Professional Documents

Culture Documents

D15M-D15-2002 Section 7 PDF

Uploaded by

SuryaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D15M-D15-2002 Section 7 PDF

Uploaded by

SuryaCopyright:

Available Formats

AASHTO/AWS D1.5M/D1.

5:2002

Reproduced with the permission of the American Welding Society (AWS), Miami, Florida - 09/15/2011

7. Stud Welding

7.1 Scope

twists, bends, or other injurious discontinuities. Radial

cracks or bursts in the head of a stud shall not be cause

for rejection, provided that the cracks or bursts do not

extend more than half the distance from the head

periphery to the shank, as determined by visual

inspection.

Section 7 contains general requirements for welding

steel studs to steel (see 7.2.7 and 1.2.2 for approved

steels). In addition, it stipulates specific requirements for

the following:

(1) Workmanship, preproduction testing, operator

qualification, and application qualification testing, when

required, all to be performed by the Contractor

(2) QC and QA inspection of stud welding during

production

(3) Mechanical properties of steel studs, and requirements for qualification of stud bases, all tests and documentation to be furnished by the stud manufacturer

Note: Heads of shear connectors or anchor studs are

subject to cracks or bursts, which are names for the same

thing. Cracks or bursts designate an abrupt interruption

of the periphery of the stud head by radial separation of

the metal. Such interruptions do not adversely affect the

structural strength, corrosion resistance, nor other functional requirements of headed studs.

7.2.6 Only bases qualified under Annex VI shall be used.

When requested by the Engineer, the Contractor shall

provide the following information:

(1) A description of the stud and arc shield

(2) Certification from the manufacturer that the stud

base is qualified as described in 7.2.4

(3) Qualification test data

7.2 General Requirements

7.2.1 Studs shall be of suitable design for arc welding to

steel members with the use of automatically timed stud

welding equipment. The type and size of the stud shall be

as specified by the drawings, specifications, or special

provisions. For headed-type studs, see Figure 7.1.

7.2.7 M270M (M270) Grades 690/690W (100/100W)

(A 709M [A 709] Grades 690/690W [100/100W]) steels

shall not be stud welded without approval of the Engineer.

7.2.2 An arc shield (ferrule) of heat-resistant ceramic or

other suitable material shall be furnished with each stud.

7.2.3 A suitable deoxidizing and arc stabilizing flux for

welding shall be furnished with each stud of 8 mm [5/16 in.]

diameter or larger. Studs less than 8 mm [5/16 in.] in diameter may be furnished with or without flux.

7.3 Mechanical Requirements

7.3.1 Studs shall be made from cold-drawn bar stock

conforming to the requirements of ASTM A 108, Specification for Steel Bars, Carbon Cold Finished, Standard

Quality Grades, Grades G10100 through G10200, inclusive, either semi-killed or killed deoxidation.

7.2.4 Only studs with qualified stud bases shall be used.

A stud base, to be qualified, shall have passed the test

described in Annex VI. The arc shield used in production

shall be the same as used in qualification tests or as

recommended by the manufacturer. Qualification of stud

bases in conformance with Annex VI shall be at the

manufacturers expense.

7.3.1.1 Mechanical property requirements of studs

other than outlined below shall be specified by the

Engineer.

7.2.5 Finish shall be produced by heading, rolling, or

machining. Finished studs shall be of uniform quality

and condition, free of injurious laps, fins, seams, cracks,

7.3.1.2 At the manufacturers option, mechanical

properties of studs shall be determined by testing either

155

Reproduced with the permission of the American Welding Society (AWS), Miami, Florida - 09/15/2011

AASHTO/AWS D1.5M/D1.5:2002

STUD WELDING

Reproduced with the permission of the American Welding Society (AWS), Miami, Florida - 09/15/2011

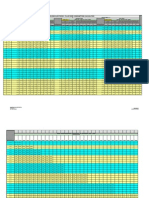

Table 7.1

Mechanical Property Requirements

for Studs (see 7.3.1.2)

Type A1

Type B2

380 MPa

[55 ksi] min

415 MPa

[60 ksi] min

345 MPa

[50 ksi] min

Elongation

(% in 50 mm [2 in.])

17% min

20% min

Reduction of area

50% min

50% min

Tensile strength

Yield strength (0.2% offset)

Note:

1. L = manufactured lengthlength specified by Engineer plus

upset distance.

Notes:

1. Type A studs shall be general purpose of any type and size used for

purposes other than shear transfer in composite beam design and

construction.

2. Type B studs shall be studs that are headed, bent, or of other configuration in 12 mm [1/2 in.] through 23 mm [7/8 in.] diameter that

are used as an essential component in composite beam design and

construction.

Standard Dimensions, mm [in.]

Shank Diameter

(C)

Length

Tolerance

(L)

Head

Diameter

(H)

Minimum

Head Height

(T)

12.7

[1/2]

+0.00

0.25 [0.010]

1.60

[1/16]

25.4 0.4

0-00[1 1/64]

7.1

[9/32]

15.9

[5/8]

+0.00

0.25 [0.010]

1.60

[1/16]

31.7 0.4

-[1-1/4 1/64]

7.1

[9/32]

19.0

[3/4]

+0.00

0.38 [0.015]

1.60

[1/16]

31.7 0.4

-[1-1/4 1/64]

9.5

[3/8]

22.1

[7/8]

+0.00

0.38 [0.015]

1.60

[1/16]

34.9 0.4

-[1-3/8 1/64]

9.5

[3/8]

25.4

[1]

+0.00

0.38 [0.015]

1.60

[1/16]

41.3 0.4

-[1-5/8 1/64]

12.7

[1/2]

completed set of in-plant quality control mechanical

tests, required by 7.3 for each stock size delivered. The

quality control test shall have been made within the six

month period before delivery of the studs.

7.3.4 When quality control tests are not available, the

Contractor shall furnish mechanical test reports conforming to the requirements of 7.3. The mechanical tests shall

be on finished studs provided by the manufacturer of the

studs. The number of tests to be performed shall be specified by the Engineer.

Figure 7.1Dimension and Tolerances of

Standard-Type Shear Connectors (see 7.2.1)

7.3.5 The Engineer may select studs of each type and

size used under the contract as necessary for checking

the requirements of 7.2 and 7.3. Furnishing these studs

shall be at the Contractors expense. Testing shall be at

the Owners expense.

(1) the steel after cold finishing, or (2) the full diameter

finished studs. In either case, the studs shall conform to

the requirements shown in Table 7.1.

7.3.2 Mechanical properties shall be determined in conformance with the applicable sections of ASTM A 370,

Test Methods and Definitions for Mechanical Testing of

Steel Products. A typical test fixture is used, similar to

that shown in Figure 7.2.

7.4 Workmanship

7.4.1 At the time of welding, the studs shall be free from

rust, rust pits, scale, oil, moisture, and other deleterious

matter that would adversely affect the welding operation.

7.3.3 Upon request by the Engineer, the Contractor shall

furnish the following:

7.3.3.1 The Contractor shall provide the stud manufacturers certification that the studs, as delivered, conform to the applicable requirements of 7.2 and 7.3.

7.4.2 The stud base shall not be painted, galvanized, nor

cadmium-plated prior to welding.

7.4.3 The areas to which the studs are to be welded shall

be free of scale, rust, moisture, and other injurious mate-

7.3.3.2 The Contractor shall provide certified copies

of the stud manufacturers test reports covering the last

156

Reproduced with the permission of the American Welding Society (AWS), Miami, Florida - 09/15/2011

STUD WELDING

AASHTO/AWS D1.5M/D1.5:2002

Reproduced with the permission of the American Welding Society (AWS), Miami, Florida - 09/15/2011

Note: The fillet weld profiles shown in Figure 3.3 do not

apply to the flash of automatically timed stud welds. The

expelled metal around the base of the stud shall be designated as flash in conformance with Annex V of this code.

It shall not be defined as a fillet weld such as those

formed by conventional arc welding. The expelled metal,

which is excess to the weld required for strength, is not

detrimental but, on the contrary, is essential to provide a

good weld. The containment of this excess molten metal

around a welded stud by the ferrule (arc shield) assists in

securing sound fusion of the entire cross section of the

stud base. The stud weld flash may have nonfusion in its

vertical leg and overlap on its horizontal leg, and it may

contain occasional small shrink fissures or other discontinuities that usually form at the top of the weld flash

with essentially radial or longitudinal orientation, or

both, to the axis of the stud. Such nonfusion, on the vertical leg of the flash, and small shrink fissures shall be

acceptable.

7.5 Technique

Figure 7.2 Typical Tension Test Fixture

(see 7.3.2)

7.5.1 Studs shall be welded with automatically timed stud

welding equipment connected to a suitable source of direct current electrode negative (DCEN) power. Welding

voltage, current, time, and gun settings for lift and plunge

should be set at optimum settings, based on past practice,

recommendations of stud and equipment manufacturer,

or both. AWS C5.4, Recommended Practices for Stud

Welding, should also be used for technique guidance.

rial to the extent necessary to obtain satisfactory welds.

These areas may be cleaned by wire brushing, scaling,

prick-punching, or grinding. Extreme care should be exercised when welding through metal decking.

7.5.2 If two or more stud welding guns are to be operated

from the same power source, they shall be interlocked so

that only one gun can operate at a time, and so that the

power source has fully recovered from making one weld

before another weld is started.

7.4.4 The arc shields or ferrules shall be kept dry. Any

arc shields which show signs of surface moisture from

dew or rain shall be oven dried at 120 C [250 F] for two

hours before use.

7.5.3 While in operation, the welding gun shall be held in

position without movement until the weld metal has

solidified.

7.4.5 Longitudinal and lateral spacings of stud shear connectors (type B) with respect to each other and to edges

of beam or girder flanges may vary a maximum of 25 mm

[1 in.] from the location shown in the drawings. The

clear distance between studs shall not be less than 25 mm

[1 in.] unless approved by the Engineer. The minimum

distance from the edge of a stud base to the edge of a

flange shall be the diameter of the stud plus 3 mm [1/8 in.]

but preferably not less than 40 mm [1-1/2 in.].

7.5.4 Welding shall not be done when the base metal

temperature is below 20 C [0 F] or when the surface is

wet or exposed to falling rain or snow.

7.5.4.1 When the temperature of the base metal is

below 0 C [32 F], one additional stud in each 100 studs

welded shall be tested by methods described in 7.7.1.3

and 7.7.1.4, except that the angle of testing shall be approximately 15 . This is in addition to the first two studs

tested for each start of a new production period or change

in set-up.

7.4.6 After welding, arc shields shall be broken free from

studs to be embedded in concrete, and, where practical,

from all other studs.

7.4.7 The studs, after welding, shall be free of any discontinuities or substances that would interfere with their

intended function. However, nonfusion on the legs of the

flash and small shrink fissures are acceptable.

7.5.4.2 Set-up includes stud gun, power source, stud

diameter, gun lift and plunge, total welding lead length, or

changes greater than 5% in current (amperage) and time.

157

Reproduced with the permission of the American Welding Society (AWS), Miami, Florida - 09/15/2011

AASHTO/AWS D1.5M/D1.5:2002

STUD WELDING

Reproduced with the permission of the American Welding Society (AWS), Miami, Florida - 09/15/2011

7.5.5 At the option of the Contractor, studs may be fillet

welded by the SMAW, provided the following requirements shall be met:

(2) Studs which are welded through decking. The

tests should be with material representative of the condition to be used in construction.

(3) Studs welded to steels other than those described

in 1.2.2.

7.5.5.1 The minimum fillet size to be used shall be the

larger of those required in Table 2.1 or Table 7.2.

7.6.2 Responsibilities for Tests. The Contractor or stud

applicator shall be responsible for the performance of

these tests. Tests may be performed by the Contractor or

stud applicator, the stud manufacturer, or by another testing agency satisfactory to all parties involved.

7.5.5.2 Welding shall be done with low-hydrogen

electrodes 4.0 mm [5/32 in.] or 4.8 mm [3/16 in.] in diameter except that a smaller diameter electrode may be

used on studs 10 mm [3/8 in.] or less in diameter or for

out-of-position welds.

7.6.3 Preparation of Specimens

7.5.5.3 The stud base shall be prepared so that the

base of the stud fits against the base metal.

7.6.3.1 Test specimens shall be prepared by welding

the studs being qualified to specimen plates of M270M

(M270) Grade 250 (36) (A 709M [A 709] Grade 250 [36])

steel or any base metal described in 1.2.2.

7.5.5.4 All rust and mill scale at the location of the

stud shall be removed from the base metal by grinding.

The end of the stud shall also be clean.

7.6.3.2 Weld position, nature of base metal and stud

surfaces, current, and time shall be recorded.

7.5.5.5 The base metal to which studs are welded

shall be preheated in conformance with the requirements

of Table 4.4.

7.6.4 Number of Specimens. Ten (10) specimens shall

be welded consecutively using recommended WPSs and

settings for each diameter, position, and surface

geometry.

7.5.5.6 Fillet welded stud bases shall be visually inspected per 6.5.

7.6.5 Tests Required. The ten (10) specimens shall be

tested using one or more of the following test methods:

bending, torquing, or tensioning.

7.6 Stud Application Qualification

Requirements

7.6.6 Test Methods

7.6.1 Prequalification. Studs which are shop or field applied in the flat (down-hand) position to a planar and horizontal surface shall be deemed prequalified by virtue of

the manufacturers stud-base qualification tests (Annex

VI), and no further application testing is required. The

limit of flat position is defined as 0 15 slope on the surface to which the stud is applied.

The following are some non-prequalified stud applications that require tests of this section:

(1) Studs which are applied on nonplanar surfaces or

to a planar surface in the vertical or overhead positions.

7.6.6.1 Bend Test. Studs shall be bend tested by being

bent 90 from their original axis. A stud application shall

be considered qualified if the studs are bent 90 and fracture occurs in the plate or shape material or in the shank

of the stud and not in the weld.

7.6.6.2 Torque Test. Studs shall be torque tested

using a torque-test arrangement that is substantially in

conformance with Figure 7.3. A stud application shall be

considered qualified if all test specimens are torqued to

destruction without failure in the weld.

7.6.6.3 Tension Test. Studs shall be tension tested to

destruction using any machine capable of supplying the

required force. A stud application shall be considered

qualified if the test specimens do not fail in the weld.

Table 7.2

Minimum Fillet Weld Size for Small

Diameter Studs (see 7.5.5.1)

Stud Diameter, ,

mm [in.]

Minimum Fillet Weld Size,

mm [in.]

10 [3/8]

10 [3/8] < 25 [1]

> 25 [1]

6 [1/4]

8 [5/16]

10 [3/8]

7.6.7 Application Qualification Test Data shall include

the following:

(1) Drawings that show shapes and dimensions of

studs and arc shields

(2) A complete description of stud and base materials

and a description (part number) of the arc shield

(3) Welding position and settings (current, time)

(4) A record which shall be made for each qualification and that record shall be available for each contract

158

Reproduced with the permission of the American Welding Society (AWS), Miami, Florida - 09/15/2011

STUD WELDING

AASHTO/AWS D1.5M/D1.5:2002

Reproduced with the permission of the American Welding Society (AWS), Miami, Florida - 09/15/2011

7.7 Production Control

7.7.1 Preproduction Testing

7.7.1.1 Before production welding with a particular

set-up (see 7.5.4.2) and with a given size and type of

stud, and at the beginning of each days or shifts production, testing shall be performed on the first two studs that

are welded. The stud technique may be developed on a

piece of material similar to the production member in

thickness and properties. If actual production thickness

is not available, the thickness may vary plus or minus

25 percent. All test studs shall be welded in the same

general position as required on the production member

(flat, vertical, or overhead).

General Note: The dimensions shall be appropriate to the size of

the stud. The threads of the stud shall be clean and free of lubricant other than the residue of cutting oil.

7.7.1.2 Instead of being welded to separate material,

the test studs may be welded on the production member,

except when separate plates are required by 7.7.1.5.

Required Torque for Testing Threaded Studs

Nominal Diameter and

Thread Pitch (mm)

Testing Torque (J)

M61

M 8 1.25

M 10 1.5

M 12 1.75

M 14 2

M 16 2

M 20 2.5

M 22 2.5

M 24 3

6

12

20

50

73

100

180

285

430

7.7.1.3 The test studs shall be visually examined.

They shall exhibit full 360 flash.

7.7.1.4 In addition to visual examination, the test shall

consist of bending the studs after they are allowed to

cool, to an angle of approximately 30 from their original

axes by either striking the studs on the head with a hammer or placing a pipe or other suitable hollow device

over the stud and manually or mechanically bending the

stud. At temperatures below 10 C [50 F], bending shall

preferably be done by continuous slow application of

load. For threaded studs, the torque test of Figure 7.3

shall be substituted for the bend test.

Required Torque for Testing Threaded Studs

Nominal Diameter

of Studs

(in.)

Threads per inch

and Series

Designated

1/4

1/4

28 UNF

20 UNC

5.0

4.2

5/16

5/16

24 UNF

18 UNC

9.5

8.6

3/8

3/8

24 UNF

16 UNC

17.0

15.0

7/16

7/16

20 UNF

14 UNC

27.0

24.0

1/2

1/2

20 UNF

13 UNC

42.0

37.0

9/16

9/16

18 UNF

12 UNC

60.0

54.0

5/8

5/8

18 UNF

11 UNC

84.0

74.0

3/4

3/4

16 UNF

10 UNC

147.0

132.0

7/8

7/8

14 UNF

9 UNC

234.0

212.0

1.0

1.0

12 UNF

8 UNC

348.0

318.0

Testing Torque

(ft-lb)

7.7.1.5 If on visual examination the test studs do not

exhibit 360 flash, or if on testing, failure occurs in the

weld zone of either stud, the WPS shall be corrected, and

two more studs shall be welded to separate material or on

the production member and tested in conformance with

the provisions of 7.7.1.3 and 7.7.1.4. If either of the second two studs fails, additional welding shall be continued

on separate plates until two consecutive studs are tested

and found to be satisfactory before any more production

studs are welded to the member.

7.7.2 Production Welding. Once production welding

has begun, any changes made to the welding set-up (see

7.5.4.2) as determined in 7.7.1 shall require that the testing in 7.7.1.3 and 7.7.1.4 be performed prior to resuming

production welding.

7.7.3 In production, studs on which a full 360 flash is

not obtained may, at the option of the Contractor, be

repaired by adding the minimum fillet weld as required

by 7.5.5 in place of the missing flash. The repair weld

shall extend at least 10 mm [3/8 in.] beyond each end of

the discontinuity being repaired.

Figure 7.3 Torque Testing Arrangement

and Table of Testing Torques (see 7.6.6.2)

159

Reproduced with the permission of the American Welding Society (AWS), Miami, Florida - 09/15/2011

AASHTO/AWS D1.5M/D1.5:2002

STUD WELDING

Reproduced with the permission of the American Welding Society (AWS), Miami, Florida - 09/15/2011

7.7.4 Operator Qualification

7.7.5.5 The areas of components exposed to view in

completed structures shall be made smooth and flush

where a stud has been removed.

7.7.4.1 The preproduction test required by 7.7.1, if

successful, shall also serve to qualify the stud welding

operator.

7.8 Inspection Requirements

7.7.4.2 Before any production studs are welded by an

operator not involved in the preproduction set-up of

7.7.1, the first two studs welded by the operator shall be

tested in conformance with 7.7.1.3 and 7.7.1.4. When

two consecutively welded studs have been tested and

found satisfactory, the operator may then weld production studs.

7.8.1 If visual inspection reveals any stud that does not

show a full 360 degree flash or any stud that has been repaired by welding, such stud shall be bent to an angle of

approximately 15 degrees from its original axis.

7.8.2 The method of bending shall be in conformance

with 7.7.1.4. The direction of bending for studs with less

than a 360 degree flash shall be opposite to the missing

portion of the flash.

7.7.5 If an unacceptable stud has been removed from a component subjected to tensile stresses, the area from which

the stud was removed shall be made smooth and flush.

7.8.3 Threaded studs shall be torque tested. Torque testing shall be in conformance with Figure 7.3.

7.7.5.1 Where in such areas the base metal has been

pulled out in the course of stud removal, SMAW with

low-hydrogen electrodes in conformance with the requirements of this code shall be used to fill the pockets,

and the weld surface shall be ground flush.

7.8.4 The inspector, where conditions warrant, may select a reasonable number of additional studs to be subjected to the tests described in 7.8.1.

7.8.5 The bent stud shear connectors (Type B) and other

studs to be embedded in concrete (Type A) that show no

sign of failure shall be acceptable for use and left in the

bent position. All bending and straightening when required shall be done without heating, before completion

of the production stud welding operation, except as

otherwise provided in the contract.

7.7.5.2 In compression areas of members, if stud failures are confined to shanks or fusion zones of studs, a

new stud may be welded adjacent to each unacceptable

area in lieu of repair and replacement on the existing weld

area (see 7.4.3). If base metal is pulled out during stud

removal, the repair provisions shall be the same as for

tension areas, except that when the depth of discontinuity

is the lesser of 3 mm [1/8 in.] or 7 percent of the basemetal thickness, the discontinuity may be faired by

grinding in lieu of filling with weld metal.

7.8.6 If, in the judgment of the Engineer, studs welded

during the progress of the work are not in conformance

with code provisions, as indicated by inspection and testing, corrective action shall be required of the Contractor

at the Contractors expense. The Contractor shall make

the set-up changes necessary to insure that studs subsequently welded will meet code requirements.

7.7.5.3 Where a replacement stud is to be provided,

the base-metal repair shall be made prior to welding the

replacement stud.

7.8.7 At the option and the expense of the Owner, the

Contractor may be required, at any time, to submit studs

of the types used under the contract for a qualification

check in conformance with the procedures of Annex VI.

7.7.5.4 Replacement studs (other than threaded type

which should be torque tested) shall be tested by bending

to an angle of approximately 15 from their original axis.

160

Reproduced with the permission of the American Welding Society (AWS), Miami, Florida - 09/15/2011

You might also like

- Aws D1-5Document3 pagesAws D1-5Angel Cipagauta0% (1)

- C955 09Document4 pagesC955 09jacr27No ratings yet

- Aashto M-180 PDFDocument11 pagesAashto M-180 PDF48181No ratings yet

- NR-L3-CIV-140-79C (Issue 2) - Section 79 Sheet Pile Walls (Mar 2010)Document4 pagesNR-L3-CIV-140-79C (Issue 2) - Section 79 Sheet Pile Walls (Mar 2010)sandycastleNo ratings yet

- PS 1804 (S)Document19 pagesPS 1804 (S)dzilioNo ratings yet

- ps1791s WELD SCREWS PROJECTION WELDINGDocument10 pagesps1791s WELD SCREWS PROJECTION WELDINGWinb SunNo ratings yet

- ANSI C80.1-2005 For Electrical Rigid Steel Conduit PDFDocument11 pagesANSI C80.1-2005 For Electrical Rigid Steel Conduit PDFErnestoNo ratings yet

- Norma Astm A 496Document6 pagesNorma Astm A 496Carlos Enrique AquinoNo ratings yet

- Design of Steel Structures: Materials, Connections, and ComponentsFrom EverandDesign of Steel Structures: Materials, Connections, and ComponentsNo ratings yet

- Repot On SMS-2 JSPL, Raigarh FinalDocument45 pagesRepot On SMS-2 JSPL, Raigarh FinalRahul Pandey100% (1)

- Weicco India HangersDocument4 pagesWeicco India HangersDnyaneshwarNo ratings yet

- Electrode CalculationDocument2 pagesElectrode Calculationtejasp8388100% (1)

- Stud Welding: 7.1 ScopeDocument8 pagesStud Welding: 7.1 ScopeAndrés OchoaNo ratings yet

- STUD WELDING REQUIREMENTS From AWS D1.1-D 1.1M-2015Document10 pagesSTUD WELDING REQUIREMENTS From AWS D1.1-D 1.1M-2015Mark Darrel AranasNo ratings yet

- 7.0 Stud Welding-1Document1 page7.0 Stud Welding-1Rohit KambleNo ratings yet

- A 704 - A 704M - 96 Qtcwnc9bnza0ts1sruqDocument4 pagesA 704 - A 704M - 96 Qtcwnc9bnza0ts1sruqdelta lab sangliNo ratings yet

- 02 Samss 008Document11 pages02 Samss 008inatt101No ratings yet

- Shop Welding InspectionDocument4 pagesShop Welding InspectionIndra Nath MishraNo ratings yet

- Steel Tapping Screws For Cold-Formed Steel Framing ConnectionsDocument5 pagesSteel Tapping Screws For Cold-Formed Steel Framing ConnectionsAlvaro Alexis Mendoza PradaNo ratings yet

- Pearlitic Malleable Iron: Standard Specification ForDocument5 pagesPearlitic Malleable Iron: Standard Specification Forquiensabe0077No ratings yet

- Astm A574Document8 pagesAstm A574nmclaughNo ratings yet

- Fabricated Deformed Steel Bar Mats For Concrete ReinforcementDocument3 pagesFabricated Deformed Steel Bar Mats For Concrete ReinforcementJosé Ramón GutierrezNo ratings yet

- STD Spec For Piping WeldingDocument14 pagesSTD Spec For Piping WeldingknsaravanaNo ratings yet

- Principles and Practices of Stud Welding: State-Of-The-Art PaperDocument0 pagesPrinciples and Practices of Stud Welding: State-Of-The-Art PaperTenkre TenNo ratings yet

- Hamad International Airport Jet Fuel System Expansion: 00 31/01/2019 Issued For Construction Ms LW LW DPDocument29 pagesHamad International Airport Jet Fuel System Expansion: 00 31/01/2019 Issued For Construction Ms LW LW DPsrp. mohammedNo ratings yet

- A 748 - A 748M - 87 R03 Qtc0oc9bnzq4tq - PDFDocument2 pagesA 748 - A 748M - 87 R03 Qtc0oc9bnzq4tq - PDFMung Duong XuanNo ratings yet

- Bolts and Rivets Tension On Nominal Gross AreaDocument1 pageBolts and Rivets Tension On Nominal Gross AreaArief MulyadiNo ratings yet

- 05210-1 TCC in Riyadh Residential Complex J10-13300 Steel JoistsDocument7 pages05210-1 TCC in Riyadh Residential Complex J10-13300 Steel JoistsuddinnadeemNo ratings yet

- Materials System SpecificationDocument7 pagesMaterials System Specificationaanouar77No ratings yet

- Shielded Transition Couplings For Use With Dissimilar DWV Pipe and Fittings Above GroundDocument4 pagesShielded Transition Couplings For Use With Dissimilar DWV Pipe and Fittings Above GroundPaulo GalvãoNo ratings yet

- A 667 - A 667M - 87 R03 Qty2ny9bnjy3tqDocument2 pagesA 667 - A 667M - 87 R03 Qty2ny9bnjy3tqdelta lab sangliNo ratings yet

- C 1460 - 04 - Qze0njaDocument4 pagesC 1460 - 04 - Qze0njaSamuel EduardoNo ratings yet

- Astm A574Document9 pagesAstm A574Jose Angel RodriguezNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 10200-1 Louvers and VentsDocument6 pagesITCC in Riyadh Residential Complex J10-13300 10200-1 Louvers and VentsuddinnadeemNo ratings yet

- Field Welding Field Welding Field Welding Field Welding Manual Manual Manual ManualDocument14 pagesField Welding Field Welding Field Welding Field Welding Manual Manual Manual Manualjaheer1No ratings yet

- A574Document7 pagesA574KAROLNo ratings yet

- Shielded Transition Couplings For Use With Dissimilar DWV Pipe and Fittings Above GroundDocument4 pagesShielded Transition Couplings For Use With Dissimilar DWV Pipe and Fittings Above GroundFernando Da RosNo ratings yet

- General Specification FOR Material, Fabrication and Installation of StructureDocument58 pagesGeneral Specification FOR Material, Fabrication and Installation of Structuredang_noex56% (9)

- Split Tee Specifications and DrawingsDocument7 pagesSplit Tee Specifications and DrawingsFareha AbdelkaderNo ratings yet

- General Technical SpecificationsDocument13 pagesGeneral Technical SpecificationsLainhatanhNo ratings yet

- Index PHP PDFDocument9 pagesIndex PHP PDFEloise CamposNo ratings yet

- ASTM A47-A47M - Spec For Ferritic Malleable Iron Castings PDFDocument5 pagesASTM A47-A47M - Spec For Ferritic Malleable Iron Castings PDFLuis Albanes100% (3)

- Pipe JointDocument12 pagesPipe Jointimrankhan22No ratings yet

- Stress Relieving As Per IS 2825Document4 pagesStress Relieving As Per IS 2825Sudhir DwivediNo ratings yet

- Suryadev T.S.for STRL FinalDocument46 pagesSuryadev T.S.for STRL Finalkrmcharigdc100% (1)

- Structural Steel Spec. and ConstructionDocument12 pagesStructural Steel Spec. and ConstructionAshwani DograNo ratings yet

- Layout of Oil & Heavy Berth Dolphin CatwalkDocument11 pagesLayout of Oil & Heavy Berth Dolphin CatwalkJoel Jeffery SarkarNo ratings yet

- 32 Samss 031Document7 pages32 Samss 031naruto256No ratings yet

- CCCC Et Ha Spec ST 649 00 Reply BDocument14 pagesCCCC Et Ha Spec ST 649 00 Reply B黄赛赛No ratings yet

- Designation B 828 - 002Document11 pagesDesignation B 828 - 002Raron1No ratings yet

- Smaw CSDocument5 pagesSmaw CSMahdi KaboodanianNo ratings yet

- Steel Quiz: Manual (Document2 pagesSteel Quiz: Manual (Seismotec EngineersNo ratings yet

- Fab & Erection Pro 20000klR1Document17 pagesFab & Erection Pro 20000klR1Gandhi OnoNo ratings yet

- Asme Section II A Sa-263Document8 pagesAsme Section II A Sa-263Anonymous GhPzn1xNo ratings yet

- (D-121) Pressure Vessels of Low Alloy Steel - Rev.1 PDFDocument8 pages(D-121) Pressure Vessels of Low Alloy Steel - Rev.1 PDFmihir_jha2No ratings yet

- UNIT NO. 5.8 Welding of Structural Steel: © Lifting Equipment Engineers Association 2012 - Training/5-8uDocument13 pagesUNIT NO. 5.8 Welding of Structural Steel: © Lifting Equipment Engineers Association 2012 - Training/5-8uYAKUBU A. AROGENo ratings yet

- Welded Steel Plain Bar or Rod Mats For Concrete ReinforcementDocument2 pagesWelded Steel Plain Bar or Rod Mats For Concrete ReinforcementGustavo SuarezNo ratings yet

- 5504Document10 pages5504hhr2412No ratings yet

- Essar Oil Limited Vadinar Refinery Expansion: 1O1O1O (O1Document17 pagesEssar Oil Limited Vadinar Refinery Expansion: 1O1O1O (O1ashish_rocksNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- ROYCHOUDHURY - Design of Machine Elements PDFDocument521 pagesROYCHOUDHURY - Design of Machine Elements PDFnoe martinezNo ratings yet

- BS WaterDocument0 pagesBS WaterAfrica OdaraNo ratings yet

- Portable Intermediate Flush Deck Stanchion: Standard Specification ForDocument4 pagesPortable Intermediate Flush Deck Stanchion: Standard Specification ForEduardoNo ratings yet

- SealsDocument142 pagesSealsvav137100% (1)

- Canam Steel DeckDocument168 pagesCanam Steel DeckAnonymous 8hx6hKN3No ratings yet

- Electrical Conductivity and ResistivityDocument3 pagesElectrical Conductivity and ResistivityYuvaraj SathishNo ratings yet

- PSV LeserDocument10 pagesPSV LeserArif LametNo ratings yet

- Oxy-Fuel Welding and CuttingDocument14 pagesOxy-Fuel Welding and CuttingImran Hanif LubisNo ratings yet

- Chemical Bonding Ans Key 01 To 14 1661942715773 1673836727008Document9 pagesChemical Bonding Ans Key 01 To 14 1661942715773 1673836727008STUDENT ARYANo ratings yet

- Basic Mechanical Engineering MCQ PDF Part 3Document10 pagesBasic Mechanical Engineering MCQ PDF Part 3kibrom atsbhaNo ratings yet

- API 6A Gate ValveDocument16 pagesAPI 6A Gate ValveJuan PabloNo ratings yet

- CoolFlow LV DatasheetDocument2 pagesCoolFlow LV DatasheetReuben WilliamsNo ratings yet

- АрилјеМетал CatalogDocument10 pagesАрилјеМетал CatalogAnonymous DjWqKpZ1No ratings yet

- Astm 355Document3 pagesAstm 355Felipe ToledoNo ratings yet

- Nipping of Reformer PigtailsDocument12 pagesNipping of Reformer PigtailsVinh Do Thanh50% (2)

- Controlador 4160Document12 pagesControlador 4160Antonio Castillo GNo ratings yet

- Butterfly Norris Series 285Document12 pagesButterfly Norris Series 285metasoniko2014No ratings yet

- Yg-1 V7plusa Endmill America YuDocument25 pagesYg-1 V7plusa Endmill America YuLuis CoolNo ratings yet

- Sheet Metal FastenersDocument15 pagesSheet Metal FastenersSudath KularathnaNo ratings yet

- FAMECADocument8 pagesFAMECADhimaz ZiroNo ratings yet

- Recreation of Ancient Iron Smelting ProcessDocument7 pagesRecreation of Ancient Iron Smelting ProcessDILRUKSHINo ratings yet

- Workshop Technology Question BankDocument3 pagesWorkshop Technology Question BankKamalakanta SahooNo ratings yet

- Experiment 1b - Identification of MaterialsDocument9 pagesExperiment 1b - Identification of MaterialsSeth Aboagye JnrNo ratings yet

- MK - Cable Support Systems PDFDocument18 pagesMK - Cable Support Systems PDFL100% (1)

- Sheet Metal Welding-Tips PDFDocument5 pagesSheet Metal Welding-Tips PDFMphilipTNo ratings yet

- STS-040 Mi3007 6in STS Series375 D8 WebDocument8 pagesSTS-040 Mi3007 6in STS Series375 D8 Webrhusseinpos4765No ratings yet

- A Handbook of Art Smithing, F. S. Meyer, 1896 PDFDocument215 pagesA Handbook of Art Smithing, F. S. Meyer, 1896 PDFPGAChamp100% (2)