Professional Documents

Culture Documents

pp4 PDF

Uploaded by

Praveen KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

pp4 PDF

Uploaded by

Praveen KumarCopyright:

Available Formats

International Journal of Engineering and Technical Research (IJETR)

ISSN: 2321-0869, Volume-3, Issue-6, June 2015

Robotic Arm Wirelessly Controlled By Android

Application

Bharat Shresth Awasthi, Sabya Sanchi Pandey, Ashish Singh, Mrs.M.V. Patil

II. RELATED WORK

Abstract In this paper, pick and place robotic arm is

designed and implemented. This robotic arm is based on android

application controlled for remote operation. In this paper,

commands are sent to the receiver to control the movement of

the robot either to move forward, backward and left or right etc

using android application device. Four motors are interfaced to

the microcontroller where two motors are used for arm and

gripper movement of the robot while the other two motors are

used for the body movement. The android application device

transmitter acts as a remote control that has the advantage of

adequate range, while the receiver end Bluetooth device is fed to

the microcontroller to drive DC motors via motor driver IC for

necessary work. Remote operation is achieved by any

smart-phone/Tablet etc., with Android OS; upon a GUI

(Graphical User Interface) based touch screen operation. This

system can be enhanced by interfacing it with a wireless camera

so that the person controlling it can view operation of the arm

and gripper remotely.

Index Terms Robotic Arm, DC Motor, Bluetooth,

Microcontroller, Graphical User Interface, Android Application

Device

I. INTRODUCTION

Robot is an integral part in automating the flexible

manufacturing system that is greatly in demand these days.

Robots are now more than a machine, as robots have become

the solution of the future as cost labor wages and customers'

demand [1]. Even though the cost of acquiring robotic system

is quite expensive but as todays rapid development and a

very high demand in quality with IS0 (International Standard

Organization) standards, human are no longer capable of such

demands. Research and development of future robots is

movingly at a verv rapid face due to the constantly improving

and upgrading of the quality standards of products. Robot and

automation is employed in order to replace human to perform

those tasks that are routine dangerous, dull and in a hazardous

area. Today In the world of advanced technology, automation

greatly increases production capability; improve product

quality and lower production cost.

In this paper, firstly related work is explained followed by

hardware design and software design. Experimental results

and conclusion is explained in the end of this paper.

Robots have their historical past though they came into

existences in 1961. A. Che Soh, S.A. Ahmad, A.J. Ishak and

K. N. Abdul Latif introduced a paper, Development of an

Adjustable Gripper for Robotic Picking and Placing

Operation in which adjustable gripper for robotic system is

designed to identify the shape and size of an object which is

needed in many applications especially for picking and

placing operation [2]. The main objective is to design a robust

gripper that can perform easier and faster picking and placing

operation for multiple shapes and sizes objects. This

adjustable gripper for robotic system can to improve the

picking and placing operation in manufacturing field in

producing more outputs without the needs to. P.S.Ramaiah,

M.Venkateswara Rao, Raghu and G.V.Satyanarayana

presented a system entitled A Microcontroller Based Four

Fingered Robotic Hand. In this paper, design and

development of a Four Fingered Robotic Hand (FFRH) using

8-bit microcontroller, sensors and wireless feedback is

explained. The design of the system is based on a simple,

flexible and minimal control strategy.

This system has 14 independent commands for all the four

fingers open and close, wrist up and down, base clockwise

and counters clockwise, Pick and Place and Home position to

move the fingers. The tendering system of the double revolute

joint mechanism and wireless feedback network provide the

hand with the ability to confirm to object topology and

therefore providing the advantage of using a simple control

algorithm. Finally, the results of the experimental work for

pick and place application is enumerated. Author Girish Patel,

and Devendra Chauhan introduced a paper entitled SIFT

Based Approach: Object Recognition and Localization for

Pick-and-Place System. In this paper, the system typically

employs machine vision to analyze the scene, identify and

locate the specified object and provide feedback to the robot

arm for subsequent operations. For successful picking, the

vision system needs to recognize the position and the

orientation of the objects, the Scale Invariant Feature

Transform (SIFT) is used for this purpose.

The proposed system is based on android application

controlled for remote operation. In this method, robotic arm is

designed and developed with a soft catching gripper.

III. HARDWARE IMPLEMENTATION

Bharat Shresth Awasthi, Sabya Sanchi Pandey, Ashish Singh,

Mrs.M.V. Patil, Dept. of Electronics, Bharati Vidyapeeth University

College of Engineering, Pune

193

The hardware implementation of pick and place arm system

consists of AVR microcontroller, DC motor, Bluetooth,

Motor Driver, Android application device and power supply.

The block diagram of proposed method is shown in Fig 1.

www.erpublication.org

Robotic Arm Wirelessly Controlled By Android Application

Fig. 1.

Block Diagram of Proposed Method

Fig. 3.

IC of ATmega16

A. AVR Microcontroller

In this paper, AVR microcontroller ATmega16 is used for

data acquisition. The high-performance, low-power Atmel

8-bit AVR RISC-based microcontroller combines 16KB of

programmable flash memory, 1KB SRAM, 512B EEPROM,

an 8-channel 10-bit A/D converter, and a JTAG interface for

on-chip debugging. The device supports throughput of 16

MIPS at 16 MHz and operates between 4.5-5.5 volts. By

executing instructions in a single clock cycle, the device

achieves throughputs approaching 1 MIPS per MHz,

balancing power consumption and processing speed. It has 1

programmable serial USART (universal synchronous

asynchronous receiver transmitter) and 32 programmable I/O

pins [3]. To write a program for microcontroller, AVR studio

software is used. Sinaprog is used to burn the program into the

microcontrollers flash memory. Fig 2 and Fig 3 shows the pin

diagram and IC of ATmega16 respectively.

B. DC Motor

In this paper, four Stepper DC motor is used to move the

arm, gripper and vehicle forward or backward. A stepper

motor is a brushless DC electric motor that divides a full

rotation into a number of equal steps. The position of motor

can be commanded to move and it holds one of these steps

without any feedback sensor. It is an open-loop controller.

When DC voltage is applied to their terminals, it rotates

continuously. It converts a train of input pulses known as

square wave pulses into a precisely defined increment in the

shaft position. Each pulse moves the shaft through a fixed

angle.

Fig. 4.

DC Stepper Motor

C. Motor Driver

Fig. 2.

Motor driver is used to drive the motors used in this paper.

Motor driver is connected to the microcontroller.

Microcontroller gives the 5 miliamp output which is not

sufficient enough to drive the DC motors thats why we use

motor driver. Fig 5 shows the diagram of motor driver.

Pin Diagram of ATmega16

194

www.erpublication.org

International Journal of Engineering and Technical Research (IJETR)

ISSN: 2321-0869, Volume-3, Issue-6, June 2015

F. Android Application Device

\

Android is the most popular operating system used in

mobile [6]. In this paper, we have developed an android

application to control the movement of robotic arm.

G. LCD Display

Fig. 5.

Motor Driver

D. Bluetooth Module

Bluetooth is a packet-based multi-layer wireless protocol

with Master-slave model. In Bluetooth, one Master may

communicate upto 7 slaves in a piconet. In this, RF Layer

operates in unlicensed ISM band of 2.4GHz. In this paper,

Bluetooth HC-05 is used which has a Chipset CSR

BC417143. The Bluetooth version is V2.0+EDR. It has Flash

8Mbit and operates at voltage 3.3V [5]. The size of Bluetooth

module is 26.9mm*13mm*2.2mm. The pin diagram of

Bluetooth and Bluetooth module are shown in Fig 6.

LCD (Liquid Crystal Display) screen is an electronic

display module. In this paper, 16x2 LCD display is used

which is very basic module and is very commonly used in

various devices and circuits. LCDs are economical, easily

programmable and have no limitation of displaying. A 16x2

LCD means it can display 16 characters per line and there are

2 such lines. The command register stores the command

instructions given to the LCD. A command is an instruction

given to LCD to do a predefined task like initializing it,

clearing its screen, setting the cursor position, controlling

display etc. The data register stores the data to be displayed on

the LCD. The data is the ASCII value of the character to be

displayed on the LCD. Fig. shows the LCD

Fig. 8.

LCD Display

IV. EXPERIMENTAL RESULTS

Fig. 6.

Pin Diagram and Module of HC-05 Bluetooth

E. Power Supply

In this paper, 12V power supply is given to the system

using the batteries. 7805 voltage regulator is used which

regulates the voltage to 5V.

Fig. 7.

In this way, we have implemented a robotic arm controlled

wirelessly by an android device. We have controlled the

various movements of arm as well as vehicle by sending

different commands from android device through Bluetooth,

such as on giving command L arm moves left, on giving

command R arm moves right, similarly for gripper open

command M and for gripper close command N is given

from android device. These results can be seen in Fig. 9, Fig.

10, Fig. 11, Fig. 12.

Fig. 9.

12V Battery

195

Gripper Close

www.erpublication.org

Robotic Arm Wirelessly Controlled By Android Application

according to the size of the object. Due to this advantage, the

robot can pick. This system can be used in various

applications like in gripper, fabrication process, and

inspection, processing, spraying, stamping and welding for

work piece.

REFERENCES

[1] Jegede Olawale, Awodele Oludele, Ajayi Ayodele, Development of a

Microcontroller Based Robotic Arm, In Proceedings of the 2007

Computer Science and IT Education Conference pg: 549-557.

[2] Robotic Arm - www. NASA explores. com from Teacher Sheets pg:1-2

[3] Datasheet of ATmega16 Microcontroller

[4] Datasheet of Bluetooth Module

[5] Robot software from Wikipedia, the free encyclopedia on 04-3-2012

[6] Andren, Gerald B., Robot Design Handbook, SRI International,

Mitsubishi Electric Company, 1988.

Fig. 10. Gripper Open

Fig. 11. Arm Left

Fig. 12. Arm Right

V. CONCLUSION

An autonomous robot with adjustable gripper that perform

pick and place operation has been successfully designed and

developed. The robot has been able to pick the object and

place it effectively. The robot is also able to perform lifting

upward and downward smoothly. By using AVR

microcontroller, the robot has performed the task perfectly

according to the program that being made. Beside than that,

the adjustable gripper with sensors is able to open its grip

196

www.erpublication.org

You might also like

- A Review Paper On Automatic BMI MonitorDocument12 pagesA Review Paper On Automatic BMI MonitorPraveen KumarNo ratings yet

- T& P Tech 26-7-2020Document29 pagesT& P Tech 26-7-2020Praveen KumarNo ratings yet

- Automatic BMI Monitor Using IOT: Block DiagramDocument2 pagesAutomatic BMI Monitor Using IOT: Block DiagramPraveen KumarNo ratings yet

- Mounika. A : Career ObjectiveDocument2 pagesMounika. A : Career ObjectivePraveen KumarNo ratings yet

- Training and Placement Wing CircularDocument35 pagesTraining and Placement Wing CircularPraveen KumarNo ratings yet

- Training and Placements TasksDocument2 pagesTraining and Placements TasksPraveen KumarNo ratings yet

- Tour XLDocument31 pagesTour XLPraveen KumarNo ratings yet

- CH 02Document47 pagesCH 02Praveen KumarNo ratings yet

- DR D.Seshappa, Principal, Tadipatri Engineering College, Tadipatri, Anantapur (DT) A.PDocument3 pagesDR D.Seshappa, Principal, Tadipatri Engineering College, Tadipatri, Anantapur (DT) A.PPraveen KumarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CSS 10 Q1 - Las W1 PDFDocument6 pagesCSS 10 Q1 - Las W1 PDFJohndion A. RulomaNo ratings yet

- ViciBox v6 InstallDocument16 pagesViciBox v6 InstallJuan Pablo BiglieriNo ratings yet

- AWS EssentialsDocument6 pagesAWS EssentialskashyapNo ratings yet

- Black Box Manual ServiceDocument9 pagesBlack Box Manual ServiceCsar BardalesNo ratings yet

- Group Policy Cmdlets in Windows PowerShellDocument3 pagesGroup Policy Cmdlets in Windows PowerShellgagnepaNo ratings yet

- Portal Info StubDocument11 pagesPortal Info Stubzamanqomaru8No ratings yet

- Sound Synthesis ATSAM9753 Integrated Digital Music InstrumentDocument23 pagesSound Synthesis ATSAM9753 Integrated Digital Music Instrumentmike_helplineNo ratings yet

- How To Make GHOST Boot ToolDocument4 pagesHow To Make GHOST Boot ToolDaniel LebreuxNo ratings yet

- Apollo OPT9608 Product NoteDocument2 pagesApollo OPT9608 Product NoteAndre MateusNo ratings yet

- Netapp Data Ontap 7-Mode CLI Pocket GuideDocument8 pagesNetapp Data Ontap 7-Mode CLI Pocket GuidePeter KidiavaiNo ratings yet

- Pylontech Low Voltage Battery Mornitoring and Maintenance Tool GuidanceDocument11 pagesPylontech Low Voltage Battery Mornitoring and Maintenance Tool GuidanceFernando DobantonNo ratings yet

- J1406 - Distributed, Concurrent, and Independent Access To Encrypted Cloud DatabasesDocument4 pagesJ1406 - Distributed, Concurrent, and Independent Access To Encrypted Cloud Databasesrajesh_d84No ratings yet

- Unsupported Commands in Cisco IOS Release 15.2 (2) S: AppendixDocument10 pagesUnsupported Commands in Cisco IOS Release 15.2 (2) S: AppendixDavid MunsellNo ratings yet

- Network SheetDocument1 pageNetwork SheetМихаил ХорошевNo ratings yet

- Creating NC FilesDocument8 pagesCreating NC FilesStelian ConstantinescuNo ratings yet

- Oracle Recommendations For RAC Cluster Interconnect and Jumbo FramesDocument3 pagesOracle Recommendations For RAC Cluster Interconnect and Jumbo Framesmcoates4500No ratings yet

- PC Memory (RAM) : Computer Memory Type Information, Help Buy The Correct TypeDocument25 pagesPC Memory (RAM) : Computer Memory Type Information, Help Buy The Correct TypeMichael ZuñigaNo ratings yet

- How To Fix Lenovo Error 'Detection Error On HDD0 (Main HDD) 'Document21 pagesHow To Fix Lenovo Error 'Detection Error On HDD0 (Main HDD) 'Yudy KurniawanNo ratings yet

- AWS Certified Developer - Associate Sample Exam QuestionsDocument4 pagesAWS Certified Developer - Associate Sample Exam QuestionsGiane Mariano100% (1)

- Configuring VLAN Interfaces: Chapter 3, "Bridging Traffic."Document30 pagesConfiguring VLAN Interfaces: Chapter 3, "Bridging Traffic."shevaNo ratings yet

- Modbus Master (Serial and TCP/IP) Driver For Field Device System Integrator ModulesDocument8 pagesModbus Master (Serial and TCP/IP) Driver For Field Device System Integrator ModulesLeonardo Gabriel Fernández GottardiniNo ratings yet

- OSY-Microproject V VDocument20 pagesOSY-Microproject V VComputer ActivityNo ratings yet

- Security NatDocument282 pagesSecurity NatShpresa SadikuNo ratings yet

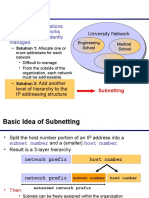

- Lect 2-Intro To SubnettingDocument11 pagesLect 2-Intro To Subnettingapi-358658237No ratings yet

- Malware AnalysisDocument3 pagesMalware AnalysisViren ChoudhariNo ratings yet

- 2014 Usa PDF BRKARC-2001Document105 pages2014 Usa PDF BRKARC-2001Nishad DadhaniyaNo ratings yet

- Exercise 2 - The User InterfaceDocument23 pagesExercise 2 - The User InterfaceManasses juniorNo ratings yet

- Syllabus - Information Technology & Its Application in BusinessDocument4 pagesSyllabus - Information Technology & Its Application in BusinessMariel AdventoNo ratings yet

- Shared Device With F-CPU S7-1500 and SINAMICS: STEP 7 Safety Advanced V13 SP1Document13 pagesShared Device With F-CPU S7-1500 and SINAMICS: STEP 7 Safety Advanced V13 SP1AlexandraLlumigusinNo ratings yet

- Intro - HPC Cluster Computing v2 PDFDocument73 pagesIntro - HPC Cluster Computing v2 PDFkucaisoftNo ratings yet