Professional Documents

Culture Documents

Sabroe CMO Maintenance Schedule

Uploaded by

Oprea MariusCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sabroe CMO Maintenance Schedule

Uploaded by

Oprea MariusCopyright:

Available Formats

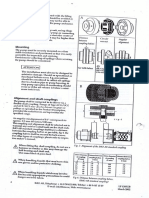

Scheduled services

No.

Operating

hours

< 1200 rpm

75

300

Operating

hours

> 1200 rpm

Activity

1.1

Remove and discard filter bag in suction filter.

Clean suction filter. Following major repair work or

in event of severe soiling of filter bag, it is recommended that a new filter bag be fitted for another

period of 50 operating hours.

1.2

Check tension of driving belts.

2.1

Check or change oil. When changing oil, change oil

filter cartridge, too. See following section:

Assessing the oil.

2.2

Clean suction filter.

2.3

Check that following function correctly:

Solenoid valves

Compressor cooling

Thermopump

Safety automatics

Heating rod

V-belt drive.

2.4

Retighten external piping connections.

2.5

Check oil return system from oil separator.

50

200

2.6

7500

Retighten coupling.

3.1

Check or change oil. When changing oil, change

oil filter cartridge, too. See following section:

Assessing the oil.

3.2

Clean suction filter.

3.3

Check that following function correctly:

Solenoid valves

Compressor cooling

Thermopump

Safety automaitcs

Heating rod

V-belt drive

Oil return system from oil separator.

3.4

For heat pump operation, inspect:

Valve seats

Cylinder linings

Pistons, gudgeon pins and gudgeon pin bearings

Piston and oil scraper rings.

5000

Change suction and discharge valve ring plates.

3.5

Finish off with a pressure drop test.

27

0171-350-EN

No.

Operating

hours

< 1200 rpm

15000

22500

Operating

hours

> 1200 rpm

Activity

4.1

Check or change oil. When changing oil, change oil

filter cartridge, too. See following section: Assessing

the oil.

4.2

Clean suction filter.

4.3

Check following:

Solenoid valves

Oil cooling system

Water cooling system for any deposits and clogging

Thermopump

Safety automatics

Heating rod

V-belt drive

Coupling and alignment

Oil return system from oil separator

Valve seats

Cylinder linings

Pistons, gudgeon pins and gudgeon pin bearings

Piston and oil scraper rings

Unloading mechanism

Seal for tightness

4.4

Change:

Suction and discharge valve ring plates

V-belts

4.5

Finish off with a pressure drop test.

5.1

Check V-belt drive

5.2

For heat pump operation, inspect:

Valve seats

Cylinder linings

Pistons, gudgeon pins and gudgeon pin bearings

Piston and oil scraper rings.

10000

15000

Change:

Suction and discharge valve ring plates.

No.

Operating

Hours

< 1200 rpm

Operating

Hours

> 1200 rpm

Activity

6.1

30000

Change compressor oil,

. Change oil filter cartridge,

Clean crankcase.

6.2

Clean suction filter.

6.3

Check following:

Solenoid valves

Oil cooling system

Water cooling system for any deposits and clogging

Thermopump

Safety automatics

Heating rod

V-belt drive

Coupling and alignment

Valve seats

Cylinder linings

Pistons, gudgeon pins and gudgeon pin bearings

Piston and oil scraper rings

Unloading mechanism

Seal for tightness

Oil pump and drive

Check valves.

6.4

Change:

Suction and discharge valve ring plates

V-belts

Half-sections of bearing for connecting rod

(does not apply to CMO compressors)

6.5

Finish off with a pressure drop test.

20000

37500

25000

As for service no. 5

45000

30000

As for service no. 4

52500

35000

As for service no. 3

10

60000

40000

Major overhaul; contact SABROE Refrigeration

Then repeat scheduled services from no. 3 inclusive.

You might also like

- Rage Against the Machine, Your Boss, Your Bills, and Everything Else: A How-To Guide to Small Acts of Revolt, Revenge, and RevolutionFrom EverandRage Against the Machine, Your Boss, Your Bills, and Everything Else: A How-To Guide to Small Acts of Revolt, Revenge, and RevolutionRating: 2.5 out of 5 stars2.5/5 (1)

- 030 Taiko KikaiDocument4 pages030 Taiko KikaiYanaNo ratings yet

- Running Engine with Failed Turbocharger BlowerDocument11 pagesRunning Engine with Failed Turbocharger Blowermihir kumar100% (1)

- PG M-Ii L1624 PDFDocument500 pagesPG M-Ii L1624 PDFMachmud SaidNo ratings yet

- Instruction Manual - CMO 28Document184 pagesInstruction Manual - CMO 28lumira75% (4)

- Temp Cont Manual For St380-r0 060316Document20 pagesTemp Cont Manual For St380-r0 060316amkrishnakumarNo ratings yet

- Marine Engine Damage from Catalytic Fines in Low Sulphur FuelDocument24 pagesMarine Engine Damage from Catalytic Fines in Low Sulphur FuelRoshan D'silva100% (2)

- Extend Fuel Injection Valve LifetimeDocument1 pageExtend Fuel Injection Valve LifetimePrinceSadhotra100% (1)

- Molykote 103brochureDocument94 pagesMolykote 103brochurevemanreddy29No ratings yet

- ABB Turbocharging TPS..-FDocument8 pagesABB Turbocharging TPS..-FAnonymous 8rb48tZS100% (1)

- PG M-Iii L2131 PDFDocument488 pagesPG M-Iii L2131 PDFnavy4No ratings yet

- Alfa Laval JWP16CDocument4 pagesAlfa Laval JWP16CdhlinvaNo ratings yet

- Instruction Manual for Reciprocating CompressorsDocument77 pagesInstruction Manual for Reciprocating CompressorsSaurabh TripathiNo ratings yet

- Nim NamDocument20 pagesNim NamMohamad JammalNo ratings yet

- Presentation - Hydraulic Oil - NewDocument14 pagesPresentation - Hydraulic Oil - NewEpure GabrielNo ratings yet

- Rta-14 1Document8 pagesRta-14 1George DomusciuNo ratings yet

- Cylinder Condition Report Plate 70711-40D: Free Lock Broken Pist. Ring Gap Type Skirt "F" (Y/N) (MM) (R/L/CPR) Guide RingDocument1 pageCylinder Condition Report Plate 70711-40D: Free Lock Broken Pist. Ring Gap Type Skirt "F" (Y/N) (MM) (R/L/CPR) Guide RingwalleyranNo ratings yet

- Seatboat Sample ArticleDocument31 pagesSeatboat Sample ArticleJoseph AlimNo ratings yet

- Prepare Lubricant List for Marine VesselDocument22 pagesPrepare Lubricant List for Marine VesselpcatruongNo ratings yet

- Welding: Ident No.: 0690709-4Document11 pagesWelding: Ident No.: 0690709-4Şansal DikmenerNo ratings yet

- Compressor York 104 ManualDocument229 pagesCompressor York 104 Manualyosep naibahoNo ratings yet

- L+V 51-60DFDocument324 pagesL+V 51-60DFEvgBelousov100% (1)

- Project Guide M20C Genset - 08.2012Document102 pagesProject Guide M20C Genset - 08.2012jorgearoncancio100% (1)

- Report: Crankshaft Deflections: Plate 70815-40FDocument1 pageReport: Crankshaft Deflections: Plate 70815-40FwalleyranNo ratings yet

- SL96-341 B&W Service LetterDocument4 pagesSL96-341 B&W Service LetterkamalNo ratings yet

- Countermeasure For SurgingDocument3 pagesCountermeasure For SurgingParthiban Nagarajan100% (1)

- Renolin 46 Hvi MSDSDocument9 pagesRenolin 46 Hvi MSDSGaurav RanjanNo ratings yet

- 706 - Performance Evaluation and General Operation - 007 PDFDocument72 pages706 - Performance Evaluation and General Operation - 007 PDFVignesh SivaNo ratings yet

- Exhaust Valve MaterialsDocument2 pagesExhaust Valve MaterialsRannier CazagrandeNo ratings yet

- Sabroe SBO ScheduleDocument2 pagesSabroe SBO SchedulecarmaNo ratings yet

- Sezione 2 PDFDocument8 pagesSezione 2 PDFMAZZI1978100% (1)

- D6R (XL) SERIE III Maintenance Interval ScheduleDocument12 pagesD6R (XL) SERIE III Maintenance Interval Schedulepedro sanchezNo ratings yet

- D6TMaintenance Interval ScheduleDocument12 pagesD6TMaintenance Interval Schedulepedro sanchezNo ratings yet

- 01 Hydraulic GroupDocument81 pages01 Hydraulic Groupgica100% (1)

- 07 Preventive Maintenance ProcedureDocument21 pages07 Preventive Maintenance ProcedureHải Lưu Minh100% (1)

- Engine Lubrication and Cooling SystemDocument36 pagesEngine Lubrication and Cooling SystemJunaid YNo ratings yet

- W32 Engine Maintenance GuideDocument12 pagesW32 Engine Maintenance GuideSalman Kapoor100% (1)

- Dismantling Hermetically Sealed CompressorDocument6 pagesDismantling Hermetically Sealed Compressorparchure123100% (2)

- Service - Service Manual Code 950 - 994 - 653Document30 pagesService - Service Manual Code 950 - 994 - 653Victor UribeNo ratings yet

- Maintenance & Trouble ShootingDocument21 pagesMaintenance & Trouble Shootingsen_subhasis_58No ratings yet

- 9.4. Lubrication and MaintenanceDocument15 pages9.4. Lubrication and MaintenanceChristian Icaza SamaniegoNo ratings yet

- Maintenance & Trouble Shooting of Voith CouplingDocument20 pagesMaintenance & Trouble Shooting of Voith Couplingsen_subhasis_58100% (1)

- Manual de Mantenimiento Cat 3500Document46 pagesManual de Mantenimiento Cat 3500Kikemol Lv ONo ratings yet

- Joyride 125-4Document13 pagesJoyride 125-4شاكر عبد الهادي الاسديNo ratings yet

- 02-Engine Mechanical SystemDocument96 pages02-Engine Mechanical Systemsalvador341100% (1)

- Jin Bei ManualDocument300 pagesJin Bei Manualrjan7pe100% (5)

- V40232 Clark C270 Torque ConverterDocument44 pagesV40232 Clark C270 Torque ConverterRemHenry100% (4)

- Engine Systems SpecificationDocument10 pagesEngine Systems SpecificationAroonBhagwandinNo ratings yet

- 912 Oil ChangeDocument4 pages912 Oil ChangeGaberNo ratings yet

- 09a-Moteur-Ewj-3.1L TDDocument68 pages09a-Moteur-Ewj-3.1L TDfizou123No ratings yet

- ENGINE LUBRICATION SYSTEMDocument24 pagesENGINE LUBRICATION SYSTEMOmar RodriguezNo ratings yet

- Service - Service Manual Code 950 - 994 - 653 (1) Kubota V2203Document30 pagesService - Service Manual Code 950 - 994 - 653 (1) Kubota V2203ynadeem100% (4)

- TDS-4S TDS-4H: Varco P/NDocument21 pagesTDS-4S TDS-4H: Varco P/NEduardo BragaNo ratings yet

- PRACTICAL_TH460-1_023826Document6 pagesPRACTICAL_TH460-1_023826eskully92No ratings yet

- Brake SystemDocument6 pagesBrake SystemSumit KatwalNo ratings yet

- Cummins Isx QSX Disassembly and Assembly Abby PDFDocument514 pagesCummins Isx QSX Disassembly and Assembly Abby PDFLyn Evans100% (3)

- SSP - 296 - d1 VW 1.4 FSI EngineDocument40 pagesSSP - 296 - d1 VW 1.4 FSI EngineGavriloae Ion75% (4)

- 3054E and 3056E Industrial Engines-Maintenance IntervalsDocument36 pages3054E and 3056E Industrial Engines-Maintenance IntervalsprabumnNo ratings yet

- Chapter 4 Part C:: Fuel and Exhaust Systems - K-Jetronic Fuel Injection - 16 Valve EnginesDocument6 pagesChapter 4 Part C:: Fuel and Exhaust Systems - K-Jetronic Fuel Injection - 16 Valve EnginesmohhizbarNo ratings yet

- LGCY Compressor Maintenance ScheduleDocument5 pagesLGCY Compressor Maintenance Schedulerais sultanNo ratings yet

- 3307 E 012 Automatic Remote Control Panel ARCPDocument8 pages3307 E 012 Automatic Remote Control Panel ARCPOprea MariusNo ratings yet

- CN-0524-G Installation of FleetMaster Technical LogDocument38 pagesCN-0524-G Installation of FleetMaster Technical LogOprea MariusNo ratings yet

- CN-0524-G Installation of FleetMaster Technical LogDocument38 pagesCN-0524-G Installation of FleetMaster Technical LogOprea MariusNo ratings yet

- Screw Pumps 1.Document1 pageScrew Pumps 1.Oprea MariusNo ratings yet

- 334967a User Manual ShipViewerDocument22 pages334967a User Manual ShipViewerOprea MariusNo ratings yet

- High Temperature Tensile Strength TestingDocument4 pagesHigh Temperature Tensile Strength TestingWalter RuedaNo ratings yet

- Liquid and Vapor Line Sizing CalculationsDocument12 pagesLiquid and Vapor Line Sizing CalculationsDana GuerreroNo ratings yet

- Hvac Ducting FundamentalDocument56 pagesHvac Ducting Fundamentalzafarbadal100% (2)

- Investigation of Risk Management Perception in Albanian Construction IndustryDocument12 pagesInvestigation of Risk Management Perception in Albanian Construction IndustryTaqwa HadidiNo ratings yet

- ADG Capability StatementDocument36 pagesADG Capability StatementADGCE100% (1)

- 15.1 Isa20 50 Control ValveDocument2 pages15.1 Isa20 50 Control Valvepastyl100% (1)

- ALP-C User Manual 2018Document42 pagesALP-C User Manual 2018SONNE INFRANo ratings yet

- Single & 3-Way Decorator Wall Switch Set Up and Operating InstructionsDocument1 pageSingle & 3-Way Decorator Wall Switch Set Up and Operating InstructionsjrmsndrNo ratings yet

- CDE Prequalification - 2023Document103 pagesCDE Prequalification - 2023sameer ahmadNo ratings yet

- DFH00191 - RAUTHERM SPEED HKV P - TI - EN - LayoutDocument4 pagesDFH00191 - RAUTHERM SPEED HKV P - TI - EN - LayoutRENSO BirouClujNo ratings yet

- Healthy Homes New ZealandDocument2 pagesHealthy Homes New ZealandKebin AbadNo ratings yet

- FLOW CONTROL VALVESDocument6 pagesFLOW CONTROL VALVESkulkarni278No ratings yet

- QFD ThesisDocument90 pagesQFD ThesisIrshad AliNo ratings yet

- Pergolas and TrellisDocument11 pagesPergolas and TrellisPARVATHY R S 170564No ratings yet

- PIP STE05121 - Anchor Bolt Design GuideDocument55 pagesPIP STE05121 - Anchor Bolt Design Guidenistiana100% (4)

- Cipet Csts Haldia STC Calender 2018 19Document1 pageCipet Csts Haldia STC Calender 2018 19Rajiv JhaNo ratings yet

- TH255C Engine CAT PartsDocument134 pagesTH255C Engine CAT PartsKevine KhaledNo ratings yet

- Single Line Diagram-Layout1Document1 pageSingle Line Diagram-Layout1Lesther SosaNo ratings yet

- Basalt FRP Reinforcing Bars For Concrete StructuresDocument6 pagesBasalt FRP Reinforcing Bars For Concrete StructuresSuresh ShanmugavelNo ratings yet

- Concrete Batch Plant Control Plan PDFDocument42 pagesConcrete Batch Plant Control Plan PDFkatfy1No ratings yet

- The Ottoman Mosques in Macedonia: ZORAN PAVLOV, Art HistorianDocument8 pagesThe Ottoman Mosques in Macedonia: ZORAN PAVLOV, Art HistorianZoran PavlovNo ratings yet

- Design of Stiffened Slabs-On-grade On Shrink-SwellDocument23 pagesDesign of Stiffened Slabs-On-grade On Shrink-SwelljoneNo ratings yet

- Manual Do BOP IEDocument18 pagesManual Do BOP IEandre vidalNo ratings yet

- Holding Down Bolts BS 7419 (Square Square) : Grade 4.6 & 8.8Document2 pagesHolding Down Bolts BS 7419 (Square Square) : Grade 4.6 & 8.8Thilan SenarathneNo ratings yet

- QuizDocument7 pagesQuizVirgilio VelascoNo ratings yet

- Light Weight Flyash Brick Using Expanded Polystyrene (EPS)Document4 pagesLight Weight Flyash Brick Using Expanded Polystyrene (EPS)jasimabdNo ratings yet

- B. Chatveera, P. LertwattanarukDocument8 pagesB. Chatveera, P. LertwattanarukArmigce PintoNo ratings yet

- HPV135 - 2650002536 - Control Piston Valves and Add-On Pieces Equipamento CATERPILLAR 938KDocument4 pagesHPV135 - 2650002536 - Control Piston Valves and Add-On Pieces Equipamento CATERPILLAR 938KRodrigues de OliveiraNo ratings yet

- PVCPressPipeSteelA 24Document1 pagePVCPressPipeSteelA 24Mustafa AlluhaibiNo ratings yet

- WS18-Chapter 23 Roof Plan LayoutDocument2 pagesWS18-Chapter 23 Roof Plan LayoutJCNo ratings yet