Professional Documents

Culture Documents

Construction Quality Management System Booklet For Cross Country Pipeline Project

Uploaded by

Rakesh RanjanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Construction Quality Management System Booklet For Cross Country Pipeline Project

Uploaded by

Rakesh RanjanCopyright:

Available Formats

Construction Quality Management System Booklet

For

Cross Country Pipeline Project

Job Number

4003/4004

Document No

2

Revision Number

G

RELIANCE

ENGINEERING ASSOCIATES (P) LIMITED

AA

Date

23/07/02

Prepared By

S.N.

Samaddar

Department/Division

Quality Management

Reviewed

By

Location:

Jamnagar

Approved

By

Hard copy of this procedure shall be treated as uncontrolled if not signed by approver

Total pages - 10

RELIANCE ENGINEERING ASSOCIATES (P) LIMITED

CONTENTS

1.

INTRODUCTION

2.

PURPOSE

3.

SCOPE

4.

REFERENCE DOCUMENT

5.

ABBREVIATIONS & DEFINITIONS

6.

APPROACH

6.1

CONCEPT

6.2

ORGANIZATION STRUCTURE, RESPONSIBILITY AND AUTHORITY FOR

QUALITY MANAGEMENT

6.3

6.4

6.5

MDR FLOW CHART

FOR FLOW CHART

SER FLOW CHART

7. ANNEXURES

I.

INSPECTION AND TEST PLANS

II.

REPORTING FORMATS

Construction Quality Management System for CCPL

Doc. No.:2QM00QMSGE002, Date 23/07/02

Page 2 of 10

Quality Management

Jamnagar

RELIANCE ENGINEERING ASSOCIATES (P) LIMITED

1. INTRODUCTION

Work for cross-country pipeline has to start in the following routes.

a) Jamnagar Bhopal Pipeline via. Ahmedabad and Indore

b) Goa-Hydrabad Pipeline via Kolhapur and Sholapur

The project is expected to move at war footing with all challenges to achieve world record in

Quality and progress. Quality Management System therefore has been designed in a manner

that following objectives are achieved.

To ensure that only job with no non-conformities are accepted and allowed for precommissioning.

To control rework by defined management system approach thus directly contributing to the

progress.

2. PURPOSE

Purpose of this document is to provide Quality Management approach for this project with detailed

responsibility and authority at each level of Management including the concerned discipline

engineers, which are responsible for carrying out the quality control/ inspection activities at site.

3. SCOPE

The scope of Quality Management approach as covered in this document is limited to construction

phase of Cross Country Pipeline activities including the pump station activities. This document will

be submitted to President (REAL) for his approval and the same shall be applicable for all

construction work of the project after his approval.

4. REFERENCE DOCUMENTS

10000QAMGE001 Apex Quality Manual REAL

5. ABBREVIATIONS & DEFINITIONS

FOR

Field observation report

HO

Head Office

HOD

Head of Department.

ITP

Inspection and Test Plan

Construction Quality Management System for CCPL

Doc. No.:2QM00QMSGE002, Date 23/07/02

Page 3 of 10

Quality Management

Jamnagar

RELIANCE ENGINEERING ASSOCIATES (P) LIMITED

MDR

Material discrepancy Report

NCR

Nonconformance Report

QMD

Quality Management Department

RO

Retail Outlets

SER

Site Engineering Request

WPS

Welding Procedure Specification

6. APPROACH

6.1

CONCEPT

The approach for managing construction quality is through quality control/ inspection and

improvement mode and covers mainly,

i.

ii.

Verification of Incoming Material

Verification of Construction activities in process

iii.

iv.

Final Inspection

System Dossier

v.

Monitoring and measurement of quality through Audit during all above phases of

construction.

Improvement based on the various findings.

vi.

The Panoramic view of approach for managing quality of above activities is given in the

following matrix.

Construction Quality Management System for CCPL

Doc. No.:2QM00QMSGE002, Date 23/07/02

Page 4 of 10

Quality Management

Jamnagar

RELIANCE ENGINEERING ASSOCIATES (P) LIMITED

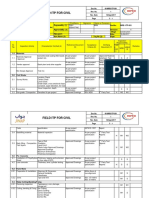

PANORAMIC VIEW OF MANAGING CONSTRUCTION QUALITY

SL

No

Stages

Scope of work

Inspection of incoming

Material (Free issue items)

1.

Incoming Material

Methodology

At REAL

Ware House

By review of material test certificates and verification of material.

(Contractor shall verify the material for its correctness before accepting from

stores.)

At Site

Random verification of material received shall be carried out.

Responsibility

Performer

Approval by

Ware House

Supervisor

Discipline

Engineer

State

Construction

manager

Site Discipline

Engineer

Spread Control

manager

Site Discipline

Engineer

Spread Control

manager

Site Discipline

Engineer

Spread Control

manager

Field QMD

Engineers

Spread QMD lead

Site Discipline

Engineer

Spread Control

manager

Site Discipline

Engineer

Spread Control

manager

Spread QMD lead

Overall

Coordinator

(QMD)/ Overallin-charge QMD

Inspection of Material

Supplied by Construction

Contractor

Site Inspection other than

Welding, NDT and

Testing

2.

Construction in process

3.

Welding, NDT and

Pressure Testing

4.

Final Inspection

Site Inspection

(Quality Records

compilation, Review and

approval)

5.

System dossiers

Final Documentation

REAL discipline engineer shall review test certificates (TC) and correlate the

TCs with mill identification marks on the material prior to its acceptance.

At site

Wherever discrepancy was noticed during identification, REAL discipline

engineer shall raise MDR. Use the MDR flow chart given in Clause 6.3 of

this document for resolve the issue.

Verify the receipt of Statutory approvals & ensure that copy is available with contractor sitein-charge. Ensure specified conditions are complied with.

Stage Inspection will be carried out and quality reports are to be prepared as per approved

Inspection and test plan.

Wherever discrepancy was noticed FOR / SER (as applicable) will be raised and resolution is

obtained as per flow charts given in this document.

Stage Inspection will be carried out and quality reports are to be prepared as per approved

Inspection and test plan.

Wherever discrepancy was noticed FOR / SER (as applicable) will be raised and resolution is

obtained as per flow charts given in this document.

All relevant Quality records will be prepared as per the requirement of the approved ITP for

the activity. Formats for construction quality activities are planned in clause 6.6 of this

document.

All approved Quality records will be compiled based on ITP relevant to activity and

discipline. (Integration by Horizontal / discipline basis)

All quality records compiled based on discipline will further compiled into system Dossier per

Spread. (Integration by Vertical / all disciplines involved)

Monitoring the job quality and overall compilation of inspection records by regular

6.

Internal Audit During

all above phases of

construction

Overall Monitoring by

Audit/ Surveillance

Construction Quality Management System for CCPL

Doc No.-2QM00QMSGE002, Date 23/07/02

surveillance visit.

Following up for the corrective actions of the audit findings.

Compiling overall re-work status and reporting to Spread Construction Manager and Overall

Coordinator QMD.

Planing over all audits and conducting as per the schedule. (Frequency of audit once in 30

days)

Reporting the overall status of quality and audit findings for the project.

Page 5 of 10

Overall

Coordinator

QMD

Overall in-charge

QMD

Quality Management

Jamnagar

RELIANCE ENGINEERING ASSOCIATES (P) LIMITED

Sr.

No.

Stages

Scope of Work

7.

Improvement in the

working system

Corrective and preventive

action against the

observations.

Construction Quality Management System for CCPL

Doc. No.-2QM00QMSGE002, Date :23/07/02

Methodology

Analysis of data from FOR, NCR, CAR

Defining the responsibility for corrective and preventive action

Page 6 of 10

Performer

Approved by

Spread Control

manager

Construction In

Charge

Quality Management

Jamnagar

RELIANCE ENGINEERING ASSOCIATES (P) LIMITED

6.2

ORGANIZATION STRUCTURE, RESPONSIBILITY & AUTHORITY

Controlling the quality of jobs being executed at site, is the responsibility of all concerned discipline engineers. (Responsibility Matrix of

discipline engineers in respect to job quality) and the functional responsibility of monitoring the approach of managing construction quality shall

be as per the following Organization structure of QMD.

Responsibilities

Conceptualizing of Quality Management System and

Overall In-charge

Quality Management

Overall In-charge

Cross Country

Pipeline Project

translating it into working system

Providing necessary training to all executives

Planing over all audit schedule, conducting with audit

team. (Frequency of audit once in 45 days)

Reporting the overall status of quality and audit

findings for the project.

Spread

Construction

Managers

Overall

Coordinator - QM

Monitoring of site by regular surveillance visit and

reporting to State chief.

Monitoring overall compilation of inspection records.

Following up for the corrective actions of the audit

findings.

Reporting to overall coordinator for the status of

corrective action.

Compiling overall re-work status.

Inspection and testing as per Inspection and test plan.

Preparation and compilation of inspection records.

Reporting re-work.

Taking corrective and preventive actions for the audit

observations.

Reviewing/forwarding contractors procedures and

Quality Plans.

Monitoring manpower suitability provided by

contractors.

Ensuring availability of latest drawings and

specifications.

Construction Quality Management System for CCPL

Doc. No.: 2QM00QMSGE002, Date 23/07/02

Spread Lead - QM

1- Each Spread

Field QMD Engineers

Site Discipline

Engineers

(Welding, NDT, Testing)

Other Activities

Functional

Administrative

Page 7 of 10

Quality Management

Jamnagar

RELIANCE ENGINEERING ASSOCIATES (P) LIMITED

6.3

MATERIAL DISCREPANCY REPORT (MDR)

Whenever material discrepancy is noticed the following flow chart (for Material

Discrepancy Report) shall be used to resolve the issue

Need for MDR is identification

at Field and warehouse

Applicable document

(Specification,

procedures etc.

Project execution group

Area Discipline Engineer /

Warehouse supervisor raises

Filled MDR format

Numbering of MDR by the

warehouse supervisor.

Numbered MDR

MDR is then sent to State

Material Coordinator / Spread

Construction Manager .

Material Control

department

Review and resolution of MDR by

Spread level Material Coordinator /

Spread Construction Manager.

Spread Construction manager gives the

MDR to the originator for necessary

action and a copy to Spread QMD lead

and Material coordinator for

information.

No

Project execution group

Is the material

acceptable?

Copy of MDR with necessary

attachments is sent to

Procurement for necessary

action with rework data.

Yes

The material is used and the

originator closes the MDR

Construction Quality Management System for CCPL

Doc. No.-2QM00QMSGE002, Date 23/07/02

Page 8 of 10

Quality Management

Jamnagar

RELIANCE ENGINEERING ASSOCIATES (P) LIMITED

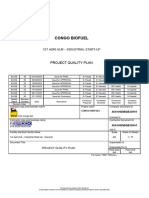

6.4

FIELD OBSERVATION REPORT (FOR)

Whenever discrepancy is noticed during construction of Cross Country Pipeline execution

the following flow chart (for Field Observation Report) shall be used to resolve the issue

Need for FOR is identification at

Field

Applicable document

(Specification,

procedures etc.

Project execution group

Area Discipline Engineer raises

FOR

Numbering of FOR by the

discipline engineer.

Filled FOR format

Numbered FOR

FOR is then sent to Spread

Construction Manager .

Review and resolution of

FOR by Spread

Construction Manager

Not resolved

Send to Engineering

/ consultant for

resolution

Resolved

Spread Construction Manager forward

the FOR to the originator for necessary

action and a copy to Spread QMD lead

for information.

Originator to verify the

corrective action taken and

close the FOR

Construction Quality Management System for CCPL

Doc. No.-2QM00QMSGE002, Date 23/07/02

Page 9 of 10

Quality Management

Jamnagar

RELIANCE ENGINEERING ASSOCIATES (P) LIMITED

6.5 SITE ENGINEERING REQUEST (SER)

Whenever any change or deviation is required for specified requirement during construction

of Cross Country Pipeline Project, the following flow chart (forSite Engineering Request )

shall be used to resolve the issue.

Identification of Information /

Request

Applicable documents

Specification,

procedures etc.

Area Discipline engineer raises SER

after consulting spread construction

manager.

Numbering of SER by Discipline

Engineer.

Filled SER format

Numbered SER

Project execution group

SER is then sent to

Engineering/consultant Manager

through Spread Construction Manager

Review of proposed resolution /

request / information required as per

SER by Engineering Manager /

Consultant

Engineering department

/Consultant

Engineering Manager / Consultant

provide necessary resolution and sends

the SER to spread Construction Manager

Spread Construction Manager gives the

SER to the originator for necessary action

Project execution group

Originator writes the rework qty,

if any, certified by SCM and hand

over the copy to Planning/QMD

for monitoring Rework

Construction Quality Management System for CCPL

Doc. No.-2QM00QMSGE002, Date :-23/07/02

Page 10 of 10

Quality Management

Jamnagar

You might also like

- Quality Control ManualDocument84 pagesQuality Control ManualMario100% (1)

- GEMSS-G-05 Rev 03 - Quality Control - Quality AssuranceDocument20 pagesGEMSS-G-05 Rev 03 - Quality Control - Quality AssuranceUmair Awan100% (1)

- ITP For Piping WorksDocument3 pagesITP For Piping WorksOrlando1949100% (3)

- Inspection Test Plan - Piping FabricationDocument5 pagesInspection Test Plan - Piping Fabricationhassan_ndt80% (5)

- RK Jain Mechanical Objective PDF DownloadDocument2 pagesRK Jain Mechanical Objective PDF DownloadRakesh Ranjan43% (14)

- Field Quality Control PlanDocument59 pagesField Quality Control Plan1339979100% (2)

- Inspection Test Plan For Civil Works Rev 01Document22 pagesInspection Test Plan For Civil Works Rev 01Eze Nonso50% (2)

- QAP StructureDocument2 pagesQAP Structureayoki100% (1)

- 26071-100-VSC-CV5-00014 - 00A Construction Method Statement For MH & CBDocument82 pages26071-100-VSC-CV5-00014 - 00A Construction Method Statement For MH & CBRezky BaskoroNo ratings yet

- 2.0 Project Quality Control PlanDocument24 pages2.0 Project Quality Control PlanAbdul Hakam Mohamed Yusof100% (6)

- Inspection Test Plan For Fabrication & Erection 2016Document14 pagesInspection Test Plan For Fabrication & Erection 2016Boj Mingi0% (1)

- Sample Quality PlanDocument17 pagesSample Quality PlanKhaled Abdelbaki100% (1)

- Piling Project Quality PlanDocument74 pagesPiling Project Quality Plan698485% (13)

- Dispersion ModelingDocument33 pagesDispersion ModelingAnuradha ChauhanNo ratings yet

- Indirectness and Euphemism PDFDocument30 pagesIndirectness and Euphemism PDFmgar10No ratings yet

- QC-GF-001 - Request For InspectionDocument1 pageQC-GF-001 - Request For InspectionDarrel Espino AranasNo ratings yet

- Quality Plan AuditDocument5 pagesQuality Plan AuditRajan100% (1)

- Itp For Ug PipelineDocument3 pagesItp For Ug PipelineJustin Alwar100% (1)

- K 3 Project Quality PlanDocument23 pagesK 3 Project Quality PlanJonathan JoeNo ratings yet

- PBI-ITP-QA-0001 Inspection and Test Plan Rev.0Document7 pagesPBI-ITP-QA-0001 Inspection and Test Plan Rev.0Tadaya KasaharaNo ratings yet

- Tepng Onshore Const Itt Project Quality PlanDocument45 pagesTepng Onshore Const Itt Project Quality PlanTrustEmmaNo ratings yet

- NDT MatrixDocument2 pagesNDT MatrixPanagiotis Chatzakos100% (1)

- TGT PVCMS Q XXX PR 0012 - Dimensional Procedure B0Document18 pagesTGT PVCMS Q XXX PR 0012 - Dimensional Procedure B0ngtchungNo ratings yet

- Rotating Itp 1Document4 pagesRotating Itp 1abdul aziz100% (1)

- ITP For Steel Structure1Document3 pagesITP For Steel Structure1吴兴泊No ratings yet

- PO No 2037-PL-PL-0058 Inspection Notification No-015 r1 PDFDocument1 pagePO No 2037-PL-PL-0058 Inspection Notification No-015 r1 PDFDadaso Baburao JamdarNo ratings yet

- Iqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Document37 pagesIqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Ali MajeedNo ratings yet

- Project Quality Plan: Document No: BK91-1312-INF-829-QAC-PLN-0001Document53 pagesProject Quality Plan: Document No: BK91-1312-INF-829-QAC-PLN-0001Berry UmpolaNo ratings yet

- ITP CIVIL WORK-Rev-1Document6 pagesITP CIVIL WORK-Rev-1Ateeq Rahman100% (1)

- Tepng Onshore Const Itt Project Quality PlanDocument42 pagesTepng Onshore Const Itt Project Quality PlanTrustEmma50% (2)

- Kc-Con-Qcp-Ss-01 - QCP Structural Steel InstallationDocument2 pagesKc-Con-Qcp-Ss-01 - QCP Structural Steel InstallationMitendra Kumar ChauhanNo ratings yet

- Project Quality PlanDocument71 pagesProject Quality PlanDaniel Dambo100% (8)

- MM ZTK 1a ZPQ Qua TPN 8055 Rev.a1Document13 pagesMM ZTK 1a ZPQ Qua TPN 8055 Rev.a1sfd640No ratings yet

- IQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFDocument15 pagesIQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFAli MajeedNo ratings yet

- Quality Plan 2 PDF FreeDocument21 pagesQuality Plan 2 PDF FreeEng.arifNo ratings yet

- Inspection and Test Plan Format: GeneralDocument4 pagesInspection and Test Plan Format: GeneralSABIR KHANNo ratings yet

- 30a100dbqb23010 - Exde06 - 77 Project Quality PlanDocument81 pages30a100dbqb23010 - Exde06 - 77 Project Quality Plansamuel madisonNo ratings yet

- Iqwq Ce1092 Qpqac 00 0002 - 0 Quality Control Procedure for Piping管道质量控制程序Document54 pagesIqwq Ce1092 Qpqac 00 0002 - 0 Quality Control Procedure for Piping管道质量控制程序Ali Majeed100% (1)

- TP-01Hydrostatic Test Cover SheetDocument4 pagesTP-01Hydrostatic Test Cover SheetAnonymous GaMb5H52100% (1)

- Project Quality PlanDocument9 pagesProject Quality PlanHasan Mahmud KhanNo ratings yet

- PLAN For Quality Assurance and ControlDocument39 pagesPLAN For Quality Assurance and ControlmutamanthecontractorNo ratings yet

- QC Sample Manual GenericDocument34 pagesQC Sample Manual GenericIan Stewart PorterNo ratings yet

- Project Quality Plan Rev 00 1 ADocument55 pagesProject Quality Plan Rev 00 1 AAhamed Naufal CaNo ratings yet

- Inspection and Test Plan Rev.0Document3 pagesInspection and Test Plan Rev.0คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Material Receiving Inspection ReportDocument2 pagesMaterial Receiving Inspection Reporttuan mai vanNo ratings yet

- Itp Bored Pile Rev 1Document10 pagesItp Bored Pile Rev 1Pandar HasibuhanNo ratings yet

- Sample ItpDocument4 pagesSample ItpWijayanto BekasiNo ratings yet

- Itp PipingDocument4 pagesItp PipingkennethNo ratings yet

- Inspection and Test Plan - StructureDocument15 pagesInspection and Test Plan - StructureFerdie OSNo ratings yet

- Method Statement: Consolidated Contractors Company & Teyseer Contracting Company J.VDocument6 pagesMethod Statement: Consolidated Contractors Company & Teyseer Contracting Company J.Vrvsreddy1972No ratings yet

- P-005 Liquid Penetant Testing ProcedureDocument13 pagesP-005 Liquid Penetant Testing ProcedureSaheb YadavNo ratings yet

- Sample MRB Index For ENIDocument1 pageSample MRB Index For ENIAnanthu Krishnan100% (1)

- Quality Requirements of ContractorsDocument15 pagesQuality Requirements of ContractorsRoshin99No ratings yet

- Project Quality Plan (8.7.2012)Document27 pagesProject Quality Plan (8.7.2012)Vinodh Palanichamy75% (4)

- QA Programme Rev.3, TERFDocument46 pagesQA Programme Rev.3, TERFUmesh Mishra100% (1)

- 220802DBQA50001 - EXCO04 - 56 Project Quality PlanDocument56 pages220802DBQA50001 - EXCO04 - 56 Project Quality PlanZainal Abidin100% (1)

- 04 Issued For Company Review RKS AKA MTA 05 Approved For Use RKS AKA MTA 05 Approved For Use RKS AKA MTADocument5 pages04 Issued For Company Review RKS AKA MTA 05 Approved For Use RKS AKA MTA 05 Approved For Use RKS AKA MTAjay2kay5793No ratings yet

- QS/QC QuestionsDocument16 pagesQS/QC QuestionsJh Hedra100% (1)

- 1 - PQP, - LNG - JETTY ADocument40 pages1 - PQP, - LNG - JETTY APuneet Vikram Singh100% (5)

- Management Review Wasit-1Document7 pagesManagement Review Wasit-1SANUNo ratings yet

- Ministry of Road Transport & Highways (Morth) : Quality Assurance PlanDocument11 pagesMinistry of Road Transport & Highways (Morth) : Quality Assurance Planfevahe756No ratings yet

- EPC QualityDocument18 pagesEPC QualityKartik BediNo ratings yet

- SCGEM Engineering and Construction Services: Construction Quality Assurance Program & Quality Control ProceduresDocument239 pagesSCGEM Engineering and Construction Services: Construction Quality Assurance Program & Quality Control ProceduresMohammed MhdyNo ratings yet

- Pole FoundationDocument13 pagesPole FoundationRakesh RanjanNo ratings yet

- FG2 Psablr1Document2 pagesFG2 Psablr1Rakesh RanjanNo ratings yet

- Annual Maintenance Quotation LetterDocument2 pagesAnnual Maintenance Quotation LetterRakesh Ranjan100% (1)

- Sample Letters by Kiran MakkarDocument4 pagesSample Letters by Kiran MakkarRakesh RanjanNo ratings yet

- CGP (Piping Engineers) Job Code:Cgp-Pip-E ResumeDocument2 pagesCGP (Piping Engineers) Job Code:Cgp-Pip-E ResumeRakesh RanjanNo ratings yet

- Dcs PLC Io Estimation TiruchyDocument2 pagesDcs PLC Io Estimation TiruchyRakesh RanjanNo ratings yet

- Model Letter For Requesting Correction or Deletion: OJ L 218, 13.8.2008, P. 60Document1 pageModel Letter For Requesting Correction or Deletion: OJ L 218, 13.8.2008, P. 60Rakesh RanjanNo ratings yet

- Maoka Na Ilaimatod: Mecon LimitedDocument7 pagesMaoka Na Ilaimatod: Mecon LimitedaviralNo ratings yet

- Vitamin B PDFDocument4 pagesVitamin B PDFRakesh RanjanNo ratings yet

- 01 Mechanical Seal ManualDocument4 pages01 Mechanical Seal ManualRakesh RanjanNo ratings yet

- CFBC Interface DocumentsDocument2 pagesCFBC Interface DocumentsRakesh RanjanNo ratings yet

- Dcs PLC Io Estimation CommentsDocument1 pageDcs PLC Io Estimation CommentsRakesh RanjanNo ratings yet

- B Complex VitaminsDocument7 pagesB Complex VitaminsRakesh RanjanNo ratings yet

- Nutrients in Foods Macro Nutrients: Carbohydrates 4 Calories/GramsDocument6 pagesNutrients in Foods Macro Nutrients: Carbohydrates 4 Calories/GramsRakesh RanjanNo ratings yet

- Lipid Metabolism During Endurance ExerciseDocument6 pagesLipid Metabolism During Endurance ExerciseRakesh RanjanNo ratings yet

- PSPCL Previous PaperDocument13 pagesPSPCL Previous PaperRakesh RanjanNo ratings yet

- Lipid Metabolism During ExerciseDocument1 pageLipid Metabolism During ExerciseRakesh RanjanNo ratings yet

- Exercise and Regulation of Carbohydrate MetabolismDocument18 pagesExercise and Regulation of Carbohydrate MetabolismIqbal PerdanaNo ratings yet

- Carbohydrates and ExerciseDocument2 pagesCarbohydrates and ExerciseRakesh RanjanNo ratings yet

- Lipid Metabolism During Endurance ExerciseDocument1 pageLipid Metabolism During Endurance ExerciseRakesh RanjanNo ratings yet

- CGPSC Previous PaperDocument69 pagesCGPSC Previous PaperRakesh RanjanNo ratings yet

- Cgpsc-Forest-Service Paper 2014Document44 pagesCgpsc-Forest-Service Paper 2014Rakesh RanjanNo ratings yet

- CGPSC Assistant Geologist PaperDocument69 pagesCGPSC Assistant Geologist PaperRakesh RanjanNo ratings yet

- Vitamin B in FoodDocument4 pagesVitamin B in FoodRakesh RanjanNo ratings yet

- CGPSC Forest Service Paper 2013Document29 pagesCGPSC Forest Service Paper 2013Rakesh RanjanNo ratings yet

- B Complex VitaminsDocument7 pagesB Complex VitaminsRakesh RanjanNo ratings yet

- Nutrients in Foods Macro Nutrients: Carbohydrates 4 Calories/GramsDocument6 pagesNutrients in Foods Macro Nutrients: Carbohydrates 4 Calories/GramsRakesh RanjanNo ratings yet

- Comparing Projects - Hoover and Shape CuttingDocument4 pagesComparing Projects - Hoover and Shape CuttingRakesh Ranjan0% (1)

- The Hoover DamDocument121 pagesThe Hoover DamCruceru RamonaNo ratings yet

- Reading Comprehension: Pratyush at Toughest QuestionsDocument40 pagesReading Comprehension: Pratyush at Toughest QuestionsJaved AnwarNo ratings yet

- Phys101l Ex104Document2 pagesPhys101l Ex104koko BunchNo ratings yet

- Safe City in Malaysia's ContextDocument8 pagesSafe City in Malaysia's Contextuyunaman100% (1)

- Data Management Platform Functionality On Revive AdserverDocument6 pagesData Management Platform Functionality On Revive AdserverJules johnNo ratings yet

- Factors Affecting Employee Turnover and Job SatisfactionDocument14 pagesFactors Affecting Employee Turnover and Job Satisfactionfarah goharNo ratings yet

- Introduction To The Web AnalysisDocument2 pagesIntroduction To The Web AnalysisAbNo ratings yet

- English 1 - R&J - Character Comparison PaperDocument2 pagesEnglish 1 - R&J - Character Comparison PaperDexter 'Koogi Mane' DaysNo ratings yet

- Online Assignment 1 Math Econ 2021 22Document6 pagesOnline Assignment 1 Math Econ 2021 22Panagiotis ScordisNo ratings yet

- Brainstorming WhahahDocument20 pagesBrainstorming WhahahJohnrey V. CuencaNo ratings yet

- Anomaly Detection Time Series Final PDFDocument12 pagesAnomaly Detection Time Series Final PDFgong688665No ratings yet

- Master of Business Administration - MBA Semester 3 ProjectDocument2 pagesMaster of Business Administration - MBA Semester 3 ProjectAnkur SharmaNo ratings yet

- The Menstrual Cycle Remedies Amenorrhea HandoutDocument3 pagesThe Menstrual Cycle Remedies Amenorrhea HandoutRoger AugeNo ratings yet

- Demo On Tableau DesktopDocument46 pagesDemo On Tableau DesktopDeepak GuptaNo ratings yet

- Company Presentation - Company ProfileDocument10 pagesCompany Presentation - Company ProfileNishtha SharmaNo ratings yet

- Unit 29 Sentence Structure in EnglishDocument11 pagesUnit 29 Sentence Structure in Englishj pcNo ratings yet

- Work Performance Report in Project ManagementDocument3 pagesWork Performance Report in Project Managementmm.No ratings yet

- Resume Updated 12 31Document2 pagesResume Updated 12 31api-436752595No ratings yet

- Wcee2012 4133Document10 pagesWcee2012 4133toyi kamiNo ratings yet

- Seven Steps To Successful Strategic PlanningDocument4 pagesSeven Steps To Successful Strategic PlanningtaimostymosNo ratings yet

- KMSC Mystery School of Self Spiritual MasteryDocument7 pagesKMSC Mystery School of Self Spiritual MasteryRalphNo ratings yet

- C Shock Press KitDocument10 pagesC Shock Press KitSusan LiNo ratings yet

- Table With Row Headers in Column A and Column Headers in Rows 5 To 7. Leading Dots Indicate SubpartsDocument2 pagesTable With Row Headers in Column A and Column Headers in Rows 5 To 7. Leading Dots Indicate SubpartsJeffrey DuqueNo ratings yet

- BlahDocument5 pagesBlahNaz KierbeyNo ratings yet

- Sampling With Automatic Gain Control 4Document31 pagesSampling With Automatic Gain Control 4anandbabugopathotiNo ratings yet

- Program Checklist PDFDocument4 pagesProgram Checklist PDFlornaNo ratings yet

- Filipino ScientistsDocument2 pagesFilipino ScientistsJohn Carlo GileNo ratings yet

- Duncan Reccommendation LetterDocument2 pagesDuncan Reccommendation LetterKilimanjaro CyberNo ratings yet

- 10 Heuristic Principles: by Jakob NielsenDocument16 pages10 Heuristic Principles: by Jakob NielsenKelum JayamannaNo ratings yet