Professional Documents

Culture Documents

Bolt Torque

Uploaded by

Arjun Singh AroraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bolt Torque

Uploaded by

Arjun Singh AroraCopyright:

Available Formats

Equipment No.

ISW-E-204

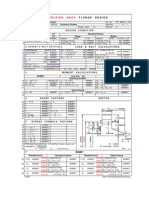

BOLT TORQUE CALCULATION FOR FOR SHELL FLANGE TO CHANNEL FLANGE

(CONSIDERING IJA GASKET)

BOLT DETAIL

MOC of bolt

SA193 Gr. B7

Modulus of elasticity of bolting material

at temperature

Bolt Size

No. of bolts

Effective length of bolt,mid nut to mid nut

Pitch diameter of threads

Eb

185469

n

lb

dm

=

=

=

=

M24

40

263.5

22.95

738.015

29520.6

IJA

Root area of 1 bolts

Root area of n bolts

Ab

GASKET DETAIL

MOC of Gasket

Modulus of elasticity of gasket material

at temperature

Gasket factor

Eg

182022

3.75

Gasket unit seating load

Thickness of Gasket

Gaket ID

Gaket OD

Gasket width

Basic gasket seating width(N/2)

Effective gasket seating width

{if bo < 6 then b = bo else b = 2.5 x sqrt(bo)}

y

tg

Gid

God

N

bo

b

=

=

=

=

=

=

=

52

3

698

724

13

6.5

6.370

Diameter at location of gasket load reaction

(God-2*b)

Actual joint-contact area of gasket(2bG)

711.26

Ag

28467.4

Internal Pressure(considering higher of both side)

Total friction factor between bolts/nut

and nut/flange surface

P

K

=

=

1.81428

0.25

CALCULATION

1 Hydrostatic end force (H)

H

=

=

=

G2P/4

x 711.26 ^ 2 x 1.81428 /4

720860.06

N

2 Total joint contact-surface compression load (Hp)

Hp

= 2bGmP

= 2 x x 6.37 x 711.26 x 3.75 x 1.81428

=

193679.33

N

mm

3 Minimum Required bolt load for gasket seating (Wm2)

Wm2 = bGy

= x 6.37 x 711.26 x 52

=

740152.199558 N

4 Decreasing compression force in gasket (F)

F

= H/[1+ (Ab Eb tg) / (Ag Eg lb)]

= 720860.06/[1 +{(29520.6 x 185469 x 3)/(28467.39 x 182022 x 263.5 )}]

=

712291.2

N

5 Initial required tightening force(tension) (Fbo)

Fbo = Hp + F

= 193679.33 + 712291.2

=

905970.53

N

6 Total tightening force required to seal joint (W)

W

= Greater of Fbo and Wm2

=

905970.53

N

=

203173.82

lb

7 Required Torque (T)

T

= K x W x dm / 12n

= 0.25 x 203173.819164118 x 0.904 / ( 12 x 40)

=

95.66

ft-lb

=

130.016

N-m

ANNEL FLANGE

N/mm2

5469

24

3.5

8.015

520.6

mm

0.904 in.

mm2

mm2

2022

N/mm2

75

5

370

N/mm2

mm

mm

mm

mm

mm

mm

1.26

mm

467.4

mm

81428

25

N/mm2

8

4

263.5 )}]

BOLT TORQUE CALCULATION for EIL reference(IF-E-102A~D)

BOLT DETAIL

MOC of bolt

SA 193 Gr B7

Modulus of elasticity of bolting material

at temperature

Bolt Size

No. of bolts

Effective length of bolt,mid nut to mid nut

Pitch diameter of threads

Eb

185469

n

lb

dm

=

=

=

=

2 1/4 in.

40

682

56

1862.725

74509

SS 316L SPWD

Root area of 1 bolts

Root area of n bolts

Ab

GASKET DETAIL

MOC of Gasket

Modulus of elasticity of gasket material

at temperature

Gasket factor

Eg

3923.12

Gasket unit seating load

Thickness of Gasket

Gaket ID

Gaket OD

Gasket width

Basic gasket seating width(N/2)

Effective gasket seating width

{if bo < 6 then b = bo else b = 2.5 x sqrt(bo)}

y

tg

Gid

God

N

bo

b

=

=

=

=

=

=

=

68.95

6.35

1400

1450

25

12.5

8.840

Diameter at location of gasket load reaction

(God-2*b)

Actual joint-contact area of gasket(2bG)

1432.32

Ag

79555.9

Hyrotest Pressure(considering higher of both side)

Total friction factor between bolts/nut

and nut/flange surface

P

K

=

=

7.2

0.25

CALCULATION

1 Hydrostatic end force (H)

H

=

=

=

G2P/4

x 1432.32 ^ 2 x 7.2 /4

11601188.68 N

2 Total joint contact-surface compression load (Hp)

Hp

= 2bGmP

= 2 x x 8.84 x 1432.32 x 3 x 7.2

=

1718406.63

N

3 Minimum Required bolt load for gasket seating (Wm2)

Wm2 = bGy

= x 8.84 x 1432.32 x 68.95

= 2742688.366443 N

4 Decreasing compression force in gasket (F)

F

= H/[1+ (Ab Eb tg) / (Ag Eg lb)]

= 11601188.68/[1 +{(74509 x 185469 x 6.35)/(79555.86 x 3923.12x682)}]

=

8214657.33

N

5 Initial required tightening force(tension) (Fbo)

Fbo = Hp + F

= 1718406.63 + 8214657.33

=

9933063.96

N

6 Total tightening force required to seal joint (W)

W

= Greater of Fbo and Wm2

=

9933063.96

N

=

2227598.44

lb

7 Required Torque (T)

T

= K x W x dm / 12n

= 0.25 x 2227598.44159021 x 2.205 / ( 12 x 40)

=

2558.26

ft-lb

=

3477.007

N-m

IF-E-102A~D)

SA 193 Gr B7

N/mm2

185469

2 1/4 in.

40

682

mm =

1862.725

74509

mm

2.205

mm2

in.

mm2

SS 316L SPWD

3923.12

N/mm2

3

68.95

6.35

1400

1450

25

12.5

8.840

N/mm2

mm

mm

mm

mm

mm

mm

1432.32

mm

79555.9

mm

7.2

0.25

N/mm2

23.12x682)}]

BOLT TORQUE CALCULATION for 155-E-1019 of Enq No. 3411

BOLT DETAIL

MOC of bolt

SA 193 Gr B7

Modulus of elasticity of bolting material

at temperature

Bolt Size

No. of bolts

Effective length of bolt,mid nut to mid nut

Pitch diameter of threads

Eb

185469

n

lb

dm

=

=

=

=

M 80

44

975

80

4076.831

179380.564

SS 316L SPWD

Root area of 1 bolts

Root area of n bolts

Ab

GASKET DETAIL

MOC of Gasket

Modulus of elasticity of gasket material

at temperature

Gasket factor

Eg

3923.12

Gasket unit seating load

Thickness of Gasket

Gaket ID

Gaket OD

Gasket width

Basic gasket seating width(N/2)

Effective gasket seating width

{if bo < 6 then b = bo else b = 2.5 x sqrt(bo)}

y

tg

Gid

God

N

bo

b

=

=

=

=

=

=

=

68.95

6.35

2240

2314

37

18.5

10.750

Diameter at location of gasket load reaction

(God-2*b)

Actual joint-contact area of gasket(2bG)

2292.50

Ag

154845.2

Hyrotest Pressure(considering higher of both side)

Total friction factor between bolts/nut

and nut/flange surface

P

K

=

=

10.38

0.25

CALCULATION

1 Hydrostatic end force (H)

H

=

=

=

G2P/4

x 2292.5 ^ 2 x 10.38 /4

42845569.87 N

2 Total joint contact-surface compression load (Hp)

Hp

= 2bGmP

= 2 x x 10.75 x 2292.5 x 3 x 10.38

=

4821878.75

N

3 Minimum Required bolt load for gasket seating (Wm2)

Wm2 = bGy

= x 10.75 x 2292.5 x 68.95

= 5338287.404837 N

4 Decreasing compression force in gasket (F)

F

= H/[1+ (Ab Eb tg) / (Ag Eg lb)]

= 42845569.87/[1 +{(179380.564 x 185469 x 6.35)/(154845.17 x 3923.12x975)

=

31581041.41 N

5 Initial required tightening force(tension) (Fbo)

Fbo = Hp + F

= 4821878.75 + 31581041.41

=

36402920.16 N

6 Total tightening force required to seal joint (W)

W

= Greater of Fbo and Wm2

=

36402920.16 N

=

8163753.76

lb

7 Required Torque (T)

T

= K x W x dm / 12n

= 0.25 x 8163753.75657492 x 3.15 / ( 12 x 44)

=

12176.05

ft-lb

=

16548.850

N-m

Enq No. 3411

SA 193 Gr B7

N/mm2

185469

M 80

44

975

mm =

4076.831

179380.564

mm

3.150

mm2

in.

mm2

SS 316L SPWD

3923.12

N/mm2

3

68.95

6.35

2240

2314

37

18.5

10.750

N/mm2

mm

mm

mm

mm

mm

mm

2292.50

mm

154845.2

mm

10.38

0.25

N/mm2

7 x 3923.12x975)}]

BOLT TORQUE CALCULATION for 155-E-1018 of Enq No. 3411

BOLT DETAIL

MOC of bolt

SA 193 Gr B7

Modulus of elasticity of bolting material

at temperature

Bolt Size

No. of bolts

Effective length of bolt,mid nut to mid nut

Pitch diameter of threads

Eb

185469

n

lb

dm

=

=

=

=

M 56

36

681

56

1862.725

67058.1

SS 316L SPWD

Root area of 1 bolts

Root area of n bolts

Ab

GASKET DETAIL

MOC of Gasket

Modulus of elasticity of gasket material

at temperature

Gasket factor

Eg

3923.12

Gasket unit seating load

Thickness of Gasket

Gaket ID

Gaket OD

Gasket width

Basic gasket seating width(N/2)

Effective gasket seating width

{if bo < 6 then b = bo else b = 2.5 x sqrt(bo)}

y

tg

Gid

God

N

bo

b

=

=

=

=

=

=

=

68.95

6.35

1392

1436

22

11

8.290

Diameter at location of gasket load reaction

(God-2*b)

Actual joint-contact area of gasket(2bG)

1419.42

Ag

73934.2

Hyrotest Pressure(considering higher of both side)

Total friction factor between bolts/nut

and nut/flange surface

P

K

=

=

9.562

0.25

CALCULATION

1 Hydrostatic end force (H)

H

=

=

=

G2P/4

x 1419.42 ^ 2 x 9.562 /4

15130750.2

N

2 Total joint contact-surface compression load (Hp)

Hp

= 2bGmP

= 2 x x 8.29 x 1419.42 x 3 x 9.562

=

2120876.17

N

3 Minimum Required bolt load for gasket seating (Wm2)

Wm2 = bGy

= x 8.29 x 1419.42 x 68.95

= 2548881.199818 N

4 Decreasing compression force in gasket (F)

F

= H/[1+ (Ab Eb tg) / (Ag Eg lb)]

= 15130750.2/[1 +{(67058.1 x 185469 x 6.35)/(73934.19 x 3923.12x681)}]

=

10809013.28 N

5 Initial required tightening force(tension) (Fbo)

Fbo = Hp + F

= 2120876.17 + 10809013.28

=

12929889.45 N

6 Total tightening force required to seal joint (W)

W

= Greater of Fbo and Wm2

=

12929889.45 N

=

2899669.40

lb

7 Required Torque (T)

T

= K x W x dm / 12n

= 0.25 x 2899669.39755352 x 2.205 / ( 12 x 36)

=

3700.10

ft-lb

=

5028.919

N-m

Enq No. 3411

SA 193 Gr B7

N/mm2

185469

M 56

36

681

mm =

1862.725

67058.1

mm

2.205

mm2

in.

mm2

SS 316L SPWD

3923.12

N/mm2

3

68.95

6.35

1392

1436

22

11

8.290

N/mm2

mm

mm

mm

mm

mm

mm

1419.42

mm

73934.2

mm

9.562

0.25

N/mm2

923.12x681)}]

BOLT TORQUE CALCULATION for 151-EE-1004 A-B of Enq No. 34

BOLT DETAIL

MOC of bolt

SA 193 Gr B7

Modulus of elasticity of bolting material

at temperature

Bolt Size

No. of bolts

Effective length of bolt,mid nut to mid nut

Pitch diameter of threads

Eb

185469

n

lb

dm

=

=

=

=

M 90

40

1105

90

5287.085

211483.4

IJA

Root area of 1 bolts

Root area of n bolts

Ab

GASKET DETAIL

MOC of Gasket

Modulus of elasticity of gasket material

at temperature

Gasket factor

Eg

182022

3.75

Gasket unit seating load

Thickness of Gasket

Gaket ID

Gaket OD

Gasket width

Basic gasket seating width(N/2)

Effective gasket seating width

{if bo < 6 then b = bo else b = 2.5 x sqrt(bo)}

y

tg

Gid

God

N

bo

b

=

=

=

=

=

=

=

52

3

2364

2444

40

20

11.180

Diameter at location of gasket load reaction

(God-2*b)

Actual joint-contact area of gasket(2bG)

2421.64

Ag

170110.6

Hyrotest Pressure(considering higher of both side)

Total friction factor between bolts/nut

and nut/flange surface

P

K

=

=

10.3

0.25

CALCULATION

1 Hydrostatic end force (H)

H

=

=

=

G2P/4

x 2421.64 ^ 2 x 10.3 /4

47440173.56

N

2 Total joint contact-surface compression load (Hp)

Hp

= 2bGmP

= 2 x x 11.18 x 2421.64 x 3.75 x 10.3

=

6570520.07

N

3 Minimum Required bolt load for gasket seating (Wm2)

Wm2 = bGy

= x 11.18 x 2421.64 x 52

=

4422874.34826048 N

4 Decreasing compression force in gasket (F)

F

= H/[1+ (Ab Eb tg) / (Ag Eg lb)]

= 47440173.56/[1 +{(211483.4 x 185469 x 3)/(170110.55 x 182022x1105)}]

=

47277578.75

N

5 Initial required tightening force(tension) (Fbo)

Fbo = Hp + F

= 6570520.07 + 47277578.75

=

53848098.82

N

6 Total tightening force required to seal joint (W)

W

= Greater of Fbo and Wm2

=

53848098.82

N

=

12076026.24

lb

7 Required Torque (T)

T

= K x W x dm / 12n

= 0.25 x 12076026.2389399 x 3.543 / ( 12 x 40)

=

22284.04

ft-lb

=

30286.930

N-m

B of Enq No. 3411

SA 193 Gr B7

N/mm2

185469

M 90

40

1105

90

5287.085

mm

3.543

mm2

211483.4

mm2

mm =

in.

IJA

182022

N/mm2

3.75

52

3

2364

2444

40

20

11.180

N/mm2

mm

mm

mm

mm

mm

mm

2421.64

mm

170110.6

mm

10.3

0.25

N/mm2

182022x1105)}]

You might also like

- Pd5500 Flange CalculationDocument6 pagesPd5500 Flange CalculationMakrand SakpalNo ratings yet

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- Body Flange Design-Appx-2Document4 pagesBody Flange Design-Appx-2Matthieu100% (1)

- Body Flange Bolt TorqueDocument1 pageBody Flange Bolt TorqueLcm Tnl100% (1)

- Design of Flanges - Loose Hub Type 2010Document58 pagesDesign of Flanges - Loose Hub Type 2010bakellyNo ratings yet

- Blind Flange Design Calculation As Per Asme Section Vii Division - 1Document4 pagesBlind Flange Design Calculation As Per Asme Section Vii Division - 1mukesh100% (2)

- SU Blind Plate ThicknessDocument2 pagesSU Blind Plate Thicknessmanoj19801226100% (1)

- Braced Legs ClaculationsDocument2 pagesBraced Legs Claculationssumit_waghmareNo ratings yet

- Flange CalculationsDocument5 pagesFlange CalculationsswapnavattemNo ratings yet

- Ring Flange CalculationDocument3 pagesRing Flange CalculationLuizNo ratings yet

- Bolt Torque ASME B16.5 Flanges - Sheet Gaskets 02Document26 pagesBolt Torque ASME B16.5 Flanges - Sheet Gaskets 02bakelly100% (7)

- Nozzle ReinforcementDocument8 pagesNozzle ReinforcementHafizi HZnumismatic0% (1)

- Design of Flanges - Full-Face Gasket 2010Document29 pagesDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- Flange CalculationsDocument3 pagesFlange CalculationssanjaysyNo ratings yet

- Wind Calculation SheetDocument32 pagesWind Calculation SheetaauppalNo ratings yet

- Max Allowable Nozzle LoadDocument1 pageMax Allowable Nozzle Loaddskr fkshNo ratings yet

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- Design of Flanges - Weld Neck Type 2010Document58 pagesDesign of Flanges - Weld Neck Type 2010bakellyNo ratings yet

- Example Calculation TorqueDocument8 pagesExample Calculation TorquePenchalaiah PodalakuruNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- ASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelDocument16 pagesASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelPanya Purahong100% (1)

- Pipe Clamp CalculationDocument3 pagesPipe Clamp CalculationmohdrashidNo ratings yet

- Nozzle Neck CalculationDocument4 pagesNozzle Neck CalculationAkshat JainNo ratings yet

- Agitator Nozzle Load Data SheetDocument1 pageAgitator Nozzle Load Data SheetAnonymous MB5YbaLrBENo ratings yet

- AB 520 Finite Element Analysis FEA Requirements PDFDocument4 pagesAB 520 Finite Element Analysis FEA Requirements PDFbello imamNo ratings yet

- Bolt TorquesDocument1 pageBolt TorquesSajal KulshresthaNo ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleNithin ZsNo ratings yet

- H200141 - Calculation of Basering Rev 0 PDFDocument9 pagesH200141 - Calculation of Basering Rev 0 PDFSani Adipura WinataNo ratings yet

- Blind Flange Thickness CalculationDocument3 pagesBlind Flange Thickness CalculationKannapiran Krishnamoorthy75% (4)

- Bolt Torque Calculation For FlangeDocument1 pageBolt Torque Calculation For Flangevishnudno1No ratings yet

- Clamped Cover Plate DesignDocument7 pagesClamped Cover Plate DesignChiedu OkonduNo ratings yet

- Bolt Torque Calculation For Girth Flange (Ref.: Dennis Moss Procedure 2-10)Document2 pagesBolt Torque Calculation For Girth Flange (Ref.: Dennis Moss Procedure 2-10)Manoj MulikNo ratings yet

- 1) Design Data: Ref: Procedure No. 3-4 Pg. No. 169, Pressure Vessel Design Manual by Dennis Moss, 4rd EditionDocument6 pages1) Design Data: Ref: Procedure No. 3-4 Pg. No. 169, Pressure Vessel Design Manual by Dennis Moss, 4rd Editionsouren1975No ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleChagar HarshpalNo ratings yet

- Bolt Torques For ASME B16.5 Flanges With Sheet Gaskets To ASME B16.21Document30 pagesBolt Torques For ASME B16.5 Flanges With Sheet Gaskets To ASME B16.21huangjlNo ratings yet

- FRP RF CalcDocument1 pageFRP RF CalcmukeshNo ratings yet

- Understanding ASME UG-45Document3 pagesUnderstanding ASME UG-45Ahmad DanielNo ratings yet

- Flat Plate - Roark & YoungDocument15 pagesFlat Plate - Roark & YoungPrasad Pingle0% (1)

- Flanges DIN2505Document35 pagesFlanges DIN2505fsalminNo ratings yet

- Blind Flange CalculationDocument12 pagesBlind Flange CalculationrajarajanNo ratings yet

- Bolt Torque ASME B16.5 Flanges - Spiral Wound GasketsDocument31 pagesBolt Torque ASME B16.5 Flanges - Spiral Wound Gasketsbakelly100% (5)

- Check 18Document6 pagesCheck 18Anonymous qBwHKusNo ratings yet

- Design Calculation Anchor Flange - ASME VIII Div 1Document6 pagesDesign Calculation Anchor Flange - ASME VIII Div 1Johakim974No ratings yet

- API 650-RF Pad CalculationDocument1 pageAPI 650-RF Pad CalculationSudhanshu67100% (2)

- FlangeCalculationASMEVIII Version5Document13 pagesFlangeCalculationASMEVIII Version5madodandembe100% (3)

- Background To Design Rules - Issue of EN13445 EN1591 Part PDFDocument19 pagesBackground To Design Rules - Issue of EN13445 EN1591 Part PDFBenoit LabreNo ratings yet

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocument30 pagesWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersmishtinilNo ratings yet

- Fin Plate Connection DesignDocument10 pagesFin Plate Connection DesigncklconNo ratings yet

- ETD Cores and Accessories ETD29: 1 e 3 e e 2 Min 2 11 0.3 15.8 0.2Document3 pagesETD Cores and Accessories ETD29: 1 e 3 e e 2 Min 2 11 0.3 15.8 0.2Marcel BlinduNo ratings yet

- Bolted Connection ToolDocument56 pagesBolted Connection ToolPrakash Singh RawalNo ratings yet

- Flange KOD Vessel Calculation - Actual ConditionDocument21 pagesFlange KOD Vessel Calculation - Actual ConditionPeter PerezNo ratings yet

- CP P26 16 2S p2616Document8 pagesCP P26 16 2S p2616blueword66No ratings yet

- 31barg CalculationDocument10 pages31barg Calculationshani5573No ratings yet

- RCC Beam Design Task-01Document29 pagesRCC Beam Design Task-01Mohamed SaheelNo ratings yet

- Bolt Torque CalculationDocument3 pagesBolt Torque Calculationshazan100% (1)

- 5.7 Asmeviii A-2 & Tema Split Backing RingDocument1 page5.7 Asmeviii A-2 & Tema Split Backing RingpastylNo ratings yet

- Flange Asme ViiiDocument21 pagesFlange Asme Viiizahidwahla1No ratings yet

- Flat Head Calculation (Based On Ug 34)Document2 pagesFlat Head Calculation (Based On Ug 34)rustamriyadiNo ratings yet

- Base Plate Design Is 800-2007Document6 pagesBase Plate Design Is 800-2007Suneesh P91% (11)

- WRC ReferenceDocument2 pagesWRC ReferenceArjun Singh AroraNo ratings yet

- Material Inconel 600Document16 pagesMaterial Inconel 600arvindgupta_2005100% (1)

- Brochure Roll Bonded Clad Plates EDocument36 pagesBrochure Roll Bonded Clad Plates EAries MarteNo ratings yet

- H3 1000XDocument1 pageH3 1000XArjun Singh AroraNo ratings yet

- Therm o DrainDocument5 pagesTherm o DrainArjun Singh AroraNo ratings yet

- 9149Document100 pages9149Arjun Singh AroraNo ratings yet

- 'Y' Forging 151-VV-1001Document1 page'Y' Forging 151-VV-1001Arjun Singh AroraNo ratings yet

- Design Calculation For Eqpt (1) - No. 511-C-001Document145 pagesDesign Calculation For Eqpt (1) - No. 511-C-001Arjun Singh AroraNo ratings yet

- Calc Bend Radii Tensile Elong DataDocument7 pagesCalc Bend Radii Tensile Elong Dataritesh_4luv7679No ratings yet

- Calc Bend Radii Tensile Elong DataDocument7 pagesCalc Bend Radii Tensile Elong Dataritesh_4luv7679No ratings yet

- AES Floating HeadDocument8 pagesAES Floating HeadArjun Singh AroraNo ratings yet

- Design Calc Saud It SampleDocument25 pagesDesign Calc Saud It SampleglazetmNo ratings yet

- Lec17 Bearing CapacityDocument57 pagesLec17 Bearing CapacityMuhammad EhtshamNo ratings yet

- Gear For Self Aligning Rotator Rev.0Document1 pageGear For Self Aligning Rotator Rev.0Arjun Singh AroraNo ratings yet

- How To Make Symbols With KeyboardDocument23 pagesHow To Make Symbols With KeyboardArjun Singh AroraNo ratings yet

- Maharashtra State Board of Technical Education: Academic CalendarDocument4 pagesMaharashtra State Board of Technical Education: Academic CalendarArjun Singh AroraNo ratings yet

- 1512 Adamson View, Edmonton Alberta T6W 0V4, Canada PHONE: 1 780 450 6695Document2 pages1512 Adamson View, Edmonton Alberta T6W 0V4, Canada PHONE: 1 780 450 6695Arjun Singh AroraNo ratings yet

- Lecorbusier Tropical Designs PDFDocument8 pagesLecorbusier Tropical Designs PDFglai RamosNo ratings yet

- Price-List Polycab Industrial Flexible CablesDocument3 pagesPrice-List Polycab Industrial Flexible CablesVirendraDwivediNo ratings yet

- WDE - Anganwadi Building - PasthalaDocument52 pagesWDE - Anganwadi Building - PasthalaGurram Lakshmi NavakanthNo ratings yet

- CatalogoDocument52 pagesCatalogoCesar PreciadoNo ratings yet

- Career Objective:: Ricky Solis SibalDocument4 pagesCareer Objective:: Ricky Solis Sibalroselyn sibalNo ratings yet

- MMS Unit IIDocument5 pagesMMS Unit IIAdula RajasekharNo ratings yet

- Common Causes of O-Ring Failure - Technical SupportDocument4 pagesCommon Causes of O-Ring Failure - Technical SupportiJordanScribdNo ratings yet

- Lectures40 41 AnnotatedDocument29 pagesLectures40 41 AnnotatedBharath NallaNo ratings yet

- Austempered Ductile Iron Castings: Standard Specification ForDocument8 pagesAustempered Ductile Iron Castings: Standard Specification ForJosé Ramón GutierrezNo ratings yet

- Polymer Plain BearingsDocument269 pagesPolymer Plain BearingsMartí BertranNo ratings yet

- 4.1 Catalogue Hang SangjinDocument77 pages4.1 Catalogue Hang SangjinKiến Huy LưuNo ratings yet

- Powder Coating Made Easy - Powder Coating 101 PDFDocument0 pagesPowder Coating Made Easy - Powder Coating 101 PDFGary Repesh100% (4)

- High Speed MachiningDocument7 pagesHigh Speed MachiningBob JonesNo ratings yet

- Behavior of Reinforced Concrete Columns Under Combined Effects of Axial and Blast-Induced Transverse LoadsDocument9 pagesBehavior of Reinforced Concrete Columns Under Combined Effects of Axial and Blast-Induced Transverse LoadsAhmed SalimNo ratings yet

- Soil NailingDocument10 pagesSoil NailingSamirsinh ParmarNo ratings yet

- Hand NotesDocument3 pagesHand Notesmehul rabariNo ratings yet

- Natural Fiber Composite Design and Characterization For Limit Stress Prediction in Multiaxial Stress StateDocument14 pagesNatural Fiber Composite Design and Characterization For Limit Stress Prediction in Multiaxial Stress Statechristian emeka okaforNo ratings yet

- Green Roof Handbook: Systems and Components For Optimal-Performance Green RoofsDocument52 pagesGreen Roof Handbook: Systems and Components For Optimal-Performance Green RoofsFarah AlSheyabNo ratings yet

- Bag Filtration Systems FTDocument51 pagesBag Filtration Systems FTMartin ŠimurdaNo ratings yet

- MESC SPE 74-014 - 2010 - Duplex-Superduplex Ss Pipe To Astm A790Document12 pagesMESC SPE 74-014 - 2010 - Duplex-Superduplex Ss Pipe To Astm A790sathi11189No ratings yet

- Bondstrand 2400 and FittingsDocument19 pagesBondstrand 2400 and FittingsChatur LingamNo ratings yet

- ME460 Exam No. 2: NameDocument1 pageME460 Exam No. 2: NameSayyadh Rahamath BabaNo ratings yet

- Plating & Joists DesignDocument3 pagesPlating & Joists Designoluomo1No ratings yet

- Technical Specifications: Proposed Two Storey Residential BuildingDocument10 pagesTechnical Specifications: Proposed Two Storey Residential BuildingAeron AcioNo ratings yet

- MEMS-module 4-5Document34 pagesMEMS-module 4-5johnnyNo ratings yet

- Bolt Torque & Bolt Tap TestDocument20 pagesBolt Torque & Bolt Tap Testbudymood100% (3)

- Ls Tube: LS Heat-Shrinkable TubingDocument88 pagesLs Tube: LS Heat-Shrinkable TubingAraceli OrtizNo ratings yet

- Shear Wall Design According ACI (SI)Document11 pagesShear Wall Design According ACI (SI)আকাশআহসান100% (2)

- Acronal 400Document1 pageAcronal 400Gustavo E Aguilar ENo ratings yet

- Ventilation SystemDocument28 pagesVentilation Systemjkhan_724384No ratings yet