Professional Documents

Culture Documents

6284 3 00 PDF

Uploaded by

npsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6284 3 00 PDF

Uploaded by

npsCopyright:

Available Formats

SECTION 3.

00

ENGINE STARTUP AND SHUTDOWN

PRESTART INSPECTION

WARNING

Be sure that the clutch, circuit breaker, or other

main power transmission device is disconnected.

Generators develop voltage as soon as the engine

starts turning. Starting the engine with equipment

engaged can cause machine damage or severe

personal injury or death.

1. Inspect drive belts (alternator or other driven equipment). Examine condition of belt and verify correct belt

tension. If a cooling fan is used, be sure it is free to

turn, properly lubricated and the belt tension is correct.

WARNING

Make certain that the barring device is disengaged

from flywheel. Remove all wrenches before engaging the starter. Starting the engine with the barring

device engaged can cause machine damage or

severe personal injury or death from tools thrown

by the barring device.

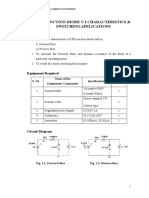

8. Using barring device turn engine over several revolutions to verify nothing will interfere with operation

(see Figure 3.00-1). The barring device is located on

the front left rear gear housing.

2. Trace entire cooling system to verify all control valves

are properly opened and all drain cocks are closed.

3. Check coolant level. If a large quantity of coolant is

added, be sure to open the cooling system air vents to

allow any air trapped in the system to escape.

4. Check for evidence of oil, fuel and coolant leaks

along all gasket surfaces.

5. Make certain all guards and shields are secure on

engine and equipment.

6. Remove all loose tools, rags, fittings, or other

equipment that may be picked up by rotating parts.

7. Air storage reservoirs for air starting systems

should be purged at least once a day to eliminate water

buildup in the tanks. This will reduce rust and scale

contamination to the air starting system. Every air starting system should include one or more drain cocks in

the air lines. Before starting the engine, bleed off some

of the compressed air. This will aid in keeping moisture

from condensing inside the air starting system.

FORM 6284 Third Edition

BARRING

DEVICE

Figure 3.00-1 Barring Device Location

9. Check oil level daily. Add oil as necessary to maintain level above low mark.

10. Operate automatic prelube system (if equipped)

until a positive indication is seen on oil pressure gauge.

11. Rotate fuel shutoff valve to start position (see

Figure 3.00-2).

3.00-1

ENGINE STARTUP AND SHUTDOWN

FUEL SHUTOFF

VALVE

STARTUP PROCEDURES

WARNING

Failure to follow the startup procedure in the operators manual may cause engine damage and could

result in severe personal injury or death.

MANUAL

DISCONNECT KNOB

VENT PLUG

Figure 3.00-2 Fuel Shutoff Valve

NOTE: Magneto equipped engines are shipped with

the ignition system grounded to prevent accidental

starting. This ground wire must be removed to operate

the engine.

All VGF engines

include hand throttle

controls for emergency shutdown procedures.

Make sure that the hand throttle is maintained in

the open position during startup and normal running conditions. Disregarding this information could

result in product damage and/or personal injury.

CAUTION

WARNING

The Deltec carburetion system must have a positive

gas shutoff valve that opens upon cranking and

closes whenever engine rotation stops. Failure to

provide the valve will cause an explosive environment resulting in severe personal injury or death.

The Deltec carburetor (see Figure 3.00-3) does not stop

the flow of fuel gasses. A positive gas shutoff valve that

opens upon cranking and closes whenever engine rotation stops must be installed before the carburetor.

Always read and follow the model specific information

in the Waukesha Operation and Maintenance Manual.

Contact Waukesha's Sales Engineering Department

for additional information or with questions regarding a

specific engine or installation.

Engines equipped with Deltec carburetors use specific

startup and shutdown procedures.

Deltec carburetors operate on a fixed venturi system

and do not have a positive fuel shut-off. This lack of

fuel shut-off within the fuel mixer means that fuel gas

will flow into the engine whenever the main gas control

valve is open. During a start and stop sequence the

engine and exhaust system may be flooded with gas.

This could cause an exhaust system explosion. To prevent this situation, Deltec carburetion systems must

have a positive gas shutoff valve that opens upon

cranking and closes whenever engine rotation stops.

WARNING

The Deltec carburetion system must have a positive

gas shutoff valve that opens upon cranking and

closes whenever engine rotation stops. Failure to

provide the valve will cause an explosive environment resulting in severe personal injury or death.

COLD WEATHER STARTING

PRESSURIZING ENGINES WITHOUT PREHEATER

Pressurizing the lubrication system is especially

important in cold weather. If there is no prelube pump,

crank the engine over several times, without fuel or

ignition, until oil pressure is indicated on the oil pressure gauge. The engine should not be started if there

is no pressure indication on the oil pressure gauge.

RESTART PROCEDURE

1. Reset tripped control before attempting to start the

engine after an emergency shutdown.

2. If an emergency shutdown or an alarm has

sounded, always find and correct the problem before

trying to start the engine.

DELTEC CARBURETOR

Figure 3.00-3 Deltec Carburetor

3.00-2

3. Reset switches on either oil pressure gauge or

water temperature gauge.

4. Reset magnetic switch on gas control valve (if

equipped).

FORM 6284 Third Edition

ENGINE STARTUP AND SHUTDOWN

SHUTDOWN PROCEDURE

1. Reduce engine load gradually.

2. Remove load by disengaging main clutch or other

power transmission device (generator circuit breaker,

etc.).

3. Place throttle control lever in medium idle speed

position and allow engine to idle for a few minutes to

equalize engine temperatures.

WARNING

After the engine is stopped, allow it to cool for at

least 10 minutes before repairing engine. Do not

restart an overheated engine or an engine that has

been shut down by the engine protection system

until the reason for the shutdown has been determined and corrected. Disregarding this information could result in severe personal injury or

death.

4. Gas engines are normally stopped by shutting off

fuel supply. Gas engines that are equipped with an

ignition switch can be stopped by placing ignition

switch in the OFF position.

WARNING

Gas supply to the engine must be shut off when

ignition power is interrupted or when any safety

switch is activated. Disregarding this information

could result in severe personal injury or death.

5. If engine is equipped with a prelube system,

postlube engine for 5 minutes after every shutdown.

2. If the engine fails to start after 15 or 20 seconds of

cranking, simultaneously discontinue cranking, close

the fuel system gas valve and turn off the ignition.

3. Upon next start attempt, follow procedure in Step

1. Waukesha recommends a maximum of three

unsuccessful start attempts. If the engine does not

start after three attempts begin troubleshooting.

NOTE: Step 3 allows the exhaust system to purge on

the next start cycle and reduce the probability of an

exhaust explosion.

NOTE: Be aware that engines equipped with Deltec

fuel systems may be factory supplied with a speed

switch that activates the main fuel valve. It is the

customer's responsibility to provide logic to open the

main valve on increasing speed (during start) and close

the main fuel valve on decreasing speed (during stop).

PLANNED SHUTDOWN DELTEC

CARBURETION

1. Shut the engine down by simultaneously closing

the main fuel valve, deactivating the shutdown

devices, stopping the breather motor (if so equipped),

and stopping the fuel gas compressors (if so

equipped).

2. Leave the ignition on for 3 to 5 seconds after the

fuel valve is closed to burn any unburned air/fuel mixture in the intake manifold and engine.

EMERGENCY SHUTDOWN DELTEC

CARBURETION

1. Shut the engine down by disengaging the external

load (if possible), closing the main fuel valve and turning off the ignition.

If the engine is being

shut down for an

extended period of time, cap the exhaust pipe to

prevent moisture or other contaminants from

entering the engine. Disregarding this information

could result in product damage.

2. Simultaneously stop the breather motor and the

fuel gas compressors (if so equipped).

STARTUP PROCEDURE DELTEC

CARBURETION

NOTE: Be sure there is gas supply to the engine.

CAUTION

NOTE: If engine fuel supply compressors are used on

your engine, the compressors should be started prior

to crank initiation.

1. Initiate cranking with the ignition system ON and

the fuel system gas valve closed. Allow 3 to 5 seconds

before opening the gas valve to allow for a purge cycle

in the engine. This purge cycle helps to reduce the

probability of an exhaust explosion.

STARTUP PROCEDURE GENERATOR

APPLICATIONS

1. Place governor throttle control lever 1/3 open. Verify main ignition switch is in ON position.

2. To start engines with prelube/start control panels,

depress and hold down the START button until the

engine starts.

If prelube system includes interlock, depress and

hold down START button (actuates prelube prior to

cranking).

If the prelube interlock is bypassed, then both

START and BYPASS buttons must be depressed

and held down.

3. Check for oil pressure indication when engine

starts.

FORM 6284 Third Edition

3.00-3

ENGINE STARTUP AND SHUTDOWN

CAUTION

If oil pressure is not

indicated within 10

seconds, shut down the engine. Never operate the

engine without adequate oil pressure indication.

Disregarding this information could result in product damage.

Do not assume that a faulty gauge or cold oil is

responsible for a no oil pressure indication. Check

that the shutdown control oil pressure reset has

released (when applicable). The engine can continue

to operate with low or no oil pressure since the reset

must be released by oil pressure before the low oil

pressure shutdown control becomes effective. The oil

pressure reset release is effected when the control

knob rotates to the RUN position, the shutdown control

reset latch knob or rod projects slightly from the body

and the switchgage lockout is released.

4. Warm engine by running with little or no load until

oil pressure reaches normal range and coolant temperature reaches 38 C (100 F).

NOTE: Oil pressure can reach 690 kPa (100 psi) with

cold oil at startup.

5. Move carburetor hand throttle to wide open position.

NOTE: Turbocharged engines are somewhat more

sensitive to the rate at which a load is applied. Apply

the load at a rate which allows the turbocharger time to

respond to the increasing exhaust as energy.

6. If possible, apply load to engine gradually to prevent overloading engine.

Engines that are required to start at temperatures

below 10 C (50 F) must be equipped with both an oil

and coolant heater. These devices allow the engine to

be started with the proper oil flow. If the heaters are

manually controlled, allow the engine to become warm

enough for normal starting.

7. Open governor throttle to desired engine speed.

Do not operate a turbocharged engine for

long periods at light loads or idle. Normal duty

cycles and occasional idle of a few minutes are

acceptable. Stop the engine if idling without load

for periods of 10 minutes or more. Disregarding

this information could result in product damage.

CAUTION

NOTE: When engines idle for extended periods or

come up to temperature with no load, the turbocharger

may be damaged with accumulated carbon. This carbon

buildup does not occur when a turbocharged engine is

operating at normal and heavy loads.

NOTE: Run a turbocharged engine to idle for three to

five minutes before shutting down. This allows the

temperature of the lubricating oil and turbochargers to

stabilize at moderate levels.

NOTE: If the engine is difficult to start, or will not run

properly, see Table 3.00-1 to troubleshoot the causes.

Table 3.00-1 Startup Troubleshooting

SYMPTOM

Doesn't start

Slow start and/or

Low power

Runs hot

PROBABLE CAUSE

REMEDY

Check controls

Follow the startup for resetting the engine controls.

Remote or automatic operation engines have special

procedures.

Check the fuel system

Verify that fuel is available to the engine. Check that

the gas valves are in the OPEN position.

Check air intake and exhaust systems

Check air filter is clean. Verify air intake or exhaust

outlet is not capped.

Check connections and auxiliary

Check throttle and governor control linkage for equipment freedom from sticking and interference. If

cranking speed is low, check the air supply (air

starter).

Check the ignition system

Check for water on ignition parts and wires, signs or

corrosion at wire terminals or broken wires. Look for

spark plugs that are worn out or poorly gapped.

Check the cooling system

Verify the following: The coolant level is correct, the

system is not air locked, the radiator is not blocked,

the shutter is open and the fan is operating. Also verify that the raw water valves are open to the heat

exchanger and that the air circulation is not poor as a

result of wind conditions or faulty installation.

NOTE: If these checks do not solve the problem, refer to the Troubleshooting Table in Chapter 5.

3.00-4

FORM 6284 Third Edition

ENGINE STARTUP AND SHUTDOWN

STARTUP PROCEDURE COMPRESSOR

APPLICATIONS

1. Set governor throttle control to 1/3 open position.

2. Pull out both manual shutdown switches.

NOTE: Be sure there is gas supply to the engine.

3. Press START button.

If the oil pressure

gauge does not indicate sufficient oil pressure within 10 seconds,

shut the engine down immediately. Never operate

the engine without the proper oil pressure indication. Failure to follow these instructions could

cause severe engine damage and/or severe personal injury.

CAUTION

FORM 6284 Third Edition

4. Check for oil pressure as soon as engine starts.

5. Warm engine by running with little or no load until

oil pressure is normal and coolant temperature

reaches 38 C (100 F).

6. Maintain oil level at FULL mark on dipstick. Check

oil level daily. Always check oil when engine is running

and at normal operating temperature.

7. Gradually apply a load to engine to avoid overload.

3.00-5

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Waukesha Reup BrochureDocument6 pagesWaukesha Reup BrochurenpsNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Waukesha Powering The World BrochureDocument12 pagesWaukesha Powering The World BrochurenpsNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- GE Waukesha VGF Bro US ScreenDocument5 pagesGE Waukesha VGF Bro US ScreennpsNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Waukesha VGF h24gld Product Sheet 1Document2 pagesWaukesha VGF h24gld Product Sheet 1nps100% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- VGF24GL GLD 8068 0710Document2 pagesVGF24GL GLD 8068 0710npsNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Waukesha Rating Charts 2016Document8 pagesWaukesha Rating Charts 2016npsNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 6284 1 15 PDFDocument31 pages6284 1 15 PDFnpsNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Chapter 1 - Safety and General: FORM 6284 Third EditionDocument1 pageChapter 1 - Safety and General: FORM 6284 Third EditionnpsNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- 6284 W 2Document1 page6284 W 2npsNo ratings yet

- Waukesha Engine, Dresser, Inc. Express Limited Warranty For Custom Engine ControlsDocument1 pageWaukesha Engine, Dresser, Inc. Express Limited Warranty For Custom Engine ControlsnpsNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 6284 W 2Document1 page6284 W 2npsNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- LDocument2 pagesLnpsNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- How To Use This Manual: FORM 6284 Third Edition XviiDocument1 pageHow To Use This Manual: FORM 6284 Third Edition XviinpsNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- 6284 4 30 PDFDocument18 pages6284 4 30 PDFnpsNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- 6284 5 00 PDFDocument9 pages6284 5 00 PDFnpsNo ratings yet

- Waukesha Engine WarrantyDocument4 pagesWaukesha Engine WarrantyastromoNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- 6284 4 55Document4 pages6284 4 55npsNo ratings yet

- 6284 Chap4 ContentsDocument1 page6284 Chap4 ContentsnpsNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 6284 4 65Document4 pages6284 4 65npsNo ratings yet

- Chapter 3 - Engine Startup and Shutdown: FORM 6284 Third EditionDocument1 pageChapter 3 - Engine Startup and Shutdown: FORM 6284 Third EditionnpsNo ratings yet

- Chapter 5 - Troubleshooting: FORM 6284 Third EditionDocument1 pageChapter 5 - Troubleshooting: FORM 6284 Third EditionnpsNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 6284 Chap2 ContentsDocument1 page6284 Chap2 ContentsnpsNo ratings yet

- 6284 4 10 PDFDocument14 pages6284 4 10 PDFnps100% (1)

- SECTION 4.45: Starting System MaintenanceDocument3 pagesSECTION 4.45: Starting System MaintenancenpsNo ratings yet

- 6284 2 30 PDFDocument7 pages6284 2 30 PDFnpsNo ratings yet

- 6284 4 60Document4 pages6284 4 60npsNo ratings yet

- 6284 4 50Document5 pages6284 4 50npsNo ratings yet

- 6284 4 40 PDFDocument6 pages6284 4 40 PDFnpsNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- 6284 4 35 PDFDocument1 page6284 4 35 PDFnpsNo ratings yet

- Getting Started With Experion Software GuideDocument28 pagesGetting Started With Experion Software Guidebeerman81No ratings yet

- B 1815Document4 pagesB 1815Angelo MachadoNo ratings yet

- Semiconductor Devices and Circuits LaboratoryDocument53 pagesSemiconductor Devices and Circuits LaboratoryKaryampudi RushendrababuNo ratings yet

- Lincoln Douglas Debate TextbookDocument115 pagesLincoln Douglas Debate TextbookRogelio Aurelio Rojas ReyesNo ratings yet

- IS30 IS50 WM CWL WM-L Schnittstellendoku enDocument250 pagesIS30 IS50 WM CWL WM-L Schnittstellendoku enspidigeNo ratings yet

- X2 ParametersDocument6 pagesX2 Parametersmanson_dataNo ratings yet

- Unit - I Dynamics of Electric Drives: Electrical Power Transmission SystemsDocument4 pagesUnit - I Dynamics of Electric Drives: Electrical Power Transmission Systemsyemane gebremichalNo ratings yet

- 02 OS90522EN15GLA0 Data StoragesDocument84 pages02 OS90522EN15GLA0 Data StoragesElego13thNo ratings yet

- Mach 3 MillDocument157 pagesMach 3 Millafricano333100% (1)

- U Series: Vortex ImpellerDocument12 pagesU Series: Vortex ImpellerNichamon NNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Quiz Sectiunea 7Document5 pagesQuiz Sectiunea 7Bogdan BrkicNo ratings yet

- Spring State Machine TransitionsDocument6 pagesSpring State Machine TransitionsGroza CristiNo ratings yet

- 04d Process Map Templates-V2.0 (PowerPiont)Document17 pages04d Process Map Templates-V2.0 (PowerPiont)Alfredo FloresNo ratings yet

- MATLAB AssignmentsDocument12 pagesMATLAB AssignmentsnilimaNo ratings yet

- Flashprint UserGuide en USDocument44 pagesFlashprint UserGuide en USdreamelarn100% (2)

- Atomic Absorption SpectrosDocument2 pagesAtomic Absorption SpectrosSirTonz100% (1)

- PROG 8011 Lab 6-W24Document2 pagesPROG 8011 Lab 6-W24kaurrrjass1125No ratings yet

- 1) Semester II /1 / IV Exam 2020 (Even) (Old / New Syllabus) BacklogDocument5 pages1) Semester II /1 / IV Exam 2020 (Even) (Old / New Syllabus) BacklogHarsh VardhanNo ratings yet

- EEE2205 Introduction To MeasurementsDocument4 pagesEEE2205 Introduction To MeasurementsKibelennyNo ratings yet

- Read and Write Action of RAM Using IC 7489Document5 pagesRead and Write Action of RAM Using IC 7489Deepak Kumbhar100% (1)

- Is.11921.1993 Fuel Efficiency StandardDocument12 pagesIs.11921.1993 Fuel Efficiency StandardParminder SinghNo ratings yet

- Calculation of The Size of The Mooring SystemDocument7 pagesCalculation of The Size of The Mooring SystemKyle RubricoNo ratings yet

- ReviewerDocument6 pagesReviewerNeo GarceraNo ratings yet

- Study of Selected Petroleum Refining Residuals Industry StudyDocument60 pagesStudy of Selected Petroleum Refining Residuals Industry StudyOsama AdilNo ratings yet

- ESM Upgrade To 72 PDFDocument46 pagesESM Upgrade To 72 PDFsantoshs2002848No ratings yet

- Design of Torque ArmDocument16 pagesDesign of Torque ArmRonak PanchalNo ratings yet

- 1421 PDFDocument12 pages1421 PDFLuis F JaureguiNo ratings yet

- Learning Objectives: Lecture 3: Moving Averages and Exponential SmoothingDocument6 pagesLearning Objectives: Lecture 3: Moving Averages and Exponential SmoothingcuriousdumboNo ratings yet

- Cabinas de Bioseguridad HealforceDocument8 pagesCabinas de Bioseguridad HealforceJose HurtadoNo ratings yet

- MWM Parts ListDocument6 pagesMWM Parts ListRuy PeñaNo ratings yet

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsFrom EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsRating: 4.5 out of 5 stars4.5/5 (2)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AFrom EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo ratings yet