Professional Documents

Culture Documents

Compressor ABC vs. B&M Comparison

Uploaded by

soekirmanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compressor ABC vs. B&M Comparison

Uploaded by

soekirmanCopyright:

Available Formats

COMPARISON BETWEEN ABC AND B&M

Helped by this document, I will explain you the clear differences make ABC compressors a

better choice than our competitor B&M.

DESIGN:

B&M:

V and W shape designs.

ABC:

Horizontally opposed cylinders design.

Advantages:

- All the forces in our compressor are balanced.

- We have absolutely no vibration in our machines.

- No need of any anti vibration pads. Just need regular industrial floor.

- Smaller friction and heat in the wearing parts > bigger durability.

- B&M compressor needs hanging cranes for maintenance, ABC do not > Not

calculated extra cost.

PRODUCTION:

B&M:

Compressors are done in the UK but with many outsourced parts

ABC:

Bare compressor, which keeps the quality of the compressor, always

assembled in Spain. The further provider is 500km far from our factory. All

parts are mechanized in our HQ in Spain.

Advantages:

- Mechanizing all the parts, we always keep the quality control.

- No third parties involved in the quality.

- All our providers are European, 100% European quality machine.

- We are able thanks to Chinese assembly to be cheaper with the same quality

(Bare compressors always produced in Spain) if price is the real issues. B&M

has not flexibility about pricing.

CYLINDERS TYPE:

B&M:

In the V type compressors, 2nd and 3rd stages always tandem cylinders.

ABC:

just one out of the 9 compressors in our range (the smallest one) has tandem

cylinder. The rest have just double acting ones.

Advantages:

- Double acting cylinders use both movements of the stroke to compress the

air they are > much bigger efficiency.

- Durability of the parts is more than 50% superior.

COMPARISON BETWEEN ABC AND B&M

NUMBER OF STAGES:

B&M:

Only 3 stage compressor.

ABC:

For almost all the flow requirements, we have the chance to let the customer

choose between 3 and 4 stage compressors. In our range we have; four 3 stage

models and five 4 stage models.

Advantages:

- In 4 stage compressors the compression ratio is smaller.

- Much better when facing hard climate conditions or high altitudes.

- More reliable compressors.

- Bigger service cycle.

B&MTERCOOLERS:

B&M:

Small size B&Mtercoolers

ABC:

Big size B&Mtercoolers.

Advantages:

- Compressors run colder > Higher durability of the parts.

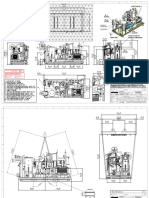

SKID:

B&M:

Multiple skid package.

ABC:

Due to the lack of vibration, we are able to assembly the compressor and all

the peripherals in a single skid.

Advantages:

-We need a smaller floor area. Although B&M claim to have a smaller area, if

we consider the motor compressor package and the rest of peripherals, we

occupy less area at site.

- The whole package is tested in running conditions, producing 40 bar air

during 72 hours. Once we give the OK, we do not need to disassemble the

machine and can send it directly to the customers site.

- Plug and Play commissioning. We do not need to assembly anything at

customers site.

- In case customer needs to relocate the compressor, it is easier to do it.

COMPARISON BETWEEN ABC AND B&M

BUSINESS ACTIVITY:

B&M:

Just PET and low pressure compressors.

ABC:

Besides PET and low pressure compressors, we produce Oil & Gas compressors

for Petrochemical, waste treatment, industrial gas, Natural gas cogeneration

activities.

Advantages:

-Obtain the know-how of the other sectors compressors production, much

more complicated than PET ones, and apply it on this application.

ENERGY SAVING:

Although all compressor manufacturers say in our catalogues, that each one of us produce the

most efficient compressors, ABC is the only one proving this fact with energy audits. During the

last years we did several energy audits in our customers sites comparing ABC compressors

with the competitors ones. We have always compared same size compressors, which were

acquired in similar years and are running in the same climate conditions and altitude. It is

important to mention that these audits are done with customer technicians as witnesses,

taking their own notes, and always using ISO certificated tools.

So, as it is obvious, we have a big interest in these audits because all of them have being

favorable to ABC. Moreover, as the only thing that all compressor manufacturers agree is that

once a complete blowing line is running, the compressor consumes nearly the 80% of the

energy, this becomes an essential issue for us.

Please have in mind that we are arranging an energy audit showroad in Pakistan for first

quarter of 2014. As you already have ABC and competition compressors we would be very glad

to audit them and show and prove how what we is just the truth. More advance in time, we

will contact you to arrange the mentioned audits.

You might also like

- BCD Rings - A New Packing Ring DesignDocument7 pagesBCD Rings - A New Packing Ring Designasamad54No ratings yet

- 2017CT CompressorSpecsAtAGlanceDocument4 pages2017CT CompressorSpecsAtAGlanceMadhana GopalNo ratings yet

- Crew CompressorDocument23 pagesCrew Compressor01666754614100% (1)

- NUOVO PIGNONE Compressor Spares (2010-37)Document4 pagesNUOVO PIGNONE Compressor Spares (2010-37)sianas1706No ratings yet

- Automation of Reciprocating Gas Engine Compressor Packages UsingDocument7 pagesAutomation of Reciprocating Gas Engine Compressor Packages UsingGnanaSekar0% (1)

- Maintenance/clearance Area: Dimensions Could Be Change +/-5 MMDocument2 pagesMaintenance/clearance Area: Dimensions Could Be Change +/-5 MMZander MctrevorNo ratings yet

- Compressor Unit Technical Data Sheet - I15.1-7.5-VDocument10 pagesCompressor Unit Technical Data Sheet - I15.1-7.5-VMohamed MusaNo ratings yet

- SNG Ii: Instruction Manual and Replacement Parts ListDocument146 pagesSNG Ii: Instruction Manual and Replacement Parts ListVictor RoblesNo ratings yet

- Ingersol-Rand-Air-Compressor PHE Booster Eng DataDocument46 pagesIngersol-Rand-Air-Compressor PHE Booster Eng Datadevilsharma100% (1)

- WP 3325 B 3 - 5 Basbooster Incl. N - Pack: Technical DataDocument2 pagesWP 3325 B 3 - 5 Basbooster Incl. N - Pack: Technical DataMarcos AssialdiNo ratings yet

- Dalian DB Pump EAP-Catalogue-English-2009Document13 pagesDalian DB Pump EAP-Catalogue-English-2009Lukarsa2013100% (1)

- Compressor Valve Reference DataDocument3 pagesCompressor Valve Reference DataHusnu KusumaNo ratings yet

- Manual Champion Pl70Document32 pagesManual Champion Pl70De Luna BraulioNo ratings yet

- Flushing Oil Flooded Rotary Screw Air Compressors Procedure enDocument2 pagesFlushing Oil Flooded Rotary Screw Air Compressors Procedure enSergiSerrano100% (1)

- CNG Filling Stations: High Pressure Compressors For Natural Gas Refuelling On Private VehiclesDocument24 pagesCNG Filling Stations: High Pressure Compressors For Natural Gas Refuelling On Private VehiclesAsesoría ContrataciónNo ratings yet

- Prezentation Envitec PDFDocument60 pagesPrezentation Envitec PDFDanilo VermezovcNo ratings yet

- Air LiquideDocument40 pagesAir LiquideSebastián RojasNo ratings yet

- Operation Manual Oil-Free Oxygen Piston Compressor Water-CooledDocument20 pagesOperation Manual Oil-Free Oxygen Piston Compressor Water-CooledPABLOBOBADILLANo ratings yet

- UPA Type Series BookletDocument122 pagesUPA Type Series BookletRicardo BarrosNo ratings yet

- 3225 C Instruction Manual: Compound 2-Stage Screw CompressorDocument182 pages3225 C Instruction Manual: Compound 2-Stage Screw CompressorAlexNo ratings yet

- F 0077 e 55Document6 pagesF 0077 e 55Bùi Cảnh TrungNo ratings yet

- Kaeser Screw Compressor BeltDocument97 pagesKaeser Screw Compressor Beltjaime adolfo LeonNo ratings yet

- Centrifugal Vs Reciprocating Compressor - Turbomachinery Magazine PDFDocument2 pagesCentrifugal Vs Reciprocating Compressor - Turbomachinery Magazine PDFReyes SanchezNo ratings yet

- Donk in Turbo CompressorsDocument16 pagesDonk in Turbo CompressorsLeon SanchezNo ratings yet

- Compressor Packager Guide WEB NewDocument4 pagesCompressor Packager Guide WEB NewJaroslav KurucNo ratings yet

- N10DC2432-4 NitrogenGenerationPlant NB216Document31 pagesN10DC2432-4 NitrogenGenerationPlant NB216ionut nicolaeNo ratings yet

- N2-GEN® T Series Nitrogen Generator - South-Tek SystemsDocument1 pageN2-GEN® T Series Nitrogen Generator - South-Tek SystemsSouth-Tek SystemsNo ratings yet

- Howden - FFP Free Floating Piston Lowres PDFDocument4 pagesHowden - FFP Free Floating Piston Lowres PDFdigecaNo ratings yet

- A-VIP Compressor BrochureDocument6 pagesA-VIP Compressor BrochureAvrinFakherniaNo ratings yet

- Screw Compressor GH-series Instruction Manual: GH250S/L, GH320SDocument111 pagesScrew Compressor GH-series Instruction Manual: GH250S/L, GH320SManh PhamNo ratings yet

- 36930071-2 Rev1 PoplDocument14 pages36930071-2 Rev1 PoplAnish SinghNo ratings yet

- Air Compressors and Their Lubrication - June 2020Document97 pagesAir Compressors and Their Lubrication - June 2020biron rumangunNo ratings yet

- Compressor Size CalulatorDocument2 pagesCompressor Size CalulatorŞef Utas Awij100% (1)

- Compressor 3Document98 pagesCompressor 3Erick GonzalezNo ratings yet

- 1 1Document9 pages1 1Ankush SehgalNo ratings yet

- Nuovo Pignone Reciprocating Compressor ManualDocument18 pagesNuovo Pignone Reciprocating Compressor ManualVICTOR HUGO ORTIZ MOSCOSO50% (2)

- Experience List - PT. Bumi Cahaya UnggulDocument5 pagesExperience List - PT. Bumi Cahaya UnggulRais RijalNo ratings yet

- PSA Oxymat Servicio de MantenimientoDocument28 pagesPSA Oxymat Servicio de Mantenimientovictor hugo valqui lopezNo ratings yet

- PDFDocument106 pagesPDFArdhi WibowoNo ratings yet

- Tuthill Blower Spec - 02Document8 pagesTuthill Blower Spec - 02Kari ConwayNo ratings yet

- LMF-GP LX15-8 - 10 - 13Document2 pagesLMF-GP LX15-8 - 10 - 13MAZEN0% (1)

- Dresser-Rand - MANUAL 7SHF162Document502 pagesDresser-Rand - MANUAL 7SHF162DAVIS VELASQUEZNo ratings yet

- 07 - Hyd2.0 Installation PDFDocument85 pages07 - Hyd2.0 Installation PDFSudhir SainiNo ratings yet

- Nism GK567GBDocument16 pagesNism GK567GBsafwan azizNo ratings yet

- 0-76150-BB0798A-13 - Rev.F DATASHEET GENE PDFDocument22 pages0-76150-BB0798A-13 - Rev.F DATASHEET GENE PDFPandiyanNo ratings yet

- GE Reciprocating Compressor BrochureDocument13 pagesGE Reciprocating Compressor Brochurearvind pillaiNo ratings yet

- PTFE HY22 HoerbigerDocument1 pagePTFE HY22 HoerbigerТатьяна ВасильеваNo ratings yet

- HG24 Series: Models HG24XXX Gear DriveDocument2 pagesHG24 Series: Models HG24XXX Gear DriveVictorNo ratings yet

- Turbocompressor Single Shaft Siemens NuevoDocument4 pagesTurbocompressor Single Shaft Siemens NuevoTabiquera Guadalupe Victoria Texcoco De MoraNo ratings yet

- 1a. BMC Brunei Recommendation ReportDocument20 pages1a. BMC Brunei Recommendation ReportALEJANDRO FIGUEROANo ratings yet

- Pa 180010Document6 pagesPa 180010Trịnh Đức HạnhNo ratings yet

- P37 To P275 High Pressure Piston Air Compressor English Tcm795-3514985Document12 pagesP37 To P275 High Pressure Piston Air Compressor English Tcm795-3514985Jozsef MagyariNo ratings yet

- Air Compressors (MOD)Document72 pagesAir Compressors (MOD)ROSHAN100% (1)

- KMBD BP(国外罗茨泵ROOTS)Document2 pagesKMBD BP(国外罗茨泵ROOTS)tutuli1990No ratings yet

- Mxcol PDFDocument8 pagesMxcol PDFJorge OsorioNo ratings yet

- ScrewCompressors XRV204 SpecSheet DigitalDocument1 pageScrewCompressors XRV204 SpecSheet DigitalBarros Arias EnriqueNo ratings yet

- Corken Compresores Amoniaco PDFDocument100 pagesCorken Compresores Amoniaco PDFNicolas BurgosNo ratings yet

- Atmospheric Relief Valve ManualDocument12 pagesAtmospheric Relief Valve ManualTarun ChandraNo ratings yet

- Boge Screw UsaDocument40 pagesBoge Screw UsaAir Repair, LLC100% (1)

- Boge Air Compressors - Screw Compressors BrochureDocument52 pagesBoge Air Compressors - Screw Compressors BrochureAir Repair, LLC100% (5)

- Binus Billing Total Sept 2017Document5 pagesBinus Billing Total Sept 2017soekirmanNo ratings yet

- CV Ridwan PpicDocument1 pageCV Ridwan PpicsoekirmanNo ratings yet

- CV Bumi Mulia BlowDocument1 pageCV Bumi Mulia BlowsoekirmanNo ratings yet

- Quotation: Soekirman Person: Diana Email: Person: TelDocument1 pageQuotation: Soekirman Person: Diana Email: Person: TelsoekirmanNo ratings yet

- Minor ProjectDocument33 pagesMinor ProjectParth KhannaNo ratings yet

- Charter PartyDocument16 pagesCharter PartyChinnadurai SenguttuvanNo ratings yet

- Formulaire Accepteur Agrege Marchand English VERSIONDocument2 pagesFormulaire Accepteur Agrege Marchand English VERSIONGerald NONDIANo ratings yet

- Sample Business CaseDocument19 pagesSample Business CasepreetigopalNo ratings yet

- Teller Job DescriptionDocument8 pagesTeller Job DescriptionDianne Bernadeth Cos-agonNo ratings yet

- Cap. 1 Hospitality Industry AccountingDocument25 pagesCap. 1 Hospitality Industry Accountingdianelys alejandroNo ratings yet

- Ch02 Recording Business Transactions SVDocument28 pagesCh02 Recording Business Transactions SVBảo DươngNo ratings yet

- SetcDocument3 pagesSetcsindhusmNo ratings yet

- Abcaus - in-CBDT Instruction-Seized Assets Other Than Cash ReleaseDocument3 pagesAbcaus - in-CBDT Instruction-Seized Assets Other Than Cash Releasebaviv70579No ratings yet

- Massey & Gail Fee Petition - LTLDocument74 pagesMassey & Gail Fee Petition - LTLKirk HartleyNo ratings yet

- New Dyeing Technology's Green Credentials: by AZM Anas, Jens Kastner, Keith Nuthall, Raghavendra Verma 12 August 2019Document4 pagesNew Dyeing Technology's Green Credentials: by AZM Anas, Jens Kastner, Keith Nuthall, Raghavendra Verma 12 August 2019JUAN SEBASTIAN BUSTOS GARNICANo ratings yet

- Undergraduate Programmes Fee Schedule: (International Only)Document12 pagesUndergraduate Programmes Fee Schedule: (International Only)GodlyNoobNo ratings yet

- Nexa: Maruti's Innovative Value CreationDocument3 pagesNexa: Maruti's Innovative Value CreationSakshi Agarwal100% (1)

- Eccouncil: Exam 712-50Document10 pagesEccouncil: Exam 712-50shenyanNo ratings yet

- Infor WMS: Architected For Agility, Usability, and ResultsDocument3 pagesInfor WMS: Architected For Agility, Usability, and Resultsyi jingNo ratings yet

- ECO 210 - MacroeconomicsDocument5 pagesECO 210 - MacroeconomicsRahul raj SahNo ratings yet

- Concept PaperDocument3 pagesConcept PaperJizelle Elaine GumaNo ratings yet

- Solutions Manual: Accounting: Building Business SkillsDocument31 pagesSolutions Manual: Accounting: Building Business SkillsNicole HungNo ratings yet

- Prerequisites: Course Information Course DescriptionDocument2 pagesPrerequisites: Course Information Course DescriptionAjit Pal SinghNo ratings yet

- PROPERTYDocument8 pagesPROPERTYHyder KhanNo ratings yet

- Lululemon Athletica Case AnalysisDocument19 pagesLululemon Athletica Case Analysiskuntodarpito100% (2)

- Background: Bangladesh Bank'S Supervision On Banking SectorDocument11 pagesBackground: Bangladesh Bank'S Supervision On Banking Sectorrajin_rammsteinNo ratings yet

- 2021-12-02 Project Scheduling by PERT CPMDocument95 pages2021-12-02 Project Scheduling by PERT CPMAries Falag-eyNo ratings yet

- Lesson 1 RIGHT OF APPRAISALDocument6 pagesLesson 1 RIGHT OF APPRAISALDi CanNo ratings yet

- Chapter 8 Unit 8Document47 pagesChapter 8 Unit 8cutefeetNo ratings yet

- HR Strategy GlobalizationDocument55 pagesHR Strategy Globalizationmyszeyka100% (1)

- U H "Eƒ ¡I" Beha Construction Y Ƒ° SÓKÝ TD Má Pî& Job Description Notes FormDocument2 pagesU H "Eƒ ¡I" Beha Construction Y Ƒ° SÓKÝ TD Má Pî& Job Description Notes FormAbrsh AbrshNo ratings yet

- LIst of CA AgentDocument12 pagesLIst of CA AgentParikshit SalvepatilNo ratings yet

- Solid Pin Conversion Kits: Equipment: Cat Loaders To Suit Machines: 990, 992C, 992G, 992K, 994C, 994D & 994FDocument2 pagesSolid Pin Conversion Kits: Equipment: Cat Loaders To Suit Machines: 990, 992C, 992G, 992K, 994C, 994D & 994FMax SashikhinNo ratings yet

- Forms of Business OrganisationDocument31 pagesForms of Business OrganisationIla SureshNo ratings yet