Professional Documents

Culture Documents

Sept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet L

Uploaded by

Rakesh0 ratings0% found this document useful (0 votes)

24 views4 pagesMud Feeder

Original Title

Mud Feeder

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMud Feeder

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views4 pagesSept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet L

Uploaded by

RakeshMud Feeder

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

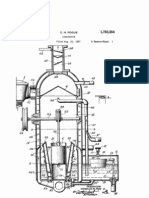

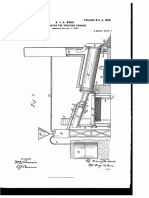

Sept.

20, 1955

H. w. HUDSPETH

2,718,435

MUD FEEDER FOR OIL WELLS

Filed July 22, 1952

2 Sheets-Sheet l

36 39

596*

INVENTOR

BY

ATTORNEYS

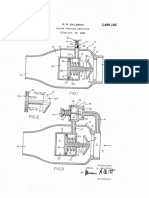

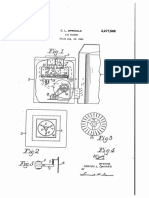

Sept. 20, 1955

2,718,435

H. w. HUDSPETH

MUD FEEDER FOR OIL WELLS

2 Sheets-Sheet 2

Filed July 22, 1952

'

INVENTOR

HuZer Z WHu Jefei/z

Z6

BY

ATTORNEY5

United States Patent 0 "me

2,718,435

Patented Sept. 20, 1955

2,718,435

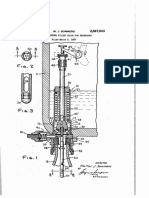

and a cylindrical valve member 22 is slidable within the

housing member 12. The valve member 22 is adapted

to be vertically moved as will be hereinafter described so

as to regulate the opening or closing of the intake ports

21. These ports 21 are disposed adjacent the lower small

end of the hopper 17 so that the dry mud within the hop

per may gravitatingly flow through the ports 21 into the

housing member 12.

MUD FEEDER FOR 01L WELLS

Hubert W. Hudspeth, Hobbs, N. Mex.

Application July 22, 1952, Serial No. 300,148

4 Claims. (Cl. 302-15)

A horizontally disposed shaft 23 is journalled dia

v10 metrically across the upper housing member 11 and has

secured within the housing member 11 a substantially T

?tting 24 which includes an arm 25 extending at right

angles to the shaft 23. A connecting link 26 is secured

at its upper end to the arm 25 and is secured at its lower

15 end to a diametrically disposed bar 27 which is secured

This invention relates to a mud feeder for oil wells.

within the upper portion of the valve member 22.

In the drilling of oil wells, mud is fed to the well so

The shaft 23 has an inner spring 28 engaging there

as to provide a means for removing the drilled-out ma

about which bears against the housing 11 and ?tting 24

terial. An object of this invention is to provide an im

and a second or outer spring 29 bears at its inner end

proved means for regulating the discharge of dry mud

against the outer side of the housing member 11 and bears

into a water pipe.

at its outer end against a nut or spring tensioning mem

Another object of this invention is to provide a mud

ber 30 mounted on the adjacent outer end of the shaft

regulator which can be mounted in conventional hoppers

23. An L-shaped coupling 31 is secured to the opposite

and which will correctly meter the mud discharged from

end of the shaft 23 and an elongated handle or crank

the hopper, and will permit the hopper to be substantially

?lled with dry mud at one operation and thereby eliminate 25 arm 32 is secured to the L 31 and extends upwardly there

the need for a constant attendant to feed the mud slowly

to prevent clogging.

A further object of this invention is to provide an im

proved mud feeding device which includes means for ad

from. The springs 28 and 29 yieldably hold crank arm

or handle 32 against a notched keeper bar 33 (Fig. 4)

which is ?xed to the outer side of the housing member 11.

The keeper bar 33 is formed adjacent the opposite ends

mitting metered quantities of air to the mud valve so as 30 thereof with stop members 34 which limit the rocking

movement of the handle 32. A cap 35 is threaded onto

to assure an even ?ow of mud.

With the above and other objects in view, my inven

tion consists in the arrangement, combination and details

of construction disclosed in the drawings and speci?cation,

the upper end of the upper housing member 11 and is

formed with a top wall 36 having a pair of sector-shaped

openings 37 which are diametrically disposed.

A valve plate 38 is pivotally mounted on a pivot 39 and

and then more particularly pointed out in the appended 35

is movable relative to the openings 37 so as to open or

claims.

close the openings for admission of air through the upper

In the drawings:

end of the upper housing member 11. A handle 39a ex

Figure 1 is a detail side elevation, partly in vertical sec

tends from the valve member 38 so that this valve member

tion, of a feeder for a mud hopper constructed according

40 can be readily adjusted to provide for opening or closing

to an embodiment of this invention,

of the openings 37.

Figure 2 is a sectional view taken on the line 2-2 of

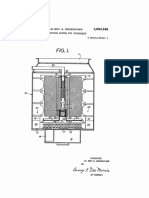

In the use and operation of this device, the feeder

Figure 1,

hereinbefore described is ?rmly set into the hopper nipple

Figure 3 is a fragmentary sectional view taken on the

16 and extends vertically and axially upwardly through

line 33 of Figure 2,

45

the hopper 17. The dry mud is then discharged into the

Figure 4 is a plan view, partly in section, of the air

hopper 17 and valve member 22 is vertically adjusted to

feeder,

provide for the desired ?ow of the dry mud into the mix

Figure 5 is a fragmentary sectional view taken on the

ing pipe 19. The force of the water ?owing horizontally

line 55 of Figure 2,

Figure 6 is a sectional view taken on the line 6--6 of 50 from the nozzle pipe 20 into the mixing pipe 19 will cause

the dry mud to be drawn downwardly into the mixing pipe

Figure 3.

19. The rate of flow of the dry mud is controlled by ver

Referring to the drawings, the numeral 10 designates

tical adjustment of the valve member 22 and the ad

generally an elongated tubular housing which is formed

justment of the air valve member 38.

of a tubular upper member 11 connected to a tubular

With a feeder as hereinbefore described, the hopper 17

lower member 12 by means of a cylindrical coupling 55

may be initially completely ?lled with the dry mud and it

member 13. The lower tubular member 12 is formed

with a reduced diameter lower end 14 which is threaded

into a cylindrical sleeve 15.

will be unnecessary for an attendant to constantly watch

arranged circumferentially about the housing member 12

I- do not mean to con?ne myself to the exact details of

the condition of the hopper after the valve members 22

The sleeve 15 snugly ?ts within a cylindrical discharge

and 38 have been initially set. As a matter of practice

nipple 16 carried by the lower end of an upwardly ?ared 60 the mud is discharged from one hundred pound bags into

or substantially conical hopper 17. The nipple 16 of the

the hopper 17 and with the use of conventional hopper

hopper 17 is mounted within an upstanding coupling nip

devices not containing valved suction devices it is neces

ple 18 carried by a horizontal water conducting pipe 19.

sary for one or more attendants to be constantly watch

The water pipe 19 is formed adjacent the lower end of the

hopper 17 with a reduced diameter pipe 20 which forms 65 ing the ?ow of the mud so that the mud will move down

wardly into the mixing pipe or chamber 19. However,

a nozzle and venturi whereby water under pressure will

with the device hereinbefore described, the device will

flow to the left, as viewed in Figure 1, and will thereby

operate without constant attendance of the operator and

form a suction for drawing downwardly into the pipe 19

the mud will evenly flow downwardly for mixing with

dry mud which is discharged into the hopper 17.

The lower housing member 12 is provided with a plu 70 the water discharged from the nozzle pipe 20 into the

mixing pipe or chamber 19.

rality of vertical elongated intake ports 21 which are

2,718,435

construction herein disclosed, but claim all variations

of said housing to vary the degree of suction in accord

falling Within the purview of the appended claims.

ance with the position of the cylindrical valve, said last

What I claim is:

:A feeder for mud hoppers including a discharge

named valve comprising a closure member for the upper

end of said housing and provided with a plurality of aper

nipple and a water actuated suction means below said

tures, and a disk pivotally mounted on said closure mem

nipple,said .feeder comprising a vertically disposed tubular

housing adapted for mounting in said nipple, said housing

ber, said disk being adjustable relative to said apertures to

control the ?ow of air through said tubular housing.

4. A feeder adapted for mounting in a mud hopper com

having a plurality of intake ports adjacent the lower por

prising a tubular upright housing ?xed at its lower end

tion thereof, a cylindrical valve slidable in said housing,

means, including a valve actuating link connected with 10 in said hopper, said housing having a plurality of intake

ports in the lower portion thereof, a cylindrical regulating

said valve for adjusting the latter relative to said ports,

valve slidable in said housing, a shaft journalled through

said link being disposed in said housing, and adjustable

said housing adjacent the upper portion thereof, a right

valve means at the upper end of said housing for regulat

angular arm ?xed relative to said shaft within said housing,

ing theentrance of air into said housing to vary the degree

ofjsuction.

12. In combination a hopper for receiving dry mud, a

water pipe connected with the lower end of said hopper

a link pivotally connected to said arm and said valve

whereby rocking of said shaft will adjust said valve rela

tive to said ports, inner and outer springs on said shaft

yieldably holding the latter against endwise movement, a

right angularly disposedhandle ?xed to one end of said

shaft, a notched keeper element ?xed to said housing and

engageable by said handle for holding the latter in an

gularly adjusted position, and adjustable valve means at

means carried by the upper portion of said housing con

the upper end of said housing for regulating the admission

nected with said valve for adjusting said valve relative to

of air through the upper end of said housing, the relative

said ports, said means including a valve actuating link dis

posed in said housing, and valve means for admitting air 25 position of said cylindrical regulating valve and said ad

justable valve means controlling the degree of suction,

into the upper end of said housing, the relative position of

said last-named valve comprising a closure member having

said cylindrical valve and said valve means determining

a plurality of sector-shaped openings extending trans

the degree of suction at the lower end of said hopper.

versely therethrough, said closure member being mounted

3. In combination a hopper for receiving dry mud said

hopper having a discharge nipple, a Water pipe connected 30 on the upper end of said housing, and a disk pivotally

connected on said closure member and adjustable rela

with the lower end of said nipple and extending at right

tive to said sector-shaped openings to control the flow of

angles relative to said hopper, a tubular upright housing

air through said tubular housing.

?xed at its lower end in said nipple, said housing having

intake ports in the lower portion thereof, a cylindrical

References Cited in the ?le of this patent

valve slidable in said housing, a shaft journalled diametri

cally across the upper portion of said housing, an arm

and extending at right angles relative to said hopper, a

tubular upright housing ?xed at its lower end in said

hopper, said housing having intake ports in the lower por

tion thereof, a cylindrical valve slidable in said housing,

UNITED STATES PATENTS

?xed to said shaft in said housing, a link connecting said

arm with said valve, a right angularly disposed handle

?xed to the outer end of said shaft, and means holding

said lever in angularly adjusted position, and a valve con

772,443

2,129,451

2,425,524

Turner _______________ __ Oct. 18, 1904

Talmage _____________ __ Sept. 6, 1938

Fontenot et al _________ __ Aug. 12, 1947

trolling the quantity of air admitted into the upper end

2,594,072

Ridley __-_ ____ __>_-_____ __ Apr. 22, 1952

You might also like

- H. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Document4 pagesH. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Josh FullerNo ratings yet

- June 7, 1955 A, D. Kinser Et Al 2,710,071: Fi'iled Nov. 17. 1951Document3 pagesJune 7, 1955 A, D. Kinser Et Al 2,710,071: Fi'iled Nov. 17. 1951محمود محمدNo ratings yet

- Us 2109297Document6 pagesUs 2109297lfilippiniNo ratings yet

- Jan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1Document5 pagesJan. 16, 1962 J. A. Lyne 3:016w99l: Filed Jan. 26, 1959 2 Sheets-Sheet 1luiscremaschiNo ratings yet

- Byyeqwla: 2 I / I I VDocument5 pagesByyeqwla: 2 I / I I VaegosmithNo ratings yet

- Carburador de Hidrógeno PatE8Document7 pagesCarburador de Hidrógeno PatE8Maximo CozzettiNo ratings yet

- Electrolytic Carburetor by Charles H. Garrett (Patent)Document11 pagesElectrolytic Carburetor by Charles H. Garrett (Patent)max386No ratings yet

- GT LL: NN W///, WM)Document5 pagesGT LL: NN W///, WM)lfilippiniNo ratings yet

- Charles Nelson Pouge (US Pat. 1750354)Document5 pagesCharles Nelson Pouge (US Pat. 1750354)GaleriaTechniki.PLNo ratings yet

- Us 2409624Document6 pagesUs 2409624Giovanni BlancoNo ratings yet

- United States Patent (191: McguganDocument6 pagesUnited States Patent (191: McguganJamesStenhouseNo ratings yet

- S Chapter 27Document14 pagesS Chapter 27jesusalbeirourbanoviverosNo ratings yet

- US2900999-metal SealDocument3 pagesUS2900999-metal Sealasen tsaiNo ratings yet

- Clem Engine Paper PresentationDocument6 pagesClem Engine Paper PresentationDankamialNo ratings yet

- US3489165Document3 pagesUS3489165换行No ratings yet

- Nov. 9, 1965 R. C. Frampton Etal 3,216,663: Filed Nov. 15, 1963 2 Sheets-Sheet 1Document5 pagesNov. 9, 1965 R. C. Frampton Etal 3,216,663: Filed Nov. 15, 1963 2 Sheets-Sheet 1Anggara T NugrahaNo ratings yet

- Buoyancy: The "Hidro" Self-Powered Generator of James KwokDocument14 pagesBuoyancy: The "Hidro" Self-Powered Generator of James KwokAlboresha RafidNo ratings yet

- In The DrawingsDocument8 pagesIn The DrawingsLalit KumarNo ratings yet

- Us 3460614Document7 pagesUs 3460614scibduser001No ratings yet

- Wellhead Connector H4 TypeDocument9 pagesWellhead Connector H4 Typeste7ieNo ratings yet

- Filed July 30, 1923: Pedal of Erator For Flush ValvesDocument3 pagesFiled July 30, 1923: Pedal of Erator For Flush ValvesmarlondijiNo ratings yet

- M. H. Butler &. C. A. Larson.: (No Model.)Document3 pagesM. H. Butler &. C. A. Larson.: (No Model.)Kosmas StefanidesNo ratings yet

- Hyper Valve PatentDocument15 pagesHyper Valve PatenttonytayicNo ratings yet

- 1972.10.10 EN Patent DragPump EnergyThic US3697190 Truncated Conical Drag PumpDocument7 pages1972.10.10 EN Patent DragPump EnergyThic US3697190 Truncated Conical Drag PumpRenier SnymanNo ratings yet

- United States Patent: SchwartzmanDocument4 pagesUnited States Patent: SchwartzmanJames LindonNo ratings yet

- US3230974 E61 PatentDocument3 pagesUS3230974 E61 Patentspanglish6969No ratings yet

- Description: (OCR Text May Contain Errors)Document3 pagesDescription: (OCR Text May Contain Errors)SachinNo ratings yet

- Negative Pressure Sanitary Installation Equipped With A Purifier of Gaseous FluidsDocument8 pagesNegative Pressure Sanitary Installation Equipped With A Purifier of Gaseous FluidsCarlos Javier Mendoza MendozaNo ratings yet

- US3317184Document4 pagesUS3317184Efabind OtNo ratings yet

- W.J. Sommers: Counter-Pressure Filler Valve For Beverages Filed March 5, 1957Document3 pagesW.J. Sommers: Counter-Pressure Filler Valve For Beverages Filed March 5, 1957bimalishaNo ratings yet

- US3094165 Wheeler Manfac-PatentDocument7 pagesUS3094165 Wheeler Manfac-Patentsoubhadra nagNo ratings yet

- Us 3378330Document5 pagesUs 3378330James LindonNo ratings yet

- June 4, 1957 B. Vonnegut - 2,794,341Document4 pagesJune 4, 1957 B. Vonnegut - 2,794,341Amit PandeyNo ratings yet

- Patent On Piles and Pile Extraction: Department of Civil EngineeringDocument7 pagesPatent On Piles and Pile Extraction: Department of Civil EngineeringVivek SharmaNo ratings yet

- Filed March 20, 1943Document8 pagesFiled March 20, 1943Andrés RamírezNo ratings yet

- OpenDocument9 pagesOpenchristian1777No ratings yet

- Bob Neal Overunity Compression Unit - US2030759Document5 pagesBob Neal Overunity Compression Unit - US2030759John CarterNo ratings yet

- 1,018,037 ... Patented Feb. 20, 1912.: .??? Coax/K Wyùkkevaoma ????Document3 pages1,018,037 ... Patented Feb. 20, 1912.: .??? Coax/K Wyùkkevaoma ????fernando Ancaya AncayaNo ratings yet

- March23, 1954 J. L, Dunnlgan Y 2,672,853: Sealed Cooling System For Internal-Combustion EnginésDocument3 pagesMarch23, 1954 J. L, Dunnlgan Y 2,672,853: Sealed Cooling System For Internal-Combustion Enginésmonem2014No ratings yet

- Aug. 15, 1967 H. Grigull Etal 3,335,462: 152088230340. B11346 Heinz 1'12? 83Document4 pagesAug. 15, 1967 H. Grigull Etal 3,335,462: 152088230340. B11346 Heinz 1'12? 83jaydevpatelNo ratings yet

- Intersecting Spherical Pressure TankDocument25 pagesIntersecting Spherical Pressure TankLuci Oktaria SitorusNo ratings yet

- United States PatentDocument5 pagesUnited States PatentJagannathan ArumugamNo ratings yet

- Apparatus For Treating Sewage.: No. 659,503. I Patented Oct. 9, I900Document4 pagesApparatus For Treating Sewage.: No. 659,503. I Patented Oct. 9, I900Abdullah SimpsonNo ratings yet

- Siled Sept. 8, 1966: T, N. NccomeDocument5 pagesSiled Sept. 8, 1966: T, N. NccomeliNo ratings yet

- March 8, 1960 Y H. A. Longino 2,927,383: Filed June 3, 1958 2 Sheets-Sheet 1Document5 pagesMarch 8, 1960 Y H. A. Longino 2,927,383: Filed June 3, 1958 2 Sheets-Sheet 1david19775891No ratings yet

- May 13, 1969 M. R. Jones: So, 1966 L Of4 Filed DecDocument16 pagesMay 13, 1969 M. R. Jones: So, 1966 L Of4 Filed DecluiscremaschiNo ratings yet

- Centrifugal CompressorDocument7 pagesCentrifugal Compressorrohan112358No ratings yet

- Filed Dec. 23, 1959: Aug. 15, 1961 L. A. Botkin 2,996,222Document4 pagesFiled Dec. 23, 1959: Aug. 15, 1961 L. A. Botkin 2,996,222sqmiNo ratings yet

- Ullage CalculationDocument6 pagesUllage CalculationAamir Shahzad100% (2)

- Us2277566 1Document3 pagesUs2277566 1Priya TiwariNo ratings yet

- Jan-1, 1935 - R. G. de La Mater Er Al 1,985,889Document8 pagesJan-1, 1935 - R. G. de La Mater Er Al 1,985,889lfilippiniNo ratings yet

- Jan. 4, L 1966 T. W. Spack 3,227,148Document6 pagesJan. 4, L 1966 T. W. Spack 3,227,148MainAvelNo ratings yet

- Inflation Of/ Balloon: Filed Mar-Ch 5, 1959Document4 pagesInflation Of/ Balloon: Filed Mar-Ch 5, 1959david19775891No ratings yet

- Once Through Boiler Recirculation PumpDocument6 pagesOnce Through Boiler Recirculation Pumpபிரசன்னகுமார் ஆனந்தன்No ratings yet

- United States Patent: KiernanDocument12 pagesUnited States Patent: KiernanharisupayNo ratings yet

- Fieie) : ' Jan. 5, 1971 N. T. Fosse Etal 3,551,958Document6 pagesFieie) : ' Jan. 5, 1971 N. T. Fosse Etal 3,551,958adrianomc25No ratings yet

- LLL Billion" .Vizíaßllllla: July 14, 1959 F.V F. EhrlchDocument6 pagesLLL Billion" .Vizíaßllllla: July 14, 1959 F.V F. EhrlchDouglas SanchezNo ratings yet

- Rig-E???': Gill!Document6 pagesRig-E???': Gill!luiscremaschiNo ratings yet

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- Hybrid Topcoat Formulations For PaperDocument11 pagesHybrid Topcoat Formulations For PaperRakeshNo ratings yet

- Process For Surface Sizing PaperDocument7 pagesProcess For Surface Sizing PaperRakeshNo ratings yet

- Llo. 715,3l5. P Atsntad Dec. 9, I902.: Cigar CutterDocument3 pagesLlo. 715,3l5. P Atsntad Dec. 9, I902.: Cigar CutterRakeshNo ratings yet

- F PenDocument3 pagesF PenRakeshNo ratings yet

- Err-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695Document3 pagesErr-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695RakeshNo ratings yet

- Vernier DesignDocument9 pagesVernier DesignRakeshNo ratings yet

- Interconnected Solar CellsDocument13 pagesInterconnected Solar CellsRakeshNo ratings yet

- Electro Magnetic MotorDocument9 pagesElectro Magnetic MotorRakeshNo ratings yet

- Load BalancingDocument16 pagesLoad BalancingRakeshNo ratings yet

- Multipurpous KeyDocument12 pagesMultipurpous KeyRakeshNo ratings yet

- Sri LankaDocument2 pagesSri LankaRakeshNo ratings yet

- Sri Lanka BuddhismDocument2 pagesSri Lanka BuddhismRakeshNo ratings yet

- Electrodes, Rods and FluxesDocument37 pagesElectrodes, Rods and FluxesSchuldich Schwarz100% (1)

- Effects of Alloying Elements On SteelDocument2 pagesEffects of Alloying Elements On SteelKISHORNo ratings yet

- Cargo Handling Manual - SOE 12k LEG (01-TECHNICAL - 1304275 - 1 - 01) PDFDocument283 pagesCargo Handling Manual - SOE 12k LEG (01-TECHNICAL - 1304275 - 1 - 01) PDFМаксим Шабатын100% (2)

- Bezinal3000 2010Document2 pagesBezinal3000 2010tanto_deep_15No ratings yet

- Delayed CokingDocument7 pagesDelayed CokingMatheus RodriguesNo ratings yet

- CBC COVID19 Product List 3 - 20 - 2020 PDFDocument10 pagesCBC COVID19 Product List 3 - 20 - 2020 PDFCandra SuryaNo ratings yet

- Transmission Towers & Lines: Download Brochure PDFDocument2 pagesTransmission Towers & Lines: Download Brochure PDFGhayas Ud-din DarNo ratings yet

- Mechanical Designer Resume TemplateDocument1 pageMechanical Designer Resume TemplateHubertNo ratings yet

- C-23 Life Cycle of Process Plants PDFDocument9 pagesC-23 Life Cycle of Process Plants PDFnike_y2k100% (1)

- Code 1 WPS Rev 0 PDFDocument18 pagesCode 1 WPS Rev 0 PDFEarl HarbertNo ratings yet

- Wiring Diagram SectionDocument76 pagesWiring Diagram Sectiondavydenkoanton5No ratings yet

- Chapter 3 Study Guide KeyDocument3 pagesChapter 3 Study Guide KeyKaren YNo ratings yet

- 3电气与信息系统L936L938ENGLISH PDFDocument62 pages3电气与信息系统L936L938ENGLISH PDFadelmomoura100% (1)

- Creating Paper From Pineapple Leaves and Corn HuskDocument6 pagesCreating Paper From Pineapple Leaves and Corn HuskAllen LuisNo ratings yet

- Comparison of Costs - Chlorine Gas Versus Hypochlorites: Application 1Document4 pagesComparison of Costs - Chlorine Gas Versus Hypochlorites: Application 1fatsoe1No ratings yet

- Bemco BrochureDocument19 pagesBemco BrochurelightsonsNo ratings yet

- Simpolo Integrity Price List 20-11-018Document1 pageSimpolo Integrity Price List 20-11-018shashirajNo ratings yet

- Friction Stir Welding - Process and Its Variables: A ReviewDocument8 pagesFriction Stir Welding - Process and Its Variables: A ReviewMulyanto MulyonoNo ratings yet

- Pile ReportDocument14 pagesPile ReportChen E LikNo ratings yet

- Tile WorksDocument5 pagesTile WorksglenNo ratings yet

- American Top Loader Washing Machine + SerialDocument67 pagesAmerican Top Loader Washing Machine + SerialMandragora officinarum100% (1)

- Supplement 1Document11 pagesSupplement 1Tabish IslamNo ratings yet

- 1282094111153Document9 pages1282094111153PaperCraft VNNo ratings yet

- Conlit Firestop Systems Installation Method StatementDocument2 pagesConlit Firestop Systems Installation Method StatementramtsanNo ratings yet

- Location Planning and AnalysisDocument42 pagesLocation Planning and AnalysisSobhit Gupta100% (2)

- LeachingDocument8 pagesLeachingRodolfoSottoJr.No ratings yet

- 2.9.4. Dissolution Test For Transdermal PatchesDocument3 pages2.9.4. Dissolution Test For Transdermal PatchesSandeep KumarNo ratings yet

- Cabin Pressure:: ExampleDocument47 pagesCabin Pressure:: ExamplePrasanth ViratNo ratings yet

- Product Life Cycle and LifeDocument3 pagesProduct Life Cycle and LifejoelNo ratings yet

- DDC SVC Man 0189Document180 pagesDDC SVC Man 0189gicuNo ratings yet