Professional Documents

Culture Documents

MBR OPEX - The Theory of Running Costs

Uploaded by

Jeremy DudleyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MBR OPEX - The Theory of Running Costs

Uploaded by

Jeremy DudleyCopyright:

Available Formats

04/10/2016

MBROPEXthetheoryofrunningcosts

HOME

News

Features

The MBR blog

MBR Jobs

ABOUT MBRS

Training and events

DIRECTORIES

Publications

MBR RESOURCES

Chinese MBR site

Useful links

Home >

Features >

MBR OPEX the theory of running costs

MBR OPEX the theory of running costs

30 September 2016

1 The operating

expenditure (OPEX) of an

MBR

About this feature

With the coming of age of the technology, the next

thing on the agenda seems to be the subject of MBR

costs. Simon Judd explains the fundamentals of

working it out. In theory. Simon can be contacted at

simon@juddwater.com.

One of the concerns of MBRs is their operational costs,

which even the most optimistic (but nonetheless realistic)

of cost analyses reveals to be marginally higher than

those of conventional activated sludge (CAS). The reasons

behind this are fairly obvious. Firstly, permeating water

through a membrane demands energy. In the case of the

immersed technologies (iMBRs) this means that the overall specic aeration demand (SAD) is higher, since air is needed both for

maintaining the process biology in the aeration tank and scouring the immersed membrane. For a sidestream MBR (sMBR) energy is

used for pumping the sludge through the membrane channels. Secondly, membranes have a limited life. Although the ceramic

membranes presumably last a lot longer, it is normal to assume a life of 8-12 years for a polymeric membrane.

To calculate the actual costs requires key information concerning the plant design and operation. For the process biology these are the

same as for CAS modelling:

1. the feed and treated water quality, and specically the COD, BOD and ammoniacal/amino nitrogen (or total Kjeldahl nitrogen, TKN);

2. the mixed liquor suspended solids (MLSS) content in the aeration tank.

If CAD packages like Biowin or West are to be used for the biological process design then the above is probably sucient, since estimates

of the key fundamental biokinetic and biochemical parameters are provided in the package. However, if starting from scratch, and if only

the actual running cost is required, then the estimated sludge yield in kgMLSS generated per kgCOD feed is needed. To complete the

calculation demands an estimate of the amount of COD and TKN required to sustain the biomass in kgCOD and TKN per kg MLSS. Finally,

the eciency of oxygen transfer from the air bubble into the biomass, the standard oxygen transfer eciency (SOTE) per unit depth has

to be estimated.

On the membrane side the key parameters inuencing OPEX are:

1. the cost and life of the membrane;

2. the permeate ux;

3. the specic aeration demand for membrane scouring (SADm) for an immersed membrane, or

4. the pressure and crossow rate of a sidestream (pumped) membrane in an sMBR;

5. the energy demand of membrane permeation (for an immersed membrane: for sMBRs it is accounted for by (4) above.

Finally, for any MBR technology there are additional costs associated with:

1. energy for pumping the sludge between tanks (aeration to membrane tank, membrane tank to anoxic zone for denitrication and also

to an anaerobic tank for P removal);

2. process control energy demand and maintenance

3. chemicals for membrane cleaning

4. labour

5. other miscellaneous site services

Apart from labour and site services, which are location and site-specic, a reasonable estimate of all other costs can be made. OPEX is

ultimately determined in units of cost per m3 of treated water. The example below refers to a simple Modied Ludzack-Ettinger (MLE)

process for nitrication-denitrication.

http://www.thembrsite.com/features/mbropextheoryrunningcosts/

1/6

04/10/2016

MBROPEXthetheoryofrunningcosts

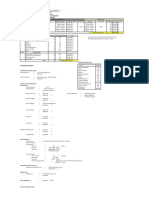

Figure 1 The Modied Ludzack-Ettinger MBR biological process conguration for denitrication.

2 Process biology OPEX

The base parameter values provided for the wastewater for treatment by an activated sludge process technology are as follows:

Advertise With

The operational expenditure (OPEX) can be determined from the equations for:

1. Oxygen demand from COD and TKN loading in g/m3 O2:

2. Aeration demand from calculated oxygen demand in Nm3 air/m3:

3. The specic aeration energy demand for air pumping in Ws/Nm3:

The specic energy demand for biological process aeration (EL,bio) in units of kWh/m3 treated water is then the product of these two

parameters:

Inserting the relevant values into Equation 1:

From Equation 2:

From Equation 4:

http://www.thembrsite.com/features/mbropextheoryrunningcosts/

2/6

04/10/2016

MBROPEXthetheoryofrunningcosts

3 Membrane separation OPEX

3.1 iMBR

The base data provided for the cost determination are listed below. EA,m is assumed to be the same as EA,bio, which is justiable if the

aerator is at the same depth. EA,bio in units of kWh/m3 is 80,000/(3,600 x 1,000) = 0.0222.

3.2 sMBR

In the case of a pumped sidestream technology tted with horizontal modules there is no air scouring of the membrane, the shear being

created by the crossow. The energy demand is therefore determined from Bernoullis equation:

where appropriate values may be:

The conversion refers to the proportion of the retentate passing through the permeate channels which is converted into permeate. This

in turn can be determined from the membrane module characteristics (specically the membrane area and the available cross-sectional

area) and the net ux. Appropriate values for a food and beverage application might be:

So, the total cross-sectional area of the tube is:

If only 85% of this cross section corresponds to the membrane channels then the available cross-sectional area is:

The retentate ow is the product of the crossow velocity v and the above available cross-sectional area:

http://www.thembrsite.com/features/mbropextheoryrunningcosts/

3/6

04/10/2016

MBROPEXthetheoryofrunningcosts

The permeate ow per module is the product of the ux and the module membrane area:

If the sludge passes through eight such tubes then the total conversion is:

This gure (EL,m for the sidestream MBR) displaces the terms for energy demand relating to membrane air scour, permeate pumping and

sludge transfer in the corresponding equation for the immersed technology:

4 Cost curves

This simplistic approach implies that OPEX is independent of ow, which is not actually the case. However, a number of published cost

analyses suggest that there is only a shallow decline of OPEX with ow. According to the study of Lo et al (2015), who considered three

dierent ows ranging from 100 to 2500 m3/d, the OPEX cost curve (in 2015 USD) from entirely heuristic data is given by:

This curve seems to be in reasonable agreement with other published studies (DeCarolis et al, 2007; Brepols et al, 2010; Young et al,

2013), generally based on much larger MBR installations.

Figure 2 MBR OPEX according to various reported studies.

Since OPEX is most sensitive to design ux and membrane life it is of some interest to correlate the cost against these two parameters

based on the assumptions given in Section 3.1. Accordingly, it can be seen that doubling the membrane life from ve to ten years

decreases the overall OPEX by 24%. However, this is based on a membrane replacement cost of $80 per m2 membrane area, which is

perhaps overly conservative. If the membrane cost is reduced to $20 per m2 membrane area then this gure comes down to 9%.

http://www.thembrsite.com/features/mbropextheoryrunningcosts/

4/6

04/10/2016

MBROPEXthetheoryofrunningcosts

Figure 3 OPEX vs ux at various membrane life periods.

Clearly, OPEX is only part of the cost calculation. For a complete analysis the capital cost (CAPEX) is needed, which then demands

information on the price of equipment, installation services largely comprising mechanical and electrical (M&E) and civil engineering,

legal and contracting costs, land and other sundry items. These vary considerably between technologies, locations and overall

approaches to costing per se (i.e. which items are included, which is a rather vexed issue). However, given that OPEX generally contributes

more to the overall total cost (TOTEX) over the life of the plant, and can be estimated reasonably easily its perhaps worth at least doing

this much before reaching for the cheque book.

Further information on MBR design and operation is provided in Industrial MBRs, by Simon Judd.

References

Brepols, B, Schfer, H., and Engelhardt, N., 2010. Considerations on the design and nancial feasibility of full-scale membrane

bioreactors for municipal applications. Water Sci. Technol. 61(10), 2461-2468.

DeCarolis, J., Adham, S., Pearce, W.R., Hirani, Z., Lacy, S., Stephenson, R., 2007. Cost trends of MBR systems for municipal wastewater

treatment, Proceedings of the Water Environment Federation, 1317 October, San Diego, 3407-3418.

Lo, C.-H., McAdam, E., and Judd, S. (2015). The cost of a small membrane bioreactor, Water Sci Technol 72(10) 1739-1746.

Young, T., Smoot, S., Peeters, J., Ct, P., 2013. When does building an MBR make sense? How variations of local construction and

operating cost parameters impact overall project economics, Proc. Water Environment Federation 8, 6354-6365.

Back to Features

Information on this page has been supplied by third parties and is not necessarily endorsed by The MBR Site. You must contact the third parties to conrm

information is accurate and complete before acting upon it. The MBR Site accepts no responsibility for any action taken or costs incurred as a result of

information on The MBR Site. The MBR Site accepts no responsibility for the content of third party websites. Any views expressed are those of the third parties

and do not necessarily reect the views of The MBR Site.

Advertise With Us

Home

About The MBR Site

The MBR blog

News

Contact us

Listings and Adverts

Need help in looking for something?

View Sitemap

info@thembrsite.com

Privacy Policy

http://www.thembrsite.com/features/mbropextheoryrunningcosts/

5/6

04/10/2016

MBROPEXthetheoryofrunningcosts

Terms and Conditions

The MBR Site is a trading division of Judd and Judd Ltd, a company registered in England and Wales, registered number 8082403.

Registered oce: Suite 2, Douglas House, 32-34 Simpson Road, Fenny Stratford, Buckinghamshire, MK1 1BA, United Kingdom. Email: info@thembrsite.com

Banner image: full treatment plant for pharmaceutical wastewater in Taizhou, Linhai Park, Zhejiang Province, China, including Shanghai MEGAVISION at sheet UF membrane modules in tw

units. Image courtesy of VALORSABIO, Lda.

Image credits:

Image for our Chinese largest plants MBRhomepage link: Image supplied by Apex Environmental

Image for our Consultants and Contractors homepage link: Image supplied by Ovivo USA, LLC.

Disclaimer: The information given on this website is reproduced in good faith. No liability is accepted for errors or omissions. The MBR Site does not endorse any products, services, organis

events or any other listing included in this site. You are strongly advised to check all information, including specications and installation details, before acting on any information given in th

website. The MBR Site links to third-party websitesnote that we are not responsible for the content of third-party websites and third-party websites are visited at your own risk. Please rea

terms and conditions and privacy policy. Use of this website indicates acceptance of these conditions.

This website is designed for modern browsers if you have problems viewing our website, you may wish to upgrade your browser.

All Content Judd and Judd Limited

http://www.thembrsite.com/features/mbropextheoryrunningcosts/

Website Amasci Creative Limited, website design Milton Keyn

6/6

You might also like

- DesalData Brochure Q1 2021Document17 pagesDesalData Brochure Q1 2021Shamma DamaniNo ratings yet

- ExxonMobil G-EMS Initiatives BOP Final Ex NotesDocument12 pagesExxonMobil G-EMS Initiatives BOP Final Ex NotesSrihari KodimelaNo ratings yet

- (2006, DUGAS) - Dissertação BaseDocument145 pages(2006, DUGAS) - Dissertação BaseSuênia FernandesNo ratings yet

- Ozonation and Biodegradation in Environmental Engineering: Dynamic Neural Network ApproachFrom EverandOzonation and Biodegradation in Environmental Engineering: Dynamic Neural Network ApproachNo ratings yet

- Sap Ewm - Erp Initial SetupDocument3 pagesSap Ewm - Erp Initial SetupVAIBHAV PARAB80% (5)

- FZ16 9B 1KD2 (Patada) PDFDocument62 pagesFZ16 9B 1KD2 (Patada) PDFPanthukalathil Ram100% (1)

- Specific Energy Consumption of Membrane Bioreactor (MBR) For SewageDocument14 pagesSpecific Energy Consumption of Membrane Bioreactor (MBR) For Sewagesulihah12No ratings yet

- Estimation of Offshore Brazilian Natural Gas Break-Even PricesDocument10 pagesEstimation of Offshore Brazilian Natural Gas Break-Even PricesMarcelo Varejão CasarinNo ratings yet

- Diborane: Click To Edit Master Subtitle StyleDocument36 pagesDiborane: Click To Edit Master Subtitle StyleSaumya GoelNo ratings yet

- Presentation of Apex Consultants - NewDocument20 pagesPresentation of Apex Consultants - NewSudhirNo ratings yet

- BCl3 / Boron TrichlorideDocument2 pagesBCl3 / Boron TrichlorideSAFC-GlobalNo ratings yet

- Unit 2 Structure and BondingDocument61 pagesUnit 2 Structure and BondingAbdulrahman Rashid AlbusaidiNo ratings yet

- Clearing Up Confusion Over Calculation of Free Cash FlowDocument6 pagesClearing Up Confusion Over Calculation of Free Cash FlowSohini Mo BanerjeeNo ratings yet

- Game Rules 2012Document19 pagesGame Rules 2012hiknikNo ratings yet

- Comparing Common Wastewater Aeration SolutionsDocument2 pagesComparing Common Wastewater Aeration SolutionsprannoyNo ratings yet

- Calculation For Heat of CombustionDocument2 pagesCalculation For Heat of CombustionFauziah MuniraNo ratings yet

- 4.basf - 855 - e 17 (TC) - Ima Spain - Up ScalinDocument27 pages4.basf - 855 - e 17 (TC) - Ima Spain - Up ScalinPaqui Miranda GualdaNo ratings yet

- Ultrafiltration for Oily Industrial WaterDocument13 pagesUltrafiltration for Oily Industrial WaterböhmitNo ratings yet

- Recent Advances in Humidification Dehumidification (HDH) Desalination Processes - Improved Designs and ProductivityDocument16 pagesRecent Advances in Humidification Dehumidification (HDH) Desalination Processes - Improved Designs and ProductivityMr NaughtyNo ratings yet

- Experiments and Modeling of Bubble Column Dehumidifier PerformanceDocument11 pagesExperiments and Modeling of Bubble Column Dehumidifier PerformanceAl-Kawthari As-SunniNo ratings yet

- ProMinent Operating Instructions Meta HM-HKDocument20 pagesProMinent Operating Instructions Meta HM-HKivan_shterevNo ratings yet

- Life Cycle Assessment of Electricity Generation in Mauritius - SIMAPRO PDFDocument11 pagesLife Cycle Assessment of Electricity Generation in Mauritius - SIMAPRO PDFLeonardo Caldas100% (1)

- Bubble Column Humidification Dehumidification Desalination SystemDocument67 pagesBubble Column Humidification Dehumidification Desalination SystemAnnjoe MathewsNo ratings yet

- Cost Estimation - Acetone Plant 1 PDFDocument2 pagesCost Estimation - Acetone Plant 1 PDFDhananjay pathareNo ratings yet

- Process Evaluation & Research PlanningDocument2 pagesProcess Evaluation & Research PlanningVictoria Sahaya RaniNo ratings yet

- Intelligen's SuperPro Designer Simulates Batch and Continuous ProcessesDocument6 pagesIntelligen's SuperPro Designer Simulates Batch and Continuous ProcessesnidejoNo ratings yet

- CHAPTER 8 Sizing and CostingDocument20 pagesCHAPTER 8 Sizing and CostingNurul Amelia Mustaffa0% (1)

- Performance Study of An Airlift Pump With Bent Riser TubeDocument10 pagesPerformance Study of An Airlift Pump With Bent Riser TubefhmollNo ratings yet

- Chemicals Zetag MSDS Powder Zetag 4190 - 0810Document6 pagesChemicals Zetag MSDS Powder Zetag 4190 - 0810PromagEnviro.comNo ratings yet

- Bw0404a Sc7 BurnDocument96 pagesBw0404a Sc7 Burnoverlord5555No ratings yet

- Volume 3 Section 2 Process Requirements-FINAL 10062010Document63 pagesVolume 3 Section 2 Process Requirements-FINAL 10062010Pavle DimitrijevicNo ratings yet

- Air Pollution ControlDocument35 pagesAir Pollution ControlPraveen YadavNo ratings yet

- Process Plant Estimating ProcedureDocument2 pagesProcess Plant Estimating Procedurerylar999No ratings yet

- A Fundamental Guide To Reverse Osmosis and Nanofiltration Membrane SystemsDocument37 pagesA Fundamental Guide To Reverse Osmosis and Nanofiltration Membrane SystemsJean RechellNo ratings yet

- Scale-Up Chemical Engineering ProcessesDocument12 pagesScale-Up Chemical Engineering ProcesseskayeNo ratings yet

- Understanding the Urea Manufacturing Process at CFCLDocument38 pagesUnderstanding the Urea Manufacturing Process at CFCLPallavNo ratings yet

- Tray Dividing Wall ColumnsDocument7 pagesTray Dividing Wall ColumnsDr. VolodymyrNo ratings yet

- SMART Digital - DDA With Profibus DP / Modbus Rtu / Profinet Io / Modbus TCPDocument2 pagesSMART Digital - DDA With Profibus DP / Modbus Rtu / Profinet Io / Modbus TCPRyan GohNo ratings yet

- Ammonia Production Simulation Using PDMSDocument10 pagesAmmonia Production Simulation Using PDMSazzatul amiraNo ratings yet

- Engineering Design - ReportDocument6 pagesEngineering Design - ReportThurya Sathsara Nishakara OwitipanaNo ratings yet

- Scale-Up - Right First TimeDocument4 pagesScale-Up - Right First TimeDoddappa Anekal0% (1)

- What Sets The SaltMaker Apart 1Document10 pagesWhat Sets The SaltMaker Apart 1Furi Sri RahimahNo ratings yet

- Forward Osmosis System AnalysisDocument27 pagesForward Osmosis System AnalysisSyed Muztuza AliNo ratings yet

- Fundamentals of Biological Wastewater Treatment - PrefaceDocument4 pagesFundamentals of Biological Wastewater Treatment - Prefaceabhi_nddNo ratings yet

- WSG (KR) - ASME - BPEDocument35 pagesWSG (KR) - ASME - BPEThomas C. Lane100% (1)

- Siemens Forty X Disc Filters Tech. Specs.Document25 pagesSiemens Forty X Disc Filters Tech. Specs.Alfonso José García LagunaNo ratings yet

- TGADocument31 pagesTGABhuvnesh SharmaNo ratings yet

- Application of CHEMCADDocument11 pagesApplication of CHEMCADAlbertIvanoAndreanNo ratings yet

- ChemCAD Tutorial 1Document37 pagesChemCAD Tutorial 1galihasyhari100% (1)

- Techno-Economic Assessment About Propylene OxideDocument5 pagesTechno-Economic Assessment About Propylene OxideIntratec SolutionsNo ratings yet

- New α-SABLIN Approach for Linear Alpha Olefins ProductionDocument3 pagesNew α-SABLIN Approach for Linear Alpha Olefins Productionsk281No ratings yet

- Hadwaco MVR Evaporator Evaluated for Rinse Water RecyclingDocument43 pagesHadwaco MVR Evaporator Evaluated for Rinse Water RecyclingLuis ValdezNo ratings yet

- Scale Up of Chemical ReactorsDocument52 pagesScale Up of Chemical ReactorsAl GhazaliNo ratings yet

- Asesmen Chemistry Cycle by EPRIDocument14 pagesAsesmen Chemistry Cycle by EPRIAbdul KadirNo ratings yet

- Project Cost EstimateDocument6 pagesProject Cost EstimateVarun MalhotraNo ratings yet

- Study of A Full Scale Oxy-Fuel Cement Rotary Kiln PDFDocument10 pagesStudy of A Full Scale Oxy-Fuel Cement Rotary Kiln PDFclaralisieNo ratings yet

- Demister Pads & Mesh Mist EliminatorsDocument14 pagesDemister Pads & Mesh Mist Eliminatorsaagarwal30No ratings yet

- Insights into Chemical Engineering: Selected Papers of P.V. DanckwertsFrom EverandInsights into Chemical Engineering: Selected Papers of P.V. DanckwertsNo ratings yet

- Mungo Park MemorialDocument1 pageMungo Park MemorialJeremy DudleyNo ratings yet

- WInHelp On Windows 10Document14 pagesWInHelp On Windows 10Jeremy DudleyNo ratings yet

- Newbrain GraphicsDocument1 pageNewbrain GraphicsJeremy DudleyNo ratings yet

- UI MapDocument1 pageUI MapJeremy DudleyNo ratings yet

- Timings For UBSC Club Champs 2017Document4 pagesTimings For UBSC Club Champs 2017Jeremy DudleyNo ratings yet

- DJM Muffett Building Blocks For NationhoodDocument32 pagesDJM Muffett Building Blocks For NationhoodJeremy DudleyNo ratings yet

- Abayomi and OyindaDocument1 pageAbayomi and OyindaJeremy DudleyNo ratings yet

- Revision TimetableDocument1 pageRevision TimetableJeremy DudleyNo ratings yet

- DPFDocument1 pageDPFJeremy DudleyNo ratings yet

- PET SymbolsDocument1 pagePET SymbolsJeremy DudleyNo ratings yet

- Nuc Medical Working Party 1977Document33 pagesNuc Medical Working Party 1977Jeremy DudleyNo ratings yet

- Nuc Medical Working Party 1977 PDFDocument33 pagesNuc Medical Working Party 1977 PDFJeremy DudleyNo ratings yet

- Ali Yahay Local Government Under Civilan RuleDocument27 pagesAli Yahay Local Government Under Civilan RuleJeremy DudleyNo ratings yet

- UI Street NamesDocument19 pagesUI Street NamesJeremy DudleyNo ratings yet

- BJ Dudley Politics in Contemporary NigeriaDocument17 pagesBJ Dudley Politics in Contemporary NigeriaAlero Elizabeth DudleyNo ratings yet

- Pdfsam - Nigerian Universities Commission Minutes 12th Meeting July 1979Document48 pagesPdfsam - Nigerian Universities Commission Minutes 12th Meeting July 1979Jeremy DudleyNo ratings yet

- AHM Kirke-Green The Federal Character of NigeriaDocument18 pagesAHM Kirke-Green The Federal Character of NigeriaJeremy DudleyNo ratings yet

- Louis Munoz Inaugral Lecture 1988Document50 pagesLouis Munoz Inaugral Lecture 1988Jeremy DudleyNo ratings yet

- Nigeria's Political System - New Rules and Participants in The GameDocument40 pagesNigeria's Political System - New Rules and Participants in The GameJeremy DudleyNo ratings yet

- Jibril Aminu NUC Memor On The Universities Crisis PDFDocument59 pagesJibril Aminu NUC Memor On The Universities Crisis PDFJeremy DudleyNo ratings yet

- Denis Austin E Pluribus PluresDocument12 pagesDenis Austin E Pluribus PluresJeremy DudleyNo ratings yet

- John Edward AdamsDocument1 pageJohn Edward AdamsJeremy DudleyNo ratings yet

- Delgeats List To Keele ConferenceDocument2 pagesDelgeats List To Keele ConferenceJeremy DudleyNo ratings yet

- Nigerian Universities Commission Annual Report 1977Document85 pagesNigerian Universities Commission Annual Report 1977Jeremy DudleyNo ratings yet

- Pdfsam - Nigerian Expatriate Staff Supplementation SchemeDocument5 pagesPdfsam - Nigerian Expatriate Staff Supplementation SchemeJeremy DudleyNo ratings yet

- Scheme (Programming Language)Document13 pagesScheme (Programming Language)Jeremy DudleyNo ratings yet

- Variations On A Theme of OrderDocument13 pagesVariations On A Theme of OrderJeremy DudleyNo ratings yet

- Letter From BiafranDocument3 pagesLetter From BiafranJeremy DudleyNo ratings yet

- Introduction To Julia: Reese Pathak David Zeng Keegan Go Stephen Boyd EE103 Stanford UniversityDocument14 pagesIntroduction To Julia: Reese Pathak David Zeng Keegan Go Stephen Boyd EE103 Stanford UniversityJeremy DudleyNo ratings yet

- Removal of h2s & Co2 - From - Biogas - by Amine - AbsorptionDocument19 pagesRemoval of h2s & Co2 - From - Biogas - by Amine - Absorptionzubair19550% (2)

- Renewable and Sustainable Energy ReviewsDocument13 pagesRenewable and Sustainable Energy ReviewsMohammadreza MalekMohamadiNo ratings yet

- MMPX 403 Parametr ListDocument30 pagesMMPX 403 Parametr ListOğuz Kağan ÖkdemNo ratings yet

- 3 0 Visual Weld InspectorDocument74 pages3 0 Visual Weld InspectorVincent Sofia RaphaelNo ratings yet

- Stage 1 Isolating Boiler Feed Pump 1. PurposeDocument3 pagesStage 1 Isolating Boiler Feed Pump 1. Purposejoseph kamwendoNo ratings yet

- Funded African Tech Startups 2020Document13 pagesFunded African Tech Startups 2020LoNo ratings yet

- AB InBev Code of Business Conduct PDFDocument10 pagesAB InBev Code of Business Conduct PDFcristian quelmis vilca huarachiNo ratings yet

- AutocadDocument8 pagesAutocadbrodyNo ratings yet

- Liability WaiverDocument1 pageLiability WaiverTop Flight FitnessNo ratings yet

- Ethical Leadership Karen May P. UrlandaDocument8 pagesEthical Leadership Karen May P. UrlandaKaren May UrlandaNo ratings yet

- Career Guidance Activity Sheet For Grade IiDocument5 pagesCareer Guidance Activity Sheet For Grade IiJayson Escoto100% (1)

- Difference Between Knowledge and SkillDocument2 pagesDifference Between Knowledge and SkilljmNo ratings yet

- HW3Document3 pagesHW3Noviyanti Tri Maretta Sagala0% (1)

- Hollow lateral extrusion process for tubular billetsDocument7 pagesHollow lateral extrusion process for tubular billetsjoaopedrosousaNo ratings yet

- Fluke - Dry Well CalibratorDocument24 pagesFluke - Dry Well CalibratorEdy WijayaNo ratings yet

- Merlin Gerin Medium VoltageDocument10 pagesMerlin Gerin Medium VoltagekjfenNo ratings yet

- 34 Annual Report 2019 20Document238 pages34 Annual Report 2019 20Rahul N PatelNo ratings yet

- Tita-111 2Document1 pageTita-111 2Gheorghita DuracNo ratings yet

- Article 4Document31 pagesArticle 4Abdul OGNo ratings yet

- United States Court of Appeals, Third CircuitDocument3 pagesUnited States Court of Appeals, Third CircuitScribd Government DocsNo ratings yet

- Lead Magnet 43 Foolproof Strategies To Get More Leads, Win A Ton of New Customers and Double Your Profits in Record Time... (RDocument189 pagesLead Magnet 43 Foolproof Strategies To Get More Leads, Win A Ton of New Customers and Double Your Profits in Record Time... (RluizdasilvaazevedoNo ratings yet

- Lecture7 PDFDocument5 pagesLecture7 PDFrashidNo ratings yet

- A - Bahasa Inggris-DikonversiDocument96 pagesA - Bahasa Inggris-DikonversiArie PurnamaNo ratings yet

- Iqvia PDFDocument1 pageIqvia PDFSaksham DabasNo ratings yet

- Concept, Types, Characteristics and ClassificationsDocument6 pagesConcept, Types, Characteristics and ClassificationsCJ FaNo ratings yet

- Pass Issuance Receipt: Now You Can Also Buy This Pass On Paytm AppDocument1 pagePass Issuance Receipt: Now You Can Also Buy This Pass On Paytm AppAnoop SharmaNo ratings yet

- Dewatering Construction Sites Below Water TableDocument6 pagesDewatering Construction Sites Below Water TableSOMSUBHRA SINGHANo ratings yet

- RoboticsDocument2 pagesRoboticsCharice AlfaroNo ratings yet

- NH School Employee Criminal Record Check FormDocument2 pagesNH School Employee Criminal Record Check FormEmily LescatreNo ratings yet