Professional Documents

Culture Documents

BS5950 End Plate Design

Uploaded by

Simon LsmOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BS5950 End Plate Design

Uploaded by

Simon LsmCopyright:

Available Formats

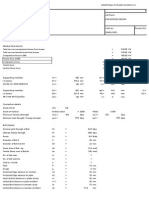

End Plate Connection Design

Calculations are inaccordance with the BS5950: Part 1: 1990 and the analysis follows the recommended

design procedure checks given in the BCSA/SCI publication "Joints in simple Construction" 2nd Edition.

Applied Tensile Force

Applied Shear

Resultant Shear

F

Vx

Vy

Vr

=

=

=

=

(Vx^2+Vy^2)^0.5

=

=

=

=

60

20

5

21

kN

kN

kN

kN

Table 33, Grade 43

Table 6, Grade 43

For Grade 43

=

=

=

=

=

43

10

460

275

410

mm

N/mm2

N/mm2

N/mm2

=

=

=

=

=

=

100

6.3

275

mm

mm

N/mm2

bgrade =

8.8

=

=

=

=

=

=

=

=

=

=

4

2

16

18

40

32

50

180

40

50

mm

mm

mm

mm

mm

mm

mm

mm

=

=

=

=

157

375

450

1035

mm2

N/mm2

N/mm2

N/mm2

130

280

mm

mm

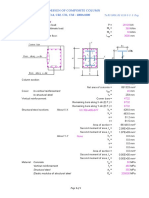

End Plate Detail

Grade of End Plate

Pgrade =

Thickness of Plate

tp

=

Bearing Strength of end plate

pbs

=

Strength

py

=

Ultimate Tensile Strength

Us

=

Supported Beam Detail

Depth

Web Thickness

Strength

D

tw

py

Bolt Connection Detail

Bolt Grade

Number of bolts

n

Number of rows

bn

Bolt Diameter

db

Hole Diameter

Dh

Min. Required Pitch of Bolts

pmin

Min. Required Edge Distance

emin

Pitch of Bolt Group (Vertical)

p

Gauge/Pitch of Bolt (Horizontal g

Edge Distance (Vertical)

e1

Edge Distance (Horizontal)

e2

=

=

=

=

=

=

=

=

=

=

Bolt

Bolt

Bolt

Bolt

=

=

=

=

Area (per bolt)

As

Shear Strength (per bolt)

ps

Bearing Strength (per bolt pt

Tensile Strength (per bolt) pbb

Length of End Plate

Width of Plate

L

W

=

=

db+2

db * 2.5

db * 2.0

Table 32, Grade 8.8

Table 32, Grade 8.8

Table 32, Grade 8.8

Bolt Group Strength in Shear

Shear Capacity of Bolt Group

For Top pair of Bolts

Ps

Ps

=

=

n*ps*As

smaller of n*ps*As

or 1/2*e1*tp*pbs

235.5

kN

92

kN

V <= Ps, Applied shear is within plain shear capacity of bolt gr V <= Ps OK!!

Bolt Group Strength in Tension

Tension Capacity of Bolt

pt

= Table 32 for grade2 =

450

N/mm2

Tension Area of Bolt

As

157

mm2

Tension Capacity of Bolt Group

Pt

282.6

kN

n * pt * As / 1000

F <= Pbt, Maximum load/bolt is within Tension capacity

F <= Pbt bolt OK!!

Combined Shear and Tension of Bolt Group

Applied Shear / Shear Capacity

Applied Tension / Tension Capacity

Combined Shear and Tension of Bolt

=

=

=

V / Ps

F / Pbt

(Fr / Ps) + (Vy / Pt)

=

=

=

0.11

0.21

0.32

<= 1.4 , OK

Bolt Group Strength in Bearing

The bearing Capacity is taken as the lesser of :

(1) Bearing Capacity of Bolt

Bearing Strength of Bolt

Thinner Material Thickness

Bearing Capacity of Bolt

pbb

tmin

Pbb

= Table 32 for grade 2 =

=

tp

=

= db * tmin * pbb / 1000 =

Fr <= Pb, Maximum load/bolt is within bearing capacity of Bolt

(2) Bearing Capacity of the Thinner Material

pbs

Bearing Strength

Bearing Capacity

Pbs

N/mm2

mm

165.6

kN

V <= Pb OK!!

= Table 33 for grade =

= db * tmin * pbs / 1000 =

Fr <= Pb, Maximum load/bolt is within bearing capacity of connecting ply

1035

10

460

N/mm2

73.6

kN

V <= Pb OK!!

Shear Capacity of End Plate

End Plate Plain Shear Strength

Shear Area

Net Shear Area

Shear Capacity

Shear Capacity

Shear Capacity of Fin Plate

Av

Avnet

Pvp1

Pvp2

Pvp

=

0.9 * tp *L

= Av - ( tp * Dh * bn )

= 0.6 * py * Av / 1000

= 0.5 * Us * Avnet /1000

=

Pvp2

=

=

=

=

=

1170

810

193.05

166.05

166.05

mm2

mm2

kN

kN

kN

V <= Pvp, Applied shear is within plain shear capacity of fin plaV <= Pvp OK!!

End Plate Block Shear Strength

Vertical Shear Area

Horizontal Shear Area

Shear Capactiy

Shear Capactiy

Block Shear Capacity

Av1

Ateff

Pvb1

Pvb2

Pvb

=

tp * ( L - e1 )

= ( e2 - 0.5 * Dh ) * tp

= 0.6 * py * Av1 / 1000

= 0.5 * Us * Ateff /1000

=

Pvb2

=

=

=

=

=

900

410

148.5

84.05

232.55

mm2

mm2

kN

kN

kN

V <= Pvb, Applied shear is within block shear capacity of fin pl V <= Pvb OK!!

Shear Capacity of Supported Beam Web at the End Plate

Shear Area

Shear Capacity

Av

Pv

=

=

0.9*L*tw

0.6*Av*py

=

=

V <= Pv, Applied hear is within shear capacity of beam web

737.1

121.6215

mm2

kN

V <= Pv OK!!

Weld Requirement

Number of runs of FW

FWr

Recommended Fillet Weld Thic smin

Max. Weld Length Allowable pe Lmax

Length of Weld provided per run

Lw

Moment of Inertia

Ix

Direct Shear

Fs

Direct Tension

Ft

=

=

=

=

=

Resultant Load

Fr

FW

pw

pwr

Try FW size

Design Strength (43 or 51)

Weld Capacity

run

mm

FWr * L^3 / 12

V / (Lw*FWr)

F / (Lw*FWr)

=

=

=

=

=

264

100

333333

0.052

0.150

mm

mm3

kN/mm

kN/mm

( Ft^2 + Fs^2 ) 1/2

0.159

kN/mm

=

=

=

Table 36, E43

FW * pw

=

=

=

6

215

0.903

mm

N/mm2

kN/mm

Fr <= pwr, the fillet weld provided is satisfactory

0.8 * tp

( L - 2 * smin)

Fr <= pwr OK!!

Tension Capacity of End Plate

Effective Length of plastic hinge

at section A-A

at section B-B

Design Tensile Strength

Moment Capacity of End Plate

at section A-A

at section B-B

Distance Between Plastic Hinges

Tying Capacity of End Plate

LeA

eeA

2*eeA+(nb-1)*peA

130

mm

e1, <= e2

40

mm

PeA

p, <= 2*e2

50

mm

LeB

c

eeB

=

=

2*eeB+(nb-1)*peB

130

80.85

mm

mm

e1, <= c + Dh/2

40

mm

PeB

p, <= 2*c + Dh

50

mm

Pu

Us/1.25

328

n/mm2

MuA

MuB

=

=

(Pu*LeA*tp^2) /4

(Pu*LeB*tp^2) /4

=

=

1.07

1.07

kNm

kNm

L

Ptp

=

=

c - Dh/2

2*(MuA+MuB)/L

=

=

71.85

59.35

mm

kN

=

1/2 * (W-2*e2-tw-2s) =

F plate

> Ptp

F <= Ptp, the applied tensile force is within prying capacity of end

NOT OK!!!

You might also like

- End Plate DesignDocument4 pagesEnd Plate DesignAgnon Fung100% (4)

- Base Plate Design - BS CodeDocument3 pagesBase Plate Design - BS Codemicheleling669667% (3)

- Connection Design SheetDocument47 pagesConnection Design SheetStephen James100% (1)

- Beam-Column Connection To BS5950Document6 pagesBeam-Column Connection To BS5950Mitra RampersadNo ratings yet

- Moment Connection - Flush End Plate-19.01.06Document48 pagesMoment Connection - Flush End Plate-19.01.06kalpanaadhi83% (6)

- BASE PLATE DESIGN OPTIMIZATIONDocument45 pagesBASE PLATE DESIGN OPTIMIZATIONMuhammed Ali60% (5)

- Combined Gusset Plate DesignDocument3 pagesCombined Gusset Plate Designkalpanaadhi100% (3)

- Design of Beam Ledge Reinforcement as per ACI 318M95Document2 pagesDesign of Beam Ledge Reinforcement as per ACI 318M95auatipu100% (1)

- Design of Base Plate For BS5950Document2 pagesDesign of Base Plate For BS5950dantevarias89% (19)

- DESIGN CALCULATION SHEET FOR SUPPORTING BEAMDocument29 pagesDESIGN CALCULATION SHEET FOR SUPPORTING BEAMTamkwokkwong83% (6)

- Pinned and fixed base plate design calculations for I-section and tube columnsDocument7 pagesPinned and fixed base plate design calculations for I-section and tube columnsabdul karee100% (6)

- Moment Connection Beam Column IS & BS SECTION FOR IS800Document29 pagesMoment Connection Beam Column IS & BS SECTION FOR IS800pjuvvadi86% (7)

- Connection Design MomentDocument4 pagesConnection Design MomentAkshit Dhawan100% (1)

- Base Plate - FixedDocument4 pagesBase Plate - Fixedbhaskardharani80% (5)

- Design of Base PlateDocument4 pagesDesign of Base PlateBenjun Balbin100% (5)

- Base Plate and Anchor Bolt DesignDocument9 pagesBase Plate and Anchor Bolt DesignShaikh Muhammad Ateeq100% (2)

- Base Plate Design Fixed RevisedDocument8 pagesBase Plate Design Fixed RevisedEngDbt80% (5)

- Design Calculation Steel Structure Power PlantDocument58 pagesDesign Calculation Steel Structure Power Plantrajeshdebnath100% (2)

- Base Plate With Moment & Axial CompressionDocument2 pagesBase Plate With Moment & Axial CompressionAnonymous b3NKZUb100% (3)

- RD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryDocument25 pagesRD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryHanuman Sharma83% (6)

- Cap Plate Trial CalculationDocument18 pagesCap Plate Trial CalculationStar100% (1)

- Moment Connection Portal FrameDocument18 pagesMoment Connection Portal Frametmssorin100% (1)

- Purlin design calculation simple spanDocument6 pagesPurlin design calculation simple spanKaren Sia100% (1)

- BS 5950 - Worked Example 2Document11 pagesBS 5950 - Worked Example 2mustafurade1100% (1)

- Base Plate DesignDocument118 pagesBase Plate Designsanjay singhNo ratings yet

- Moment Connection DETAIL 2Document5 pagesMoment Connection DETAIL 2way2vaseemNo ratings yet

- Z Purlin DesignDocument22 pagesZ Purlin DesignGautam PaulNo ratings yet

- Welded Splice ConnectionDocument14 pagesWelded Splice Connectionamitkukna0% (1)

- Fin Plate Connection DesignDocument10 pagesFin Plate Connection DesigncklconNo ratings yet

- Calculation Sheet: Base Plate & Anchor Bolt Design - Moment Connection Base Plate DataDocument1 pageCalculation Sheet: Base Plate & Anchor Bolt Design - Moment Connection Base Plate DataLaurence Arcon Banal0% (1)

- Baseplate Design Input DataDocument166 pagesBaseplate Design Input DataAnonymous ciKyr0t86% (7)

- Base Plate Design - 8m Span - Max Vertical LoadDocument7 pagesBase Plate Design - 8m Span - Max Vertical Loadnitin400No ratings yet

- Evo Design - Structural Design: Calculation SheetDocument7 pagesEvo Design - Structural Design: Calculation SheetAnand.5No ratings yet

- Design of Headed Concrete AnchorDocument121 pagesDesign of Headed Concrete AnchorkalpanaadhiNo ratings yet

- Column Base Plate (Eurocode)Document4 pagesColumn Base Plate (Eurocode)_at_to_No ratings yet

- End-Plate-Design BS CodeDocument15 pagesEnd-Plate-Design BS CodeRaymond SabadoNo ratings yet

- Base Plate DesignDocument8 pagesBase Plate DesignHiep Truong Tuan100% (1)

- Moment ConnectionDocument15 pagesMoment Connectionnitin400No ratings yet

- End Plate Connection Design CalculationsDocument4 pagesEnd Plate Connection Design CalculationsFodor ZoltanNo ratings yet

- Base Plate DesignDocument32 pagesBase Plate DesignGautam Sharma50% (2)

- Gusset Plate Design for Cleveland Clinic Abu DhabiDocument4 pagesGusset Plate Design for Cleveland Clinic Abu Dhabikalpanaadhi75% (4)

- Beam Section Properties & Connection DesignDocument24 pagesBeam Section Properties & Connection DesignStar100% (1)

- Base PlateDocument32 pagesBase PlateSunil SinghNo ratings yet

- End Plate ConnectionDocument10 pagesEnd Plate ConnectionMohamed Tahar Allagui100% (1)

- Base Plate Design for Column SupportDocument180 pagesBase Plate Design for Column Supportbuildcon62% (13)

- Design of Composite Steel Girder BridgeDocument10 pagesDesign of Composite Steel Girder BridgesorowareNo ratings yet

- Hollow Section Bracing Connetion - LRFDDocument5 pagesHollow Section Bracing Connetion - LRFDkalpanaadhiNo ratings yet

- Section Size: W200X36: Refer Appendix D For Support ReactionsDocument10 pagesSection Size: W200X36: Refer Appendix D For Support Reactionsramuce04No ratings yet

- Base Plate Design Is 800-2007Document6 pagesBase Plate Design Is 800-2007Suneesh P91% (11)

- Base PlateDocument6 pagesBase PlatejasonjasonNo ratings yet

- Design of Pad Footing - Worked Example To Eurocode 2Document11 pagesDesign of Pad Footing - Worked Example To Eurocode 2Shamsul Bahrin SulaimanNo ratings yet

- Isolated Footing DesignDocument14 pagesIsolated Footing DesignDhandapany ArunNo ratings yet

- MOMENT EndplateDocument8 pagesMOMENT Endplatemoseslugtu6324No ratings yet

- Ba Culvertf TestDocument16 pagesBa Culvertf TestsanjuktaacharyyaNo ratings yet

- Aci BeamDocument6 pagesAci BeamkumsbamaNo ratings yet

- 4-Base Plate - Pin ConnectionDocument3 pages4-Base Plate - Pin ConnectionMUTHUKKUMARAMNo ratings yet

- Ub 254 Fin Plate To Column Web - LRFDDocument10 pagesUb 254 Fin Plate To Column Web - LRFDihpeterNo ratings yet

- Project: Matrade Exhibition Center-Main Roof: Calculation For Steel Column Base PlateDocument10 pagesProject: Matrade Exhibition Center-Main Roof: Calculation For Steel Column Base PlateYANIshaNo ratings yet

- HAMTeK annexure 5.3a - Design of Base Plate and Anchor BoltsDocument7 pagesHAMTeK annexure 5.3a - Design of Base Plate and Anchor BoltsVenkatesha HebbarNo ratings yet

- ACI Pad Foundation ExampleDocument7 pagesACI Pad Foundation ExampleEm MarNo ratings yet

- Composite Beam Secondary: Construction StageDocument8 pagesComposite Beam Secondary: Construction StageSimon LsmNo ratings yet

- Lecture 2 Beams - Concrete CenterDocument99 pagesLecture 2 Beams - Concrete Centerwanksta67No ratings yet

- Composite Column Design 14Document4 pagesComposite Column Design 14Simon Lsm0% (1)

- Properties of Soils AppendixDocument5 pagesProperties of Soils Appendixpinkuru100% (1)

- Sci - Lift Calculation - 1Document6 pagesSci - Lift Calculation - 1Simon LsmNo ratings yet

- BLK 6 Meteorological DataDocument1 pageBLK 6 Meteorological DataSimon LsmNo ratings yet

- Bolt Anchor FBN II12312018 154029Document5 pagesBolt Anchor FBN II12312018 154029Simon LsmNo ratings yet

- WSH Guidelines Anchorage NewDocument26 pagesWSH Guidelines Anchorage NewRahmat MohamedNo ratings yet

- WIND LOAD DuopitchDocument15 pagesWIND LOAD DuopitchSimon LsmNo ratings yet

- BLK 6 Stafford Peak Accel LongitudinalDocument3 pagesBLK 6 Stafford Peak Accel LongitudinalSimon LsmNo ratings yet

- Bolt Anchor FBN II12312018 154029Document5 pagesBolt Anchor FBN II12312018 154029Simon LsmNo ratings yet

- DD Cen TS 1992-4-2-2009Document34 pagesDD Cen TS 1992-4-2-2009Simon LsmNo ratings yet

- Economic Concrete Frame Elements To Ec2Document192 pagesEconomic Concrete Frame Elements To Ec2ocenkt88% (17)

- Lateral Load Analysis Data TablesDocument80 pagesLateral Load Analysis Data TablesSimon LsmNo ratings yet

- Lateral Load Analysis Data TablesDocument80 pagesLateral Load Analysis Data TablesSimon LsmNo ratings yet

- How To Design Concrete Structures Using Eurocode 2Document104 pagesHow To Design Concrete Structures Using Eurocode 2Adil Javed Chaudhary97% (36)

- Lateral Load Analysis Data TablesDocument80 pagesLateral Load Analysis Data TablesSimon LsmNo ratings yet

- Column Base Plate (Eurocode)Document4 pagesColumn Base Plate (Eurocode)_at_to_No ratings yet

- Bca BDDocument35 pagesBca BDlim kang haiNo ratings yet

- MSB Part 9 ConnectionsDocument2 pagesMSB Part 9 ConnectionsSana UllahNo ratings yet

- Economic Concrete Frame Elements To Ec2Document192 pagesEconomic Concrete Frame Elements To Ec2ocenkt88% (17)

- Material Requirements for Steel and Concrete StructuresDocument38 pagesMaterial Requirements for Steel and Concrete StructuresSimon LsmNo ratings yet

- Weldment Strength Excel CalculationsDocument38 pagesWeldment Strength Excel CalculationsRAMSINGH CHAUHAN100% (4)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Material Requirements for Steel and Concrete StructuresDocument38 pagesMaterial Requirements for Steel and Concrete StructuresSimon LsmNo ratings yet

- HDB Requirements For A&a Work On HDB PremisesDocument16 pagesHDB Requirements For A&a Work On HDB PremisesYam BalaoingNo ratings yet

- Lap - Anchorage Length - EC 2Document9 pagesLap - Anchorage Length - EC 2Simon LsmNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Control System Components (ICE 3015): Zeroing SynchrosDocument18 pagesControl System Components (ICE 3015): Zeroing SynchrosmeenasundarNo ratings yet

- Catalog 201506 PDFDocument75 pagesCatalog 201506 PDFDairo OvalleNo ratings yet

- Moodle User Manual for UJ StudentsDocument14 pagesMoodle User Manual for UJ StudentsalexNo ratings yet

- Motorola68k 2Document114 pagesMotorola68k 2SoumyabrataPatraNo ratings yet

- iNTERRUPTOR 3AF01 PDFDocument27 pagesiNTERRUPTOR 3AF01 PDFJames IzquierdoNo ratings yet

- MS - Electrical Second FixDocument9 pagesMS - Electrical Second Fixirfan vpNo ratings yet

- Hydraulic Fracturing ReferencesDocument1 pageHydraulic Fracturing ReferencesMaulin GogriNo ratings yet

- Professor Course TimetableDocument25 pagesProfessor Course TimetablesabitavabiNo ratings yet

- Water ChemistryDocument14 pagesWater ChemistryJosé Luis Nava RebollarNo ratings yet

- Disposable Bioreactors - A Short ReviewDocument5 pagesDisposable Bioreactors - A Short ReviewjhpjayantNo ratings yet

- KITZ ProductDocument44 pagesKITZ Productkingathur26681No ratings yet

- CV - Hamdullah UÇAR-ıngDocument3 pagesCV - Hamdullah UÇAR-ıngHamdullah UcarNo ratings yet

- Market ValidationDocument24 pagesMarket ValidationJefferson AdlawanNo ratings yet

- IEC 61892-1 - Mobile and Fixed Offshore Units - Electrical Installations - Part 1 General Requirements and Conditions PDFDocument26 pagesIEC 61892-1 - Mobile and Fixed Offshore Units - Electrical Installations - Part 1 General Requirements and Conditions PDFmauricio_rodrigues09100% (1)

- Homework 7Document5 pagesHomework 7Mi LaNo ratings yet

- BECK USA Electrical ActuatorsDocument56 pagesBECK USA Electrical ActuatorsnprashanNo ratings yet

- Vijeo Citect +PowerConnect Installation GuideDocument12 pagesVijeo Citect +PowerConnect Installation GuidePavun RajNo ratings yet

- Crystal 14Document382 pagesCrystal 14DaveyNo ratings yet

- Measuring wavelength of light using diffraction gratingDocument5 pagesMeasuring wavelength of light using diffraction gratingSaksham BargujarNo ratings yet

- p92-3838 Harness - Front Chassis CumminsDocument11 pagesp92-3838 Harness - Front Chassis CumminsDiego LiraNo ratings yet

- RES-p Personal Profile:: Name Date of Birth Marital Status Address: Mail IDDocument4 pagesRES-p Personal Profile:: Name Date of Birth Marital Status Address: Mail IDkspNo ratings yet

- Steam Tank Pressure & QualityDocument5 pagesSteam Tank Pressure & QualityAri Reza KNo ratings yet

- Watertight Bulkheads Protect Passenger ShipsDocument6 pagesWatertight Bulkheads Protect Passenger Shipsoussama achouriNo ratings yet

- 3 PatentsDocument4 pages3 PatentsNaresh GollapalliNo ratings yet

- Gledhill Vented Installer Brochure 2019 v11.6 WEBDocument13 pagesGledhill Vented Installer Brochure 2019 v11.6 WEBzourawar khanNo ratings yet

- MagnetronDocument45 pagesMagnetronAnonymous c75J3yX33100% (2)

- Pa80 User PDFDocument10 pagesPa80 User PDFNenad StankovNo ratings yet

- Drawing Register NavigationDocument27 pagesDrawing Register NavigationAbd Aziz MohamedNo ratings yet

- Chapter 8 Ionic Chain PolymerizationDocument34 pagesChapter 8 Ionic Chain PolymerizationelnurorucluNo ratings yet

- Chapter 7: Communication Elements and Features: 701 GeneralDocument30 pagesChapter 7: Communication Elements and Features: 701 GeneralawasthyNo ratings yet