet

- Belt and Chain DrivesDocument10 pagesBelt and Chain DrivesJagdip ShethNo ratings yet

- Chain Maintenance ManualDocument8 pagesChain Maintenance ManualLam DesmondNo ratings yet

- DUO CONE SEALS-install, CaterpillarDocument16 pagesDUO CONE SEALS-install, CaterpillarLuisNo ratings yet

- Tabla Tension Correas GatesDocument4 pagesTabla Tension Correas Gatesvibrador0% (1)

- 5 - Rocker Lever AssemblyDocument7 pages5 - Rocker Lever AssemblyКеня КеняNo ratings yet

- TE32+MANUAL (FZ Transm) (009-040)Document32 pagesTE32+MANUAL (FZ Transm) (009-040)Marco GuachunNo ratings yet

- Front Wheel Drive Axle For TLD 828, 929 & TXL-838 Cargo LoadersDocument30 pagesFront Wheel Drive Axle For TLD 828, 929 & TXL-838 Cargo LoadersCarlos SolisNo ratings yet

- 2005 Radium Shock Service ManualDocument16 pages2005 Radium Shock Service ManualvoxborNo ratings yet

- Taber Abrasion TesterDocument4 pagesTaber Abrasion TesterAkbar KamalNo ratings yet

- 4 Wire Rope SlingsDocument22 pages4 Wire Rope SlingsMuhammad Shahid MahmoodNo ratings yet

- Floating JointDocument0 pagesFloating JointsugirinNo ratings yet

- Applied Failure Analysis Hydraulic Cylinder Seal Failure AnalysisDocument22 pagesApplied Failure Analysis Hydraulic Cylinder Seal Failure AnalysisCatalinUrsuNo ratings yet

- Design Notes 4 V-BeltDocument12 pagesDesign Notes 4 V-BeltPeter IyereNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- The GMSG Guideline For Determining The Bond Efficiency of Industrial Gri...Document18 pagesThe GMSG Guideline For Determining The Bond Efficiency of Industrial Gri...jlfyNo ratings yet

- Selenoid eDocument9 pagesSelenoid ejlfyNo ratings yet

- GekkoDocument6 pagesGekkojlfyNo ratings yet

- 2.0 Equipment Information: IPJ 1500 User Instructions: Operations, MaintenanceDocument3 pages2.0 Equipment Information: IPJ 1500 User Instructions: Operations, MaintenancejlfyNo ratings yet

- Posibles Soluciones en La OperaciónDocument3 pagesPosibles Soluciones en La OperaciónjlfyNo ratings yet

- Filtro de AireDocument7 pagesFiltro de AirejlfyNo ratings yet

- GekkoDocument6 pagesGekkojlfyNo ratings yet

- 2.0 Equipment Information: IPJ 1500 User Instructions: Operations, MaintenanceDocument3 pages2.0 Equipment Information: IPJ 1500 User Instructions: Operations, MaintenancejlfyNo ratings yet

- Posibles Soluciones en La OperaciónDocument3 pagesPosibles Soluciones en La OperaciónjlfyNo ratings yet

- Motor FalconDocument4 pagesMotor FalconjlfyNo ratings yet

- Digital PresureDocument11 pagesDigital PresurejlfyNo ratings yet

- Regulador de PrecionDocument7 pagesRegulador de PrecionjlfyNo ratings yet

- Seguridad y TransporteDocument6 pagesSeguridad y TransportejlfyNo ratings yet

- Falcon C ConcentradoDocument6 pagesFalcon C ConcentradojlfyNo ratings yet

- C1000-R3.1 Installation, Operations, and Maintenance ManualDocument8 pagesC1000-R3.1 Installation, Operations, and Maintenance ManualjlfyNo ratings yet

- 5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForceDocument4 pages5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForcejlfyNo ratings yet

- Parametros OperativosDocument5 pagesParametros OperativosjlfyNo ratings yet

- Condiciones de OperacionDocument2 pagesCondiciones de OperacionjlfyNo ratings yet

- ComisionamientoDocument2 pagesComisionamientojlfyNo ratings yet

- 5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForceDocument4 pages5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForcejlfyNo ratings yet

- Especificaciones 2Document8 pagesEspecificaciones 2jlfyNo ratings yet

- C1000-R3.1 Installation, Operations, and Maintenance ManualDocument8 pagesC1000-R3.1 Installation, Operations, and Maintenance ManualjlfyNo ratings yet

- Rinse AUTO Is The Standard Operating Mode For Most ApplicationsDocument6 pagesRinse AUTO Is The Standard Operating Mode For Most ApplicationsjlfyNo ratings yet

- C1000-R3.1 Installation, Operations, and Maintenance ManualDocument6 pagesC1000-R3.1 Installation, Operations, and Maintenance ManualjlfyNo ratings yet

- Descripcion FalconDocument4 pagesDescripcion FalconjlfyNo ratings yet

- Rinse AUTO Is The Standard Operating Mode For Most ApplicationsDocument6 pagesRinse AUTO Is The Standard Operating Mode For Most ApplicationsjlfyNo ratings yet

- C1000-R3.1 Installation, Operations, and Maintenance ManualDocument6 pagesC1000-R3.1 Installation, Operations, and Maintenance ManualjlfyNo ratings yet

- Falcon c1000Document9 pagesFalcon c1000jlfyNo ratings yet

- Jaw Part3Document6 pagesJaw Part3jlfy100% (1)

- Jaw Part2Document6 pagesJaw Part2jlfyNo ratings yet

- Helac Series PowerTilt Service Manual HY34-1410Document60 pagesHelac Series PowerTilt Service Manual HY34-1410bkmin7No ratings yet

- Ecolink Flood FL007 150 200wDocument5 pagesEcolink Flood FL007 150 200wMohammad WildhanNo ratings yet

- Spare Parts List: Pusher Leg RockdrillsDocument16 pagesSpare Parts List: Pusher Leg RockdrillsMatheus Tavares100% (1)

- RackerDocument1 pageRackerDavid MayNo ratings yet

- Powerpress ANDRITZDocument4 pagesPowerpress ANDRITZCesar LapaNo ratings yet

- Miter Shooting BoardDocument1 pageMiter Shooting BoardJaime MontielNo ratings yet

- S7400 PLC ManualDocument734 pagesS7400 PLC Manualchandakbera100% (1)

- Road Speed Limiter AUSTDocument5 pagesRoad Speed Limiter AUSTRiki KrisnaldiNo ratings yet

- 2012 MasiDocument25 pages2012 MasicanaxisNo ratings yet

- LCE Series DC-AC Inverter 1.5 KVA: SpecificationsDocument1 pageLCE Series DC-AC Inverter 1.5 KVA: SpecificationsRigoberto CabezasNo ratings yet

- Outdoor - Units - MOU 12HDN1 - MOUB 36HDN1 R220075500920 - MOUB 48HDN1 R220075700690 - MOUD 60HDN1 R - MOUA 60HRDN1Document48 pagesOutdoor - Units - MOU 12HDN1 - MOUB 36HDN1 R220075500920 - MOUB 48HDN1 R220075700690 - MOUD 60HDN1 R - MOUA 60HRDN1Muhidin KozicaNo ratings yet

- Datasheet BMXAMM0600 PDFDocument4 pagesDatasheet BMXAMM0600 PDFFelipeNo ratings yet

- Chapter 2 Slides - Overcurrent Protection of RelaysDocument68 pagesChapter 2 Slides - Overcurrent Protection of RelaysDale Steyn100% (3)

- Everest EverestDocument24 pagesEverest Everestabhi24shekNo ratings yet

- Yamato Z610, Z612 PARTS BOOK PDFDocument44 pagesYamato Z610, Z612 PARTS BOOK PDFIvan Ortiz López100% (1)

- 6GK50050BA001AB2 Datasheet enDocument2 pages6GK50050BA001AB2 Datasheet enLuis BritoNo ratings yet

- Probus 215rkdlde00 SCB (Euro 4.5)Document343 pagesProbus 215rkdlde00 SCB (Euro 4.5)Manuel RibeiroNo ratings yet

- Samsung Plasma TV TipsDocument75 pagesSamsung Plasma TV TipsErick Rodriguez100% (3)

- Yciv York Air Cooled Screw Chiller PDFDocument334 pagesYciv York Air Cooled Screw Chiller PDFHewa Akrey100% (2)

- Model: Frequency: Fuel Type: C2250 D5 50 Diesel: Generator Set Data SheetDocument3 pagesModel: Frequency: Fuel Type: C2250 D5 50 Diesel: Generator Set Data SheetLizbeth TrujilloNo ratings yet

- Sandvik: SLC S30 SH292 MP JB10Document1 pageSandvik: SLC S30 SH292 MP JB10Themba MafaNo ratings yet

- Enventory 1Document11 pagesEnventory 1Albert Jay Oring TuicoNo ratings yet

- Introduction To HEVDocument106 pagesIntroduction To HEVKhaire Sushom100% (1)

- 4054 ACtrossDocument18 pages4054 ACtrossRudi KurniawanNo ratings yet

- Crawler Crane Thorough Examination Assessment Paper11Document5 pagesCrawler Crane Thorough Examination Assessment Paper11majdi jerbiNo ratings yet

- Culligan o Ring DirectoryDocument30 pagesCulligan o Ring DirectoryCarl Schleif0% (1)

- Torque-Air Brake FittingsDocument2 pagesTorque-Air Brake Fittingsyoga_jpbmbmNo ratings yet

- Ansi Scte 02-2006Document9 pagesAnsi Scte 02-2006liuyx866No ratings yet

- 6000!CCO - 6000 COO - Manual Instalare Si Fisa TehnicaDocument2 pages6000!CCO - 6000 COO - Manual Instalare Si Fisa TehnicaMohamed Abdel MageedNo ratings yet

- SuSD.1.F.008-Electrical Data SheetDocument6 pagesSuSD.1.F.008-Electrical Data SheetHonnie Mae PaduaNo ratings yet