Professional Documents

Culture Documents

B1 (200X400)

Uploaded by

Sham TajasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B1 (200X400)

Uploaded by

Sham TajasCopyright:

Available Formats

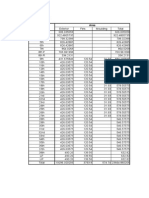

Concrete Frame Design

ACI 318-08 Beam Section Design

Beam Element Details (Summary)

Level

Element

Unique Name

Section ID

Combo ID

Station Loc

Length (mm)

LLRF

Type

2nd Floor

B4

81

B200X400

Envelope All

3850

4000

Sway Special

Section Properties

b (mm)

h (mm)

bf (mm)

ds (mm)

dct (mm)

dcb (mm)

200

400

200

40

40

Material Properties

Ec (MPa)

f'c (MPa)

Lt.Wt Factor (Unitless)

fy (MPa)

fys (MPa)

24855.58

21

275.79

275.79

Design Code Parameters

T

CTied

CSpiral

Vns

Vs

Vjoint

0.9

0.65

0.75

0.75

0.6

0.85

Design Moment and Flexural Reinforcement for Moment, Mu3

Design

-Moment

kN-m

Top

(+2 Axis)

Design

+Moment

kN-m

-21.9951

Bottom (-2 Axis)

10.9976

-Moment

Rebar

mm

+Moment

Rebar

mm

Minimum

Rebar

mm

Required

Rebar

mm

255

340

340

127

169

169

Shear Force and Reinforcement for Shear, Vu2

Shear Vu2

kN

Shear Vc

kN

Shear Vs

kN

Shear Vp

kN

Rebar Av /S

mm/m

19.94

19.94

13.7347

334.73

Beam: B1-200X400 (2B1S1)

Design Data

Beam Depth

400

mm

Beam Width

200

mm

Main Bar size

12

mm

Secondary Bar size

10

mm

Clear concrete cover on sides

40

mm

Clear concrete cover on top

40

mm

Clear concrete cover on bottom

40

mm

Ultimate Positve Moment

22

kN-m

Ultimate Negative Moment

11

kN-m

0.85

------

0.850

min = 1.4/Fy

0.005

min = Fc'/3Fy

0.006

0.005

0.038

0.028

Design Parameters

Computation of

If 28

Fc' MPa

use

If Fc' > 28 MPa

use = 0.85-.05(Fc'-28)/7

Design

Computation of min

Design min

Computation of bal

bal = 0.85 (600/(600+Fy)Fc'/Fy

Computation of max

max = 0.75 bal

Flexure Design of Midspan Section

Maximum moment at midspan, Mu+

Mu+

22.00

kN-m

0.049

0.051

0.004

0.005

350.255

mm2

Bar Size

12

mm

Number of Bars

pcs.

2

As = Ndb /4

339.2928

mm2

Effective Depth, d

344

mm

26.136

mm

Mu+ = fFcbd2(1-0.59)

By Quadratic Equation

Required Steel Ratio, & Steel Area, As reqd

= Fc'/Fy

Design

Asreqd = bd

Bar Selection and Arrangement

Moment Capacity of Section, Mcap

Actual Steel Area, As

a = AsFy/0.85Fc'b

Mcap = fAsFy(d-a/2)

= 27.7900041 kN-m

Design: PASSED

Flexure Design of Support Section

Maximum moment at support, MuMu-

11

kN-m

Mu- = fFcbd2(1-0.59)

By Quadratic Equation

0.02459144

=

0.025

Required Steel Ratio, & Steel Area, Asreqd

=

Fc'/Fy

0.002

0.005

350.255

mm2

Bar Size

12

mm

Number of Bars

pcs.

2

As = Ndb /4

339.2928

mm2

Effective Depth, d

344

mm

26.136

mm

Design

Asreqd = bd

Bar Selection and Arrangement

Moment Capacity of Section, Mcap

Actual Steel Area, As

a = AsFy/0.85Fc'b

Mcap = fAsFy(d-a/2)

= 27.7900041 kN-m

Design:

PASSED

Shear Design

Shear Stress on Concrete

Vc = 1/6

Fc

0.764

MPa

Ultimate Shear Stress

Vu = Vu/bd

0.336

MPa

Design: Stirrups not Required

Excess Shear Stress on Stirrups

Vs =

Vu - Vc

------

MPa

S = AvFy/Vsb

------

mm

S = Av/0.0015b

------

mm

300.000

------

mm

------

MPa

------

------

------

Stirrups Spacing

a.

b.

Use S =

300

Max. spacing of stirrups

if

V

sFc'

< 1/3

Smax = d/2

if

sV

Fc'

> 1/3

Smax = d/4;

Fc' =

1/3

Use Smax = d/4

------

Length Requiring Stirrups

Ls = d + (0.6L -d)Vs/Vu

Beam: B1-200X400 (2B1S1)

400

3 pcs.

12 mm RSB

400

200

200

at midspan

at support

10 mm stirrups S @ 125

L/4

1000

3 pcs. 12 mm RSB

L/4

1000

L/5

800

L/5

800

10 mm stirrups S @ 300

800

800

L

4000

NOTE:

1. ALL QUANTITIES ARE IN MM UNLESS SPECIFIED

2. THE FIRST STIRRUP SHALL BE LOCATED 50mm MAXIMUM FROM THE FACE OF THE SUPPORT.

3. LAP SPLICES SHALL NOT BE LOCATED WITHIN THE BEAM/COLUMN JOINT, NOR WITHIN A DISTANCE OF 2H.

4. LAP SPLICES SHALL BE ENCLOSED BY HOOP STIRRUPS AT A MAXIMUM SPACING OF D/4 OR 101, WHICHEVER IS SMALLER.

Beam: B1-200X400 (2B1S1)

Design Data

Beam Depth

400

mm

Beam Width

200

mm

Main Bar size

12

mm

Secondary Bar size

10

mm

Clear concrete cover on sides

40

mm

Clear concrete cover on top

40

mm

Clear concrete cover on bottom

40

mm

Ultimate Positve Moment

22

kN-m

Ultimate Negative Moment

11

kN-m

0.85

------

0.850

min = 1.4/Fy

0.005

min = Fc'/3Fy

0.006

0.005

0.038

0.028

Design Parameters

Computation of

If 28

Fc' MPa

use

If Fc' > 28 MPa

use = 0.85-.05(Fc'-28)/7

Design

Computation of min

Design min

Computation of bal

bal = 0.85 (600/(600+Fy)Fc'/Fy

Computation of max

max = 0.75 bal

Flexure Design of Midspan Section

Maximum moment at midspan, Mu+

Mu+

22.00

kN-m

0.049

0.051

0.004

0.005

350.255

mm2

Bar Size

12

mm

Number of Bars

pcs.

2

As = Ndb /4

339.2928

mm2

Effective Depth, d

344

mm

26.136

mm

Mu+ = fFcbd2(1-0.59)

By Quadratic Equation

Required Steel Ratio, & Steel Area, As reqd

= Fc'/Fy

Design

Asreqd = bd

Bar Selection and Arrangement

Moment Capacity of Section, Mcap

Actual Steel Area, As

a = AsFy/0.85Fc'b

Mcap = fAsFy(d-a/2)

= 27.7900041 kN-m

Design: PASSED

Flexure Design of Support Section

Maximum moment at support, MuMu-

11

kN-m

Mu- = fFcbd2(1-0.59)

By Quadratic Equation

0.02459144

=

0.025

Required Steel Ratio, & Steel Area, Asreqd

=

Fc'/Fy

0.002

0.005

350.255

mm2

Bar Size

12

mm

Number of Bars

pcs.

2

As = Ndb /4

339.2928

mm2

Effective Depth, d

344

mm

26.136

mm

Design

Asreqd = bd

Bar Selection and Arrangement

Moment Capacity of Section, Mcap

Actual Steel Area, As

a = AsFy/0.85Fc'b

Mcap = fAsFy(d-a/2)

= 27.7900041 kN-m

Design:

PASSED

Shear Design

Shear Stress on Concrete

Vc = 1/6

Fc

0.764

MPa

Ultimate Shear Stress

Vu = Vu/bd

0.336

MPa

Design: Stirrups not Required

Excess Shear Stress on Stirrups

Vs =

Vu - Vc

------

MPa

S = AvFy/Vsb

------

mm

S = Av/0.0015b

------

mm

300.000

------

mm

------

MPa

------

------

------

Stirrups Spacing

a.

b.

Use S =

300

Max. spacing of stirrups

if

V

sFc'

< 1/3

Smax = d/2

if

sV

Fc'

> 1/3

Smax = d/4;

Fc' =

1/3

Use Smax = d/4

------

Length Requiring Stirrups

Ls = d + (0.6L -d)Vs/Vu

Beam: B1-200X400 (2B1S1)

400

3 pcs.

12 mm RSB

400

200

200

at midspan

at support

10 mm stirrups S @ 125

L/4

1000

3 pcs. 12 mm RSB

L/4

1000

L/5

800

L/5

800

10 mm stirrups S @ 300

800

800

L

4000

NOTE:

1. ALL QUANTITIES ARE IN MM UNLESS SPECIFIED

2. THE FIRST STIRRUP SHALL BE LOCATED 50mm MAXIMUM FROM THE FACE OF THE SUPPORT.

3. LAP SPLICES SHALL NOT BE LOCATED WITHIN THE BEAM/COLUMN JOINT, NOR WITHIN A DISTANCE OF 2H.

4. LAP SPLICES SHALL BE ENCLOSED BY HOOP STIRRUPS AT A MAXIMUM SPACING OF D/4 OR 101, WHICHEVER IS SMALLER.

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1ES7YK4AC6GBPC8Document2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1ES7YK4AC6GBPC8Sham TajasNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1ES7YK4AC6GBPC8Document1 pageETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1ES7YK4AC6GBPC8Sham TajasNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Design Input: Slab: 1Document14 pagesDesign Input: Slab: 1Sham TajasNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Rectification AccomplishmentDocument3 pagesRectification AccomplishmentSham TajasNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Midterm ExamDocument4 pagesMidterm ExamSham TajasNo ratings yet

- Payback Method: Initial Investment (170,000,000.00) PHPDocument12 pagesPayback Method: Initial Investment (170,000,000.00) PHPSham TajasNo ratings yet

- FEMA 451 Compl - Struct Analysis Performance-BasedDocument85 pagesFEMA 451 Compl - Struct Analysis Performance-BasedGeorge Sanches100% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)