Professional Documents

Culture Documents

Heat Exchanger Exergy Evaluation

Uploaded by

Gurjeet SinghCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heat Exchanger Exergy Evaluation

Uploaded by

Gurjeet SinghCopyright:

Available Formats

See

discussions, stats, and author profiles for this publication at:

https://www.researchgate.net/publication/286562463

Energy and exergy analysis of a parallel

and counter-flow heat exchangers using

measured data

ARTICLE in STROJNISKI VESTNIK MARCH 2007

Impact Factor: 0.82

READS

3 AUTHORS, INCLUDING:

Antun Galovic

University of Zagreb

16 PUBLICATIONS 35 CITATIONS

SEE PROFILE

All in-text references underlined in blue are linked to publications on ResearchGate,

letting you access and read them immediately.

Available from: Antun Galovic

Retrieved on: 20 January 2016

Strojniki vestnik - Journal of Mechanical Engineering 53(2007)3, 158-164

Strojniki vestnik - Journal of Mechanical Engineering 53(2007)3, 158-164

UDK - UDC 536.27

Izvirni znanstveni lanek - Original scientific paper (1.01)

Energijska in eksergijska analiza sotonih in protitonih

prenosnikov toplote z uporabo merilnih podatkov

Energy and exergy analysis of a parallel and counter-flow heat exchangers using

measured data

Antun Galovi1 - Marija ivi2- Ahmet Can3

( University of Zagreb, Croatia; 2J.J. Strossmayer University of Osijek, Croatia; 3Trakya University, Turkey)

1

Prispevek podaja energijsko in eksergijsko analizo sotonih in protitonih loilnih prenosnikov

toplote z uporabo marilnih podatkov. Sestavili smo merilno progo, na kateri smo merili vstopne in izstopne

temperature in masni tok vode. Za doloitev brezrazsenega razmerja izgubljene eksergije in preneenega

toplotnega toka v odvisnosti od brezrazsenih parametrov prenosnika toplote: razmerja absolutnih

temperatur na vstopu pT, razmerja toplotnih moi p3 in tevila enot prenosnika toplote p2, smo razvili

analitini model. Za vse primere smo izraunali tudi uinkovitost prenosa toplote. Rezultate smo prikazali

v ustreznih brezrazsenih diagramih.

2007 Strojniki vestnik. Vse pravice pridrane.

(Kljune besede: prenosniki toplote, energijske analize, eksergijske analize, izmerjene vrednosti)

This paper presents an energy and exergy analysis of a parallel and counter-flow recuperative heat

exchangers using experimental data. An experimental rig was constructed to measure the inlet and outlet

temperatures and the mass flow rates of streams. The analytical model was developed to obtain a nondimensional relationship between the destroyed exergy and exchanged heat-flow rate as a function of the

non-dimensional parameters of a heat exchanger: the ratio of inlet absolute temperatures, pT, the ratio of

the heat-capacity rates, p3, and the number of heat-transfer units, p2. The effectiveness of the heat exchange

is also calculated for each case. The results are shown in appropriate non-dimensional diagrams.

2007 Journal of Mechanical Engineering. All rights reserved.

(Keywords: heat exchangers, energy analysis, exergy analysis, measured values)

0 INTRODUCTION

Energy-exergy analyses of heat exchangers

have been the subject of much research over the

past few decades, [1] to [7]. These analyses are

based on the first and the second laws of

thermodynamics. From such analyses the

parameters for the improved operation of a heat

exchanger can be obtained.

The destroyed exergy or the lost available

work of a heat exchanger is due to two factors: the

transfer of heat across the stream-to-stream temperature difference and the frictional pressure drop that

accompanies the circulation of fluid through the

apparatus. Taking into account these two parameters it is possible to optimize a heat exchanger on

an entropy-generation minimization or on a minimum

158

Galovic.p65

destruction of exergy ([8] and [9]). In this work the

exergy destruction due to the pressure drop is neglected, because from experimental data it was clear

that the pressure drop was very small.

1 DESCRIPTION OF THE MEASURING RIG

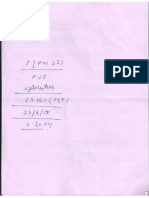

Figure 1. shows the experimental setup of the

heat exchanger.

The studied heat exchanger was double

pipe type with only one passage of every stream.

The streams were a hot-water stream (as the stronger stream) and a cold-water stream (as the weaker

one). The mass flow rate of the weaker stream was

kept constant and equal to 0.002 kg/s. The values of

the mass flow rate of the stronger stream were 0.004,

0.006, 0.008 or 0.01 kg/s. As can be seen from Figure

Galovi A. - ivi M. - Can A.

158

19. 6. 2007, 8:57

Strojniki vestnik - Journal of Mechanical Engineering 53(2007)3, 158-164

Heating Tank

N

Heater

Jt21'

t3

To Supply

Or Drain

J1t'5

Temperature

Indicator

J1''

Temperature

Limit Switch

(Behind)

Heat

Exchanger

Re-set Switch

Supply

High

Flow

Meter

Heater Control

Drain

Control

Valves

J1'

t

J 1t''6

Water Flow

Meter

Low Flow Meter

To Drain

Or Supply

''

Jt22

Pump

Fig. 1. The experimental rig

1, the inlet and outlet temperatures of the streams

were measured. In each of four cases (for the each

value of the mass flow rate), the inlet temperature of

the stronger stream was kept constant and the inlet

temperature of the weaker stream was varied four

times. From the obtained four sets of the measured

data, for each of the four cases, both for a parallel

and a counter-flow heat exchanger, two non dimen-

sional parameters (p1 and p3) were calculated. The

parameters are presented in the appropriate diagrams,

as shown in Figures 2 and 3.

The total heat exchanger area was 0.08 m2.

For each point the exchanged-heat flow rate

and the exergy destruction (entropy generation) are

calculated by using the equations of the following

mathematical model.

0.7

0.7

p3=0.50

p3=0.33

p3=0.25

p3=0.20

0.6

p1

p3=0

0.5

0.4

p1

p3=1

0.5

0.4

0.3

0.2

0.1

0.1

0

0.2

0.4

0.6

p2

p3=0

0.3

p3=0.50

0.2

p3=0.50

p3=0.33

p3=0.25

p3=0.20

0.6

0.8

Fig. 2. The positions of the measured operation

points for a parallel-flow heat exchanger

1.2

p3=0.50

0.2

0.4

159

0.6

p2

0.8

1.2

Fig. 3. The positions of the measured operation

points for a counter-flow heat exchanger

Energijska in eksergijska analiza - Energy and exergy analysis

Galovic.p65

p3=1

19. 6. 2007, 8:57

159

Strojniki vestnik - Journal of Mechanical Engineering 53(2007)3, 158-164

2 MATHEMATICAL MODEL

The exchanged-heat flow rate between two

streams can be calculated using the following

equation ([10] and [11]):

Q& = C1 (J1' - J1'' ) = C2 (J2'' - J2' )

(1).

The heat exchanger effectiveness e is usually

defined as:

J ' - J ''

Q&

e = p 1 = 1' 1' =

J1 - J2 Q& max

(2).

The exchanged-heat flow rate Q& can be rewritten as:

Q& = e Q& max = e C1 (J1' - J2' )

(3).

Since the pressure drop of the two streams is

neglected, the entropy generation can be calculated

from the following equation [11]:

T ''

T ''

S&gen = C1 ln 1' + C2 ln 2'

T1

T2

(4).

Using Equations (1) and (2), it is easy to transform Equation (4) into the form:

C T '

T '

S&gen = C1ln 1-e 1- 2' + C2 ln 1+ 1 e 1' - 1 (5).

T1

C2 T2

If the following terms for two nondimensional parameters

pT =

T2'

C

; p3 = 1

T1'

C2

(6)

are introduced into Equation (5), the equation for

the entropy generation assumes the following form:

- 1 (7).

S&gen = C1ln (1-e ( 1-p T ) ) + C2 ln 1+p 3e

p

T

After multiplying the above equation by the

environmental temperature, T0, the equation for the

irreversibility or the exergy destruction is obtained

as:

I& = Exdestr = T0 S&gen

= T0 C1ln (1-e (1-p T ) ) + C2 ln 1+p 3e

- 1

p

T

(8).

The above equation can be written in a nondimensional form. For that purpose, it will be divided

by the product of the heat capacity rate of the weaker

stream, C1, and the environmental temperature, T0,

as follows:

160

Galovic.p65

I&

1

= ln (1-e (1-p T ) ) + ln 1+p 3e

- 1

p3

T0C1

pT

(9).

Because the scope of this work is to show

the ratio of the irreversibility and the exchangedheat flow rate, it is useful to write Equation (1) in a

non-dimensional form, dividing it by the product

C1T1' :

Q&

q1 =

= e (1 - p T )

(10).

CT'

i1 =

1 1

Finally, Equation (9) is divided by Equation

(10), and a relevant ratio is obtained:

1

1

- 1

ln (1-e (1-p T ) ) + ln 1+p 3e

p3

i1

p T (11).

=

e (1 - p T )

q1

For a parallel heat exchanger the

effectiveness e is obtained using the following

formula [10]:

e=

1- e ( 3)

1+ p3

- 1+ p p 2

and for a counter heat-transfer heat exchanger e is

estimated as [10]:

e=

1- e (

- 1-p 3 )p 2

1 - p 3e (

- 1-p 3 )p 2

(13).

where:

p2 =

kA0

C1

(14).

As can be seen, this ratio is a function of the

non-dimensional parameters p3 and e = p1, which represent the operation points of the heat exchanger

and which are obtained by the energy analysis of

heat exchangers. The additional parameters for irreversibility or exergy destruction are the input temperature ratia, pT, and the ambient temperature, T0.

3 CALCULATION RESULTS AND DISCUSSION

The diagrams in Figures 4 and 5 present

the values of i1 and i1/q1 for a parallel-heat-flow heat

exchanger, and the diagrams in Figures 6 and 7 for a

counter-flow heat exchanger. These values are

calculated using Equations (9) to (11) and Equations

(12) and (13) for the parallel and the counter heat

exchanger, respectively. The black points in the

diagrams represent the values of the operating

points, which are presented in Figures 2 and 3.

Galovi A. - ivi M. - Can A.

160

(12).

19. 6. 2007, 8:57

Strojniki vestnik - Journal of Mechanical Engineering 53(2007)3, 158-164

0.012

i1

0.01

0.7

0.012

0.65

0.01

0.6

0.008

i1

0.004

0.6

0.5

0.006

0.45

0.004

0.6

0.7

0.8

0.9

p2

a) p3=0.50

1.1

i1

0.3

1.2

0.012

i1

0.7

0.6

0.008

p T=1.07

pT=1.11

pT=1.14

pT=1.17

i1

0.5

0.6

0.7

0.8

0.9

0.3

1.2

1.1

p2

b) p3=0.33

0.7

0.65

0.01

0.6

0.008

0.5

0.5

0.002

0.4

0.35

0.5

0.6

0.7

0.8

p2

0.9

1.1

0.45

0.004

0.4

0.55

0.006

0.45

0.004

0.35

0.55

0.006

0.45

0.012

0.65

0.01

0.5

0.002

0.35

0.5

0.55

0.4

0.4

0.002

0.65

0.008

0.55

0.006

0.7

0.002

0.3

1.2

0.35

0.5

0.6

0.7

0.8

p2

0.9

0.3

1.2

1.1

c)p3=0.25

d) p3=0.20

Fig. 4. The non-dimensional irreversibility i1 and the effectiveness e as a function of p2 and the parametric

curves pT for a) p3=0.50, b) p3=0.33, c)p3=0.25 and d) p3=0.20 for a parallel flow heat exchanger

i1

q1

0.12

0.12

0.1

0.1

i1

q1

0.08

0.06

0.06

0.04

0.04

0.02

0.02

0.5

0.6

0.7

0.8

p2

0.9

1.1

1.2

a) p3=0.50

0.12

i1

pT=1.07

pT=1.11

pT=1.14

pT=1.17

0.6

0.7

0.8

p2

0.9

1.1

1.2

1.1

1.2

b) p3=0.33

0.1

0.08

i1

q1

0.06

0.08

0.06

0.04

0.04

0.02

0.02

0.5

0.12

0.1

i1

q1

0.08

0.5

0.6

0.7

0.8

p2

c)p3=0.25

0.9

1.1

1.2

0.5

0.6

0.7

0.8

p2

0.9

d) p3=0.20

Fig. 5. Relative non-dimensional irreversibility i1/q1 as a function of p2 and the parametric curves pT for

a) p3 = 0.50, b) p3 = 0.33, a) p3 = 0.25, a) p3 = 0.20 for a parallel-heat-flow heat exchanger

Energijska in eksergijska analiza - Energy and exergy analysis

Galovic.p65

161

19. 6. 2007, 8:57

161

Strojniki vestnik - Journal of Mechanical Engineering 53(2007)3, 158-164

0.012

i1

0.7

0.012

0.65

0.01

0.5

0.004

0.55

0.006

0.45

0.5

0.45

0.004

0.4

0.002

0

0.4

0.002

0.35

0.5

0.6

0.7

0.8

0.9

p2

1.1

0.3

1.2

i1

a) p3=0.50

0.012

0.7

0.55

0.006

p T=1.07

p T=1.11

p T=1.14

p T=1.17

i1

0.6

0.7

0.8

0.9

1.1

p2

0.9

1.1

0.3

1.2

b) p3=0.33

0.7

0.65

0.01

0.6

0.55

0.5

0.45

0.4

0.002

0.35

0.5

0.8

0.004

0.4

0.7

0.006

0.45

0.002

0.6

0.008

0.5

0.004

0.5

0.012

0.6

0.008

0.35

0.65

0.01

i1

0.6

0.008

0.55

0.006

0.65

0.01

i1

0.6

0.008

0.7

0.3

1.2

0.35

0.5

0.6

0.7

0.8

p2

p2

0.9

1.1

0.3

1.2

c) p3=0.25

d) p3=0.20

Fig.6. Non-dimensional irreversibility i1 and effectiveness e as a function of p2 and the parametric curves

pT for a) p3=0.50, b) p3=0.33, c)p3=0.25 d) p3=0.20 for a counter-flow heat exchanger

i1

q1

0.12

0.12

0.1

0.1

i1

q1

0.08

0.06

0.06

0.04

0.04

0.02

0.02

0.5

0.6

0.7

0.8

p2

0.9

1.1

1.2

a) p3=0.50

0.12

i1

pT=1.07

pT=1.11

pT=1.14

pT=1.17

0.1

i1

q1

0.08

0.5

0.7

0.8

p2

0.9

1.1

1.2

b) p3=0.33

0.12

0.1

0.08

i1

q1

0.06

0.08

0.06

0.04

0.04

0.02

0.02

0.6

0.5

0.6

0.7

0.8

p2

0.9

1.1

1.2

0.5

0.6

0.7

0.8

p2

0.9

1.1

1.2

c)p3=0.25

d) p3=0.20

Fig. 7. Relative non-dimensional irreversibility i1/q1 as a function of p2 and the parametric curves pT for

a) p3=0.50, b) p3=0.33, c) p3=0.25, d) p3=0.20 for a counter-flow heat exchanger

162

Galovic.p65

Galovi A. - ivi M. - Can A.

162

19. 6. 2007, 8:57

Strojniki vestnik - Journal of Mechanical Engineering 53(2007)3, 158-164

The above diagrams clearly show the relationship between the dimensionless values of i1 and the

dimensionless parameters p2, p3 and pT. For each diagram it is possible to directly read the values of i1 and

e for every case. It is obvious that the given values of

p2 and p3 do not have a significant influence on i1, but

they have an influence on e. The pT ratio has the greatest influence on i1, but it has no influence on e. This

can be quantitatively seen from Figures 4a and 4d,

where the values p3 = 0.5 and 0.2 and parametric values

pT =1.11; 1.14 and 1.17 have the same value of p2 = 0.76

and 1.09 respectively. For p3 = 0.5, all operation points

have the same value of e, i.e., e = 0.455, with the

exergy destruction increasing from 0.0028 to 0.0078.

On the other hand, for p3 = 0.2 and the same parametric

values of pT and p2 of 1.09, the value of e is equal to

0.61. The associated exergy destructions are 0.0040,

0.0067 and 0.0076 respectively.

It is obvious that parallel- and counter-heatflow heat exchangers have very small values of the

ratio i1 and i1/q1 for the measured operation points.

It is not possible to make a comparison with respect

to exergy destruction and heat-transfer effectiveness

of the researched cases, because they did not have

the same non-dimensional p2 variables.

4 CONCLUSION

The presented analytical relationship

between the dimensionless exergy destruction and

the heat-transfer effectiveness of a heat exchanger

seems to be rather convenient, because it relates the

dimensionless parameters (p3; p2 and pT as additional

parameter) relevant to the operation of a heat

exchanger and the exergy destruction of a parallel

and a counter-flow heat exchanger. It is possible to

include the values of the measured operation points

into the presented mathematical model and simultaneously calculate the heat-transfer effectiveness and

the exergy destruction of the considered heat exchangers. It can be concluded that the exergy

destruction for each case of both investigated heat

exchangers is small. The main reason for such a

conclusion is the fact that the operation values of

pT close to 1.

Furthermore, by introducing additional

exergy destruction due to the pressure drop in the

model, it is possible to develop an analytical model

for the minimization of heat exchangers exergy

destruction.

5 NOMENCLATURE

A0

C

Ex

I&

i1

k

Q&

q1

S&

T

T0

overall heat-transfer area, m2

heat-capacity rate of the stream, W/K

exergy, W

exergy destruction, W

non-dimensional exergy destruction

overall heat-transfer coefficient, W/(m2K)

heat-transfer rate, W

non-dimensional heat-flow rate

entropy generation rate, W/K

thermodynamic (absolute) temperature, K

ambient temperature, K

Greek Letters

e, p1 heat-exchanger effectiveness

J

pT

p2

p3

Celsius temperature, oC

ratio of inlet absolute temperatures, K

number of heat-transfer units

ratio of heat-capacity rates

Subscripts

1

weaker stream

2

stronger stream

destr

destruction

gen

generated

Superscripts

inlet

outlet

6 REFERENCES

[1] Bejan, A., (1977) Second law analysis in heat transfer, Energy, 5, (1977), pp. 721-732 .

[2] Rant, Z. (1956) Exergie, ein neues Wort fr technische Arbeitsfhigkeit. Forschung Ing. Wesens 22(1956),

pp. 36-37.

[3] Rant, Z. (1964) Thermodynamische Bewertung der Verluste bei technischen Energieumwandlungen,

BWK 16(1964), pp. 453-457.

Energijska in eksergijska analiza - Energy and exergy analysis

Galovic.p65

163

19. 6. 2007, 8:57

163

Strojniki vestnik - Journal of Mechanical Engineering 53(2007)3, 158-164

[4] Can, A., Buyruk, E., Eryener, D., (2002) Exergoeconomic analysis of condenser type heat exchangers,

Exergy- an International Journal 2(2002) , pp.113-118.

[5] Galovi, A., Virag Z., Mudrini, S., (2003), Non-dimensional entropy analysis of condenser and/or

evaporator type heat exchangers, Transactions of Famena, 27(2003), pp. 1-9.

[6] Gregorig, R. (1973) Wrmeaustausch und Wrmeaustauscher, Verlag Sauerlnder, Frankfurt am Main.

[7] Galovi, A., M. ivi, M. Andrassy, (2003) Entropijska analiza sotonih prenosnikov toplote, Strojniki

vestnik 49 (2), pp.100-110.

[8] Bejan, A., (1988) Advance engineering thermodynamics, John Willey and Sons, New York.

[9] Bejan, A. (1996) Entropy generation minimizaton, CRC Press, New York.

[10] Bonjakovi, F., K. F. Knoche, (1997) Technische Thermodynamik, Teil II, Steinkopf Verlag, Darmstadt.

[11] engel, Y.,Boles, M., A., (1994) Thermodynamics: an engineering approach, McGraw-Hill Book Company,

New York.

Authors Addresses:

Prof. Dr. Antun Galovi

University of Zagreb

Faculty of Mechanical Engineering and

Naval Architecture

Ivana Luia 5

10000 Zagreb, Croatia

antun.galovic@fsb.hr

Dr. Marija ivi

J.J. Strossmayer University of Osijek

Mechanical Engineering Faculty

35000 Slavonski Brod, Croatia

marija.zivic@sfsb.hr

Prof. Dr. Ahmet Can

Trakya University

Faculty of Mechanical Engineering and

Architecture

22030 Edirne, Turkey

Prejeto:

Received:

Sprejeto:

Accepted:

7.2.2006

164

Galovic.p65

25.10.2006

Odprto za diskusijo: 1 leto

Open for discussion: 1 year

Galovi A. - ivi M. - Can A.

164

19. 6. 2007, 8:57

You might also like

- Capital Investment Decision Methods and CalculationsDocument45 pagesCapital Investment Decision Methods and CalculationsGurjeet SinghNo ratings yet

- Book Chapter On Ethanol As Automotive FuelDocument30 pagesBook Chapter On Ethanol As Automotive FuelGurjeet SinghNo ratings yet

- Capital Investment Decision Methods and CalculationsDocument45 pagesCapital Investment Decision Methods and CalculationsGurjeet SinghNo ratings yet

- 6 - Estimation of Thermodynamic Characteristics of Food Processing PlantDocument15 pages6 - Estimation of Thermodynamic Characteristics of Food Processing PlantGurjeet SinghNo ratings yet

- List of Ugc Publications: Sr. No - Authors Title Journal Publisher Location Issn/Isbn Impact Factor Year of PublicationDocument2 pagesList of Ugc Publications: Sr. No - Authors Title Journal Publisher Location Issn/Isbn Impact Factor Year of PublicationGurjeet SinghNo ratings yet

- Production Management Module 1 Course NotesDocument25 pagesProduction Management Module 1 Course NotesRajesh BapuNo ratings yet

- 2 - CFD Analysis of Laminar Heat Transfer in A ChannelDocument10 pages2 - CFD Analysis of Laminar Heat Transfer in A ChannelGurjeet SinghNo ratings yet

- 4 - Exergy and Thermo-Economic Analysis of Ghee.Document17 pages4 - Exergy and Thermo-Economic Analysis of Ghee.Gurjeet SinghNo ratings yet

- Automation Ch04Document20 pagesAutomation Ch04Gurjeet SinghNo ratings yet

- Steam Boilers, Engines, Nozzles and TurbinesDocument58 pagesSteam Boilers, Engines, Nozzles and TurbinesGurjeet SinghNo ratings yet

- 6 - Estimation of Thermodynamic Characteristics of Food Processing PlantDocument15 pages6 - Estimation of Thermodynamic Characteristics of Food Processing PlantGurjeet SinghNo ratings yet

- PLC 1 3Document44 pagesPLC 1 3Sayyadh Rahamath BabaNo ratings yet

- Lec 1Document15 pagesLec 1Gurjeet SinghNo ratings yet

- 6 - Estimation of Thermodynamic Characteristics of Food Processing PlantDocument15 pages6 - Estimation of Thermodynamic Characteristics of Food Processing PlantGurjeet SinghNo ratings yet

- Source Publication List For Web of Science: Science Citation Index ExpandedDocument143 pagesSource Publication List For Web of Science: Science Citation Index ExpandedGarima GuptaNo ratings yet

- Source Publication List For Web of Science: Science Citation Index ExpandedDocument143 pagesSource Publication List For Web of Science: Science Citation Index ExpandedGarima GuptaNo ratings yet

- Mms Assignment No. 1 Session 16171Document7 pagesMms Assignment No. 1 Session 16171Gurjeet SinghNo ratings yet

- Ave Sessional-1 Solution 15161 Sep 2015Document14 pagesAve Sessional-1 Solution 15161 Sep 2015Gurjeet SinghNo ratings yet

- PPT-6 Basic Aspects of DiscretizationDocument9 pagesPPT-6 Basic Aspects of DiscretizationGurjeet SinghNo ratings yet

- Heat Transfer Augmentation in Double Pipe Heat Exchanger PDFDocument15 pagesHeat Transfer Augmentation in Double Pipe Heat Exchanger PDFGurjeet SinghNo ratings yet

- Cheese MakingDocument6 pagesCheese MakingGurjeet SinghNo ratings yet

- Basic considerations for designing residential air conditioning systemsDocument29 pagesBasic considerations for designing residential air conditioning systemsGurjeet SinghNo ratings yet

- RAC Lecture 10Document18 pagesRAC Lecture 10api-373446667% (3)

- PPT-2 Modeling and Simulation Brief IdeaDocument26 pagesPPT-2 Modeling and Simulation Brief IdeaGurjeet SinghNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chapter-1 of F.mensurationDocument8 pagesChapter-1 of F.mensurationpradeeppoddarNo ratings yet

- Dissertation Le Juge Administratif Et Le Droit InternationalDocument8 pagesDissertation Le Juge Administratif Et Le Droit InternationalPayPeopleToWritePapersWestValleyCityNo ratings yet

- Contact: 10 Archana Aboli, Lane 13, V G Kale Path, 850 Bhandarkar Road, Pune-411004Document12 pagesContact: 10 Archana Aboli, Lane 13, V G Kale Path, 850 Bhandarkar Road, Pune-411004immNo ratings yet

- Central Venous Access Devices (Cvads) andDocument68 pagesCentral Venous Access Devices (Cvads) andFitri ShabrinaNo ratings yet

- Cityam 2011-09-19Document36 pagesCityam 2011-09-19City A.M.No ratings yet

- Soal EnglishDocument7 pagesSoal EnglishRieZky RamadhaniNo ratings yet

- Zapffe, Peter Wessel - The Last Messiah PDFDocument13 pagesZapffe, Peter Wessel - The Last Messiah PDFMatias MoulinNo ratings yet

- (Stem - Pc11T-Iie-1) : Self-Learning Home Task (SLHT) 5Document7 pages(Stem - Pc11T-Iie-1) : Self-Learning Home Task (SLHT) 5Naddy RetxedNo ratings yet

- An Approach to Defining the Basic Premises of Public AdministrationDocument15 pagesAn Approach to Defining the Basic Premises of Public AdministrationAlvaro CamargoNo ratings yet

- Semester I Listening Comprehension Test A Good Finder One Day Two Friends Went For A Walk. One of Them Had A Dog. "See HereDocument13 pagesSemester I Listening Comprehension Test A Good Finder One Day Two Friends Went For A Walk. One of Them Had A Dog. "See HereRichard AndersonNo ratings yet

- Q1-Music 8-Thailand & LaosDocument22 pagesQ1-Music 8-Thailand & LaosYbur Hermoso-MercurioNo ratings yet

- As Work: Self Perceptions and Perceptions of Group Climate Predictors of Individual Innovation atDocument17 pagesAs Work: Self Perceptions and Perceptions of Group Climate Predictors of Individual Innovation atMuqadas KhanNo ratings yet

- Sereno's Dissenting Opinion Re TruthCommDocument35 pagesSereno's Dissenting Opinion Re TruthCommGerald MagnoNo ratings yet

- Group 2Document3 pagesGroup 2sharmisthahalder21No ratings yet

- English Language (1122)Document26 pagesEnglish Language (1122)TD X Mzinda100% (1)

- [4]Document693 pages[4]Ali Mohammed AlkafajyNo ratings yet

- Copticmanuscript 00 CoelDocument468 pagesCopticmanuscript 00 Coelbavly barsomNo ratings yet

- Computers in Human Behavior: Aideen Lawlor, DR Jurek KirakowskiDocument11 pagesComputers in Human Behavior: Aideen Lawlor, DR Jurek KirakowskiAlejandro BejaranoNo ratings yet

- ALL INDIA NURSING TEST REVIEWDocument102 pagesALL INDIA NURSING TEST REVIEWDr-Sanjay SinghaniaNo ratings yet

- 7 Ways To Shortlist The Right StocksDocument10 pages7 Ways To Shortlist The Right Stockskrana26No ratings yet

- Akhila-Rasamrta-Murtih Prasrmara-Ruci-Ruddha-Taraka-PalihDocument44 pagesAkhila-Rasamrta-Murtih Prasrmara-Ruci-Ruddha-Taraka-PalihSauri ChaitanyaNo ratings yet

- AntimonyDocument72 pagesAntimony沈益No ratings yet

- Section 504 Sample Accommodations and Modifications: Examples of General AccommodationsDocument16 pagesSection 504 Sample Accommodations and Modifications: Examples of General AccommodationsRukhsana KhanNo ratings yet

- Watch Blow Fly Arrang e Sleep Go Cook Clean Hear Cut Give Fall Open See Listen Carry Visit Buy Bring Write Bake Make Sit Play DrawDocument3 pagesWatch Blow Fly Arrang e Sleep Go Cook Clean Hear Cut Give Fall Open See Listen Carry Visit Buy Bring Write Bake Make Sit Play DrawEmily NytNo ratings yet

- Hamlet Act 3 Scene 1Document4 pagesHamlet Act 3 Scene 1Αθηνουλα ΑθηναNo ratings yet

- Senior Java Developer With 4 Years Experience ResumeDocument5 pagesSenior Java Developer With 4 Years Experience ResumedivaNo ratings yet

- Anita Desai PDFDocument9 pagesAnita Desai PDFRoshan EnnackappallilNo ratings yet

- QDEGNSWDocument2 pagesQDEGNSWSnehin PoddarNo ratings yet

- This Judgemen T Ranked 1 in The Hitlist.: Doc Id # 66804Document19 pagesThis Judgemen T Ranked 1 in The Hitlist.: Doc Id # 66804Kapil DemlaNo ratings yet

- Rubric WordsmithDocument6 pagesRubric Wordsmithapi-200845891No ratings yet

![[4]](https://imgv2-1-f.scribdassets.com/img/document/396226966/149x198/c657f32573/1545578422?v=1)