Professional Documents

Culture Documents

Power Transmition Notes

Uploaded by

Kyriakos MichalakiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power Transmition Notes

Uploaded by

Kyriakos MichalakiCopyright:

Available Formats

1 of 1

Theoretical External Collapse Pressure for Piping

(Method is not per ASME.)

3/12/2012, PipeExp3.xls

Client:

Description:

Customer No.:

Item No.:

Owner No.:

Dwg. No.:

Prepared By

Date

Rev.

0

1

2

3

4

The user is responsible for verifying that method and results are correct.

This method is not allowed for ASME vessels and pipes, except per ASME BPV Code, UG-28, F.

Method - 1

Theoretical External Pressure for Elastic Collapse :

"Elastic collapse occurs in the elastic region of the material's stress-strain curve. For thin-walled pipes,

elastic collapse is the predominate mode of failure (i.e., those pipes with a T / D of 0.10 or less). ..."

Reference paper: Chemical Engineering, April 30, 1984, "Sizing Pipe for External Pressure", by M. Mikasinovic and P. A. Marcucci.

Elastic Collapse pressure given by Von Mises' Equation:

2

Pe = 1/3 [ N - 1 + ( 2N - 1 - ) / ( N ( 2L / D) - 1) ] ( 2E / (1 - ) ) ( T / D) +

2

Eq. (1)

( 2E / ( N -1 ) ) * T / D / ( N ( 2L / D ) + 1 )

Number of lobes, N, created during elastic collapse. Since N is a physical constant, it must be an integer.

Lobes:

Minimum N = 2 (Here, the pipe's cross-section would somewhat resemble a figure-8.).

2

6 1/8

N = [ ( 1 - ) / (3(T / D) ) ( 2(D / (2L)) - ( D / (2L) ) + 5 ( D / (2L) - 3( 1 + )( D / (2L)

This method has the following conditions:

Design Temperature:

Material:

min. to

100

N >= 2,

Eq. (11)

L / D <= 15, and 0.005 <= T / D <=0.10

deg. F = min. to 38 deg. C

Material Data per ASME B31.3 -2010 Tables A-1 and A-1A

ASTM A312 TP304L SS Pipe S30403 EFW single butt 18Cr-8Ni

Elastic modulus at design temp., E =

Poisson's ratio, =

0.305

28.3

Electric fusion welded pipe, single butt seam

Min. yield stress, Sy = 25.0 ksi = 172 MPa

Msi = 195122 MPa

Notes: (1,2,3,4a,5,6)

Min. metal temp. = -425 F = -254 C

Outside diameter

User-defined

D=

16.000

in. = 406.4 mm

Nominal thickness

User-defined

T=

0.160

in. = 4.06 mm

T / D = 0.01

Dimension units:

Imperial

T / D is between 0.005 and 0.10. Thus the pipe shall be considered as thin-walled, and this method may be applied.

External pressure, P =

5.86

Safety Factor, Fs =

bar

3.0

85 psi = 586 kPa = 5.98 kg/cm^2 = 5.86 bar

L = Distance between stiffening elements (includes flanges, fittings, rings)

Maximum L / D = 15

Calculate N per Eq. (11) above. Then, round N up to the next integer.

44.0

2.75

N=

External design pressure, P Fs = Pd =

Pe =

Theoretical External Collapse Pressure per Eq. (1) above:

L=

L/D=

in. = 1117.6 mm

= the number of lobes created at collapse.

255.0

psi = 1758 kPa = 17.93 kg/sqcm = 17.58 bar

266

psi = 1834 kPa = 18.71 kg/sqcm = 18.34 bar

OK. Your external design pressure is less than theoretical collapse pressure.

Calculate stress in pipe at collapse, using a modified hoop stress formula,

S = P / (2 (T / D))

S=

13

ksi = 92 MPa

Stiffening Ring

Continue below only if your design requires stiffening ring/s.

Pipe O.D.

Stiffening ring may be sized for the above L / D since Pd does not exceed Pe, and L / D does not exceed 15:

3

Minimum required moment of inertia of stiffening ring, I = 1/28 D L Pd / E

Material is like the pipe.

Available moment of inertia,

Modulus of elasticity, E =

3

Ia = 1/12 tr hr

28.3 x 10^6 psi

I =

0.058

in^4 = 24141 mm^4

Thickness, tr =

0.500

in. = 12.7 mm

Height, hr =

1.250

in. = 31.75 mm

Ia =

0.0814

in^4 = 33881 mm^4

Stiffening ring size is OK.

tr

hr

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 3.10 - Valves - Modeling Dynamics - Engineering LibreTextsDocument5 pages3.10 - Valves - Modeling Dynamics - Engineering LibreTextsKyriakos MichalakiNo ratings yet

- Hygienic Equipment Design and Problematic Areas in Cleaning and Disinfection of Equipment SurfacesDocument20 pagesHygienic Equipment Design and Problematic Areas in Cleaning and Disinfection of Equipment SurfacesKyriakos MichalakiNo ratings yet

- M - Stainless Steel Take Up FramesDocument4 pagesM - Stainless Steel Take Up FramesKyriakos MichalakiNo ratings yet

- Configuration DesignDocument61 pagesConfiguration DesignKyriakos MichalakiNo ratings yet

- At The Heart of DairyDocument12 pagesAt The Heart of DairyEnrique MurgiaNo ratings yet

- The Engineering Design Process - Choose The Best SolutionDocument4 pagesThe Engineering Design Process - Choose The Best SolutionKyriakos MichalakiNo ratings yet

- Transfer Panels: For Food, Dairy, Beverages, and CosmeticsDocument4 pagesTransfer Panels: For Food, Dairy, Beverages, and CosmeticsKyriakos MichalakiNo ratings yet

- Six Required Specifications - Tips On Selecting NozzlesDocument6 pagesSix Required Specifications - Tips On Selecting NozzlesKyriakos MichalakiNo ratings yet

- Food Process ChartDocument5 pagesFood Process ChartKyriakos MichalakiNo ratings yet

- Eng-Pump Selection, Sizing and Interpretation of Performance CurvesDocument19 pagesEng-Pump Selection, Sizing and Interpretation of Performance CurvesHussain100% (2)

- Habasit Cleandrive Positive Drive Belts Engineering Guide: Habasit - Solutions in MotionDocument40 pagesHabasit Cleandrive Positive Drive Belts Engineering Guide: Habasit - Solutions in MotionKyriakos MichalakiNo ratings yet

- Habasit Cleandrive™ Monolithic Belts Engineering Guide: Habasit - Solutions in MotionDocument88 pagesHabasit Cleandrive™ Monolithic Belts Engineering Guide: Habasit - Solutions in MotionKyriakos MichalakiNo ratings yet

- A Methodology For Model Selection in Engineering Design: Rajesh RadhakrishnanDocument10 pagesA Methodology For Model Selection in Engineering Design: Rajesh RadhakrishnanKyriakos MichalakiNo ratings yet

- Design Criteria and ConstraintsDocument19 pagesDesign Criteria and ConstraintsKyriakos MichalakiNo ratings yet

- SteamTraps PDFDocument123 pagesSteamTraps PDFUsMan ZaFarNo ratings yet

- Marine Calorifier Supplier, China Marine Calorifier Manufacturer - Hi-Sea MarineDocument4 pagesMarine Calorifier Supplier, China Marine Calorifier Manufacturer - Hi-Sea MarineKyriakos MichalakiNo ratings yet

- Stainless Steel BV1XS Boilers with Removable Steam ExchangersDocument4 pagesStainless Steel BV1XS Boilers with Removable Steam ExchangersKyriakos MichalakiNo ratings yet

- 2-Port Self-Acting Temperature Control Valve Selection For Heating and Cooling ApplicationsDocument17 pages2-Port Self-Acting Temperature Control Valve Selection For Heating and Cooling ApplicationsKyriakos MichalakiNo ratings yet

- Piping & Instrumentation Diagrams (P&IDs) StandardDocument111 pagesPiping & Instrumentation Diagrams (P&IDs) StandardKalidass BackNo ratings yet

- Design of Monorail SystemsDocument20 pagesDesign of Monorail SystemsAshfaq Anwer50% (2)

- Steel Braced Frame BLDG PDFDocument11 pagesSteel Braced Frame BLDG PDFEljay VinsonNo ratings yet

- Design of Monorail SystemsDocument20 pagesDesign of Monorail SystemsAshfaq Anwer50% (2)

- 4097 19335 1 PBDocument7 pages4097 19335 1 PBhbookNo ratings yet

- Industrial Screens Brochure JOHNSON SCREENS WFDDocument16 pagesIndustrial Screens Brochure JOHNSON SCREENS WFDMark JohnsonNo ratings yet

- Rectangular Tank CalculationDocument28 pagesRectangular Tank CalculationMohammed EljammalNo ratings yet

- Bottle Filling Production Line 1 PDFDocument32 pagesBottle Filling Production Line 1 PDFKyriakos MichalakiNo ratings yet

- Filter Sterilization Guide Steam SterilizationDocument43 pagesFilter Sterilization Guide Steam SterilizationJitendra Yadav100% (1)

- Conveyorsystem 180307094730Document51 pagesConveyorsystem 180307094730Kyriakos MichalakiNo ratings yet

- 304 - Fms - Transilon Calculation Methods Conveyor Belts - en PDFDocument16 pages304 - Fms - Transilon Calculation Methods Conveyor Belts - en PDFAndressa EgerNo ratings yet

- Engineering: ManualDocument85 pagesEngineering: Manualsabinum100% (3)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- VisiLogic Software Manual-LadderDocument158 pagesVisiLogic Software Manual-LadderEduardo Vasquez CastroNo ratings yet

- Manual 800 KvaDocument87 pagesManual 800 Kvavicvarg100% (3)

- Memory Map and Address DecodingDocument9 pagesMemory Map and Address DecodingGhozi AlNo ratings yet

- Advanced Data Structures and ImplementationDocument56 pagesAdvanced Data Structures and ImplementationSyam Prasad Reddy BattulaNo ratings yet

- 06 HVAC Plumbing PDFDocument727 pages06 HVAC Plumbing PDFTamNo ratings yet

- P1 Conservation and Dissipation of Energy Student Book AnswersDocument11 pagesP1 Conservation and Dissipation of Energy Student Book AnswersjoeNo ratings yet

- Electrical Measurements LabDocument40 pagesElectrical Measurements Labmdayyub100% (4)

- Correlation Study and Regression Analysis of Water Quality Assessment of Nagpur City, IndiaDocument5 pagesCorrelation Study and Regression Analysis of Water Quality Assessment of Nagpur City, IndiaShakeel AhmadNo ratings yet

- Propeller DesignDocument74 pagesPropeller DesignBambang Teguh Setiawan75% (4)

- RCC BEAM DESIGN AND SERVICEABILITYDocument15 pagesRCC BEAM DESIGN AND SERVICEABILITYprashmceNo ratings yet

- YCMOU-6th Semester Question Papers-7Document5 pagesYCMOU-6th Semester Question Papers-7phase_shekhar21No ratings yet

- Cotta Transfer Case Lube PlanDocument3 pagesCotta Transfer Case Lube PlanMatias Alfredo Contreras KöbrichNo ratings yet

- Node diagnostics report for RBS6601WDocument9 pagesNode diagnostics report for RBS6601WWilson DiazNo ratings yet

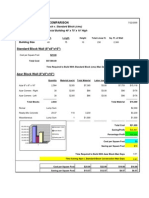

- AZAR Block CostcomparisonDocument8 pagesAZAR Block CostcomparisontckittuNo ratings yet

- Using Electricity SafelyDocument1 pageUsing Electricity SafelymariaNo ratings yet

- Schneider LV Switchboard Inspection GuideDocument59 pagesSchneider LV Switchboard Inspection GuideAlp Arslan Ok100% (1)

- InverterDocument8 pagesInverterrajinipre-1No ratings yet

- Staircase Preliminary Design Based On NBC and IS CodeDocument10 pagesStaircase Preliminary Design Based On NBC and IS CodeEducation. HubNo ratings yet

- Sap MM LSMWDocument18 pagesSap MM LSMWMani balan100% (1)

- Module 1: Introduction Introduction To Tribology: Fig. 1.1: Carbon Graphite SealDocument18 pagesModule 1: Introduction Introduction To Tribology: Fig. 1.1: Carbon Graphite Sealbansalmohit01No ratings yet

- FAA Significant Regulatory DifferencesDocument3 pagesFAA Significant Regulatory DifferencesOpteron K.No ratings yet

- Catalog Advantys AS-I IP20-IP67 - 803510 - DIA3ED2040909EN - 200408Document30 pagesCatalog Advantys AS-I IP20-IP67 - 803510 - DIA3ED2040909EN - 200408Jean MarzanNo ratings yet

- Operation Manual: Daikin Room Air ConditionerDocument92 pagesOperation Manual: Daikin Room Air ConditionerbenNo ratings yet

- 5TH Week EnergyDocument6 pages5TH Week EnergyMira VeranoNo ratings yet

- Vinay Quality ResumeDocument3 pagesVinay Quality Resumevinay kumarNo ratings yet

- BPCL Kochi Refinery MS BLOCK PROJECT Piping Material SpecificationDocument1 pageBPCL Kochi Refinery MS BLOCK PROJECT Piping Material SpecificationDeepak DayalNo ratings yet

- Strength and Insulating Properties of Building Blocks Made From Waste MaterialsDocument7 pagesStrength and Insulating Properties of Building Blocks Made From Waste Materialsmjrobust05No ratings yet

- 050, 051Document28 pages050, 051kefaja67% (3)

- Tabla 1 Engine ControlDocument2 pagesTabla 1 Engine Controljulio montenegroNo ratings yet

- List of Projects Related To Transportation Highway and BridgesDocument5 pagesList of Projects Related To Transportation Highway and BridgesOyedotun TundeNo ratings yet