Professional Documents

Culture Documents

9852 1007 01K Maintenance Instructions COP 1840

Uploaded by

wawaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9852 1007 01K Maintenance Instructions COP 1840

Uploaded by

wawaCopyright:

Available Formats

Atlas Copco

Maintenance instructions

Hydraulic Rock drills

COP 1840, 1840EX

Atlas Copco Rock Drills AB

rebro, Sweden

Atlas Copco Rock Drills AB, 2009, All rights reserved

No. 9852 1007 01k

Copyright 2009, Atlas Copco Rock Drills AB, Sweden

Any unauthorised use or copying of the contents or any part thereof is prohibited.

This applies in particular to trademarks, model denominations, part numbers and drawings.

Atlas Copco Rock Drills AB

SE-70191 rebro, Sweden

CONTENTS

CONTENTS

1.

GENERAL .......................................................................................................... 5

1.1

1.2

2.

SERVICE INTERVAL.......................................................................................... 7

2.1

2.2

2.3

2.4

2.5

3.

TIGHTENING THE SIDE BOLTS...................................................................................... 12

RETIGHTENING THE SIDE BOLTS................................................................................. 12

ACCUMULATORS............................................................................................ 13

5.1

5.2

5.3

5.4

5.5

5.6

6.

CONNECTING THE HOSES ............................................................................................ 10

TIGHTENING TORQUES ................................................................................. 11

4.1

4.2

5.

BEFORE STARTING A NEW OR NEWLY OVERHAULED ROCK DRILL ......................... 8

AFTER EACH SHIFT WHEN USING A NEW OR NEWLY OVERHAULED ROCK DRILL 8

FOR EACH SHIFT .............................................................................................................. 8

AFTER EVERY 40TH PERCUSSION-HOUR ..................................................................... 9

EVERY 400TH PERCUSSION-HOUR:............................................................................... 9

HOSE CONNECTIONS .................................................................................... 10

3.1

4.

ENVIRONMENT.................................................................................................................. 5

SAFETY REGULATIONS.................................................................................................... 5

WARNING BOXES.............................................................................................................. 5

THE FOLLOWING GENERAL SAFETY RULES MUST BE OBSERVED .......................... 6

SAFETY LABEL LOCATION............................................................................................. 13

SAFETY LABEL INSTRUCTIONS .................................................................................... 13

CHARGING THE ACCUMULATORS................................................................................ 13

CHECKING THE ACCUMULATORS IN THE EVENT OF HOSE VIBRATION................. 14

INTAKE AND DAMPER ACCUMULATORS ..................................................................... 14

REPLACING INTAKE AND DAMPER ACCUMULATOR.................................................. 14

DISMANTLING.................................................................................................................. 15

ASSEMBLY ....................................................................................................................... 15

REPLACING THE RETURN ACCUMULATOR................................................................. 15

DISMANTLING.................................................................................................................. 15

ASSEMBLY ....................................................................................................................... 15

CHANGING THE HYDRAULIC MOTOR.......................................................... 16

DISMANTLING.................................................................................................................. 16

ASSEMBLY ....................................................................................................................... 16

7.

FILLING WITH LUBRICATING OIL AND BLEEDING THE SYSTEM ............. 17

8.

SETTINGS ........................................................................................................ 18

8.1

8.2

8.3

9.

SETTING OF ECL LUBRICATING SYSTEM.................................................................... 18

SETTING DAMPER PRESSURE...................................................................................... 18

SETTING EXTRACTOR PRESSURE............................................................................... 19

REMOVING THE FRONT HEAD...................................................................... 20

9.1

EXTRACTOR FRONT HEAD............................................................................................ 20

10. CHECKING THE FRONT HEAD ...................................................................... 21

10.1 EXTRACTOR FRONT HEAD............................................................................................ 22

11. REPLACING THE FLUSHING HEAD AND DRIVER....................................... 23

DISMANTLING.................................................................................................................. 23

ASSEMBLY ....................................................................................................................... 23

11.1 EXTRACTOR FRONT HEAD............................................................................................ 24

DISMANTLING.................................................................................................................. 24

ASSEMBLY ....................................................................................................................... 24

CONTENTS

12. MOUNTING THE FRONT HEAD ..................................................................... 25

12.1 EXTRACTOR FRONT HEAD ........................................................................................... 25

13. SLINGING, WEIGHT, STORAGE AND STROKE LENGTH SETTING ............ 26

13.1

13.2

13.3

13.4

SLINGING ........................................................................................................................

ROCK DRILL WEIGHTS ..................................................................................................

LONG-TERM STORAGE .................................................................................................

STROKE LENGTH SETTING...........................................................................................

BASIC SETTING ..............................................................................................................

26

26

26

26

26

14. LUBRICATION ................................................................................................. 29

14.1 LUBRICATION OF GEAR ................................................................................................ 29

15. HYDRAULIC AND LUBRICANT RECOMMENDATIONS................................ 31

15.1 HYDRAULIC FLUID ......................................................................................................... 31

15.2 PNEUMATIC TOOL OIL ................................................................................................... 32

15.3 GREASE........................................................................................................................... 32

GENERAL 1

1. GENERAL

1.2 SAFETY REGULATIONS

The Safety chapter contains important information

for the prevention of accidents.

This instruction is intended as a guide when

performing maintenance on your rock drill.

WARNING BOXES

The instructions include warnings.

1.1 ENVIRONMENT

Warnings are preceded by a heading (Danger,

Warning and Caution).

ENVIRONMENTAL REGULATIONS

Care for the environment!

WARNING BOXES

Leaking hydraulic couplings and grease are

hazardous to the environment.

Danger

Indicates an imminent risk of serious or fatal

injury if the warning is not heeded.

Changing oils, hydraulic hoses and various

types of filter can be hazardous to the environment.

Always collect oil residues, oil spillage, oily

waste and residues and spilt grease. Deal with

according to local provisions.

Warning

Indicates hazards or hazardous procedures

which could result in serious or fatal injury if the

warning is not heeded.

Use biodegradable hydraulic and lubricating

oils where possible.

Caution

Indicates hazards or hazardous procedures

which could result in personal injury or

damage to property if the warning is not

heeded.

GENERAL 1

THE FOLLOWING GENERAL SAFETY RULES

MUST BE OBSERVED

IMPORTANT!

IMPORTANT!

Make sure that the rock drill has been maintained in accordance with the applicable instructions.

Read through the maintenance instructions

carefully before starting maintenance work.

Follow the instructions given and local regulations.

Before moving the rig and rock drill or starting to

drill, make sure that there are no personnel in

the immediate vicinity of the drill rig.

Do not use or intervene in the rock drill unless

you have been trained to do so.

Checks and adjustments that are necessary

when the rock drill is in operation must be

carried out by at least two persons. One person

must then be present at the operating station

and have a good view of the work.

Never attempt to carry out maintenance while

the rock drill is in operation.

Ensure that the hydraulic, water and air systems

are depressurised and that the electrical system

is de-energised prior to removing the rock drill

or starting work on the system.

Always wear a helmet and earmuffs when drilling. Follow local regulations

Use approved lifting devices when handling the

rock drill. Avoid lifting heavy weights yourself.

Make sure that the place of work is well ventilated.

To prevent injury during service and maintenance, all components that could possibly move

or drop must be supported safely on blocks or

trestles, or secured by means of adequately

dimensioned slings.

Make sure that the safety labels are fitted, clean

and fully legible.

Particular attention must be paid to all warnings

in the instructions.

Check that the hoses used are of the right

quality, and that all hose connections are in

good condition and properly tightened. Hoses

that loosen could cause serious injury.

Use only Atlas Copco original parts. Any

damage or malfunction caused by the use of

non-original Atlas Copco parts is not covered by

warranty or product liability.

SERVICE INTERVAL 2

2. SERVICE INTERVAL

IMPORTANT!

Read all safety regulations before starting to work

on the machine.

Observe great cleanliness when intervening in

the rock drill or its hydraulic circuit.

Order numbers for the repair kits are in the

rock drills spare parts catalogue.

The following parts may be changed at the

work site in accordance with the instructions

given:

WARNING!

shank adapter

driver

front head parts

accumulators

hydraulic motor

screws

connections

Before starting any maintenance work, make

sure that the electrical system is dead.

There is a risk of injury if these instructions are

not observed!

CAUTION!

Other repairs must be carried out in a suitable

workshop in accordance with the repair

instructions for the rock drill.

Exercise caution when jointing drill rods and

with drill bit handling. Watch your fingers!

Make sure that clothes do not come too close

to rotating machine parts.

IMPORTANT!

Negligence could cause serious injury.

Ensure bolted joints are tightened to the

correct tightening torques after every 40

percussion hours and when reconditioning the

rock drill.

Always use hearing protection when drilling.

High noise levels damage the hearing.

Never attempt maintenance or intervene in the

rock drill, connections or hoses while the

hydraulic, lubrication or flushing systems are

pressurised. Air or oil can spray out at high

pressure and high temperature. There is a risk

of serious injury to the eyes and skin.

IMPORTANT!

Servicing should be carried out at appropriate

time intervals based on local conditions. The

condition of the rock has a major affect on the

amount wear and with that the need of servicing.

SERVICE INTERVAL 2

IMPORTANT!

Any defect must be rectified in the designated workshop

2.1 BEFORE STARTING A NEW OR

NEWLY OVERHAULED ROCK

DRILL

Action

Chapter

Connect up the hoses

Charge the accumulators

Select a suitable hydraulic oil and lubricant

Fill the lubricating system with oil

Adjust and set the lubricating system

Set the damper pressure

Set the extractor unit pressure

3

5

15

7

8

8

8

2.2 AFTER EACH SHIFT WHEN USING

A NEW OR NEWLY OVERHAULED

ROCK DRILL

Action

Chapter

Tighten all threaded unions

2.3 FOR EACH SHIFT

Action

Chapter

Check that air and lubricating oil escape from the hole in the front head

Check that the drill rigs damper pressure gauge is showing normal values. Check

that the drill rigs damper pressure gauge is showing normal values. In the event of

deviation, adjust the damper pressure.

Check that the shank adapter threads are not damaged

Keep an eye on the hydraulic hoses. If they vibrate too much, check the accumulators

Check that the machine does not leak. If the flushing medium leaks from the flushing

head, replace the seals and O-rings

When replacing the shank adapter or removing the front head, check the internal

components including piston, driver and the visible parts of the rotation chuck bushing

In the event of oil leakage from the front head: close percussion and only activate

the damper in order to determine if the leakage is coming from the percussion or

damper.

10

8

10

5

10

10

10

SERVICE INTERVAL 2

2.4 AFTER EVERY 40TH PERCUSSION-HOUR

Action

Chapter

Grease the gear

Tighten all threaded unions

Check the safety labels on the accumulators. Replace them if they are damaged or

illegible

Check the accumulators

14

4

5

5

2.5 EVERY 400TH PERCUSSIONHOUR:

Action

Chapter

Dismantle the rock drill from the drill rig. Transport the rock drill to an appropriate

workshop for servicing

13

IMPORTANT!

Always function test the rock drill after service.

HOSE CONNECTIONS 3

3. HOSE CONNECTIONS

CAUTION!

3.1 CONNECTING THE HOSES

Never attempt maintenance or any work in the

rock drill, connections or hoses while the

hydraulic, lubrication or flushing systems are

pressurised. Air or oil can spray out at high

pressure and high temperature. There is a risk

of serious injury to the eyes and skin.

Clean the rock drills hose connections before

undoing the protective caps.

Never remove a protective cap until the hose is

ready to be connected.

Always store the rock drill with all hose connections plugged. Use suitable protective caps, and

make sure that they are clean.

Pressure hoses with an internal diameter of 19

mm (3/4") or greater are of the quality SAE 100

R9R (high-pressure hose with four layers of

steel reinforcement). For reasons of safety,

under no circumstance may these hoses be

replaced with hoses of a lower quality. There is

a risk of injury if these instructions are not

observed!

1250 0210 53

5

2

6

1.

2.

3.

4.

5.

Drainage

Rotation left

Rotation right

Percussion return

Inlet impact mechanism

6. Flushing air/water

7. Lubricating air

8. Damper, intake

9. Extractor unit, return

10.Extractor unit, intake

10

10

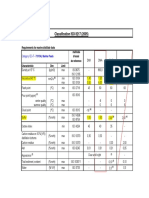

TIGHTENING TORQUES 4

4. TIGHTENING TORQUES

5 1

3A

14

3A 2

9

13

12

11

8 9 10

3B

15

16

1250 0210 54

13

Lubricate the nuts threads and the washers

contact surfaces with Never-Seez Regular Grade.

Ref.

No.

Qty.

Check point

Torque

Nm

1

2

3A

3B

4

2

1

2

3

3

Side bolts

Front bolt

Side bolt

Side bolts EX

Back head

300

300

350

300

220

5

6

1

4

Regulating plug

Accumulator

80

220

7

8

4

2

65

30

Hydraulic motor

Clamping attachment, return

accumulator

Rock drill mounting

250

10

11

1

4

Plug

Valve end plates

45

145

12

Connecting plate

120

13

14

1

4

Flushing connector

Intake, flushing medium

300

90

15

16

1

1

Intake, extractor unit

Return, extractor unit

120

120

11

Instructions

Tighten the rear nuts

Tighten the front bolt

Tighten the front nuts

Tighten the front nuts

Tighten the screws alternately to full

torque, top bolt last

Tighten the screws alternately to full

torque

Tighten the nuts alternately

Tighten the screws alternately to full

torque

Tighten the screws alternately to full

torque

Tighten the screws alternately to full

torque

Tighten the screws alternately to full

torque

TIGHTENING TORQUES 4

4.1 TIGHTENING THE SIDE BOLTS

4.2 RETIGHTENING THE SIDE BOLTS

Not extractor unit version

Undo the front nuts (3A) so that the tension releases.

1250 0219 79

If the threads are seized, remove the nuts and

clean and lubricate them with Never-Seez

Regular Grade.

3B

Tighten the front nuts (3A) manually.

Both versions

Tighten the rear nuts (1) to the tightening torque.

Tighten the side bolt (2) to the tightening torque.

Tighten the front bolts (3A or 3B) to the tightening torque.

3A

Check whether the side bolts, nuts or washers

have cracks, scratches or rust. Replace

damaged side bolts, nuts and washers.

Lubricate the threads and contact surfaces of

the side bolt (2), nuts and washers with NeverSeez Regular Grade.

Tighten the rear nuts (1) to the tightening torque.

Tighten the side bolt (2) to the tightening torque.

Tighten the front bolts (3A or 3B) to the tightening torque.

12

ACCUMULATORS 5

5. ACCUMULATORS

5.3 CHARGING THE ACCUMULATORS

Check the safety labels on the accumulators.

Replace them if they are damaged or illegible.

1250 0210 55

5.1 SAFETY LABEL LOCATION

221

CAUTION!

231

211

Charge the accumulators when assembled on

the rock drill. There is a risk of injury if these

instructions are not observed!

221.Damper accumulator

211.Intake accumulator

231.Return accumulator

WARNING!

A gas other than N 2 could cause an explosion.

5.2 SAFETY LABEL INSTRUCTIONS

Remove the protective cap (A).

1250 0210 56

Open the valve nut (B) by 2-3 turns, and connect

the gas hose.

Open the gas valve (C).

Charge the accumulators with nitrogen gas (N 2)

to the correct pressure in accordance with the

following:

NB! Charge at the bottom if possible rather than

too high.

1. Read the operators instructions carefully before

service or replacement of the accumulator.

2. Must be charged with nitrogen only

Damper

accumulator (221)

20-25 bar

Intake

accumulator (211)

30-40 bar

(80-100 bar)*

Return

accumulator (231)

Must not be

charged with N2

*Intake accumulator 30-40 bar under collaring pressure.

Normal 80-100 bar. Max. 100 bar.

Tighten the valve nut (B) and close the gas valve

(C).

Remove the gas hose and screw in the protective cap (A) to the accumulator valve.

13

ACCUMULATORS 5

5.4 CHECKING THE ACCUMULATORS

IN THE EVENT OF HOSE VIBRATION

RETURN ACCUMULATOR

INTAKE AND DAMPER ACCUMULATORS

1250 0210 58

1250 0210 59

A

B

231 C

Position the rock drill in horizontal position.

211 221

Remove the stopper with O-ring (C). If oil

escapes then the diaphragm is damaged.

Push in the control valves pin (A). If the accumulator is charged, the pin protrudes 4.5 mm

and is hard to push in.

If the pin is easy to press in then the gas pressure has disappeared (broken diaphragm or

defective filler valve). NB! The damper accumulators pin is slightly easier to press in.

Replace the accumulator, diaphragm and/or

filler valve if they are damaged.

Replace the accumulator and/or diaphragm if

they are damaged.

If the diaphragm is in contact against the outer

tube, press diaphragm with a cylindrical (blunt)

mandrel (7-9 mm). See Figure A. The correct

position for the diaphragm is, see Figure B.

Refit the stopper and O-ring (C).

Charge by means of admitting air at atmospheric pressure into the accumulator.

Charge the new accumulator after replacement.

.......... NB! The seat of the filler valve is easily

deformed by repeated opening/closing. The

filler valve must be replaced frequently.

5.5 REPLACING INTAKE AND

DAMPER ACCUMULATOR

221

82

BA

1250 0210 60

53

211

C

82

BA

WARNING!

All gas must be released prior to fitting by

means of removing the protective cap (A),

undoing the valve nut (B) and opening it 2-3

turns.

There is a risk of injury if these instructions are

not observed

14

ACCUMULATORS 5

5.6 REPLACING THE RETURN ACCUMULATOR

CAUTION!

Defective bolts may lead to dangerous oil

leakage or the accumulator working loose. Oil

spray can injure the eyes and skin.

CAUTION!

Ensure that the hydraulic, water and air

systems are depressurised before starting

work on the system.

Parts that come loose can cause serious injury.

DISMANTLING

Remove the accumulators (221, and 211) with

the sealing rings (82) by undoing the bolts (C

and D). Send the accumulators to a workshop

for reconditioning!

For reasons of safety, under no circumstance

may the pressure hoses be replaced with

hoses of a lower quality. The hoses must be

high-pressure hoses with four layers of steel

reinforcement, quality SAE 100R9R.

There is a risk of injury if these instructions are

not observed!

ASSEMBLY

Locate the sealing rings (82) in the grooves on

the intermediate section (53).

1250 0210 61

Make sure that the sealing rings (82) do not get

damaged during the assembly.

Fit the damper accumulator (221) on the rock

drills left-hand side and the intake accumulator

(211) on the rock drills right-hand side (hose

side). Fit with undamaged original bolts (D)

length of 70 mm and (C) length 100 mm.

Replace the bolts in pairs even if only one bolt is

corroded or damaged in some other way.

23

A

21

11

B

24

25

231

Tighten the bolts (C and D) alternately to tightening torque 220 Nm.

DISMANTLING

Remove the hydraulic hose (A) from the return

accumulator (231).

Charge the accumulators with nitrogen gas (N

2).

Remove the return accumulator (231) by removing the nuts (24) and the bolts (23).

Pull away the clamp (21) and unscrew the accumulator from the nipple (B).

Send the return accumulator to a workshop for

overhauling.

ASSEMBLY

Screw in the return accumulator (231) onto the

nipple (B) in such a way that the stopper (11) is

accessible for checking the accumulators

diaphragm.

Fit the clamp (21) onto the return accumulator.

Fit the rock drills with the bolts (23) and the nuts

(24).

Connect the hydraulic hose (A) to the return

accumulator (231).

15

CHANGING THE HYDRAULIC MOTOR 6

6. CHANGING THE

ASSEMBLY

Make sure that the groove ring (130) is fitted in

the coupling (249).

HYDRAULIC MOTOR

Lubricate the couplings splines with grease and

fit the coupling (249) on the hydraulic motor

(241).

1250 0210 62

241

248

Replace the gasket (248) if it is damaged.

Fit the gasket (248) and the hydraulic motor

(241) on the cylinder (3). Tighten the nuts (246)

to tightening torque 65 Nm.

246

Connect the hydraulic hoses (A). Check that the

correct direction of rotation is obtained.

249 130

DISMANTLING

Detach the hydraulic hoses (A).

Undo the nuts (246) and remove the hydraulic

motor (241).

Pull out the coupling (249).

16

FILLING WITH LUBRICATING OIL AND BLEEDING THE SYSTEM 7

7. FILLING WITH LUBRICATING OIL AND BLEEDING

THE SYSTEM

CAUTION!

Never work on the lubrication system when it is

pressurised.

Lubricating oil could spray out.

There is a risk of serious injury to the eyes and

skin.

IMPORTANT!

Use the recommended lubrication air pressure

and recommended lubrication oil. Some

moving parts on the rock drill are lubricated

with oil mixed with compressed air. Is important that these parts receive good lubrication.

Check the level in the lubricating oil tank for every

shift. Exercise cleanliness and fill with the right

grade oil.

NB! If the lubricating system has been empty of

oil, it must be bled after filling.

17

SETTINGS 8

8. SETTINGS

8.2 SETTING DAMPER PRESSURE

8.1 SETTING OF ECL LUBRICATING

SYSTEM

ECL=Electric Controlled Lubrication

Rock drill lubrication must be set with regard to the

local conditions.

Start the lubricating system.

1250 0210 72

Check the lubricating air pressure at the rock

drill using a pressure gauge. The pressure

should be 2-3 bar. If the pressure is too low,

clean the restriction or increase the diameter of

the restriction.

NB! The setting should take place at normal

operating temperature for the hydraulic oil.

Set the correct lubricating oil dose.

Pump (3217 8667 50)

35-40 pulses/minute

Pump (3217 8667 52)

20-25 pulses/minute

Fully close the constant flow valve (B) on the drill

rig.

Connect a pressure gauge (A), calibrated for 060 bar, between the hose and the damper union

(1).

After setting, check that the correct pulse

frequency has been obtained and that oil is

emerging from the front heads hole and

between the shank adapter and front guide.

Pressurise the damper circuit.

Check that the shank adapter is unloaded and in

the forward position.

Adjust the constant flow valve until the pressure

gauge (A) shows 30-35 bar at the rock drill

(operator panel shows 10-15 bar higher value).

Read off the drill rigs damper pressure gauge. If

this pressure gauge later shows another value,

make a new pressure setting.

Disconnect the pressure gauge (A) and connect

the hose to the union (1).

18

SETTINGS 8

8.3 SETTING EXTRACTOR PRESSURE

1250 0210 73

P

B

Fully close the constant flow valve (B) on the drill

rig.

Connect a pressure gauge (A), calibrated for 060 bar, between the hose and the extractor

units intake union (P).

Connect the extractor unit circuit by activating

the return feed and running the cradle against

the stop. Let the lever remain in this position.

Adjust the constant flow valve (B) until the pressure gauge (A) shows 20-25 bar.

Disconnect the pressure gauge (A) and connect

the hose to the union (P).

19

REMOVING THE FRONT HEAD 9

9. REMOVING THE FRONT

HEAD

172

CAUTION!

Never attempt to carry out maintenance while

the drill rig is in operation.

1250 0210 76

Ensure that the hydraulic and air systems are

depressurised before starting any work.

There is a risk of injury if these instructions are

not observed!

300

252 251

NB! Always clean the outside of the rock drill

before disassembly.

Remove the front side-bolt nuts (251) with their

washers (252).

Remove the front head (172) by pulling the

shank adapter (300).

Then pull the shank adapter from the front head.

1250 0210 75

180

Always check the internal components, also

when replacing the shank adapter.

179

178

9.1 EXTRACTOR FRONT HEAD

173 177

Remove the flushing hose (A).

162

Remove the connecting plate (177) and nipple

(173) by removing the bolts (178) and washers

(179).

1250 0210 77

Remove the cup seal (180).

300

252 251

Remove the front side-bolt nuts (251) with their

washers (252).

Remove the front head (162) by pulling the

shank adapter (300) or by tapping with a copper

hammer.

Then pull the shank adapter from the front head.

Always check the internal components, also

when replacing the shank adapter.

20

CHECKING THE FRONT HEAD 10

10. CHECKING THE FRONT

HEAD

192

300 172 190 174 191 176

A 131 132

1250 0210 74

F

173

175

131

185

185

1m

m

2 mm

173

21

m 132

1m

86

175 190 174

192

191

176

175

300

53 mm

D

Check that air and lubricating oil escape

between the shank adapter (300) and front

guide (173), and also out of the hole (B)

If the rotation chuck bushing (132) is worn more

than 1 mm or the piston (21) impact surface is

damaged in any way then the rock drill must be

sent to a workshop for inspection. NB! Fit the

rotation chuck bushing so that the lubricating

grooves (D) are aligned towards the damper

piston (86).

Blow clean the lubricating air ducts (A) in the

front head (172) with compressed air and check

that the restrictions (E) are open.

Replace the guide (173) if the inside diameter

exceeds 53 mm.

Replace the shank adapter (300) if the thread is

worn out or the impact surface is warped or

chipped, or if the front or rear end surfaces of the

splines are worn.

Check the O-rings (190-192) and flushing seals

(175,176) if air is escaping from the hole (C) in

the front head. Replace the O-rings and flushing

seals if they are worn or damaged.

Replace the flushing head (174) if it is seriously

corroded, or if it contains cracks.

Replace the stop ring (185) if it is worn by more

than 1 mm.

Look inside the gear housing and check the

splines on the driver (131). If the splines are less

than 2 mm in width, the driver must be changed.

Fit a new driver with the aid of a suitable

mandrel and a copper hammer.

21

CHECKING THE FRONT HEAD 10

131

162

170

172 168

171 193

185

194

185

195

185

196

185

182

167

169

300

10.1 EXTRACTOR FRONT HEAD

21

F

1250 0210 88

163

181

131

2 mm

132

194

193 185

m 132

1m

182

196

185 195

D

169 167

163

53 mm

300

181

170 168 171,172

1 mm

grooves (D) are aligned towards the damper

piston (86).

Check that air and lubricating oil escape

between the shank adapter (300) and front

guide (163), and also out of the hole (B)

Replace the shank adapter (300) if the thread is

worn out or the impact surface is warped or

chipped, or if the front or rear end surfaces of the

splines are worn.

Blow clean the lubricating air ducts (A) in the

front head (162) with compressed air and check

that the restrictions (E) are open.

Replace the guide (163) if the inside diameter

exceeds 53 mm.

Check that the drill sleeve (F), to be used with

upwards directed drilling, is not damaged and

rotates with the shank adapter.

Check the O-rings (193-195) and flushing seals

(185) if air is escaping from the hole (C) in the

front head. Replace the O-rings and flushing

seals if they are worn or damaged.

Replace the extractor units piston (181) if the

surface against the shank adapter has worn

more than 1 mm. When replacing the extractor

units piston check the seals (167,168) and Orings (169-172). Replace the seals and O-rings

if they are worn or damaged.

Replace the flushing head (182) if it is seriously

corroded, or if it contains cracks.

Look inside the gear housing and check the

splines on the driver (131). If the splines are less

than 2 mm in width, the driver must be changed.

Fit a new driver with the aid of a suitable

mandrel and a copper hammer.

If the rotation chuck bushing (132) is worn more

than 1 mm or the piston (21) impact surface is

damaged in any way then the rock drill must be

sent to a workshop for inspection. NB! Fit the

rotation chuck bushing so that the lubricating

22

REPLACING THE FLUSHING HEAD AND DRIVER 11

11. REPLACING THE

ASSEMBLY

FLUSHING HEAD AND

DRIVER

D

V

CAUTION!

Exercise care when dismantling flushing head

and the driver. Watch your fingers!

174

Press the flushing head (174) into the front head

using a mandrel and sleeve.

NB! The flushing head must be reversed so that

the lubricating grooves are turned upwards.

V

173

174

1250 0210 89

1250 0210 50

DISMANTLING

Make sure that the flushing hole in the flushing

head (174) aligns with the hole in the front head.

185

Use a mandrel and suitable sleeve to push out

the guide (185), the flushing head (174) and the

stop ring (173) from the front head.

131

1250 0210 49

1250 0210 51

131

B

117

Use a mandrel and plastic hammer to fit the

driver (131) in the drill sleeve (117).

The driver (131) is pulled out manually or with an

extractor (C) and an expander 37-46 mm, alternatively with dismantling tool (A)(3115 2724 80).

23

REPLACING THE FLUSHING HEAD AND DRIVER 11

11.1 EXTRACTOR FRONT HEAD

Tap in the rotation chuck bushing (132) with a

suitable copper mandrel.

131

A 182

198

197

184

183

263

183

103

263

AB

Fit the O-rings (193-196) and the seals (185) in

the flushing head (182).

Important! The seals (185) must be turned in

accordance with the illustration.

Remove the flushing hose (C) from the nipple

(263).

Remove the nipple (183) and its O-rings and

support ring.

Fit the flushing head (182) in the cover plate

(153) and tap it in with a copper hammer. Check

carefully that the flushing intake in the cover is

aligned with the hole in the flushing head.

Press the removal tool (A) (3115 2724 80) into

the gear housing (103) until the tool moves to

the stop, i.e. the tools splines-equipped section

has then passed the drivers (131) splines.

Fit the O-rings (197,198) and the support ring

(184) on the nipple (183).

Turn the removal tool clockwise slightly.

Fit the nipples (183,263 and B) and the nut (A).

Tap out the driver (131) and flushing head (182)

using the sliding hammer (B).

Torque tighten the nipple (183) to 300 Nm and

the nipple (263) to 180 Nm.

Normally the rotation chuck bushing (132)

follows as well when removing the driver. If this

is not the case, then remove the rotation chuck

bushing using a puller and an expander.

1250 0210 8

ASSEMBLY

103

185

195

196

132

1250 0210 83

1250 0210 81

153

DISMANTLING

182

Exercise care when dismantling flushing head

and the driver. Watch your fingers!

193

194

185

Tap the driver (131) into the drill sleeve in the

gear housing (103) using a mandrel (A) and a

copper hammer.

CAUTION!

131 A

132

Fit the rotation chuck bushing (132) so that the

lubricating grooves are aligned towards the

damper piston.

24

MOUNTING THE FRONT HEAD 12

12. MOUNTING THE FRONT

After assembly

Check that air and lubricating oil escapes out of

the hole in the front head and between the shank

adapter and front guide.

HEAD

12.1 EXTRACTOR FRONT HEAD

172

1250 0210 78

1250 0210 8

162

300 162

263 188

300

161

186

252 251

Fit the shank adapter (300) in the extractor units

front head (162).

252 251

Fit the stop ring and shank adapter (300) in the

front head (172).

Fit the cylindrical pin (188).

Fit the front head (162) on the side bolts (186).

Make sure that the pin (162) is fitted in the cover

plate. Position the front head (172) on the side

bolts (161).

Apply grease, type Never Seez, onto the

threads of the side bolts (186).

Apply grease, type Never Seez, onto the

threads of the side bolts (161).

Fit the washers (252) and nuts (251).

Fit the washers (252) and nuts (251).

Check the tightening torques on the rear sidebolt nuts and the front side bolt.

Check the tightening torques on the rear sidebolt nuts and the front side bolt.

Following which, tighten the nuts (251) alternately to a torque of 300 Nm.

Following which, tighten the nuts (251) alternately to a torque of 350 Nm.

Connect the flushing hose to the nipple (263).

After assembly

Check that air and lubricating oil escapes out of

the hole in the front head and between the shank

adapter and front guide.

1250 0210 79

180

173 177

179

178

Fit the cup seal (180) into the flushing head.

Fit the connecting plate (177) to the front head

using the washers (179) and bolts (178). Tighten

the bolts to a torque of 90 Nm.

Fit the nipple (173) on the connecting plate.

Tighten the nipple to tightening torque 300 Nm.

Fit the flushing hose (A) and tighten the nut.

25

SLINGING, WEIGHT, STORAGE AND STROKE LENGTH SETTING 13

13. SLINGING, WEIGHT,

13.2 ROCK DRILL WEIGHTS

STORAGE AND STROKE

LENGTH SETTING

13.1 SLINGING

COP 1840

184 kg

COP 1840EX

247 kg

1250 0184 84

1250 0184 87

13.3 LONG-TERM STORAGE

If the rock drill is not going to be used for a

long time, the following precautions should be

taken.

Make sure that the rock drill is safely slung for

lifting. Make sure that the rock drill is securely

anchored for transportation.

Check that all connections, including the one for

the flushing medium, are properly capped with

protective caps of the right size.

caution!

Clean the rock drill carefully. Use degreasing

agent and rinse with water.

Lifting devices and straps must be approved

for lifting 500 kg.

Incorrect lifting devices could cause the rock

drill to start moving or fall down.

Clean thoroughly and oil in the front head

components in contact with flushing medium

(especially in high air humidity).

Incorrect operation could cause crushing

damage.

Release gas from the accumulators.

Store the rock drill in a dry place.

13.4 STROKE LENGTH SETTING

63

1250 0210 52

66

BASIC SETTING

On cylinder (66) there is a plug (63). Turning the

plug changes the stroke length of the piston.

There are two different positions. They are

shown on the plug (63) by punched dots. For

26

SLINGING, WEIGHT, STORAGE AND STROKE LENGTH SETTING 13

example, when two dots are shown upward the

setting is 2

27

SLINGING, WEIGHT, STORAGE AND STROKE LENGTH SETTING 13

28

LUBRICATION 14

14. LUBRICATION

1

1250 0210 87

14.1 LUBRICATION OF GEAR

Unscrew the bleed plug (1).

Lubricate with heat-resistant grease through the

nipple (2) until new grease escapes through the

hole (3).

Tighten the plug (1).

29

LUBRICATION 14

30

HYDRAULIC AND LUBRICANT RECOMMENDATIONS 15

15. HYDRAULIC AND LUBRICANT RECOMMENDATIONS

15.1 HYDRAULIC FLUID

A good hydraulic fluid provides superior protection against wear, rust and oxidisation as well as good antifoaming and air and water separation properties.

In order to ensure a lowest level on these properties the mineral oil based and synthetic (polyalphaolefin)

hydraulic fluids must conform to the standard ISO 11158 HM/HV or DIN 51524 HLP/HVLP.

Environmentally friendly hydraulic fluids must fulfil ISO 15380

It is essential to chose a hydraulic fluid of a suitable viscosity for the operating temperature of the drill rig.

Select a viscosity grade (VG) and viscosity index (VI) as specified in the following table. A high viscosity

index reduces the effect of temperature on the hydraulic fluid.

Normal operating

temp. C

Viscosity 25-50 cSt

Min start temp. C

(Viscosity min. 1000 cSt)

Max temp. C

Viscosity grade VG

(ISO 3448)

Viscosity index VI

+50 to +70

+45 to +60

+35 to +50

+25 to +40

+10 to +25

+5

-5

-10

-15

-25

80

75

65

55

35

ISO VG 100

ISO VG 68

ISO VG 46

ISO VG 32

ISO VG 15

Min. 100

Min. 100

Min. 100

Min. 100

Min. 100

IF THE VISCOSITY IS TOO LOW:

The hydraulic fluid may not form a lubricating layer between surfaces, thus increasing the risk of wear.

The hydraulic fluid can leak past seals more easily in the rock drill thus increasing fluid losses and increasing energy requirements.

IF THE VISCOSITY IS TOO HIGH:

Flow losses in the hydraulic lines will be high increasing energy consumption and pressure levels, putting

increased strain on seals.

The risk of cavitation will increase, thus also the risk of damage to the rock drill and hydraulic pumps.

The hydraulic fluid must be filtered to a purity of 20/18/15 in accordance to ISO 4406.

The viscosity will change during the period that the hydraulic fluid is used. In general viscosity will drop with

increased operating hours. To ensure that the viscosity of the fluid does not drop to a critical level before

the recommended service interval, a hydraulic fluid of sufficient stability must be used. The viscosity in cSt

of suitable hydraulic fluids shall drop a maximum of 25% when tested for shear stability in accordance with

DIN 51350-6 at 100 C.

THE HYDRAULIC FLUID MUST BE CHANGED AT REGULAR INTERVALS. FACTORS INFLUENCING

THE INTERVAL BETWEEN CHANGES:

The viscous stability of the hydraulic fluid as specified above. The hydraulic fluid must be changed before

the viscosity drops to a critical level.

Contamination with water. If the hydraulic fluid becomes cloudy and light grey, the water content has

become such that the hydraulic fluid must be changed.

Deterioration of properties such as oxidation inhibition and anti-foaming.

ENVIRONMENT!

Excess and/or waste hydraulic fluid must be disposed of in an environmentally suitable manner and in

accordance with regulatory requirements.

31

HYDRAULIC AND LUBRICANT RECOMMENDATIONS 15

15.2 PNEUMATIC TOOL OIL

Atlas Copco recommends the use of Atlas Copco COP OIL which has been specially developed for our

hydraulic rock drills. COP OIL is an environmentally friendly, degradable oil which can be used in ambient

temperatures between -25 C and +50 C.

COP OIL can be ordered with the following part numbers:

Quantity

Part number

1 can of 10 litres

48 cans of 10 litres

1 barrel of 208 litres

3115 3125 00

3115 3126 00

3115 3127 00

If COP OIL is not available then the oil should have the following properties:

Use an oil with good lubricating properties intended for compressed air tools.

The oil must have good adhesion capacity.

The oil must have additives that prevent foam formation.

Depending on ambient temperature, the oil should have the following viscosity grades if the viscosity

index (VI) is about 100:

Ambient temperature C

Viscosity grade (ISO 3448)

-25 to 0

-10 to +20

+10 to +50

VG 15-32

VG 32-46

VG 46-68

The oil must have an EP additive which covers the following load-bearing properties:

ASTM D 2783

Min. 250 kg

ASTM D 4172 (40 kg)

Max. 0.5 mm

15.3 GREASE

NB! Because of the operating temperature in the rock drill gear housing, always use a high-temperature

grease with lithium complex soap based on a synthetic base fluid (polyalphaolefin/synthetic ester) with additives that protect against oxidation, corrosion and wear at high loads and with EP additive.

NLGI number

Drop point

Base oil viscosity

1.5

250 C

400-600 mm2/s

at 40 C

32

Operating

Temperature

-40 to +150 C

HYDRAULIC AND LUBRICANT RECOMMENDATIONS 15

33

You might also like

- Picture Gallery: The Pictures Shown Here, Can Be Found in The Gallery Folder On The Cd-RomDocument11 pagesPicture Gallery: The Pictures Shown Here, Can Be Found in The Gallery Folder On The Cd-RomwawaNo ratings yet

- Data Report Page 2 PDFDocument1 pageData Report Page 2 PDFwawaNo ratings yet

- PowerROC 3D Angle Indicator enDocument28 pagesPowerROC 3D Angle Indicator enwawaNo ratings yet

- Data Report Page 2 PDFDocument1 pageData Report Page 2 PDFwawaNo ratings yet

- Start PDFDocument1 pageStart PDFwawaNo ratings yet

- Test CertDocument1 pageTest CertwawaNo ratings yet

- Model Powerroc T35 Serial No. X013156DA Date 9 / 12 / 2012: Instructions For Ordering Replacement PartsDocument1 pageModel Powerroc T35 Serial No. X013156DA Date 9 / 12 / 2012: Instructions For Ordering Replacement PartswawaNo ratings yet

- Top Hammer Tools: Tool Recommendations For Surface DrillingDocument1 pageTop Hammer Tools: Tool Recommendations For Surface DrillingwawaNo ratings yet

- P.E.D. Declaration of Conformity: RP/QC/142 Rev 3 (16/02/2005)Document1 pageP.E.D. Declaration of Conformity: RP/QC/142 Rev 3 (16/02/2005)wawaNo ratings yet

- CID MID FMI-CaterpillarDocument191 pagesCID MID FMI-CaterpillarDeusdedit Motta86% (37)

- D7 Parts Book 9853619020Document897 pagesD7 Parts Book 9853619020wawa100% (2)

- Data Report Page 2Document1 pageData Report Page 2wawaNo ratings yet

- Picture Gallery: The Pictures Shown Here, Can Be Found in The Gallery Folder On The Cd-RomDocument11 pagesPicture Gallery: The Pictures Shown Here, Can Be Found in The Gallery Folder On The Cd-RomwawaNo ratings yet

- 9840 0424 77 Hydraulic DiagramDocument16 pages9840 0424 77 Hydraulic DiagramwawaNo ratings yet

- PowerROC Series Safety ManuallDocument30 pagesPowerROC Series Safety ManuallwawaNo ratings yet

- PowerROC 3D Angle Indicator enDocument28 pagesPowerROC 3D Angle Indicator enwawaNo ratings yet

- Shop Manual-Pc600-7 PDFDocument229 pagesShop Manual-Pc600-7 PDFwawaNo ratings yet

- Extec Manual - OldDocument187 pagesExtec Manual - OldSalAme75% (4)

- C15 TroubleshootingDocument456 pagesC15 Troubleshootingابومحمد نايف94% (68)

- Shop Manual-Pc600-7 PDFDocument229 pagesShop Manual-Pc600-7 PDFwawaNo ratings yet

- Sk200-6 Pump & Regulator ExplainingDocument17 pagesSk200-6 Pump & Regulator Explainingeng_ebrahim_200096% (73)

- ScribdDocument1 pageScribdDefi UnikasungtiNo ratings yet

- Sk200-6 Pump & Regulator ExplainingDocument17 pagesSk200-6 Pump & Regulator Explainingeng_ebrahim_200096% (73)

- CAT Installation InstructionDocument2 pagesCAT Installation InstructionwawaNo ratings yet

- Sk200-6 Pump & Regulator ExplainingDocument17 pagesSk200-6 Pump & Regulator Explainingeng_ebrahim_200096% (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Energy Conservation Oppurtunities in Boiler SystemDocument34 pagesEnergy Conservation Oppurtunities in Boiler SystemSiddharth Jain67% (3)

- Classification ISO 8217 (2005)Document5 pagesClassification ISO 8217 (2005)Salah JallaliNo ratings yet

- Week 6 - Sample Final TestDocument4 pagesWeek 6 - Sample Final TestMai Thúy VyNo ratings yet

- National Science Olympiad: SyllabusDocument4 pagesNational Science Olympiad: SyllabusawaninderNo ratings yet

- 1Document26 pages1Maribel Bihag AlcantaraNo ratings yet

- Syllabus of Diploma in Electrical EngineeringDocument17 pagesSyllabus of Diploma in Electrical EngineeringJoson Chan100% (1)

- General Design Considerations for Chemical Plant DesignDocument27 pagesGeneral Design Considerations for Chemical Plant DesignTeddy Ekubay GNo ratings yet

- Resume Dr. R.N.MukerjeeDocument13 pagesResume Dr. R.N.MukerjeeRahul Mukerjee100% (1)

- Germany and Japan's Remarkable Post-WWII Economic ComebackDocument5 pagesGermany and Japan's Remarkable Post-WWII Economic ComebackHANNALEENo ratings yet

- Fluid MechDocument10 pagesFluid MechPrasant KumarNo ratings yet

- 2013 Midterm 3Document16 pages2013 Midterm 3billbyoag123No ratings yet

- Energy Manipulation and MeditationDocument6 pagesEnergy Manipulation and Meditationapi-246292178100% (1)

- 1SDA081063R1 t5n 630 Ekip e Lsig in 630a 3p F FDocument3 pages1SDA081063R1 t5n 630 Ekip e Lsig in 630a 3p F FBolivar MartinezNo ratings yet

- KPSC/ KSEB/ SSC Electrical Score Academy: Questions: 75Document9 pagesKPSC/ KSEB/ SSC Electrical Score Academy: Questions: 75sreevasanthNo ratings yet

- Enclosed Control Product Guide: April 2008Document456 pagesEnclosed Control Product Guide: April 2008MED-ROBIN2000No ratings yet

- Liebhaber NESC 2017 ChangesDocument80 pagesLiebhaber NESC 2017 ChangesEdgar ZapanaNo ratings yet

- Automatic Street Light Control Using LDRDocument39 pagesAutomatic Street Light Control Using LDRAyush Kumar100% (1)

- ChE 525: Physical & Chemical Principles Mock Board 3Document6 pagesChE 525: Physical & Chemical Principles Mock Board 3Kuo Garol SarongNo ratings yet

- Ed Current DynamometerDocument3 pagesEd Current DynamometerOM MUNGELWARNo ratings yet

- OSHA Citations Against O&G and Ducci ElectricDocument107 pagesOSHA Citations Against O&G and Ducci ElectricRepublican-AmericanNo ratings yet

- Short and Open Circuit Test On TransformerDocument1 pageShort and Open Circuit Test On TransformerRyan DagsilNo ratings yet

- Symmetry & Crystal StructuresDocument37 pagesSymmetry & Crystal StructuresNurnajihah Sukimi JiehaNo ratings yet

- MeasurementDocument4 pagesMeasurementJemason100% (1)

- Chapter 8 ObjectivesDocument3 pagesChapter 8 ObjectivesdaddlescoopNo ratings yet

- 937 Letter AttchamentDocument8 pages937 Letter AttchamentNeeta RautelaNo ratings yet

- ECE 1312 Chapter 1Document19 pagesECE 1312 Chapter 1Fatihah AinaNo ratings yet

- High Efficiency Battery Charger Using DC-DC ConverterDocument4 pagesHigh Efficiency Battery Charger Using DC-DC ConvertersanilNo ratings yet

- 3/27/2016 Portable AC On Rent Pune - Portable AC Rentals Pune - AC Rentals Pune On SulekhaDocument3 pages3/27/2016 Portable AC On Rent Pune - Portable AC Rentals Pune - AC Rentals Pune On SulekhadcoolsamNo ratings yet

- KR AGILUS Hygienic Machine Fast Cleaning Food PharmaDocument2 pagesKR AGILUS Hygienic Machine Fast Cleaning Food PharmaValke Athletes HandcareNo ratings yet

- Pipe Sizes and Flow Rates for Air Flush DrillingDocument14 pagesPipe Sizes and Flow Rates for Air Flush DrillingzapspazNo ratings yet