Professional Documents

Culture Documents

Relief Valves and Relief Systems

Uploaded by

talangocdayCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Relief Valves and Relief Systems

Uploaded by

talangocdayCopyright:

Available Formats

10/25/2016

Reliefvalvesandreliefsystems

Reliefvalvesandreliefsystems

Areliefsystemisanemergencysystemfordischarginggasduringabnormalconditions,bymanualorcontrolledmeansorbyanautomaticpressurereliefvalvefroma

pressurizedvesselorpipingsystem,totheatmospheretorelievepressuresinexcessofthemaximumallowableworkingpressure(MAWP).

Contents[hide]

1Components

2Designconsiderations

3Reliefdeviceselection

3.1Determiningindividualreliefloads

3.2Causesofoverpressure

3.3Typesofpressurereliefdevices

3.3.1Reliefvalves

3.3.2Rupturediskdevices

3.3.3Reliefsystemconsiderations

3.4Specialconsiderations

3.4.1Setpressure

3.4.2Backpressure

3.4.3Dualreliefvalves

3.4.4Multiplereliefvalves

3.5Sizingthereliefdevice

3.5.1Blockeddischarge

3.5.2Gasblowby

3.5.3Fireorthermalexpansion

3.6Installationconsiderations

3.7Inletpiping

3.8Dischargepiping

3.9Reactiveforces

3.10Tailpipeconsiderations

3.11Rapidcycling

3.12Resonantchatter

3.13Isolation(block)valves

3.14Reliefvalveconfigurations

3.15Guidelinesfordeterminingthenumberofreliefdevices

3.16Liquiddischargeconsiderations

4References

5NoteworthypapersinOnePetro

6Externallinks

7Seealso

8Category

Components

Thereliefsystemmayinclude:

Thereliefdevice

Thecollectionpiping

Flashbackprotection

Agasoutlet

http://petrowiki.org/Relief_valves_and_relief_systems

1/8

10/25/2016

Reliefvalvesandreliefsystems

Ascrubbingvesselshouldbeprovidedforliquidseparationifliquidhydrocarbonsareanticipated.Thereliefsystemoutletmaybeeitherventedorflared.Ifdesignedproperly,

ventorflareemergencyreliefsystemsfrompressurevesselsmaybecombined.

Somefacilitiesincludesystemsfordepressuringpressurevesselsintheeventofanemergencyshutdown.Thedepressuringsystemcontrolvalvesmaybearrangedtodischarge

intothevent,flare,orreliefsystems.Thepossibilityoffreezingandhydrateformationduringhighpressurereleasestotheatmosphereshouldbeconsidered.

Designconsiderations

Therearethreemainengineeringconsiderationswhendesigningormodifyingareliefsystem:

Determiningthereliefrequirementsofindividualpiecesofequipmentandselectingtheappropriatedevicestohandletheimposedloads.

Designingareliefheadersystemthatwillhandletheimposedloadsorexpansionmodifications.

Definingreasonabletotalreliefloadsforthecombinedreliefheaderordisposalsystemanddesigninganappropriatedisposalsystemwithminimumadverseimpactto

personnelsafety,plantprocesssystemintegrity,andtheenvironment.

Theseconsiderationsareinterrelatedinsuchawaythatmakesitimpossibletoestablishaproceduralguidelinethatwouldbevalidformostcases.Thedesignofoneportionof

areliefsystemmustbeconsideredinlightofitseffectsonthereliefsystem.

Reliefdeviceselection

Determiningindividualreliefloads

Thereareanumberofindustrycodes,standards,andrecommendedpracticesthatprovideguidanceinthesizing,selection,andinstallationofreliefdevicesandsystems.The

AmericanSoc.ofMechanicalEngineers(ASME)PressureVesselCode,Sec.VIII,Division1,paragraphUG127,liststhereliefvalvecoderequirements. [1]RP520,Part1,

providesanoverviewofthetypesofreliefdevices,causesofoverpressure,reliefloaddetermination,andproceduresforselectingandsizingreliefdevices. [2]RP520,Part2,

providesguidanceontheinstallationofreliefdevices, [3]andRP521providesguidanceontheselectionanddesignofdisposalsystems. [4]

Causesofoverpressure

Themostcommoncausesofoverpressureinupstreamoperationsareblockeddischarge,gasblowby,andfire.Whentheworstcasereliefloadiscausedbyacontrolvalve

failingtoopen(blockeddischarge),thereliefdeviceshouldbesizedwithfullsizedtriminthecontrolvalve,eveniftheactualvalvehasreducedtrim.Whentheworstcaserelief

loadiscausedbygasblowby,thereliefdeviceshouldbesizedwithfullsizedtriminthesmallestvalveintheliquidoutletline,eveniftheactualvalvehasreducedtrim.Many

vesselsareinsulatedforenergysavings.Thermalinsulationlimitstheheatabsorptionfromfireexposureaslongasitisintact.Itisessentialthateffectiveweatherprotectionbe

providedsothatinsulationwillnotberemovedbyhighvelocityfirehosestreams.

Typesofpressurereliefdevices

Thetwoprimarytypesofreliefdevicesarethereliefvalveandrupturedisk.

Reliefvalves

Thethreebasictypesofpressurereliefvalvesareconventionalspringloaded,balancedspringloaded,andthepilotoperated.

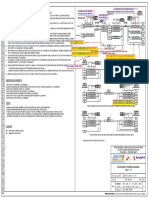

Conventionalspringloaded.Intheconventionalspringloadedvalve(Fig.1),thebonnet,spring,andguideareexposedtothereleasedfluids.Ifthebonnetisventedto

theatmosphere,reliefsystembackpressuredecreasesthesetpressure.Ifthebonnetisventedinternallytotheoutlet,reliefsystembackpressureincreasesthesetpressure.

Theconventionalspringloadedvalveisusedinnoncorrosiveservicesandwherebackpressureislessthan10%ofthesetpoint.

Balancedspringloaded.Thebalancedspringloadedvalveincorporatesameanstoprotectthebonnet,spring,andguidefromthereleasedfluidsandminimizesthe

effectsofbackpressure.Thediskareaventedtotheatmosphereisexactlyequaltothediskareaexposedtobackpressure.Thesevalvescanbeusedincorrosiveordirty

http://petrowiki.org/Relief_valves_and_relief_systems

2/8

serviceandwithvariablebackpressure.

10/25/2016

Reliefvalvesandreliefsystems

Pilotoperated.Thepilotoperatedvalveiscombinedwithandcontrolledbyanauxiliarypressurepilot.Theresistanceforceonthepistoninthemainvalveisassistedby

theprocesspressurethroughanorifice.Thenetseatingforceonthepistonactuallyincreasesastheprocesspressurenearsthesetpoint.

Fig.1Conventionalspringloadedpressurereliefvalue.

Rupturediskdevices

Therupturediskdeviceisanonreclosingdifferentialpressuredeviceactuatedbyinletstaticpressure.Therupturediskisdesignedtoburstatsetinletpressure.Thedevice

includesarupturediskandadiskholder.Therupturediskmaybeusedalone,inparallelwith,orinconjunctionwithpressurereliefvalves.Theyaremanufacturedinavarietyof

materialswithvariouscoatingsforcorrosionresistance.

Reliefsystemconsiderations

Theentirereliefsystemmustbeconsideredbeforeselectingtheappropriatereliefdevice.Thereliefheadersshouldbedesignedtominimizepressuredrop,thusallowingfor

futureexpansionandadditionalreliefloads.

Conventionalspringloadedreliefvalveconsiderations.Conventionalvalvesrequirethereliefheaderbackpressure(superimposedplusbuiltup)tobelessthan10%of

thesetpressureofthelowestsetreliefvalvetiedintotheheader.

Balancedspringloadedvalveconsiderations.Balancedspringloadedvalvesallowtheuseofsmallerreliefheadersbecauseofthelargerpressuredropsallowed,under

maximumreliefflowconditions,asaresultofhigherallowablebackpressure(40%).Balancedvalvesandreliefheadersaredesignedasasystemtooperateatahigher

backpressure.Thebalancedvalveismoreexpensivethanconventionalvalveshowever,thetotalcostoftheuseofbalancedvalvesplusthesmallerheadersystemmaybe

lower.Capacityisreducedatthelargerbackpressure,soitmaynotbethesolutionforallbackpressureproblems.Inthebellowsmodel,thebellowsisaflexiblepressure

vesselthathasamaximumbackpressurelimitthatislowerinlargervalvesizes.Bellowsareavailableinalimitednumberofmaterialsandmaydeterioraterapidlyunder

certainexposureconditions.Bellowsshouldbecheckedperiodicallyforleakage.Aleakingbellowdoesnotprovidebackpressurecompensation,anditallowstherelief

headertoleaktotheatmosphere.Thebalancedvalvecommonlyisusedtotieanewlowpressurereliefloadintoanexistingheavilyloadedreliefheaderortoprotectthe

reliefvalvetopworksfromcorrosivegasesinthereliefheader.

Pilotoperatedvalveconsiderations.Pilotoperatedvalvesshouldbeconsideredforallcleanserviceswithintheirtemperaturelimitations.Theyarewellsuitedfor

pressuresbelow15psigandareavailablewiththepilotpressuresensinglineconnectedtoeitherthevalveinletortoadifferentpoint.Pilotoperatedvalvesprovidetight

shutoffwithverynarrowmarginsbetweenoperatingpressureandsetpressure.

Specialconsiderations

Whenselectingtheappropriatereliefdevicestohandletheimposedloads,severalissuesmustbeconsidered.

http://petrowiki.org/Relief_valves_and_relief_systems

3/8

10/25/2016

Reliefvalvesandreliefsystems

Setpressure

ReliefdevicesarenormallysettorelieveattheMAWP.Thegreaterthemarginbetweenthesetpressureandtheoperatingpressure,thelesslikelihoodthereisofleakage.

Asidefromtherequirementstocompensateforsuperimposedbackpressure,thereisnoreasontosetareliefdeviceatlessthantheMAWP.

Backpressure

Thebackpressureattheoutletofeveryreliefdeviceshouldbesuchthatthedevicecanhandleitsdesigncapacitywiththecalculatedbackpressureunderthedesignrelief

conditions.

Dualreliefvalves

Itiscommonpracticetoinstalltworeliefvalvesincriticalprocessapplicationswhereashutdowncannotbetolerated.Theintentisthatifthefirstreliefvalveliftsandfailsto

reseat,asecondreliefcanbeswitchedintoservicebeforethefirstvalveisremovedformaintenance,withoutshuttingdownorjeopardizingtheprocess.Thisisaccomplishedby

pipingthereliefvalvesinparallelandbyputtinga"carsealed"fullportballorgateblockvalveontheinletandoutletofeachreliefvalve.Onesetofblockvalvesissealedopen

andtheothersealedclosed.ASMEapprovedselectorvalvesareavailable,whichsimplifyreliefvalveswitching.Thisprovidesaninterlockofparallelinletandoutletblockvalves

andensuresfullprotectionfortheprocessequipment.

Multiplereliefvalves

Multiplereliefvalvesarerequiredwhenthereliefloadexceedsthecapacityofthelargestavailablereliefvalve.Itisgoodpracticetoinstallmultiplereliefvalvesforvaryingloads

tominimizechatteringonsmalldischarges.ASMESec.VIII,Division1,3andRP520,Part1, [2]bothstipulatea10%accumulationabovetheMAWPforasinglereliefvalve

anda16%accumulationabovetheMAWPformultiplereliefvalves.TheprimaryreliefvalvemustbesetatorbelowtheMAWP.Supplementalreliefvalvesshouldhavestaged

pressures.Thehighestpressuremaybesetnohigherthan105%abovetheMAWP.Ifdifferentsizedreliefvalvesareused,thesmallestreliefvalveshouldbesettothelowest

pressure.

Sizingthereliefdevice

Themostdifficultfactorsforspecifyingareliefdevicearedeterminingthelimitingcauseofpressurerelief,determiningthereliefloadandpropertiesofthedischargefluid,and

selectingtheproperreliefdevice.Whentheloadsareknown,thesizingstepsarestraightforward.RP520,Part1,providesformulasfordeterminingthereliefvalveorificearea

forvapor,liquid,andsteamrelief. [2]Fig.2showsstandardorificesavailablebyletterdesignation,orificearea,andbodysize.Thesizeofareliefvalveshouldbecheckedforthe

followingconditions.

Fig.2Pressurereliefvalueorificedesignations.

http://petrowiki.org/Relief_valves_and_relief_systems

4/8

10/25/2016

Reliefvalvesandreliefsystems

Blockeddischarge

Onedesignconditionforthesizingofareliefvalveistoassumethatitmusthandlethetotaldesignflowrate(gasplusliquid)intothecomponent.Itispossibletoisolatea

processcomponentorpipingsegmentformaintenancebyblockingallinletsandoutlets.Onstartup,alloutletvalvescouldbeleftclosedinadvertently.Iftheinletsourcecanbe

atahigherpressurethantheMAWPoftheprocesscomponent,onlyaproperlysizedreliefvalvecouldkeeptheprocesscomponentfromrupturingasaresultofoverpressure.

Gasblowby

Ontanksandlowpressurevesselsnormallyreceivingliquidsfromhigherpressureupstreamvessels,themaximumflowratethroughthereliefvalveoftenisdeterminedbygas

blowby.Thissituationoccurswhenthelevelcontrollerorlevelcontrolvalveoftheupstreamvesselfailsintheopenpositionoradrainvalvefromanupstreamvesselfailsinthe

openposition,allowingliquidand/orgastoflowintothecomponentevaluated.Underblowbyconditions,boththenormalliquidandgasoutletsonthecomponentbeing

evaluatedarefunctioningproperly.However,thegasflowintothecomponentcouldgreatlyexceedthecapacityofthenormalgasoutlet.Thisexcessgasflowmustbehandled

bythereliefvalvetokeepfromexceedingthecomponentsMAWP.Gasblowbyconditionsalsocanoccurwhenapressureregulatorfeedingacomponentfailsintheopen

position,creatingahigherthandesignedinletflowrateofgas.

Gasblowbyrateisthemaximumthatcanflowgiventhepressuredropbetweentheupstreamcomponentandthecomponentbeingevaluated.Incomputingthemaximumrate

thatcanflowbecauseofpressuredrop,considerationshouldbegiventotheeffectsofcontrolvalves,chokes,andotherrestrictedorificesintheline.Amoreconservative

approachwouldbetoassumethatthesedeviceshavebeenremovedorhavethemaximumsizedorificethatcouldbeinstalledinthedevice.

Fireorthermalexpansion

Thepressureinprocesscomponentsexposedtotheheatfromafirewillriseasthefluidexpandsandtheprocessliquidvaporizes.Fortanksandlargelowpressurevessels,the

needtoventtheliberatedgasmaygovernthesizeoftheventorreliefvalve.Firesizingareliefvalveonlykeepspressurebuilduptolessthan120%oftheMAWP.Ifthe

componentissubjectedtoafireforalongtime,itmayfailatapressurelessthantheMAWPbecauseametalsstrengthdecreasesastemperatureincreases.

Oncomponentsthatcanbeisolatedfromtheprocess,itispossiblefortheprocessfluidcontainedinthecomponenttobeheated.Thisisespeciallytrueforcold(relativeto

ambient)serviceorwhenthecomponentisheated(suchasafiredvesselorheatexchanger).Itisalsotrueforcompressorcylindersandcoolingjackets.Thereliefvalveson

suchcomponentsshouldbesizedforthermalexpansionofthetrappedfluids.Thisnormallywillnotgovernthefinalsizeselectedunlessnoreliefvalveisneededfortheother

conditions.

Installationconsiderations

Theinstallationofareliefdevicerequirescarefulconsiderationoftheinletpiping,pressuresensinglines(whereused),andstartupprocedures.Poorinstallationmayrenderthe

reliefdeviceinoperableorseverelyrestrictthevalvesrelievingcapacity.Eitherconditioncompromisesthesafetyofthefacility.Manyreliefvalveinstallationshaveblockvalves

beforeandafterthereliefvalveforinservicetestingorremovalhowever,theseblockvalvesmustbecarsealedorlockedopen.

Inletpiping

RP520,Part2, [3]andASMEcode[1]limittheinletpressurelosstoaPSVof3%ofsetpressurewherethepressurelossisthetotaloftheinletloss,lineloss,andblockvalve

loss(ifused).Lossiscalculatedwiththemaximumratedflowthroughthereliefvalve.Tominimizetheinletpressuredroptoareliefvalve,aconservativeguidelineistokeep

theequivalentlengthtodiameterratiooftheinletpipingtothereliefvalveat5orless.Forpressuredroplimitationsandtypicalpipingconfigurations,refertoRP520,Part2. [3]

Dischargepiping

Thedischargepipingshouldbedesignedsothatthebackpressuredoesnotexceedanacceptablevalueforanyreliefvalveinthesystem.Pipingdiametersgenerallyshouldbe

largerthanthevalveoutletsizetolimitbackpressure.Liftandsetpressuresofpilotoperatedreliefvalveswiththepilotventedtotheatmospherearenotaffectedby

backpressurehowever,ifthedischargepressurecanexceedtheinletpressure(e.g.,tanksstoringlowvaporpressurematerial),abackflowpreventer(vacuumblock)mustbe

used.Thesetpressureforbalancedspringloadedreliefvalveswillnotbeasaffectedbybackpressureasconventionalspringloadedreliefvalvesare.Balancedreliefvalveswill

sufferreducedliftasbackpressureincreases.

http://petrowiki.org/Relief_valves_and_relief_systems

5/8

10/25/2016

Reliefvalvesandreliefsystems

Reactiveforces

Onhighpressurevalves,thereactiveforcesduringreliefaresubstantialandexternalbracingmayberequired.RefertotheformulasinRP520,Parts1[2]and2[3]forcomputing

theseforces.

Tailpipeconsiderations

Reliefvalvesthatarenotconnectedtoaclosedreliefsystemshouldhavetailpipestodirecttherelievinggasestoasafeareaawayfrompersonnel.Thetailpipeshouldbesized

foramaximumexitvelocityof500ft/s.Thisensuresthatthegas/airmixtureisbelowthelowerflammablelimitorlowerexplosivelimitatapproximately120pipediameters

awayfromthetailpipe.Tailpipesshouldbesupportedatthebottomoftheelbow.Asmallholeora"weephole"(minimumofin.indiameter)shouldbeinstalledinthe

bottomoftheelbowtodrainliquidsthatenterthroughthetailpipeopening.Theweepholeshouldbepointedawayfromprocesscomponents,especiallythoseclassifiedasan

ignitionsource.

Rapidcycling

Rapidcyclingcanoccurwhenthepressureatthevalveinletdecreasesatthestartofthereliefvalveflowbecauseofexcessivepressurelossinthepipingupstreamofthevalve.

Undertheseconditions,thevalvewillcyclerapidly,aconditionreferredtoas"chattering."Chatteringiscausedbythefollowingsequence.Thevalverespondstothepressureat

itsinlet.Ifthepressuredecreasesduringflowbelowthevalvereseatpoint,thevalvewillclosehowever,assoonastheflowstops,theinletpipepressurelossbecomeszero

andthepressureatthevalveinletrisestovesselpressureonceagain.Ifthevesselpressureisstillequaltoorgreaterthanthereliefvalvesetpressure,thevalvewillopenand

closeagain.Anoversizedreliefvalvemayalsochatterbecausethevalvemayquicklyrelieveenoughcontainedfluidtoallowthevesselpressuretomomentarilyfallbackto

belowsetpressure,onlytorapidlyincreaseagain.Rapidcyclingreducescapacityandisdestructivetothevalveseatinadditiontosubjectingallthemovingpartsinthevalveto

excessivewear.Excessivebackpressurealsocancauserapidcycling,asdiscussedpreviously.

Resonantchatter

Resonantchatteroccurswhentheinletpipingproducesexcessivelossatthevalveinletandthenaturalacousticalfrequencyoftheinletpipingapproachesthenaturalfrequency

ofthevalvesmovingparts.Thehigherthesetpressure,thelargerthevalvesize,orthegreatertheinletpipepressureloss,themorelikelyresonantchatterwilloccur.

Resonantchatterisuncontrollable,thatis,oncestarteditcannotbestoppedunlessthepressureisremovedfromthevalveinlet.Inactualpractice,thevalvecanbreakdown

beforeashutdowncantakeplacebecauseoftheverylargemagnitudeoftheimpactforceinvolved.Toavoidchattering,thepressuredropfromthevesselnozzletotherelief

valveshouldnotexceed3%ofthesetpressure.RP520,Part2coversthedesignofreliefvalveinletpiping.5Pilotoperatedreliefvalveswithremotesensingpilotscan

operatewithhigherinletpipingpressuredrops.

Isolation(block)valves

ThereisnoindustrystandardorRPforisolationvalves,andpracticesvarywidely.Installedisolationblockvalvesallowthetestingofspringloadedreliefvalvesinplace,thus

eliminatingtheneedtoremovethevesselfromservicewhilebenchtestingthereliefvalve,andallowthereliefdevicetobeisolatedfromtheclosedreliefsystemwhen

performingmaintenanceandrepair.TheASMEUnfiredPressureVesselCodeallowstheuseofisolationvalvesbelowreliefvalves. [1]ASMEPressureVesselCode,Appendix

M,describesspecialmandatoryrequirementsforisolationvalves.TheASMEBoilerCode[1]prohibitsthem,andtheU.S.OccupationalSafetyandHealthAdmin. [5]prohibits

themoninstrumentairreceivers.Becauseimproperuseofanisolationvalvemayrenderareliefvalveinoperative,thedesign,installation,andmanagementoftheseblock

valvesshouldbeevaluatedcarefullytoensurethatplantsafetyisnotcompromised.SeeRP520,Part2,fortypicalblockvalveinstallationsunderreliefvalves. [3]

Reliefvalveconfigurations

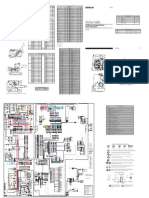

ThereisnoindustrystandardorRPthataddressesthistopic.SomeofthemorecommonreliefvalueconfigurationsarelistedhereandareshowninFig.3.

Installationoffullopenisolation(block)valvesupstreamanddownstreamofreliefvalves.Isolationvalvesshouldbecarsealedopen(lockedopen),andalogshouldbe

kept.Thesevalvesshouldbediscouragedwherethepotentialoverpressureistwicethemaximumallowablepressure.Atestconnectionshouldbeprovidedonallspring

loadedreliefvalves.Theinstallationoftworeliefvalves(100%redundant)shouldbeconsideredsothatonereliefvalvecanbeleftinserviceatalltimes.

http://petrowiki.org/Relief_valves_and_relief_systems

6/8

Installationofpilotoperatedvalveswithoutisolationvalves.Thisconfigurationallowsforthetestingofpilotsetpressureonlyandrequiresfullplantshutinforrelief

valverepairandmaintenance.

10/25/2016

Reliefvalvesandreliefsystems

Installationofthreewayvalveswithoneportopentoatailpipeoraventstack.Thisconfigurationallowsforvalvemaintenanceandrepairwithoutrequiringplantshutin

andensuresapathtotheatmosphereifthethreewayvalveisleftinthewrongposition.

Installationoftwotwowayvalves,connectedbymechanicallinkage,andtworeliefvalves.Thisconfigurationprovidesalltheadvantagesofisolationvalves.Inaddition,

itisimpossibletoisolateaprocesscomponentbymistake.Theonlydisadvantageofthisconfigurationistheinitialcost.

Installationofacheckvalveinlieuofanisolationvalve.ThisconfigurationisnotallowedbytheASMEPressureVesselCodebecausethecheckvalvemayfailorcause

excessivepressuredrop. [1]

Fig.3Reliefvalveconfigurations.

Guidelinesfordeterminingthenumberofreliefdevices

ThereisnoindustrystandardorRPfordeterminingthenumberofreliefdevices,andinstallationsvarywidely.Sometimestherearetworeliefdevices(100%standby)on

vesselsreceivingproductiondirectlyfromthewells.TheprimaryreliefvalveissetatMAWP.Ifthesecondreliefdeviceisanotherreliefvalve,thesetpressureofthesecond

reliefvalveisset10%abovetheprimaryreliefvalve.Ifthesecondreliefdeviceisarupturedisk(entirelyredundantagainstallpossiblerelievingscenarios),thepressureisset

at15to25%abovetheprimaryreliefdevice.Thissettingensuresthattherupturediskwillnotrupturewhenthedesignprimaryrelievingrateisreachedatthesetpressureplus

10%overpressure.Primaryandstandbyreliefratesareconsideredadequateforfiresizing.

Somecompaniesinstalltworeliefvalvesonallcriticalinstallationssothatplantshutdownsarenotrequiredduringtestingandmaintenance.Ifthesecondaryreliefdeviceis

beingcountedontoprovideanyportionofanyrequiredrelievingcapacity(blockeddischarge,gasblowby,fire,etc.),thenthesecondarydeviceshouldbesetinaccordancewith

therulesofRP520,Parts1[2]and2, [3](i.e.,ASMESec.VIII,Division1,paragraphUG134). [1]

Liquiddischargeconsiderations

Condensedmistshaveliquiddropletsthatarelessthan20to30mindiameter.Testingandexperiencehaveshownthatwithaslightwind,theenvelopeofflammabilityfor

thistypeofmististhesameasthatforavapor.Liquidswillsettletograde,thuspresentingafireandpollutionhazardtherefore,thereliefdeviceshouldbeinstalledinthe

vaporspaceofprocessvesselswithanLSHthatalarmsandshutsinflowwhenactivated.TheLSHshouldbesetnohigherthan15%abovethemaximumoperatinglevel,

whilethereliefvalveshouldbesetnohigherthantheMAWPoftheprocesscomponent.Scrubbersandknockoutdrumsshouldbeinstalledinflare,vent,andrelieflinesto

separateandremoveliquiddropletsfromthedischarge.

References

1. 1.0 1.1 1.2 1.3 1.4 1.5PressureVessels.2001.InBoilerandPressureVessel,Code,Sec.8,Divisions1and2.NewYorkCity:ASME.

2. APIRP520,DesignandInstallationofPressureRelievingSystemsinRefineries,PartI,seventhedition.2000.Washington,DC:API.

3. 3.0 3.1 3.2 3.3 3.4 3.5APIRP520,DesignandInstallationofPressureRelievingSystemsinRefineries,Part2,fifthedition.2003.Washington,DC:API.

http://petrowiki.org/Relief_valves_and_relief_systems

2.0 2.1 2.2 2.3 2.4

7/8

10/25/2016

Reliefvalvesandreliefsystems

4.APIRP521,GuideforPressureRelievingandDepressuringSystems,fourthedition.1999.Washington,DC:API.

5.OccupationalSafetyandHealthStandards,regulations,29CFRPart1910.1999.Washington,DC:USDept.ofLabor.

NoteworthypapersinOnePetro

UsethissectiontolistpapersinOnePetrothatareaderwhowantstolearnmoreshoulddefinitelyread

Externallinks

APIStandards

Seealso

Safetysystems

Recommendedmethodsforsafetyanalysis

Flareandventdisposalsystems

PEH:Safety_Systems

Category

Categories: 6.3.5Processsafety

YR

http://petrowiki.org/Relief_valves_and_relief_systems

8/8

You might also like

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsFrom EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahNo ratings yet

- CHH2 Pid All AlDocument28 pagesCHH2 Pid All AlRanchojiNo ratings yet

- Flare System DesignDocument2 pagesFlare System Designomar alnasserNo ratings yet

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7From EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7No ratings yet

- PidDocument85 pagesPidvermaakash22No ratings yet

- Smokelesss Flare - Air AssistsedDocument19 pagesSmokelesss Flare - Air AssistsedvasuNo ratings yet

- 14 Hot Oil Systems v3Document14 pages14 Hot Oil Systems v3sssss100% (1)

- Phast: Tutorial ManualDocument42 pagesPhast: Tutorial ManualNitesh KirnakeNo ratings yet

- E PR 460Document37 pagesE PR 460khorzooNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- 08a PDFDocument36 pages08a PDFProcess EngineerNo ratings yet

- Pipenet Vision Spray/Sprinkler Module User and Reference ManualDocument235 pagesPipenet Vision Spray/Sprinkler Module User and Reference Manualfoad-7No ratings yet

- FlaresimDocument436 pagesFlaresimMohamed Ali Boumaraf100% (1)

- Insights into Chemical Engineering: Selected Papers of P.V. DanckwertsFrom EverandInsights into Chemical Engineering: Selected Papers of P.V. DanckwertsNo ratings yet

- Flaresim Getting StartedDocument116 pagesFlaresim Getting Startedfiqry DarwansyahNo ratings yet

- Pipenet Transient ExamplesDocument94 pagesPipenet Transient ExamplesdehriyaNo ratings yet

- DynamicModel7 3 PDFDocument224 pagesDynamicModel7 3 PDFArcangelo Di TanoNo ratings yet

- KO DrumDocument3 pagesKO DrumArynda Dimas SadewoNo ratings yet

- Chemical Reactor Analysis and Applications for the Practicing EngineerFrom EverandChemical Reactor Analysis and Applications for the Practicing EngineerNo ratings yet

- Structured What If Technique A Complete Guide - 2020 EditionFrom EverandStructured What If Technique A Complete Guide - 2020 EditionNo ratings yet

- User's GuideDocument30 pagesUser's GuideAnonymous Wd2KONNo ratings yet

- PID Standard PitfallsDocument9 pagesPID Standard PitfallskrazylionNo ratings yet

- Process Safeguarding - PSE02Document2 pagesProcess Safeguarding - PSE02Sarfraz AliNo ratings yet

- Vapor-Liquid Equilibria Using Unifac: A Group-Contribution MethodFrom EverandVapor-Liquid Equilibria Using Unifac: A Group-Contribution MethodNo ratings yet

- Energy Optimization Using Pinch Analysis: Practical ConsiderationsDocument10 pagesEnergy Optimization Using Pinch Analysis: Practical ConsiderationsconfyNo ratings yet

- Plant Engineering and Design The Ultimate Step-By-Step GuideFrom EverandPlant Engineering and Design The Ultimate Step-By-Step GuideNo ratings yet

- Safeguarding Memorandum - EnggcyclopediaDocument6 pagesSafeguarding Memorandum - EnggcyclopediamzqaqilaNo ratings yet

- WP UniSim Design Blowdown Utility PDFDocument21 pagesWP UniSim Design Blowdown Utility PDFMinh Hoàng NguyễnNo ratings yet

- Handbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28From EverandHandbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28No ratings yet

- Adv 8 1Document10 pagesAdv 8 1Micu Ionut BogdanNo ratings yet

- IFP Materials PDFDocument38 pagesIFP Materials PDFProcess EngineerNo ratings yet

- Process Isolation Guidelines - Refining, Hydrocarbons, Oil, and Gas - CheresourcesDocument5 pagesProcess Isolation Guidelines - Refining, Hydrocarbons, Oil, and Gas - Cheresourcesjayrolling dollazNo ratings yet

- 15-501-EP-RP-003 - Rev.3 (Blowdown and Vent Study)Document238 pages15-501-EP-RP-003 - Rev.3 (Blowdown and Vent Study)Umair A. KhanNo ratings yet

- AutoCAD 2016 Tutorials For Chemical Engineering BasicDocument2 pagesAutoCAD 2016 Tutorials For Chemical Engineering BasicLi ChNo ratings yet

- CRP Sampling Literature PDFDocument8 pagesCRP Sampling Literature PDFgullenariNo ratings yet

- Depressurisation: A Practical Guide Updated For Version 3.2 / 2004Document20 pagesDepressurisation: A Practical Guide Updated For Version 3.2 / 2004Samuel ValbuenaNo ratings yet

- Distillation Column Design FactorsDocument2 pagesDistillation Column Design FactorsArunkumarNo ratings yet

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979From EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonNo ratings yet

- FLARENET Getting Started GuideDocument60 pagesFLARENET Getting Started Guidealastairwong90No ratings yet

- Process Engineer - Blowdown Valve (BDV) To Flare SystemDocument4 pagesProcess Engineer - Blowdown Valve (BDV) To Flare SystemIOCPC100% (1)

- 11-3085 Energy Analyzer Jump StartDocument26 pages11-3085 Energy Analyzer Jump StartOmesh BoroleNo ratings yet

- Engineering 003-Civil Structural Design Criteria On ShoreDocument22 pagesEngineering 003-Civil Structural Design Criteria On Shoremarin cristian100% (1)

- Vapor Liquid Separator PDFDocument10 pagesVapor Liquid Separator PDFClemenNo ratings yet

- Natural Gas Processing from Midstream to DownstreamFrom EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNo ratings yet

- Wall Metal Temperature During Emergency DepressurizationDocument7 pagesWall Metal Temperature During Emergency Depressurizationmihaileditoiu2010No ratings yet

- Depressuring Systems PDFDocument32 pagesDepressuring Systems PDFkumar_chemicalNo ratings yet

- Technip Separations PDFDocument61 pagesTechnip Separations PDFProcess EngineerNo ratings yet

- Calculate Compressed Air ReceiversDocument1 pageCalculate Compressed Air ReceiverssgrsthNo ratings yet

- Instrument Process Datasheet (IPDS)Document3 pagesInstrument Process Datasheet (IPDS)Vraja KisoriNo ratings yet

- Instrumentation and Process Control: Pamantasan NG Lungsod NG MaynilaDocument52 pagesInstrumentation and Process Control: Pamantasan NG Lungsod NG MaynilaAmiel DionisioNo ratings yet

- Impact of Emergency Shutdown Devices On Relief System Sizing and Design PDFDocument21 pagesImpact of Emergency Shutdown Devices On Relief System Sizing and Design PDFB rgNo ratings yet

- Pressure Safety Valves: Selection, Sizing & DesignDocument19 pagesPressure Safety Valves: Selection, Sizing & DesignAbdulAbdulNo ratings yet

- Article PSV Specific HeatDocument6 pagesArticle PSV Specific Heatprq123No ratings yet

- Process Designing of Breather ValvesDocument15 pagesProcess Designing of Breather ValvesGuglielmoNo ratings yet

- BMW 730dDocument17 pagesBMW 730dtalangocdayNo ratings yet

- FT 3021Document1 pageFT 3021talangocdayNo ratings yet

- Tag Number: 10-FG - 3020CDocument1 pageTag Number: 10-FG - 3020CtalangocdayNo ratings yet

- FT 3021Document1 pageFT 3021talangocdayNo ratings yet

- FT 3021Document1 pageFT 3021talangocdayNo ratings yet

- 7 Chi Tiec Thao LapDocument10 pages7 Chi Tiec Thao LaptalangocdayNo ratings yet

- Tag Number: 10-FG - 3020CDocument1 pageTag Number: 10-FG - 3020CtalangocdayNo ratings yet

- Tag Number: 10-FG - 3020CDocument1 pageTag Number: 10-FG - 3020CtalangocdayNo ratings yet

- 10-D-DJB-5340. Position Damage As BelowDocument4 pages10-D-DJB-5340. Position Damage As BelowtalangocdayNo ratings yet

- Tu Hoc Dan Guitar Solo-Tap 1Document236 pagesTu Hoc Dan Guitar Solo-Tap 1talangocdayNo ratings yet

- Fe 3024Document1 pageFe 3024talangocdayNo ratings yet

- Tagcore TypicalDocument1 pageTagcore TypicaltalangocdayNo ratings yet

- Fe 3023Document1 pageFe 3023talangocdayNo ratings yet

- Over ViewDocument3 pagesOver ViewtalangocdayNo ratings yet

- Cylinder Head AssemblyDocument4 pagesCylinder Head AssemblytalangocdayNo ratings yet

- A RichardsonDocument30 pagesA Richardsonplasma411nyNo ratings yet

- Document Number: Document TitleDocument8 pagesDocument Number: Document TitletalangocdayNo ratings yet

- ST7920Document49 pagesST7920jmcs87100% (2)

- Camry 2az - Fe 2008Document13 pagesCamry 2az - Fe 2008talangocday100% (1)

- Document Number: Document TitleDocument7 pagesDocument Number: Document TitletalangocdayNo ratings yet

- STM CanDocument1 pageSTM CantalangocdayNo ratings yet

- AbbreviationDocument1 pageAbbreviationtalangocdayNo ratings yet

- HD44780Document60 pagesHD44780nzltfNo ratings yet

- Automotive Electrical SystemsDocument101 pagesAutomotive Electrical SystemsMos CraciunNo ratings yet

- Versa ValveDocument24 pagesVersa ValvetalangocdayNo ratings yet

- Electrical Cable ScheduleDocument268 pagesElectrical Cable Scheduletalangocday100% (1)

- Ball Valve 1Document7 pagesBall Valve 1talangocdayNo ratings yet

- STMDocument25 pagesSTMLeidy SaavedraNo ratings yet

- Flow RegimeDocument2 pagesFlow RegimetalangocdayNo ratings yet

- Specification Ranger DX800Document4 pagesSpecification Ranger DX800Nugraha SandyNo ratings yet

- SteeringDocument30 pagesSteeringanisa yuliaNo ratings yet

- Main EnginesDocument79 pagesMain EnginesRajesh Kumar100% (1)

- Martini L1 IntroductionDocument12 pagesMartini L1 IntroductionphdcaoNo ratings yet

- Elec-Thrtl-Ctrls-98 Cummin PDFDocument58 pagesElec-Thrtl-Ctrls-98 Cummin PDFjuanNo ratings yet

- Hubbel ATS PDFDocument16 pagesHubbel ATS PDFalexiuteodorNo ratings yet

- Chapter 9 - Motion Along A Straight LinesDocument5 pagesChapter 9 - Motion Along A Straight Linesahmadkamil9286% (7)

- Gulf Gear WT: High Performance Industrial Gear OilDocument1 pageGulf Gear WT: High Performance Industrial Gear Oilatripathi2009No ratings yet

- Mechanics Prob 2Document3 pagesMechanics Prob 2Paul Angelou CiriacoNo ratings yet

- Henry Berger ResumeDocument1 pageHenry Berger Resumeapi-581806915No ratings yet

- R 11 Tumansky in Reality & Its MaintenanceDocument9 pagesR 11 Tumansky in Reality & Its MaintenanceAdithya AnandhanNo ratings yet

- Irwin, Kraft, Paris and Wells 1967Document78 pagesIrwin, Kraft, Paris and Wells 1967Nelson AlvarezNo ratings yet

- 004 VSL Datasheets US-ADocument22 pages004 VSL Datasheets US-Akmabd100% (1)

- Gear Materials, Properties, and ManufactureDocument347 pagesGear Materials, Properties, and ManufactureFrançois Steinmetz91% (11)

- Calculus Variations NOTES1Document107 pagesCalculus Variations NOTES1vc94No ratings yet

- JIS - Valve StandardsDocument10 pagesJIS - Valve StandardsPrateek GuptaNo ratings yet

- Macho para Roscas PDFDocument74 pagesMacho para Roscas PDFecavalinNo ratings yet

- Nonlinear Material Properties of StructuralDocument9 pagesNonlinear Material Properties of Structuralkhawaja AliNo ratings yet

- Commercial CO Refrigeration Systems: Guide For Subcritical and Transcritical CO ApplicationsDocument44 pagesCommercial CO Refrigeration Systems: Guide For Subcritical and Transcritical CO ApplicationsChrise5502No ratings yet

- OsmaDrain Jointing Quick GuideDocument2 pagesOsmaDrain Jointing Quick GuideHatem AbdelnabiNo ratings yet

- Weldable Coupler PDFDocument4 pagesWeldable Coupler PDFMirjana VeljkovicNo ratings yet

- SQ LOD200 v01 AllSizesDocument3 pagesSQ LOD200 v01 AllSizesharute gundamNo ratings yet

- Outline, Genset: A055J590 ArrowDocument2 pagesOutline, Genset: A055J590 ArrowmahranNo ratings yet

- Plane Stress LoadingDocument19 pagesPlane Stress LoadingAjeet Kumar100% (1)

- 315B Forest Swing Machine Electrical System: 7RZ284-UPDocument2 pages315B Forest Swing Machine Electrical System: 7RZ284-UPGilvan JuniorNo ratings yet

- Science 10 Motion ReviewDocument5 pagesScience 10 Motion ReviewVishal PonugotiNo ratings yet

- Repair Parts Sheet Turbo II Air Pumps: L2533 Rev. O 04/01 For Date Codes Beginning With The Letter "O"Document12 pagesRepair Parts Sheet Turbo II Air Pumps: L2533 Rev. O 04/01 For Date Codes Beginning With The Letter "O"Roberto RodriguezNo ratings yet

- 1-s2.0-S1359431121013430-Main (Innovations in Pulsating Heat Pipes From Origins To Future Perspectives)Document9 pages1-s2.0-S1359431121013430-Main (Innovations in Pulsating Heat Pipes From Origins To Future Perspectives)noxNo ratings yet

- Gears: Pinion Gear, Step Down DriveDocument42 pagesGears: Pinion Gear, Step Down DriveIshan VermaNo ratings yet