Professional Documents

Culture Documents

DTC Versa

Uploaded by

wolfhbOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DTC Versa

Uploaded by

wolfhbCopyright:

Available Formats

DTC P0725 ENGINE SPEED SIGNAL

DTC P0725 ENGINE SPEED SIGNAL

Description

PFP:24825

A

UCS005ZX

The engine speed signal is sent from the ECM to the TCM.

B

CONSULT-II Reference Value

UCS005ZY

Remarks: Specification data are reference values.

Item name

Condition

Display value

ENG SPEED SIG

Engine running

Closely matches the tachometer reading.

ACC PEDAL OPEN

Released accelerator pedal - Fully depressed accelerator pedal

0.0/8 - 8.0/8

On Board Diagnosis Logic

D

UCS005ZZ

This is not an OBD-II self-diagnostic item.

Diagnostic trouble code P0725 ENGINE SPEED SIG with CONSULT-II is detected when TCM does not

receive the engine speed signal (input by CAN communication) from ECM.

CVT

Possible Cause

UCS00600

Harness or connectors

(The ECM to the TCM circuit is open or shorted.)

G

DTC Confirmation Procedure

UCS00601

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If DTC Confirmation Procedure has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch ERASE on SELF-DIAG RESULTS and then perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-II

1.

2.

3.

Turn ignition switch ON and select DATA MONITOR mode for

TRANSMISSION with CONSULT-II.

Start engine and maintain the following conditions for at least 10

consecutive seconds.

PRI SPEED SEN: More than 1000 rpm

If DTC is detected, go to CVT-101, "Diagnostic Procedure" .

M

BCIA0031E

Diagnostic Procedure

1.

UCS00602

CHECK DTC WITH ECM

With CONSULT-II

Turn ignition switch ON. (Do not start engine.)

Select SELF-DIAG RESULTS mode for ENGINE with CONSULT-II. Refer to EC-116, "SELF-DIAG

RESULTS MODE" .

OK or NG

OK

>> GO TO 2.

NG

>> Check the DTC detected item. Refer to EC-116, "SELF-DIAG RESULTS MODE" .

1.

2.

Revision: June 2006

CVT-101

2007 Versa

DTC P0725 ENGINE SPEED SIGNAL

2.

CHECK DTC WITH TCM

With CONSULT-II

Turn ignition switch ON. (Do not start engine.)

Select SELF-DIAG RESULTS mode for TRANSMISSION with CONSULT-II. Refer to CVT-60, "SELFDIAGNOSTIC RESULT MODE" .

OK or NG

OK

>> GO TO 3.

NG

>> Check the DTC detected item. Refer to CVT-60, "SELF-DIAGNOSTIC RESULT MODE" .

If DTC of CAN communication line is detected, go to CVT-68, "DTC U1000 CAN COMMUNICATION LINE" .

1.

2.

3.

CHECK INPUT SIGNALS

With CONSULT-II

Start engine.

Select ECU INPUT SIGNALS in DATA MONITOR mode for

TRANSMISSION with CONSULT-II.

3. While monitoring ENG SPEED SIG, check for engine speed

change corresponding to ACC PEDAL OPEN.

1.

2.

Item name

Condition

Display value

ENG SPEED SIG

Engine running

Closely matches the

tachometer reading.

ACC PEDAL OPEN

Released accelerator

pedal - Fully depressed

accelerator pedal

0.0/8 - 8.0/8

SCIA4504E

OK or NG

OK

>> GO TO 4.

NG

>> Check ignition signal circuit. Refer to EC-576, "IGNITION SIGNAL" .

4.

CHECK DTC

Perform CVT-101, "DTC Confirmation Procedure" .

OK or NG

OK

>> INSPECTION END

NG

>> GO TO 5.

5.

CHECK TCM

1. Check TCM input/output signals. Refer to CVT-54, "TCM Input/Output Signal Reference Values" .

2. If NG, re-check TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK

>> INSPECTION END

NG

>> Repair or replace damaged parts.

Revision: June 2006

CVT-102

2007 Versa

DTC P1701 TRANSMISSION CONTROL MODULE (POWER SUPPLY)

DTC P1701 TRANSMISSION CONTROL MODULE (POWER SUPPLY)

Description

PFP:31036

A

UCS0062D

When the power supply to the TCM is cut OFF, for example because the battery is removed, and the self-diagnosis memory function stops, malfunction is detected.

B

NOTE:

Since P1701 TCM-POWER SUPPLY will be indicated when replacing TCM, perform diagnosis after

erasing SELF-DIAG RESULTS

CVT

On Board Diagnosis Logic

UCS0062E

This is not an OBD-II self-diagnostic item.

Diagnostic trouble code P1701 TCM-POWER SUPPLY with CONSULT-II is detected when TCM does

not receive the voltage signal from the battery power supply.

This is not a malfunction message. (Whenever shutting OFF a power supply to the TCM, this message

appears on the screen.)

Possible Cause

UCS0062F

Harness or connectors

(Battery or ignition switch and TCM circuit is open or shorted.)

DTC Confirmation Procedure

UCS0062G

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-II

1.

2.

3.

4.

Turn ignition switch ON. (Do not start engine.)

Select DATA MONITOR mode for TRANSMISSION with

CONSULT-II.

Wait for at least 2 consecutive seconds.

If DTC is detected, go to CVT-147, "Diagnostic Procedure" .

L

BCIA0031E

Revision: June 2006

CVT-145

2007 Versa

DTC P1701 TRANSMISSION CONTROL MODULE (POWER SUPPLY)

Wiring Diagram CVT POWER

UCS0062H

BCWA0679E

Revision: June 2006

CVT-146

2007 Versa

DTC P1701 TRANSMISSION CONTROL MODULE (POWER SUPPLY)

TCM terminals data are reference values, measured between each terminal and ground.

Terminal

Wire color

10

19

Item

Condition

Data (Approx.)

Battery voltage

0V

Battery voltage

0V

Power supply

CVT

Power supply

25

Ground

Always

0V

28

Power supply

(memory back-up)

Always

Battery voltage

48

Ground

Always

0V

Diagnostic Procedure

UCS0062I

1. CHECK DTC

Turn ignition switch ON. (Do not start engine.)

Select SELF-DIAG RESULTS mode for TRANSMISSION

with CONSULT-II.

3. Erase self-diagnostic results. Refer to CVT-32, "HOW TO

ERASE DTC (WITH CONSULT-II)" .

4. Turn ignition switch OFF, and wait for 5 seconds or more.

5. Start engine.

6. Confirm self-diagnostic results again. Refer to CVT-60, "SELFDIAGNOSTIC RESULT MODE" .

Is the P1701 TCM-POWER SUPPLY displayed?

YES >> GO TO 2.

NO

>> INSPECTION END

1.

2.

BCIA0031E

2. CHECK TCM POWER SOURCE, STEP 1

1.

2.

Turn ignition switch OFF.

Check voltage between TCM connector terminal and ground.

Name

Connector

Terminal

Condition

Voltage

(Approx.)

Power supply

(memory backup)

E32

28 - Ground

Always

Battery

voltage

OK or NG

OK

>> GO TO 3.

NG

>> GO TO 4.

Revision: June 2006

SCIA4783E

CVT-147

2007 Versa

DTC P1701 TRANSMISSION CONTROL MODULE (POWER SUPPLY)

3. CHECK TCM POWER SOURCE, STEP 2

1.

2.

Turn ignition switch ON. (Do not start engine.)

Check voltage between TCM connector terminals and ground.

Name

Connector

Terminal

Voltage

(Approx.)

Condition

Battery

voltage

Power supply

10 - Ground

0V

SCIA4784E

E31

Battery

voltage

Power supply

19 - Ground

0V

Power supply

(memory

back-up)

E32

28 - Ground

Battery

voltage

Always

OK or NG

OK

>> GO TO 5.

NG

>> GO TO 4.

4. DETECT MALFUNCTIONING ITEM

Check the following.

Harness for short or open between battery and TCM connector terminal 28

Harness for short or open between ignition switch and TCM connector terminal 10, 19

10 A fuse (No.49, located in the IPDM E/R)

20 A fuse (No.53, located in the IPDM E/R)

Ignition switch. Refer to PG-4, "POWER SUPPLY ROUTING CIRCUIT" .

OK or NG

OK

>> GO TO 5.

NG

>> Repair or replace damaged parts.

5. CHECK TCM GROUND CIRCUIT

1.

2.

3.

Turn ignition switch OFF.

Disconnect TCM connector.

Check continuity between TCM connector terminals and ground.

Name

Connector

Ground

E32

Terminal

25

Continuity

Yes

48

OK or NG

OK

>> GO TO 6.

NG

>> Repair open circuit or short to ground or short to power

in harness or connectors.

SCIA2671E

Revision: June 2006

CVT-148

2007 Versa

DTC P1701 TRANSMISSION CONTROL MODULE (POWER SUPPLY)

6. CHECK DTC

Perform CVT-145, "DTC Confirmation Procedure" .

OK or NG

OK

>> INSPECTION END

NG

>> GO TO 7.

7. CHECK TCM

CVT

1. Check TCM input/output signals. Refer to CVT-54, "TCM Input/Output Signal Reference Values" .

2. If NG, re-check TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK

>> INSPECTION END

NG

>> Repair or replace damaged parts.

Revision: June 2006

CVT-149

2007 Versa

DTC P2A00 A/F SENSOR 1

DTC P2A00 A/F SENSOR 1

Component Description

PFP:22693

UBS00QNP

The air fuel ratio (A/F) sensor 1 is a planar one-cell limit current sensor. The sensor element of the A/F sensor 1 is composed an electrode layer, which transports ions. It has a heater in the element.

The sensor is capable of precise measurement = 1, but also in the

lean and rich range. Together with its control electronics, the sensor

outputs a clear, continuous signal throughout a wide range.

The exhaust gas components diffuse through the diffusion layer at

the sensor cell. An electrode layer is applied voltage, and this current

relative oxygen density in lean. Also this current relative hydrocarbon density in rich.

Therefore, the A/F sensor 1 is able to indicate air fuel ratio by this

electrode layer of current. In addition, a heater is integrated in the

sensor to ensure the required operating temperature of about 800C

(1,472F).

PBIB3353E

PBIB3354E

CONSULT-II Reference Value in Data Monitor Mode

UBS00QNQ

Specification data are reference values.

MONITOR ITEM

A/F SEN1 (B1)

CONDITION

Engine: After warming up

SPECIFICATION

Maintaining engine speed at

2,000 rpm

Fluctuates around 2.2V

On Board Diagnosis Logic

UBS00QNR

To judge the malfunction, the A/F signal computed by ECM from the A/F sensor 1 signal is monitored not to be

shifted to LEAN side or RICH side.

DTC No.

Trouble diagnosis name

DTC detecting condition

P2A00

2A00

Air fuel ratio (A/F) sensor 1

circuit range/performance

Revision: June 2006

The output voltage computed by ECM from the

A/F sensor 1 signal is shifted to the lean side

for a specified period.

The A/F signal computed by ECM from the A/F

sensor 1 signal is shifted to the rich side for a

specified period.

EC-540

Possible Cause

Air fuel ratio (A/F) sensor 1

Air fuel ratio (A/F) sensor 1 heater

Fuel pressure

Fuel injector

Intake air leaks

2007 Versa

DTC P2A00 A/F SENSOR 1

DTC Confirmation Procedure

UBS00QNS

A

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

EC

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

WITH CONSULT-II

1.

2.

3.

4.

5.

6.

7.

8.

9.

Start engine and warm it up to normal operating temperature.

Turn ignition switch OFF and wait at least 10 seconds.

Turn ignition switch ON and select SELF-LEARNING CONT in WORK SUPPORT mode with CONSULT-II.

Clear the self-learning coefficient by touching CLEAR.

Turn ignition switch OFF and wait at least 10 seconds.

Start engine and keep the engine speed between 3,500 and

4,000 rpm for 1 minute under no load.

Let engine idle for 1 minute.

Keep engine speed between 2,500 and 3,000 rpm for 20 minutes.

If 1st trip DTC is detected, go to EC-543, "Diagnostic Procedure"

.

PBIB2035E

WITH GST

1.

2.

3.

4.

5.

Start engine and warm it up to normal operating temperature.

Turn ignition switch OFF and wait at least 10 seconds.

Disconnect mass air flow sensor harness connector.

Start engine and let it idle for at least 5 seconds.

Stop engine and reconnect mass air flow sensor (1) harness

connector.

6. Select Service $03 with GST and make sure that DTC P0102 is

detected.

7. Select Service $04 with GST and erase the DTC P0102.

8. Start engine and keep the engine speed between 3,500 and

4,000 rpm for 1 minute under no load.

9. Let engine idle for 1 minute.

10. Keep engine speed between 2,500 and 3,000 rpm for 20 minutes.

11. Select Service $07 with GST.

If 1st trip DTC is detected, go to EC-543, "Diagnostic Procedure" .

Revision: June 2006

EC-541

L

BBIA0701E

2007 Versa

DTC P2A00 A/F SENSOR 1

Wiring Diagram

UBS00QNT

BBWA2631E

Revision: June 2006

EC-542

2007 Versa

DTC P2A00 A/F SENSOR 1

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II.

A

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in damage to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

EC

TERMINAL

NO.

WIRE

COLOR

ITEM

CONDITION

DATA (DC Voltage)

C

Approximately 2.9 - 8.8V

[Engine is running]

A/F sensor 1 heater

Warm-up condition

Idle speed

(More than 140 seconds after starting

engine)

E

PBIA8148J

[Engine is running]

49

53

A/F sensor 1

A/F sensor 1

Warm-up condition

Engine speed: 2,000 rpm

Approximately 1.8V

Output voltage varies with air fuel

ratio.

[Ignition switch: ON]

Approximately 2.2V

G

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnostic Procedure

UBS00QNU

1. CHECK GROUND CONNECTIONS

1.

2.

Turn ignition switch OFF.

Loosen and retighten ground screws on the body.

Refer to EC-150, "Ground Inspection" .

BBIA0698E

: Vehicle front

1.

Body ground E24

4.

Body ground E15

2.

Engine ground F9

3.

Engine ground F16

OK or NG

OK

>> GO TO 2.

NG

>> Repair or replace ground connections.

Revision: June 2006

EC-543

2007 Versa

DTC P2A00 A/F SENSOR 1

2. RETIGHTEN AIR FUEL RATIO (A/F) SENSOR 1

Loosen and retighten the air fuel ratio (A/F) sensor 1 (2).

Air fuel ratio (A/F) sensor harness connector (1)

Tightening torque: 50 N-m (5.1 kg-m, 37 ft-lb)

>> GO TO 3.

BBIA0699E

3. CHECK FOR INTAKE AIR LEAK

1. Start engine and run it at idle.

2. Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK

>> GO TO 4.

NG

>> Repair or replace.

Revision: June 2006

EC-544

2007 Versa

DTC P2A00 A/F SENSOR 1

4. CLEAR THE SELF-LEARNING DATA.

1.

2.

3.

4.

With CONSULT-II

Start engine and warm it up to normal operating temperature.

Select SELF-LEARNING CONT in WORK SUPPORT mode with CONSULT-II.

Clear the self-learning control coefficient by touching CLEAR.

Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0171 and P0172 detected?

Is it difficult to start engine?

EC

E

PBIB2035E

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF.

3. Disconnect mass air flow sensor (1) harness connector.

4. Restart engine and let it idle for at least 5 seconds.

5. Stop engine and reconnect mass air flow sensor harness connector.

6. Make sure DTC P0102 is displayed.

7. Erase the DTC memory. Refer to EC-60, "HOW TO ERASE

EMISSION-RELATED DIAGNOSTIC INFORMATION" .

8. Make sure DTC P0000 is displayed.

9. Run engine for at least 10 minutes at idle speed.

BBIA0701E

Is the 1st trip DTC P0171 and P0172 detected?

Is it difficult to start engine?

Yes or No

Yes

>> Perform trouble diagnosis for DTC P0171 or P0172. Refer to EC-276, "DTC P0171 FUEL INJECTION SYSTEM FUNCTION" or EC-284, "DTC P0172 FUEL INJECTION SYSTEM FUNCTION" .

No

>> GO TO 5.

5. CHECK HARNESS CONNECTOR

M

1.

2.

3.

Turn ignition switch OFF.

Disconnect A/F sensor 1 harness connector (1).

Air fuel ratio (A/F) sensor (2)

Check harness connector for water.

Water should no exist.

OK or NG

OK

>> GO TO 6.

NG

>> Repair or replace harness connector.

BBIA0699E

Revision: June 2006

EC-545

2007 Versa

DTC P2A00 A/F SENSOR 1

6. CHECK AIR FUEL RATIO (A/F) SENSOR 1 POWER SUPPLY CIRCUIT

1.

2.

Turn ignition switch ON.

Check voltage between A/F sensor 1 terminal 4 and ground with

CONSULT-II or tester.

Voltage: Battery voltage

OK or NG

OK

>> GO TO 8.

NG

>> GO TO 7.

PBIB3308E

7. DETECT MALFUNCTIONING PART

Check the following.

Harness connectors E8, F8

Harness for open or short between A/F sensor 1 and fuse

>> Repair or replace harness or connectors.

8. CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1.

2.

3.

Turn ignition switch OFF.

Disconnect ECM harness connector.

Check harness continuity between the following terminals. Refer to Wiring Diagram.

A/F sensor 1 terminal

ECM terminal

49

53

Continuity should exist.

4.

Check harness continuity between ECM terminals 49, 53 or A/F sensor 1 terminals 1, 2 and ground.

Refer to Wiring Diagram.

Continuity should not exist.

5. Also check harness for short to power.

OK or NG

OK

>> GO TO 9.

NG

>> Repair open circuit or short to ground or short to power in harness or connectors.

9. CHECK A/F SENSOR 1 HEATER

Refer to EC-165, "Component Inspection" .

OK or NG

OK

>> GO TO 10.

NG

>> GO TO 11.

10. CHECK INTERMITTENT INCIDENT

Perform EC-143, "TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT" .

OK or NG

OK

>> GO TO 11.

NG

>> Repair or replace.

Revision: June 2006

EC-546

2007 Versa

DTC P2A00 A/F SENSOR 1

11. REPLACE AIR FUEL RATIO (A/F) SENSOR 1

A

Replace air fuel ratio (A/F) sensor 1.

CAUTION:

Discard any air fuel ratio (A/F) sensor which has been dropped from a height of more than 0.5 m EC

(19.7 in) onto a hard surface such as a concrete floor; use a new one.

Before installing new air fuel ratio (A/F) sensor, clean exhaust system threads using Heated Oxygen Sensor Thread Cleaner tool J-43897-18 or J-43897-12 and approved anti-seize lubricant.

C

>> GO TO 12.

D

12. CONFIRM A/F ADJUSTMENT DATA

1.

2.

Turn ignition switch ON.

Select A/F ADJ-B1 in DATA MONITOR mode with CONSULT-II.

3. Make sure that 0.000 is displayed on CONSULT-II screen.

OK or NG

OK

>> INSPECTION END

NG

>> GO TO 13.

H

PBIB3201E

Revision: June 2006

EC-547

2007 Versa

DTC P2A00 A/F SENSOR 1

13. CLEAR A/F ADJUSTMENT DATA

1.

2.

3.

With CONSULT-II

Start engine and warm it up to normal operating temperature.

Select SELF-LEARNING CONT in WORK SUPPORT mode with CONSULT-II.

Clear the self-learning control coefficient by touching CLEAR.

PBIB2035E

Without CONSULT-II

Start engine and warm it up to normal operating temperature.

Turn ignition switch OFF.

Disconnect mass air flow sensor harness (1) connector.

Restart engine and let it idle for at least 5 seconds.

Stop engine and reconnect mass air flow sensor harness connector.

6. Make sure DTC P0102 is displayed.

7. Erase the DTC memory. Refer to EC-60, "HOW TO ERASE

EMISSION-RELATED DIAGNOSTIC INFORMATION" .

8. Make sure DTC P0000 is displayed.

1.

2.

3.

4.

5.

BBIA0701E

>> GO TO 14.

14. CONFIRM A/F ADJUSTMENT DATA

1.

2.

3.

Turn ignition switch OFF and then ON.

Select A/F ADJ-B1 in DATA MONITOR mode with CONSULT-II.

Make sure that 0.000 is displayed on CONSULT-II screen.

>> INSPECTION END

PBIB3201E

Removal and Installation

UBS00QNV

AIR FUEL RATIO SENSOR

Refer to EM-21, "EXHAUST MANIFOLD" .

Revision: June 2006

EC-548

2007 Versa

DTC P2135 TP SENSOR

DTC P2135 TP SENSOR

Component Description

PFP:16119

UBS00QN9

Electric throttle control actuator consists of throttle control motor,

throttle position sensor, etc. The throttle position sensor responds to

the throttle valve movement.

The throttle position sensor has two sensors. These sensors are a

kind of potentiometers which transform the throttle valve position into

output voltage, and emit the voltage signal to the ECM. In addition,

these sensors detect the opening and closing speed of the throttle

valve and feed the voltage signals to the ECM. The ECM judges the

current opening angle of the throttle valve from these signals and the

ECM controls the throttle control motor to make the throttle valve

opening angle properly in response to driving condition.

PBIB0145E

CONSULT-II Reference Value in Data Monitor Mode

UBS00QNA

Specification data are reference values.

MONITOR ITEM

THRTL SEN 1

THRTL SEN 2*

CONDITION

SPECIFICATION

Ignition switch: ON

(Engine stopped)

Accelerator pedal: Fully released

More than 0.36V

Shift lever: D (A/T, CVT), 1st (M/T)

Accelerator pedal: Fully depressed

Less than 4.75V

*: Throttle position sensor 2 signal is converted by ECM internally. Thus, it differs from ECM terminal voltage signal.

On Board Diagnosis Logic

UBS00QNB

This self-diagnosis has the one trip detection logic.

NOTE:

If DTC P2135 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643.

Refer to EC-430, "DTC P0643 SENSOR POWER SUPPLY" .

DTC No.

P2135

2135

Trouble diagnosis name

DTC detecting condition

Throttle position sensor

circuit range/performance

Rationally incorrect voltage is sent to ECM

compared with the signals from TP sensor 1

and TP sensor 2.

Possible cause

Harness or connector

(TP sensor 1 and 2 circuit is open or

shorted.)

Electric throttle control actuator

(TP sensor 1 and 2)

FAIL-SAFE MODE

When the malfunction is detected, the ECM enters fail-safe mode and the MIL lights up.

Engine operation condition in fail-safe mode

The ECM controls the electric throttle control actuator in regulating the throttle opening in order for the idle position to be within +10

degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal condition.

So, the acceleration will be poor.

Revision: June 2006

EC-526

2007 Versa

DTC P2135 TP SENSOR

DTC Confirmation Procedure

UBS00QNC

A

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

EC

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10V at idle.

WITH CONSULT-II

1.

2.

3.

4.

Turn ignition switch ON.

Select DATA MONITOR mode with CONSULT-II.

Start engine and let it idle for 1 second.

If DTC is detected, go to EC-529, "Diagnostic Procedure" .

F

SEF058Y

WITH GST

Follow the procedure WITH CONSULT-II above.

H

Revision: June 2006

EC-527

2007 Versa

DTC P2135 TP SENSOR

Wiring Diagram

UBS00QND

BBWA2657E

Revision: June 2006

EC-528

2007 Versa

DTC P2135 TP SENSOR

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in damage to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMINAL

NO.

EC

WIRE

COLOR

ITEM

CONDITION

DATA (DC Voltage)

[Ignition switch: ON]

33

LG

Throttle position sensor 1

Engine stopped

Shift lever: D (A/T, CVT), 1st (M/T)

Accelerator pedal: Fully released

C

More than 0.36V

[Ignition switch: ON]

Engine stopped

Shift lever: D (A/T, CVT), 1st (M/T)

Accelerator pedal: Fully depressed

Less than 4.75V

[Ignition switch: ON]

34

Throttle position sensor 2

Engine stopped

Shift lever: D (A/T, CVT), 1st (M/T)

Accelerator pedal: Fully released

F

Less than 4.75V

[Ignition switch: ON]

Engine stopped

Shift lever: D (A/T, CVT), 1st (M/T)

Accelerator pedal: Fully depressed

More than 0.36V

[Engine is running]

36

72

Sensor ground

(Throttle position sensor)

Sensor power supply

(Throttle position sensor)

Warm-up condition

Idle speed

Approximately 0V

[Ignition switch: ON]

Approximately 5V

Diagnostic Procedure

J

UBS00QNE

1. CHECK GROUND CONNECTIONS

1.

2.

Turn ignition switch OFF.

Loosen and retighten ground screw on the body.

Refer to EC-150, "Ground Inspection" .

BBIA0698E

: Vehicle front

1.

Body ground E24

4.

Body ground E15

2.

Engine ground F9

3.

Engine ground F16

OK or NG

OK

>> GO TO 2.

NG

>> Repair or replace ground connections.

Revision: June 2006

EC-529

2007 Versa

DTC P2135 TP SENSOR

2. CHECK THROTTLE POSITION SENSOR POWER SUPPLY CIRCUIT

1.

Disconnect electric throttle control actuator (1) harness connector.

: Vehicle front

Turn ignition switch ON.

2.

PBIB3325E

3.

Check voltage between electric throttle control actuator terminal

2 and ground with CONSULT-II or tester.

Voltage: Approximately 5V

OK or NG

OK

>> GO TO 3.

NG

>> Repair open circuit or short to ground or short to power

in harness or connectors.

PBIB3311E

3. CHECK THROTTLE POSITION SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1.

2.

3.

Turn ignition switch OFF.

Disconnect ECM harness connector.

Check harness continuity between electric throttle control actuator terminal 4 and ECM terminal 36.

Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK

>> GO TO 4.

NG

>> Repair open circuit or short to ground or short to power in harness or connectors.

4. CHECK THROTTLE POSITION SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1.

Check harness continuity between the following;

electric throttle control actuator terminal 1 and ECM terminal 33,

electric throttle control actuator terminal 3 and ECM terminal 34.

Refer to Wiring Diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK

>> GO TO 5.

NG

>> Repair open circuit or short to ground or short to power in harness or connectors.

5. CHECK THROTTLE POSITION SENSOR

Refer to EC-531, "Component Inspection" .

OK or NG

OK

>> GO TO 7.

NG

>> GO TO 6.

Revision: June 2006

EC-530

2007 Versa

DTC P2135 TP SENSOR

6. REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

1.

2.

3.

Replace the electric throttle control actuator.

Perform EC-78, "Throttle Valve Closed Position Learning" .

Perform EC-78, "Idle Air Volume Learning" .

EC

>> INSPECTION END

7. CHECK INTERMITTENT INCIDENT

Refer to EC-143, "TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT" .

>> INSPECTION END

E

Component Inspection

UBS00QNF

THROTTLE POSITION SENSOR

1.

2.

3.

4.

5.

Reconnect all harness connectors disconnected.

Perform EC-78, "Throttle Valve Closed Position Learning" .

Turn ignition switch ON.

Set shift lever to D position (A/T, CVT) or 1st position (M/T).

Check voltage between ECM terminals 33 (TP sensor 1 signal),

34 (TP sensor 2 signal) and ground under the following conditions.

Terminal

33

(Throttle position sensor 1)

34

(Throttle position sensor 2)

6.

7.

8.

Accelerator pedal

Voltage

Fully released

More than 0.36V

Fully depressed

Less than 4.75V

Fully released

Less than 4.75V

Fully depressed

More than 0.36V

If NG, replace electric throttle control actuator and go to the next

step.

Perform EC-78, "Throttle Valve Closed Position Learning" .

Perform EC-78, "Idle Air Volume Learning" .

Removal and Installation

J

PBIB3038E

UBS00QNG

ELECTRIC THROTTLE CONTROL ACTUATOR

Refer to EM-18, "INTAKE MANIFOLD" .

M

Revision: June 2006

EC-531

2007 Versa

DTC P0725 ENGINE SPEED SIGNAL

DTC P0725 ENGINE SPEED SIGNAL

Description

PFP:24825

A

UCS005O1

The engine speed signal is sent from the ECM to the TCM.

B

CONSULT-II Reference Value

UCS005O2

Remarks: Specification data are reference values.

Item name

Condition

ENGINE SPEED

Display value

Engine running

Approximately matches the tachometer reading.

On Board Diagnosis Logic

AT

UCS005O3

This is an OBD-II self-diagnostic item.

Diagnostic trouble code P0725 ENGINE SPEED SIG with CONSULT-II or 9th judgement flicker without

CONSULT-II is detected when TCM does not receive the proper voltage signal from ECM.

Possible Cause

UCS005O4

Harness or connector

(Circuit is open or shorted.)

DTC Confirmation Procedure

UCS005O5

CAUTION:

Always drive vehicle at a safe speed.

If performing this DTC Confirmation Procedure again, always turn ignition switch OFF and wait

at least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-II

1.

2.

3.

4.

Turn ignition switch ON and select DATA MONITOR mode for

A/T with CONSULT-II.

Touch START.

Start engine and maintain the following conditions for at least 10

consecutive seconds.

VEHICLE SPEED: 10 km/h (6 MPH) or more

THROTTLE POSI: More than 1.0/8

SLCT LVR POSI: D position

If the check result is NG, go to AT-115, "Diagnostic Procedure" .

BCIA0031E

WITH GST

M

Follow the procedure WITH CONSULT-II.

WITHOUT CONSULT-II

1.

2.

3.

4.

Start engine.

Drive vehicle under the following conditions for more than 10 seconds.

Selector lever position: D position

Vehicle speed: Higher than 10 km/h (6 MPH)

Throttle position: Greater than 1.0/8 of the full throttle position

Perform self-diagnosis. Refer to AT-90, "Diagnostic Procedure Without CONSULT-II" .

If the check result is NG, go to AT-115, "Diagnostic Procedure" .

Revision: June 2006

AT-113

2007 Versa

DTC P0725 ENGINE SPEED SIGNAL

Wiring Diagram AT ENGSS

UCS005O6

BCWA0652E

Revision: June 2006

AT-114

2007 Versa

DTC P0725 ENGINE SPEED SIGNAL

TCM terminal data are reference values, measured between each terminal and ground.

Terminal

Wire color

39

Item

Condition

Judgement standard (Approx.)

Refer to EC-105 .

Engine speed signal

and

Diagnostic Procedure

UCS005O7

1. CHECK DTC WITH ECM

AT

Check DTC with CONSULT-II ENGINE.

Turn ignition switch ON and select SELF-DIAGNOSTIC RESULTS mode for ENGINE with CONSULT-II.

Refer to EC-113, "CONSULT-II Function (ENGINE)" .

OK or NG

OK

>> GO TO 2.

NG

>> Check ignition signal circuit for engine control. Refer to EC-576, "IGNITION SIGNAL" .

2. CHECK INPUT SIGNAL

With CONSULT-II

1. Start engine.

2. Select TCM INPUT SIGNALS in DATA MONITOR mode for A/T with CONSULT-II.

3. Read out the value of ENGINE SPEED. Check engine speed

changes according to throttle position.

Item name

Condition

Display value

ENGINE SPEED

Engine running

Approximately matches the tachometer reading.

J

SCIA4730E

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM harness connector terminal and

ground.

item

Connector

Terminal

Condition

Judgement standard

(Approx.)

Engine

speed signal

E32

39 Ground

and

Refer to EC-105 .

SCIA3265E

OK or NG

OK

>> GO TO 4.

NG

>> GO TO 3.

Revision: June 2006

AT-115

2007 Versa

DTC P0725 ENGINE SPEED SIGNAL

3.

1.

2.

3.

CHECK HARNESS BETWEEN TCM AND ECM

Turn ignition switch OFF.

Disconnect ECM connector and TCM connector.

Check continuity between ECM connector and TCM connector.

Item

Connector

Terminal

TCM

E32

39

ECM

F10

13

Continuity

Yes

4.

5.

If OK, check harness for short to ground and short to power.

If OK, check continuity between body ground and transaxle

assembly.

6. Reinstall any part removed.

OK or NG

OK

>> GO TO 4.

NG

>> Repair open circuit or short to ground or short to power in harness or connectors.

SCIA7173E

4. CHECK DTC

Perform AT-113, "DTC Confirmation Procedure" .

OK or NG

OK

>> INSPECTION END

NG

>> GO TO 5.

5. CHECK TCM

1. Check TCM input/output signal. Refer to AT-78, "TCM Terminals and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK

>> INSPECTION END

NG

>> Repair or replace damaged parts.

Revision: June 2006

AT-116

2007 Versa

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Dynagen 2014 SpecSheets ES52 PDFDocument2 pagesDynagen 2014 SpecSheets ES52 PDFBrianHaze100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Integrated Waste Management PDFDocument7 pagesIntegrated Waste Management PDFTechsrijan DriveNo ratings yet

- KAESER SX6 Service ManualDocument100 pagesKAESER SX6 Service ManualYassin AlkadyNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Section 13 (Masonry) - Qcs 2010Document36 pagesSection 13 (Masonry) - Qcs 2010gendy350% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Punching, Perforating, Blanking, NibblingDocument2 pagesPunching, Perforating, Blanking, NibblingTtrraanneeOonneeNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Miniature Vane Shear Test AstmDocument20 pagesMiniature Vane Shear Test Astmsitti.aNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Pipeline Risk Management Basic ManualDocument6 pagesPipeline Risk Management Basic ManualhemnNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

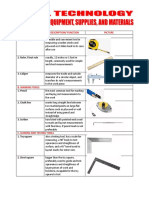

- Tool/ Equipment Description/ Function Picture A. Measuring ToolsDocument13 pagesTool/ Equipment Description/ Function Picture A. Measuring ToolsNicolas AntiguaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Akay Acoustics of Friction PDFDocument24 pagesAkay Acoustics of Friction PDFgene_sparcNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Radial Piston PumpDocument4 pagesRadial Piston PumpSamuel TanNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Technical Specifications-CombinedDocument12 pagesTechnical Specifications-CombinedsaravananNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Compostable PackagingDocument2 pagesCompostable PackagingLAVANYA KOTHANo ratings yet

- Equipment List Corn Oil Update Terbaru 01-10-2011Document8 pagesEquipment List Corn Oil Update Terbaru 01-10-2011ayiep1202No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Bright Septic TankDocument1 pageBright Septic TankNiđe VezeNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Gravelite - Lightweight AggregateDocument2 pagesGravelite - Lightweight Aggregateholyhandgrenade69No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Linear ScaleDocument19 pagesLinear ScaleHà ChínhNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Materials Notes Sem 2Document161 pagesMaterials Notes Sem 2rishigoel284No ratings yet

- BITZER Output Data: Created On: 16/05/2017 16:44:22Document5 pagesBITZER Output Data: Created On: 16/05/2017 16:44:22Hasan Syaiful INo ratings yet

- Merit Safety SolutionsDocument4 pagesMerit Safety SolutionsradeonunNo ratings yet

- Tutorial Chapter 02 - AnswerDocument8 pagesTutorial Chapter 02 - AnswerFateh Hakeem100% (4)

- Xseries Wrap Around Bottle HeaterDocument2 pagesXseries Wrap Around Bottle HeaterNoneNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Marine BoilerDocument30 pagesMarine BoilerCarloNo ratings yet

- Bimbar InflatableDocument36 pagesBimbar InflatableMelissa MorganNo ratings yet

- Daftar PustakaDocument4 pagesDaftar PustakapetricokydoNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 9040 Washing and SterilizationDocument1 page9040 Washing and SterilizationCalidad LassNo ratings yet

- CH312 Experiment 3 - Soil Chemistry ReportDocument5 pagesCH312 Experiment 3 - Soil Chemistry ReportNarelle Iauma100% (1)

- New Text DocumentDocument6 pagesNew Text DocumentsadsdNo ratings yet

- Cream Separator - SKSD100 - en PDFDocument2 pagesCream Separator - SKSD100 - en PDFAmlan BanerjeeNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Effect of Operating Conditions On COP of VCRDocument9 pagesEffect of Operating Conditions On COP of VCRSatheesh ChandranNo ratings yet

- Mobrey CLT PDFDocument18 pagesMobrey CLT PDFAnonymous Oydnu9No ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)