Professional Documents

Culture Documents

Global Supply Chain Update

Uploaded by

Saikumar SelaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Global Supply Chain Update

Uploaded by

Saikumar SelaCopyright:

Available Formats

APR Supply Chain Council 2010

Global Supply Chain Update

Singapore, April 8th 2010

Security Systems

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

Main Message SCC 2009, Zhuhai

Lets see

what we actually have

achieved

how far we achieved

our Supply Chain

Excellence targets

what we are going to

do this year to continue

striving for Supply

Chain Excellence and

driving our supply

chain processes to

world class

Last SCC (when the economic crisis started) we asked to focus on results

Security Systems

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

SC Excellence @ ST | Major achievements

1

SC

integration

8

2

IT

harmonization

Transport

optimization

Value

added

services

to

continuously

drive STs

supply chain

processes to

world class!

Supplier

integration

6

Order and

prospect

mgmt.

Competence

mgmt. 3

Product

portfolio

mgmt.

4

We strive for SC excellence and we drive our SC processes to world class

Security Systems

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

Achievements (1/4) | Integration and Harmonization

1 Supply Chain Integration

Set-up of one integrated supply chain merging the formerly

separated supply chains of ST and Telex with entirely integrated

processes, infrastructure, organization and IT systems

Migration of BU CO from Oracle to SAP and successful go live

Realizing economies of scale by relocation of Telex products into

one joint CDC and one BU orderdesk per region

2 IT Harmonization

SAP rolled out to NSO CN & HK, NSO NL exp/ASA EMEA, NSO

US exp, BU CRS

BeAT online ordering and tracking tool rolled out to STDE, STNL,

STES, STPO and STNA further roll-outs in SEE, STBE, STGB and

STFR planned for 2010

Security Systems

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

Achievements (2/4) | Competence and Complexity

3 Competence management @ ST (CptM@ST)

CptM@ST supports a structured development of our personnel to

the right defined qualification level for their respective roles

Set-up of the Supply Chain Academy (SCA), covering the functions

Logistics, Purchasing and Manufacturing

Gap analysis performed and training measures developed

4 Product portfolio management

Reduced supply chain complexity (products, parts, processes) and

cost by streamlining of the product portfolio achieved portfolio

reduction c. 15 %

Setup of a guideline to consider impacts on supply chain costs in

product design (standardization and postponement)

Security Systems

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

Achievements (3/4) | Supply Chain Processes

5 Order and prospect management

Early information about expected lead time to NSO and customer

through requested date proposal

Prospect management process defined and rolled out

Integration of order desks NSO exp NL and regional BU EMEA

6 Supplier integration

Rollout of SupplyOn to better integrate our suppliers and hence to

extend our supply chain

Lead time and inventory reduction by standardized procurement

models (supported by SupplyOn) which also helps to reduce the

complexity in dealing with c. 1500 raw material suppliers

Number of raw material suppliers has been reduced by c. 20 %

Savings of c. 7 m EUR for raw materials and trade goods compared

to 2008

Security Systems

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

Achievements (4/4) | Supply Chain Network

7 Value added services

Value adding services set-up in CDC for Make-to-Order

configuration (e. g. assembling enclosure, setting country code,

testing) resulting in closure of six local warehouses

Commercial return checks now done not only for packing but also

for version, release, use etc.

8 Transport optimization

Global transport cost visibility for c. 80 % of our transport cost

achieved by rolling out a transport management system

Freight invoice verification available

Transport policies defined to foster consolidation of shipments

Tariff renegotiation (e. g. sea freight APR<->EMEA) and better cost

consciousness contributing to freight cost savings of c. 13 m EUR

compared to 2008

Security Systems

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

Supply Chain Excellence @ ST | Results

Stabilize

Delivery Performance

to >90% / >98%

RLIP

90,0%

88,5%

83,0%

80

65,5%

2007

Act .

70

2008

Act .

2009

Act .

2010

Plan

93,1%

96,4%

97,0%

2008

Act .

2009

Act .

2010

Plan

83,1%

100

Delivery

Performance

2007

Act .

Avoid lost

sales

SC Costs

12,7%

90

CLIP

GEZ

79

12,5%

77

11,4%

77

11,4%

72

2007

Act .

2008

Act .

2009

Act .

Reduce

Supply Chain Costs

to <10%

2010

Plan

5

10

Supply

Chain

Excellence

15

20

Costs

Reduce supply

chain cost

2007

Act .

Capital

employed

Manage working

capital

2008

Act .

2009

Act .

2010

Plan

Reduce

GEZ

to <60 days

Great progress made on Costs and Delivery Performance GEZ will follow!

Security Systems

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

Monthly Delivery Performance (xLIP) 2009/2010

100%

CLIP Target 2009: 96,8%

Monthly Delivery Performance

96,6%

95%

CLIP Target 2010: 97,0%

94,3%

96,4%

93,1%

96,4%

RLIP Target 2010: 90,0%

89,9%

90%

96,2%

96,4%

88,5%

86,0%

85%

RLIP Target 2009: 88,1%

83,0%

85,5%

82,0%

80%

2008

month Avg.

85,3%

2009

Avg.

Delivery perf. dropped in Q4, current RLIP 5%-points below PY/target

Security Systems

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

Weekly Delivery Performance and Backlog

Weekly Delivery Performance and Backlog (BLP)

100%

35

CLIP ST

95%

30

25

90%

RLIP ST

85%

20

15

10

80%

32,4 29,6 29,1 27,5 27,3 26,8 27,2 26,3 25,7 25,4 26,1 24,2 23,9 21,3 19,6 18,9

75%

0

week 48 49 50 51

2

3

4

5

6

7

8

9

10 11 12 13

Backlog @ 18,9 m EUR c. 6 m EUR above normal level of 13 m EUR

Security Systems

10

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

Weekly Delivery Performance and Backlog (BLP)

VS

100%

CO

20

100%

20

18

95%

16

12

95%

16

12

85%

80%

75%

100%

16

12

95%

2

75%

90%

12

20

18

95%

16

14

90%

12

10

85%

10

85%

6

80%

2

0

100%

14

48 49 50 51 2 3 4 5 6 7 8 9 10 11 12

CRS

16

10

75%

6

80%

18

14

80%

48 49 50 51 2 3 4 5 6 7 8 9 10 11 12

20

18

85%

10

ACS

20

90%

12

85%

48 49 50 51 2 3 4 5 6 7 8 9 10 11 12

FIR

95%

14

90%

48 49 50 51 2 3 4 5 6 7 8 9 10 11 12

100%

16

2

75%

18

95%

10

6

80%

20

14

90%

10

85%

100%

18

14

90%

IN

6

80%

2

75%

0

48 49 50 51 2 3 4 5 6 7 8 9 10 11 12

2

75%

0

48 49 50 51 2 3 4 5 6 7 8 9 10 11 12

Security Systems

11

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

Supply Chain Excellence @ ST | Inventory/GEZ 09

400

103

98

110

95

350

300

250

RSO

200

150

BU

100

50

MP

0

[m EUR]

80

94

92

88

88

80

100

86

84

82

80

80

GEZ avg.

209

41

106

75

207

214

47

43

99

76

104

81

77

90

80

70

201

42

97

76

195

44

93

73

202

184

178

40

172

167

40

163

39

158

37

37

151

148

37

36

33

91

68

89

63

87

60

83

60

80

60

179

77

57

73

71

55

54

41

39

87

103

60

50

40

30

20

65

73

10

0

12.08 Avg. 02.09 03.09 04.09 05.09 06.09 07.09 08.09 09.09 10.09 11.09 12.09 Avg.

08

09

Avg.

Plan

[days]

66 m EUR inventory reduction (31 %) in 2009 GEZ remains unchanged @ 80d

Security Systems

12

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

5

Inventory Development PB per RSO (in m EUR)

46,3

4

40,9

4,1

43,1

4,3

4,6

3

43,8

42,2

4,6

4,5

39,9

4,2

39,9

4,6

39,1

39,1

37,2

36,9

36,6

3,3

3,3

3,4

4,1

35,8

3,2

39,1*

41,5

3,5

4,0

4,1

21,6

21,6

13,5

13,5

14,5

12.09

FC

BP

33,3

3,5

AMEC

24,5

24,3

2

22,4

23,1

24,1

23,5

22,0

21,8

21,5

20,8

20,5

20,8

19,4

18,8

APR

1

17,7

14,5

13,9

14,5

15,1

13,8

13,5

13,6

13,1

13,1

12,4

13,2

11,0

EMEA

12.08

12.08

02.09

03.09

04.09

05.09

06.09

07.09

08.09

09.09

10.09

11.09

12.09

* internal

EMEA RSO inventory decrease from Russia and Italy

Security Systems

13

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

GEZ Development PB per RSO (in days)

70

74

62

65

60

61

65

60

59

58

57

55

52

54

51

APR

50

50

40

30

20

10

18

14

5

12.08

21

15

6

02.09

20

15

20

20

20

19

19

19

18

18

14

14

14

13

14

13

13

13

03.09

04.09

05.09

06.09

08.09

09.09

10.09

11.09

07.09

-GEZ unchanged

Security Systems

14

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

18

17

12

12

12.09

FC

16

RSO

12

EMEA

AMEC

BP

APR Supply Chain Council 2010

Supply Chain Costs (in m EUR/% NGU) | ST PB

Inventory Cost

Freight Cost

thereof Inbound

thereof Outbound

Packaging Cost

Log. Personnel Cost

thereof Physical Logistics

thereof Administrative Logistics

Duties

TOTAL SUPPLY CHAIN COST

Act 08

Act 09

14,3

40,0

16,2

23,8

1,3

45,0

25,7

19,3

12,8

113,4

11,2

26,4

9,9

16,5

1,1

41,0

24,4

16,6

9,6

89,2

Act 08

% NGU

1,6%

4,4%

1,8%

2,6%

0,1%

4,9%

2,8%

2,1%

1,4%

12,5%

Act 09

% NGU

1,4%

3,4%

1,3%

2,1%

0,1%

5,2%

3,1%

2,1%

1,2%

11,4%

Plan 10

% NGU

1,4%

3,5%

1,6%

1,9%

0,1%

5,1%

2,9%

2,2%

1,2%

11,4%

In 2009 supply chain costs are 11,4% of NGU, which is 1,1%-points below PY

and 0,9%-points below plan. These savings contribute 7,1 m EUR vs. plan and

8,7 m EUR vs. PY to STs DB5 despite effects like fixed/ variable costs and under

proportional decrease in log. activity vs. NGU decrease

Savings in supply chain costs contribute 8,7 m EUR to STs DB5 in 2009

Security Systems

15

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

Log. Personnel Costs | Administrative Logistics

Personnel

Capacity

Costs

per PC

[#]

358

30

34

13

39

39

151

43

[k EUR/ 34

PC]

76

55

53

15

29

32

88

2,3

1,9

0,7

0,6

Administrative

Personnel Costs

[in m EUR]

0,2

12,4

12,4

4,5

1,4

0,8

Total

BU

Planning

BU Order CDC Admin

Desk

MP

Planning

MP Admin

NSO Order ASA Admin

Desk

HQ

Order desk activities in BU and NSO account for c. 50% of PC and costs

Security Systems

16

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

Log. Personnel Costs | Physical Logistics

Personnel

Capacity

[#]

398

108

240

29

21

11

34

57

(86,5)

Costs [k EUR/

per PC

PC]

23

40

4,4

(3,4)

Physical

Personnel Costs

[in m EUR]

9,4

including

CDC Lanc.

CDC Mor

CDC Tilbug

(ST-Staff)

(Ex-CDC Sab)

2,8

1

1,2

Total

CDC Operations

MP Whse.

NSO Whse.

ASA Whse.

Physical personnel costs mainly generated by CDC will go down in 2010

Security Systems

17

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

Supply Chain Excellence @ ST | Projects 2010

Supply chain performance management

Supply Chain Performance

Management

Supply chain integration

STEP-IN SAP roll-out in NSOs

and manufacturing plants

Supply chain network

Supply chain organization

Supply Chain

Improvement

Organization

SC collaboration

Customer

Satisfaction

Supplier Collaboration

Product portfolio mgmt.

Quality

Delivery

Costs

Source

Make

Plan

Supply chain process

Planning Concept (VMI, CIP)

Process Excellence

Portfolio Management

IT

Deliver

Y

Z

& performance improvement

Productivity Improvement

Lead Time Management

Security Systems

18

Distribution Network

Transport and Customs

Optimization

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

Competence Management @ ST

Roles

Structured process for

associate development

As Is competency

assessment and definition of

development actions

Competence

Management Process

11 Bosch ST wide roles in

logistics, 9 in purchasing and

15 in manufacturing

Competency Model

STs Supply Chain, Process

& SAP Training

Bosch Supply Chain

Academy

Supply Chain Academy

Security Systems

19

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

Supply Chain Academy Approach

I. Preparation

3

Product Know How

Business Administration

Purchasing Basics

Purchasing

Finance and

Cost Accounting and Planning

Controlling

Logistics Basics

Logistics

RB-/GB-Logistics

Procurement Concepts

Transportation and Storage Concepts

Quality in Logistics

Production Planning and Control Concepts

Supply Chain Design

Supply Chain Planning Tools

Sales Planning Processes and Standard Distribution

Inventory Management Processes

Production Planning and Control Process

Procurement Processes

Transportation and Storage Processes

Competence

Field

Competence

Business Administration

Sales and

Interface between Logistics and Sales&Marketing

LOGCompetence

Matrix

Status: 01/23/2009

Competence field

(Level 1)

Competence field

Technology

Competence area

(Leve l 2)

Enginee ring

Production

Customs and Commercial Law

Transportation and Assurance Law, Logistics

Guarantee and Product Liability

Metaprofessional Competences

Enterpreneural

Mindset &

Application of Leadership Instruments

Leadership

Leadership Strength

Future Orientation

Results Orientation

Methodological

Project Management

Competence

Competence field

Business

Administration

Purchasing Basics

2

2

W arehouse

Ope rator

(UBG+AA)

Cost Accounting and Plann ing

Finance and

Controlling

Logistics

Production Planning and

Contro l Concepts

Sup ply Chain Design

Methodological

Competencies

Leadership

Entrepreneurial

Mindset

Project

Management

Process

Management

Working

Techniques

Communication

Cooperation

Warehouse &

Tran sport

Coordinator

(UBG+AA)

Warehouse &

Transp ort

Officer

(UBG+AA)

Project and

Process

M anager

(UBG+AA)

1 2 3 4

1

2

LOGCompetence

Matrix

Line Manager

Logistics

(UBG+AA)

1 2 3 4 5

2

Project Ma nagement

Process Managem ent

12

BPS System Understanding

Quality Management

23

34

45

CW 44

CW 45

RB

Advanced

seminar

SCA-LOG

02

RB-/GB-Logistics

ST

Basic

seminar

SCA-LOG

01

BPS 100

BPS-LLB

SCA- RB

LOG03

Inventory

Management

SCALOG04

Incoterms

RB

Products and

systems

IT Systems

Product Know-how

Business

Administration

Logistics

ST

GB-specific

RB

2

2

3

3

3

3

3

3

1

2

- No knowledge, Skill required

- Basic

3

4

5

- Competent

- Specialist

- Champion

Which is the rolespecific required

competency level?

Inventory Management

Process

Metaprofessional

RB

RB

SCA LOG06

SAP

Parameter

Which competencybuild up measures

are existing/ need to

be developed?

CW 46

CW 47

CW 48

CW 49

CW 50

Startletter

by BV

SC

Transportation & Storage

Concepts

3

3

3

2

Competence

2

2

3

2

Competence

Field

1

1

Competency

Category

Technology

2

2

2

1

1

1

3

1

2

1

2

1

3

1

1

2

3

Production

2 3 4 5

2

3

2

2

Procurement

Planner

(UBG+AA)

3

3

2

2

2

Competence

(Level 3)

Product Development Process

3

3

Engineering

2

3

2

1

1

1

2

2

2

2

2

1

1

1

2

1

1

2

2

2

1

3

2

2

2

2

2

2

1

1

Working Te chniques

Results Orientation

1

2

2

1

1

1

2

2

2

1

1

1

1

1

3

3

2

2

1

2

2

2

2

2

2

1

2

2

3

2

2

2

2

BPS-Meeting

28.10.09:

Information

about project

and CptM.setting

by LOG, PUR

Enabling

Instruction

for all target

groups

(HRD)

Transfering into

CptM.-tool

(HRD)

BU, CDC,

ASA, SC

1 Procurement

planner

2 Production

planner

Mail: Reminder

halftime by HRD

3 Distribution

planner

4 Customer order

desk officer

5Customer Service

7 Warehouse &

Monitoring KPIs and agreements with 3PL /

forwarders. Management and support of

WMS+TMS applications.

Ensuring Replenishment of DCs and plant-toplant deliveries. Production planning &

scheduling (including levelling).

8 Warehouse &

Ensuring In- and Outbound deliveries

(plants/DC) in regards to compliance with

customer requirements and foreign trade rules.

Responsible for demand planning based on

sales forecast. Sets planning parameters for

replenishment of associated DCs.

9 Project and

Responsible for supply chain projects, process

and IT system improvement activities +

logistics process optimization.

Handling incoming orders and Order change

management.

10 Line Manager

Formally responsible for a group or department

within the logistics function.

Not applicable for Bosch ST.

11

WH Systems and

HRL

HRL

Mail & Conference call:

How to use the

CptM-Tool by

HRD

Setting

Finishing competence profil,

role, level, measures

Transfering into CptM.-tool

Mail & Conference call:

Information about project

and CptM.-setting by HRD

operator

Not applicable for Bosch ST.

Transport

Officer

Process Manager

Logistics

STEP 1: General Data

STEP 2: Competence

Assessment

GAP Analysis

How does the CptM Tool

work?

Who will be evaluated?

What is the As Is competency

per employee?

Where are the competence

GAPs?

STEP 3: Definition of

Measures

Results

STEP 4: Summary of

Measures

Discussion/ MAG per

employeee

What are appropriate

measures to close the GAPs?

How many employees in Total

have GAPs where?

Which measures have been

defined for the department?

Which measures to fix during

MAG for the employee?

Mail: Last call for

analysis by HRD

Based on Gap-Analysis (= follow-up process)

Mail & Conference call:

Information about project

and CptM.-setting by HRD

HRL

Instructions

Data Aggregation

Mail: Reminder for

analysis E.CW51

by HRD

Mail: Reminder

halftime by HRD

Finishing

Enabling

Last adaption of CptM.-Setting

(MGE)

Instruction for

Manufacturing

(HRD)

Transfering into CptM.-tool

(HRD)

Analysis

HRL

HRL

Accomplishment of Gap-Analysis

Manufacturing

Mail: Reminder halftime by HRD

Manuf. & HRL

Mail & Conference

call: How to use the

CptM-tool by HRD,

MGE

Accomplishment of Performance Review (MAG)

Based on Gap-Analysis

(= follow-up process)

HRL

Mail: Reminder for analysis E.CW53 by HRD

Training Program

(Vorlesungsverzeichnis)

Engineering (AA)

Logistics

6 Warehouse

Transport

Coordinator

2010

Accomplishment of Performance Review (MAG)

Responsible for the procurement of semifinished goods, raw materials and trade goods

CW 53

BU, CDC, ASA,

SC

BU, CDC, ASA, SC

Mail & Conference call:

Information about project

and CptM.-setting

by LOG, PUR

BPS-Meeting

28.10.09: Information

about project and

CptM.-setting by

MGE

CW 52

Accomplishment of Gap-Analysis

Mail & Conference call:

How to use the CptM-tool

by HRD, LOG, PUR

BU, CDC, ASA

Manufacturing

CW 51

End of

Gap-Analysis

Finishing

Last adaption of

CptM.-Setting

(LOG, PUR)

2

Role Cluster

Definition

As Is Competency

Analysis

Implementation Plan

1

2

2

2

2

2

2

3

2

2

Transpo rtation- and Storage

Processes

Interface betwee n Logistics

1

and Sales & Marketing

Customs- and Commercial

1

Law

Transpo rtation- and Insurance 1

Law, Logistic Service Provider

Guarantee and Product L iability 1

Commun ication Skills and

Techniques

Cooperation

2

3

Sales Planning Processes and

Sta ndard Distribution

Inventory Man agement

Processes

Production Planning and

Contro l Processes

Procuremen t Processes

App lication of Lea dership

Application of

Instruments

Leadership

Leadership Strength

Leadership

Strength

Future Orie nta tion Future Orientation

Results

Orientation

Logistic Basics

RB-/GB-Logistics

Procuremen t Concepts

(Source and Deliver)

Transpo rtation- and Storage

Concepts

Quality in Logistics

Sup ply Chain Planning Tools

Social

Competencies

Which competencies

are needed for

LOG & PUR?

Customer

Order Desk

Officer

(UBG+AA)

Distribution

Planner

(UBG+AA)

Produ ction

Pla nner

(UBG+AA)

2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5

Competence area

(Level 2)

IT System s

Purchasing

Sales and

Marketing

Legal

Communication Skills and Techniques

Cooperation

1

1

BPS System Understanding

Products and

systems

Product Know-how

Process Management

Work Techniques

Social

Competences

Procurement

Planner

(UBG+AA)

Competence

(Level 3)

Product Developm ent Process

Quality Managem ent

Marketing

Legal Issues

Training Matrix

Target group: LOG/PUR

BU, CDC, SC, ASA

IT Systems

Target group:

HRL

Competence

Product Development Process

BPS

Quality Management

Concepts

Products and

Systems

Processes

Competence

Field

Technologie

Process

4

To Be Competency

Requirements

Target group:

Manufacturing

Competency

Matrix

TG: HRL

II. Implementation

Responsible for the warehouse in- and

outbound handling in the CDC/NSO.

Which roles do we

have in LOG &PUR?

Next step for CptM@ST is to derive competency GAPs and define measures

Security Systems

20

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

SCA Role Cluster Definition LOG

2

planner

BU Operational

Buyer

SC Operational

Buyer

Production

planner

SC Planner

3 Distribution

4 Customer order 6 Warehouse

planner

BU Planner

NSO Buyer

Planner

BU ASA Spare

Parts Planner /

Buyer

desk officer

CDC Order

Desk Officer

NSO Order

Desk Officer

NSO Counter

Sales Officer

BU ASA Order

Desk Officer

NSO ASA Order

Desk Officer

NSO RMA Desk

Officer

operator

Legend:

SC Supply Center

BU Business Unit

NSO National Sales Organisation

CDC - Continental Distribution Center

SC Material

Handler

SC Warehouse

Staff

SC Incoming

Quality Inspector

SC Coordinator

Inbound

CDC Inbound

Planner/

Coordinator

CDC Pick

Operator

CDC Packer

CDC Stock

Integrity

Coordinator

BU ASA

Warehouse

Operator

Not applicable for Bosch ST (not listed):

(5) Customer Service Logistics

(11) Warehouse Systems and Engineering (AA)

1 Procurement

46 ST LOG roles have been allocated to 9 Bosch wide role clusters

Security Systems

21

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

SCA Role Cluster Definition LOG

7 Warehouse &

Transport

Coordinator

CDC Application

Manager

(WMOS)

8 Warehouse &

Transport

Officer

SC Shipment

Officer

SC Foreign

Trade Repres.

SC Export

Control Officer

(ECO)

SC Warehouse

Supervisor

BU Export

Control Officer

(ECO)

CDC Customs

Supervisor

CDC Whse.

Manager

CDC Whse.

Supervisor

CDC Teamleader Outb

(WMOS)

NSO Whse.

Team Leader

NSO Export

Control Officer

(ECO)

NSO ASA Team

Leader

9 Project and

10 Line Manager

Process Manager

SCM Project

Manager

(Overall)

Supply Chain

Performance

Manager &

Controller

(Overall)

Logistics

Not applicable for Bosch ST (not listed):

(5) Customer Service Logistics

(11) Warehouse Systems and Engineering (AA)

Regional

Logistics

Manager

BU Logistics

Manager

BU Controller

(part of logistics

management)

SC Logistics

Manager

NSO Logistics

Manager

BU ASA Local

Service

Manager

Legend:

SC Supply Center

BU Business Unit

NSO National Sales Organisation

CDC - Continental Distribution Center

46 ST LOG roles have been allocated to 9 Bosch wide role clusters

Security Systems

22

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

GAP Analysis Key Figures

Manufacturing (MGE)

Purchasing (PUR)

Logistics (LOG)

[# employees]

Warehouse Operator

17

Role Cluster

Procurement Planner

30

26

Warehouse &Transport Officer

22

Production Planner

23

Customer Order Desk Officer

20

11

Distribution Planner 0 10

19

17

Project and Process Manager 12 9

12

12

Line Manager Logistics

11

11

4 43

Warehouse &Transport Coordinator 02 3

18

17

18

93

93

46

59

59

20

8

64

64

49

49

37

37

27

27

APR

AMEC

EMEA

55

GAP analysis performed for MAG 2010 in 2009 worldwide per Role Cluster

Security Systems

23

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

GAP Analysis

Manufacturing (MGE)

Purchasing (PUR)

Logistics (LOG)

Quality in Logistics

RB-/GB-Logistics

Sales Planning Processes and Standard Distribution Processes

Transportation- and Storage Concepts

Top Ten GAP Competencies

Transportation- and Storage Processes

Working Techniques

Process Management

BPS System Understanding

Purchasing Basics

Procurement Concepts (Source and Deliver)

Competencies

Cost Accounting and Planning

Production Planning and Control Processes

Project Management

Supply Chain Planning Tools

Product Development Process

Communication Skills and Techniques

Production Planning and Control Concepts

Future Orientation

Procurement Processes

Logistic Basics

Supply Chain Design

Customs- and Commercial Law

Results Orientation

Inventory Management Processes

IT Systems

Quality Management

Top Ten Best Competencies

Transportation- and Insurance Law , Logistic Service Provider

Cooperation

Leadership Strength

Application of Leadership Instruments

Product Know -how

Interface betw een Logistics and Sales & Marketing

Guarantee and Product Liability

0%

10%

GAP

20%

30%

As Is = To Be

40%

50%

60%

70%

80%

Higher

33 competencies per Role cluster have been evaluated

Security Systems

24

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

90%

100%

APR Supply Chain Council 2010

GAP Analysis Result Detail

# employees:

357

Logistics (LOG)

Top Ten GAP Competencies

Top Ten Best Competencies

Quality in Logistics

Inventory Management

Processes

RB-/GB-Logistics

IT Systems

Sales Planning Processes and Standard Distribution

Processes

Quality Management

Transportation- and Storage Concepts

Transportation- and Insurance

Law, Logistic Service Provider

Transportation- and Storage Processes

Cooperation

Working Techniques

Leadership Strength

Process Management

Application of Leadership

Instruments

BPS System Understanding

Product Know-how

Purchasing Basics

Interface between Logistics

and Sales & Marketing

Procurement Concepts (Source and Deliver)

Guarantee and Product

Liability

Prioritized

for 2010

0%

10% 20%

30% 40% 50% 60% 70%

80% 90% 100%

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

Major gaps in Logistics Quality and knowledge of RB-/GB-Logistics

Security Systems

25

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

100%

APR Supply Chain Council 2010

GAP Analysis Results

# employees:

37

Top Ten GAP Competencies

RC4 Customer Order Desk Officer

[% employees]

Cost Accounting and Planning

RB-/GB-Logistics

Working Techniques

Sales Planning Processes and Standard Distribution Processes

Product Development Process

Logistic Basics

Quality in Logistics

Communication Skills and Techniques

Transportation- and Storage Concepts

IT Systems

0%

GAP

As Is = To Be

10% 20% 30% 40% 50% 60% 70% 80% 90%

Higher

100

%

Cost Accounting and RB-/GB-Logistics are the biggest gaps

Security Systems

26

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

Supply Chain Excellence @ ST | Results

Stabilize

Delivery Performance

to >90% / >98%

RLIP

90,0%

88,5%

83,0%

80

65,5%

2007

Act .

70

2008

Act .

2009

Act .

2010

Plan

93,1%

96,4%

97,0%

2008

Act .

2009

Act .

2010

Plan

83,1%

100

Delivery

Performance

2007

Act .

Avoid lost

sales

SC Costs

12,7%

90

CLIP

GEZ

79

12,5%

77

11,4%

77

11,4%

72

2007

Act .

2008

Act .

2009

Act .

Reduce

Supply Chain Costs

to <10%

2010

Plan

5

10

Supply

Chain

Excellence

15

20

Costs

Reduce supply

chain cost

2007

Act .

Capital

employed

Manage working

capital

2008

Act .

2009

Act .

2010

Plan

Reduce

GEZ

to <60 days

Great progress made on Costs and Delivery Performance GEZ will follow!

Security Systems

27

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

STs Competitive (Dis-)Advantages | CSS 2009

Products

Products

12

Customer Service

Customer Service

11

-2

After Sales

Tech Support

Training

16

Marketing

15

Sales Representative

9

-30

-20

-10

Delivery

AMEC

Global

Delivery

10

20

After Sales

11

Tech Support

Training

11

Marketing

14

Sales Representative

30

15

-15

Competitive (Dis-)/Advantage

-10

-5

10

15

10

20

30

Customer Service

Delivery

Slight competitive advantage

Major competitive advantage

-5

Products

Customer Service

Delivery

After Sales

APR

EMEA

Competitive disadvantage

Products

After Sales

Tech Support

Tech Support

Training

17

Training

16

Marketing

16

Marketing

15

Sales Representative

13

Sales Representative

6

-30

-20

-10

10

20

30

-30

-20

-10

Great progress made, but delivery is perceived as a competitive disadvantage

Security Systems

28

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

One Global Supply Chain Organization?

Security Systems

29

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

APR Supply Chain Council 2010

Only a strong and solid Supply Chain Community

ensures

competitiveness

and leads to

customer

satisfaction!

Security Systems

30

Internal | ST/DL, -/LOG | April 8, 2010 | APR Supply Chain Council 2010 | Robert Bosch GmbH 2010. All rights reserved, also regarding any

disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Coal & Husk Cost SavingsDocument1 pageCoal & Husk Cost SavingsSaikumar SelaNo ratings yet

- Analysis of Cold Chain IndustryDocument151 pagesAnalysis of Cold Chain IndustryAravind GanesanNo ratings yet

- Coal SpecsDocument2 pagesCoal SpecsSaikumar SelaNo ratings yet

- CIFDocument2 pagesCIFSaikumar SelaNo ratings yet

- Statement of Facts: Details of Daily WorkingDocument20 pagesStatement of Facts: Details of Daily WorkingSaikumar SelaNo ratings yet

- Kanban Roadmap 2016Document28 pagesKanban Roadmap 2016Saikumar SelaNo ratings yet

- VmiDocument6 pagesVmiSaikumar SelaNo ratings yet

- Change ManagementDocument6 pagesChange ManagementSaikumar SelaNo ratings yet

- Shipping MGRDocument1 pageShipping MGRSaikumar SelaNo ratings yet

- Clearing and Forwarding Goal SheetDocument21 pagesClearing and Forwarding Goal SheetSaikumar SelaNo ratings yet

- Industrial Security ManualDocument30 pagesIndustrial Security ManualSaikumar SelaNo ratings yet

- Global SCMDocument23 pagesGlobal SCMSaikumar SelaNo ratings yet

- E-Supply Chains - Virtually Non-Existing: Research NoteDocument8 pagesE-Supply Chains - Virtually Non-Existing: Research NoteSaikumar SelaNo ratings yet

- E Commerce and E Supply Chain PDFDocument28 pagesE Commerce and E Supply Chain PDFSaikumar SelaNo ratings yet

- SCM PDFDocument4 pagesSCM PDFAbdul SattarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Serpentines Guntner GCODocument8 pagesSerpentines Guntner GCOsergioantoniozavalaNo ratings yet

- Companies ListDocument12 pagesCompanies ListAnkit BulsaraNo ratings yet

- Assignment 06Document8 pagesAssignment 06Abdurehman Ullah khanNo ratings yet

- Fairlane PinsDocument46 pagesFairlane PinsMario MereniNo ratings yet

- ProdDocument25 pagesProdmadhumithaNo ratings yet

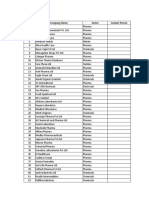

- Businesses Across Texas Say NO To SB 10 & HB 1774 (3-23-17)Document41 pagesBusinesses Across Texas Say NO To SB 10 & HB 1774 (3-23-17)Mona FultsNo ratings yet

- English Proficiency Test For Aviation: Set 10-PilotDocument13 pagesEnglish Proficiency Test For Aviation: Set 10-PilotDessy KuzmanovaNo ratings yet

- Work Activity Base Production Rates: Grade ItemsDocument3 pagesWork Activity Base Production Rates: Grade ItemsroldskiNo ratings yet

- Coke Vs PepsiDocument21 pagesCoke Vs PepsiJon100% (1)

- 8.12.01.15 - Catálogo Chancador de Cono CH890 y CH895Document5 pages8.12.01.15 - Catálogo Chancador de Cono CH890 y CH895gytomanNo ratings yet

- Pipeline Equipment and ConstructionDocument16 pagesPipeline Equipment and ConstructionHansLopezNo ratings yet

- Mercedes Benz OIL'sDocument2 pagesMercedes Benz OIL'sAndo TamkõrvNo ratings yet

- AMEC Specification For Titanium 01Document9 pagesAMEC Specification For Titanium 01cenkturkerNo ratings yet

- Production Technology Ch26Document19 pagesProduction Technology Ch26Nimmagadda BharathNo ratings yet

- List of Licensed RubberDocument102 pagesList of Licensed Rubberprakhar khareNo ratings yet

- Parts of An AirportDocument2 pagesParts of An AirportSol PeiranoNo ratings yet

- Sabre Spirit - Ship Detail - Sea-WebDocument7 pagesSabre Spirit - Ship Detail - Sea-Webdiegocely700615No ratings yet

- Construction & Maintenance of Post Tensioned Slab On Ground FoundationsDocument32 pagesConstruction & Maintenance of Post Tensioned Slab On Ground FoundationssamuelNo ratings yet

- Nioec-Sp-70-12 (R1) (Ed2)Document7 pagesNioec-Sp-70-12 (R1) (Ed2)aminNo ratings yet

- Pprroojjeecctt Hhaannddbbooookk: Residential and Small CommercialDocument44 pagesPprroojjeecctt Hhaannddbbooookk: Residential and Small CommercialJLNo ratings yet

- Tyre GripDocument2 pagesTyre GripjoebriffaNo ratings yet

- Massachusetts CDL Manual - Massachusetts CDL HandbookDocument504 pagesMassachusetts CDL Manual - Massachusetts CDL HandbookpermittestNo ratings yet

- Blast Furnace in BSPDocument51 pagesBlast Furnace in BSPAbhishek KhareNo ratings yet

- Bollhoff Rivnut USADocument36 pagesBollhoff Rivnut USAAce Industrial SuppliesNo ratings yet

- Christiantrulsson Flsmidth 140216160452 Phpapp01 PDFDocument44 pagesChristiantrulsson Flsmidth 140216160452 Phpapp01 PDFvale9102No ratings yet

- Wallenius Wilhelmsen HistoryDocument28 pagesWallenius Wilhelmsen Historymanayani52100% (1)

- Types and Meanings of Traffic Signs and Pavement Markings 1 I. International Traffic SignsDocument12 pagesTypes and Meanings of Traffic Signs and Pavement Markings 1 I. International Traffic SignsRmae LongakitNo ratings yet

- Sustainability Assignment ENGG1000 Janush AdabjouDocument7 pagesSustainability Assignment ENGG1000 Janush AdabjouJanush AbadjouNo ratings yet

- 4050 Douglas StreetDocument4 pages4050 Douglas Streett3hbiggyNo ratings yet

- Competition in LubeDocument14 pagesCompetition in LubeSuresh MalodiaNo ratings yet