Professional Documents

Culture Documents

Will Bill Mill & Drill? A Case by Prof Sridar Natarajan

Uploaded by

sadiqusOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Will Bill Mill & Drill? A Case by Prof Sridar Natarajan

Uploaded by

sadiqusCopyright:

Available Formats

WILL BILL MILL & DRILL?

A case by Prof Sridar Natarajan

Sri Castings was established by Bill in December 2007 with an investment

of Rs. 5 Million. Its objective was to manufacture and sell raw castings for

an ancillary supplier to the automobile industries in Tamil Nadu. The plant

was located on two acres of land acquired on a long-term concessional

lease rental of Rs. 100,000 a month

The machinery was purchased and installed in a record period of 3 months

and its first batch of castings itself was found acceptable by the ancillary Brake Drums Ltd. As Mr. Phadke, GM, Materials of Brake Drums Ltd.

stated, Sri Castings was the first company in BDLs 5 years of existence

whose samples were found to meet BDLs stringent quality requirements

in the first shipment itself.

With a relentless commitment to quality and a supportive client, Sri

Castings posted good results better than expected in the financial year

2008-09, ending with a profit of Rs. 10 lakhs. It was during the annual get

together at BDL that Bill broached the subject of getting additional casting

orders to supply. Sri Castings was working only one shift now, which was

resulting in an inefficient utilization of his Electric Arc Furnace. Additional

orders could result in a better utilization of the Furnace, which could work

for 16 hours instead of 8. Bill would be willing to pass on some of the

benefits of the better utilization to BDL in terms of better prices.

In May 2009, Sri Castings got additional orders from BDL that promised a

doubling of their turnover and a sixty percent increase in profits. Bills

employee strength grew to 50; he hired a full-time Production Manager, a

Metallurgical Engineer from a reputed Engineering College in Coimbatore.

Knowing that handling of volumes would bring with it possibilities of

quality problems, he also hired a full-time Quality Assurance supervisor.

Once again, Bills commitment and hard work paid off. He closed 2009-10

with a turnover of Rs. 21 million and a profit of Rs. 1.7 million. Not only

did he better his estimates, he also increased his ROI by 4.8%.

Not surprisingly, in the annual get-together for 2010, it was Mr. Phadke

who broached the topic for additional orders to Sri Castings. Bill, he said

(they were now on first-name terms), would you be interested in a new

order? We are on the lookout for a raw casting supplier for a smaller

drum. Would I be able to handle it without additional investment,

asked Bill? Afraid not, Bill. This is a slightly complicated product. But the

margins would be fairly attractive! Could I get back to you on this,

Phadke? Maybe a week?

In a weeks time Bill got back in the negative. Sorry, Phadke, but I want

to consolidate the scrap sourcing this year. I wont have time for a

complicated product. No hard feelings? Not at all. In fact, I am happy

to note that you are consolidating. Maybe I will get some benefit out of

your consolidation, eh? Yeah, maybe, came the answer with a smile.

There was definitely a lot of mutual respect between the two.

It was during his scrap consolidation travel that he came across this

advertisement for the sale of a machine shop Rs. 1.65 million for the

entire machinery on an as-is-where-is basis. The advertisement

triggered off a thought process hitherto never considered. Should he start

machining his castings? He was not sure of the answer, but, trusting his

instincts he went and visited the Shop. The machines were both good and

in good condition it would easily have a useful life of 5 years; the records

were maintained professionally. He was convinced that Rs. 1.65 million

for the entire machinery was a good bargain.

He returned and had a first round of discussions with Mr. Murali, his

Production Manager, who was immediately excited about the prospect.

With his confidence now strengthened, Bill immediately sent a proposal to

BDL requesting that he send them machined castings instead of raw

products. His proposal clearly provided details of the machine shop that

he was planning to acquire in order to service BDL. This was July 2010.

After several rounds of discussions between Phadke and Bill, the MD of

BDL agreed to meet Bill to discuss and finalize the proposal. Though it

was a good 3 months after the advertisement had been released, Bill was

in regular touch with the Shop and ensured it was still available a task

which required a lot of persuasion and cajoling.

The meeting with the MD was very productive. Mr. Shome, the MD, was

very supportive, on the one hand, but equally down-to-earth on the other.

It so happens Mr. Bill that we are actually planning to offload some of our

internal machining activities, so your timing is perfect! However, you

need to consider the following points before we finalize the deal.

a. The machining unit has to be a separate entity, as it was against

the policy of BDL to have the same supplier perform the casting

and the machining.

b. The machining charges would be a percentage of the cost of the

castings. This meant that if the foundry became more efficient,

the machining charges would have to reduce!

c. The initial contract would be for a period of 5 years commencing

1 April 2011, after which they would reconsider the arrangement

Mr. Bill promised to revert after re-considering his workings.

Bill and Murali sat down with their calculators and data sheets (Annexure

1). A separate entity meant additional fixed costs. Also, Bill noted that

the orders from BDL would only require 50% of the capacity of the

Machine Shop. Could he get orders from the other ancillary suppliers?

He went back to Phadke, his friend and well-wisher who introduced him to

three more companies that were already getting their castings machined

outside. Mr. Bill visited these companies and, after speaking to the

owners, was convinced that he would be able to utilize his machines at

least 70% of the capacity in the first year itself. The companies he met

assured him of the orders, providing he was competitive in his pricing. His

experience with BDL told him that he was very cost effective in his

operations.

Having accounted for the revenue side of the projections, Bill and Murali

worked out the costs based on the following assumptions:

The company could be setup in the Sri Castings campus, which

had an area of 20,000 square feet that was unused. Consequently,

there would be no cost for land.

For the first two years, Murali would be totally in-charge of the

production activities of both Sri Castings and the new company.

While the time spent on the new plant could affect the production of

the existing castings in terms of contribution loss of around Rs. 5

lakhs in the first year and Rs. 7 lakhs in the second year, Bill felt it

was worth it.

The fixed costs for the new plant was estimated to be as follows:

o Salary of machine operators: Rs. 70,000 p.m.

o Salary of other personnel:

Rs. 30,000 p.m.

o Other overheads:

Rs. 50,000 p.m.

o Interest costs:

Rs. 10,000 p.m.

The new plant will be depreciated using the SLM.

The tax rate is 30%.

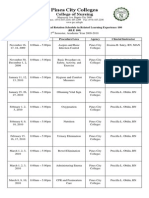

The castings planned to be produced by Sri Castings in the coming 5

years are shown below.

*Picture source - Internet

The casting weights and materials are shown below.

Component

Weight

Material

SC-120

20kgs

SG Iron

SC-220

20 kgs

Grey Iron

SC-1425

25 kgs

SG Iron

SC-2425

25 kgs

Grey Iron

SC-1430

30 kgs

SG Iron

SC-2430

30 kgs

Grey Iron

SC-1635

35 kgs

SG Iron

SC-1640

40 kgs

SG Iron

The prices of Grey Iron and SG Iron in Rs. per ton are expected to

vary as given below.

Material

2011-12

2012-13

2013-14

2014-15

2015-16

Grey Iron

18,000

19,000

20,000

21,000

21,500

SG Iron

20,000

21,000

22,000

23,000

23,500

The estimate of production of castings at Sri Castings for the next 5

years is as given below.

Units per year

Component

2011-12

2012-13

2013-14

2014-15

2015-16

SC-120

4,000

4,000

4,200

4,200

4,500

SC-220

3,000

3,200

3,200

3,500

3,500

SC-1425

6,000

6,000

6,000

6,000

6,000

SC-2425

5,000

5,500

6,200

6,500

7,000

SC-1430

6,000

6,500

7,000

7,500

8,000

SC-2430

6,000

5,500

5,500

5,200

4,000

SC-1635

5,000

5,000

5,500

5,500

5,500

SC-1640

5,000

6,000

6,500

6,500

7,000

Sri Castings charges BDL at the rate of the raw material cost + a

40% increase to take care of fixed costs and profit margin.

Bill felt that if the machining charges were more than 7% of the cost

of the product, BDL would not accept their proposal. However, he

was positive that if he charged 5% of the product cost as his

machining charges, he would be a very profitable venture and his

investment would be giving him his desired return of 20%.

Advise Bill on his investment proposal. Should he start this venture?

Should he charge 5% of the product cost as his charges? Will he

generate his return of 20%?

ANNEXURE 1 - DATA SHEET FOR INVESTMENT IN MACHINE SHOP

Table 1: Machine cost details

Machine

Numbers

Operations

executable

Cost (Rs.)

CNC M/c

One

Milling

Turning

Shaping

800,000

Lathe (Manual)

Two

Turning

480,000

Drilling Machine

One

Drilling

Tapping

Chamfering

75,000

Grinder

One

Grinding

35,000

Tooling

260,000

Additional fixed

350,000

assets

Total (funded 50% internally and 50% through a 5year Term Loan of 12% interest)

2,000,000

You might also like

- Powder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsFrom EverandPowder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsRating: 4.5 out of 5 stars4.5/5 (17)

- GMAT Flashcards v4Document119 pagesGMAT Flashcards v4gmatclub2100% (2)

- New Hemi Engine Swaps: How to Swap 5.7L, 6.1L, 6.4L & Hellcat Engines into Almost Anything: How to Swap 5.7L, 6.1L, 6.4L & Hellcat Engines into Almost AnythingFrom EverandNew Hemi Engine Swaps: How to Swap 5.7L, 6.1L, 6.4L & Hellcat Engines into Almost Anything: How to Swap 5.7L, 6.1L, 6.4L & Hellcat Engines into Almost AnythingNo ratings yet

- Reading Comprehension Animals Copyright English Created Resources PDFDocument10 pagesReading Comprehension Animals Copyright English Created Resources PDFCasillas ElNo ratings yet

- HAF F16 ManualDocument513 pagesHAF F16 Manualgreekm4dn3ss86% (7)

- Mil PRF 46010FDocument20 pagesMil PRF 46010FSantaj Technologies100% (1)

- Roller Compacted Concrete PDFDocument34 pagesRoller Compacted Concrete PDFAdrian Luis Hernandez Garcia67% (3)

- Transformers Classics: UK Vol. 3 PreviewDocument10 pagesTransformers Classics: UK Vol. 3 PreviewGraphic PolicyNo ratings yet

- Army National Guard Military Funeral Honors Soldier S Training SOP 23 Nov 15Document203 pagesArmy National Guard Military Funeral Honors Soldier S Training SOP 23 Nov 15LuisAndresBellavista100% (1)

- CPM ExamplesDocument198 pagesCPM ExamplesnaveedsidhuNo ratings yet

- Isavasya UpanishadDocument5 pagesIsavasya UpanishadskmrrlNo ratings yet

- International History 1900-99Document5 pagesInternational History 1900-99rizalmusthofa100% (1)

- Component III - NEGOTIATIONDocument5 pagesComponent III - NEGOTIATIONvideo pediaNo ratings yet

- Project Delay Case Study and Concurrent Model AnalysisDocument2 pagesProject Delay Case Study and Concurrent Model AnalysisGaurav Dharmadhikari0% (1)

- Fly Ash Brick Production PlanDocument25 pagesFly Ash Brick Production PlanHiren PatelNo ratings yet

- Bharat Forge CaseDocument33 pagesBharat Forge Caseeverakash_104355063No ratings yet

- Paper - Timing - Important:-: CA Foundation Business Law - FCA Slot - 60 MARK'S 1.5 Hour'sDocument3 pagesPaper - Timing - Important:-: CA Foundation Business Law - FCA Slot - 60 MARK'S 1.5 Hour'sSohan AgrawalNo ratings yet

- HRM AssignmentDocument6 pagesHRM AssignmentSiba Narayan DoraNo ratings yet

- 76925bos61942 6Document10 pages76925bos61942 6nerises364No ratings yet

- Chairmans Statement 2019Document5 pagesChairmans Statement 2019Narendra MauryaNo ratings yet

- MadmDocument272 pagesMadmfaizthemeNo ratings yet

- Indian Electricals Weighs Accepting Trial Order for Vending MachinesDocument8 pagesIndian Electricals Weighs Accepting Trial Order for Vending MachinesJoseph MathewNo ratings yet

- The Following Are The Objectives of The StudyDocument6 pagesThe Following Are The Objectives of The StudyChetan SankhlaNo ratings yet

- Case 5 - Bajaj Auto LTDDocument3 pagesCase 5 - Bajaj Auto LTDHimanshu TiwariNo ratings yet

- MOCK TEST-V LAW+BCRnDocument10 pagesMOCK TEST-V LAW+BCRnCheshta TolaniNo ratings yet

- Business Plan: MBA (Master of Business Administration)Document12 pagesBusiness Plan: MBA (Master of Business Administration)Beerappa RamakrishnaNo ratings yet

- Session 8 Krishna Tools Case StudyDocument7 pagesSession 8 Krishna Tools Case Studyabhishek tripathyNo ratings yet

- Kamdhenu Limited Is Poised To Move Forward With Smart City Project in BiharDocument2 pagesKamdhenu Limited Is Poised To Move Forward With Smart City Project in BiharManojNo ratings yet

- India's cement demand to grow double digits long termDocument1 pageIndia's cement demand to grow double digits long termrahulgosarrNo ratings yet

- 78338bos62701 10Document10 pages78338bos62701 10nerises364No ratings yet

- Law & BCR Prelim Paper 30 - 11-23Document5 pagesLaw & BCR Prelim Paper 30 - 11-23roshanchoudhary4350No ratings yet

- F4MYS 2014 Jun QDocument5 pagesF4MYS 2014 Jun QKaito KirinoNo ratings yet

- June 2013 QDocument3 pagesJune 2013 QBuddhika Lakmal ABèyNo ratings yet

- BALL BEARING MANUFACTURING PROJECTDocument53 pagesBALL BEARING MANUFACTURING PROJECTSagar HaraneshaNo ratings yet

- DM DCFDocument2 pagesDM DCFAJAY GOYALNo ratings yet

- Samrat Mallick Manufacturing Company Case Study SolvedDocument5 pagesSamrat Mallick Manufacturing Company Case Study SolvedSamrat MallickNo ratings yet

- 71810bos57772 Inter p2qDocument9 pages71810bos57772 Inter p2qSakshi KhandelwalNo ratings yet

- Marketing Case Study - MM1 (EPGPX02, GROUP-06)Document5 pagesMarketing Case Study - MM1 (EPGPX02, GROUP-06)kaushal dhapareNo ratings yet

- 2-2mys 2003 Dec QDocument6 pages2-2mys 2003 Dec Qqeylazatiey93_598514No ratings yet

- Corporate and Business Law (Malaysia) : Monday 12 December 2011Document4 pagesCorporate and Business Law (Malaysia) : Monday 12 December 2011leeNo ratings yet

- Economic and Political WeeklyDocument2 pagesEconomic and Political WeeklyKamalDeep SidhuNo ratings yet

- CASE - Krishna Steels - 2013Document4 pagesCASE - Krishna Steels - 2013Anurag SharmaNo ratings yet

- Take Home Quiz - UASDocument2 pagesTake Home Quiz - UASMonalusiNo ratings yet

- Decision MakingDocument5 pagesDecision MakingPrasanna SharmaNo ratings yet

- Analyzing Equipment Replacement and Product Lifecycle CostsDocument1 pageAnalyzing Equipment Replacement and Product Lifecycle CostsDIMPI 2122069No ratings yet

- Project Report On SailDocument92 pagesProject Report On SailAjay KumarNo ratings yet

- Corporate Accounting and Financial ManagementDocument8 pagesCorporate Accounting and Financial ManagementPrabhakar TripathiNo ratings yet

- Project Report On Performnace AppraisalDocument126 pagesProject Report On Performnace AppraisalRatan ShuklaNo ratings yet

- ACFrOgDaNGFQt7WBqX0JLdS5pS5B6d9UAzcMCZ2mekyeV5FCk4MF1Hu44y86qaiaXwmQMSg CTrxhLTNSwZba063YqfFHrerkzEIHquFOTdD3 pyWIqmbqbMUaPGCYG cDe7QVqLj5lpynzktdzMDocument2 pagesACFrOgDaNGFQt7WBqX0JLdS5pS5B6d9UAzcMCZ2mekyeV5FCk4MF1Hu44y86qaiaXwmQMSg CTrxhLTNSwZba063YqfFHrerkzEIHquFOTdD3 pyWIqmbqbMUaPGCYG cDe7QVqLj5lpynzktdzM2K18/AE/049 SARTHAK THAREJANo ratings yet

- Y 2011 Earnings Call - Jindal Saw Dt-13 May'11: OperatorDocument33 pagesY 2011 Earnings Call - Jindal Saw Dt-13 May'11: OperatorSandeep Aanand ShawNo ratings yet

- Neptune Readymix A Iimk ReportDocument11 pagesNeptune Readymix A Iimk Reportjoseph vinoyNo ratings yet

- Working Capital Management at Abhinandan EngineersDocument60 pagesWorking Capital Management at Abhinandan EngineersSushil HongekarNo ratings yet

- Mock 12Document6 pagesMock 12Asad HanifNo ratings yet

- A Summer Internship ReportDocument55 pagesA Summer Internship ReportShyam C A100% (1)

- Corporate and Business Law (Malaysia) : Monday 12 December 2011Document4 pagesCorporate and Business Law (Malaysia) : Monday 12 December 2011Vincent Chia Wei SengNo ratings yet

- Certificate in Accounting and Finance Mock Exam QuestionsDocument6 pagesCertificate in Accounting and Finance Mock Exam QuestionsUsman Ahmed ManiNo ratings yet

- Success Story - Acquisition of Customer DRA Infracon PVT LTD and Key LearningsDocument2 pagesSuccess Story - Acquisition of Customer DRA Infracon PVT LTD and Key Learningsranjan0013No ratings yet

- Shree CementDocument53 pagesShree CementRoma Pareek100% (3)

- Corporate and Business Law: (Malaysia)Document6 pagesCorporate and Business Law: (Malaysia)loniazproNo ratings yet

- Rupal Bothra InternshipDocument27 pagesRupal Bothra Internshiptejalsahu5432No ratings yet

- Berger Paints India LTD: Company ReportDocument11 pagesBerger Paints India LTD: Company ReportHimanshu JoshiNo ratings yet

- 05CASE 3 Write RightDocument5 pages05CASE 3 Write RightSradha SahaNo ratings yet

- BSE Limited The National Stock Exchange of India Limited: RAM Chandr A RawatDocument18 pagesBSE Limited The National Stock Exchange of India Limited: RAM Chandr A RawatManish PatraNo ratings yet

- SPML Infra Debt To Reduce Substantially With Cabinet Decision On Arbitration Awards (Company Update)Document2 pagesSPML Infra Debt To Reduce Substantially With Cabinet Decision On Arbitration Awards (Company Update)Shyam SunderNo ratings yet

- KM Tyres Company: Executive SummaryDocument2 pagesKM Tyres Company: Executive Summary62Anil ReddyL100% (1)

- Final Mock Spring 2023Document6 pagesFinal Mock Spring 2023broken GMDNo ratings yet

- Coal Miner Bets On Steel Mills To Boost Profit - Corporate India - BloombergDocument3 pagesCoal Miner Bets On Steel Mills To Boost Profit - Corporate India - BloombergNasrul SalmanNo ratings yet

- Case of RhinoDocument6 pagesCase of Rhinokarizmatic_kushNo ratings yet

- GRR Studies DiagramsDocument27 pagesGRR Studies Diagramssadiqus100% (1)

- What Is Injection Moulding ProcessDocument42 pagesWhat Is Injection Moulding ProcesssadiqusNo ratings yet

- Minitab ExercisesDocument17 pagesMinitab ExercisessadiqusNo ratings yet

- 50 Analytics Projects!Document52 pages50 Analytics Projects!sadiqusNo ratings yet

- Basic StatsDocument6 pagesBasic StatsPavithra MaddipetlaNo ratings yet

- ICRA Ferrous MetalsDocument7 pagesICRA Ferrous MetalssadiqusNo ratings yet

- TPMDocument40 pagesTPMPalkesh TrivediNo ratings yet

- Basic StatsDocument6 pagesBasic StatsPavithra MaddipetlaNo ratings yet

- Mehi Connected Communities Implementation Grant Transformation Plan TemplateDocument5 pagesMehi Connected Communities Implementation Grant Transformation Plan TemplatesadiqusNo ratings yet

- QuizDocument3 pagesQuizsadiqusNo ratings yet

- Rotary Nagar ProjectDocument9 pagesRotary Nagar ProjectsadiqusNo ratings yet

- Gung Ho!: by K. Blanchard & S. BowlesDocument23 pagesGung Ho!: by K. Blanchard & S. BowlessadiqusNo ratings yet

- Kenyan Hotel Industry OutlookDocument7 pagesKenyan Hotel Industry OutlooksadiqusNo ratings yet

- TCE Power MIS - SadiqDocument9 pagesTCE Power MIS - SadiqsadiqusNo ratings yet

- Practice Problem SetDocument3 pagesPractice Problem SetsadiqusNo ratings yet

- Satyam Scam HTDocument4 pagesSatyam Scam HTsadiqusNo ratings yet

- Project ManagementDocument33 pagesProject ManagementsadiqusNo ratings yet

- P6 Processflow PMDocument3 pagesP6 Processflow PMsadiqusNo ratings yet

- CR GmatclubDocument5 pagesCR GmatclubsadiqusNo ratings yet

- Ice-Cream ConesDocument6 pagesIce-Cream ConesAlfonso El SabioNo ratings yet

- Pines City Colleges: College of NursingDocument2 pagesPines City Colleges: College of NursingmagisasamundoNo ratings yet

- Solutions Manual For Corporate Finance, 6e Jonathan BerkDocument7 pagesSolutions Manual For Corporate Finance, 6e Jonathan Berksobiakhan52292No ratings yet

- Old Testament Books Bingo CardsDocument9 pagesOld Testament Books Bingo CardsSiagona LeblancNo ratings yet

- Noise Pollution Control Policy IndiaDocument10 pagesNoise Pollution Control Policy IndiaAllu GiriNo ratings yet

- Week 10 8th Grade Colonial America The Southern Colonies Unit 2Document4 pagesWeek 10 8th Grade Colonial America The Southern Colonies Unit 2santi marcucciNo ratings yet

- Connotative and Denotative, Lexical and StylisticDocument3 pagesConnotative and Denotative, Lexical and StylisticEman Jay FesalbonNo ratings yet

- Towards A Socially Responsible Management Control SystemDocument24 pagesTowards A Socially Responsible Management Control Systemsavpap78No ratings yet

- Gautam KDocument12 pagesGautam Kgautam kayapakNo ratings yet

- Whipping Cream PowderDocument2 pagesWhipping Cream PowderSALCON ConsultancyNo ratings yet

- FINAL Conflicts 2019 Official Guidelines PDFDocument48 pagesFINAL Conflicts 2019 Official Guidelines PDFxsar_xNo ratings yet

- SSC CGL Tier 2 Quantitative Abilities 16-Nov-2020Document17 pagesSSC CGL Tier 2 Quantitative Abilities 16-Nov-2020aNo ratings yet

- Pinto Pm2 Ch01Document21 pagesPinto Pm2 Ch01Mia KulalNo ratings yet

- CHILD WIFE FinalDocument9 pagesCHILD WIFE FinalProcurement WVMC100% (1)

- Appellate Tribunal Inland Revenue Rules, 2010Document18 pagesAppellate Tribunal Inland Revenue Rules, 2010Shahbaz KhanNo ratings yet

- 2 Obligations General Provisions 1156 1162Document15 pages2 Obligations General Provisions 1156 1162Emanuel CenidozaNo ratings yet

- Literature Circles Secondary SolutionsDocument2 pagesLiterature Circles Secondary Solutionsapi-235368198No ratings yet

- Stakeholder Management Plan Case Study 1Document2 pagesStakeholder Management Plan Case Study 1Krister VallenteNo ratings yet

- 41720105Document4 pages41720105renu tomarNo ratings yet

- Deep Work Book - English ResumoDocument9 pagesDeep Work Book - English ResumoJoão Pedro OnozatoNo ratings yet

- Java Thread Priority in MultithreadingDocument3 pagesJava Thread Priority in MultithreadingMITALI SHARMANo ratings yet

- Potato Tuber CropsDocument103 pagesPotato Tuber CropsNani NazirNo ratings yet

- A Project Report On Working Capital Management of Hindalco For The Last Five YearsDocument83 pagesA Project Report On Working Capital Management of Hindalco For The Last Five YearsBabasab Patil (Karrisatte)0% (1)