Professional Documents

Culture Documents

Business Process Improvement - Milano

Uploaded by

Sukanta JanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Business Process Improvement - Milano

Uploaded by

Sukanta JanaCopyright:

Available Formats

INDIAN INSTITUTE OF MANAGEMENT BANGALORE

Post-Graduate Programme (PGP) Elective Course

Course Title: Business Process Improvement

Number of Credits: Three

Term: VI

Faculty: Haritha Saranga (harithas@iimb.ernet.in)

Office: D-108

Phone: 3130

Context of the course

Increasingly the success of business is dictated by the degree of efficiency and

quality of the business processes that lie beneath the core competencies of an

organization. Successful organizations are constantly improving their processes

to stay ahead taking advantage of latest technologies, while the followers are

not far behind in catching up with the frontier firms. Organizations that are not

in the race soon cease to exist in todays world of global competition. As a

result, there is a greater need for managers and consultants to not only know

how to design and analyze a business process but to be able to identify ways to

improve the process and sustain the improvements in the long run to meet the

organizational objectives more effectively.

Objectives of the Course

This course focuses on analysis and improvement of processes used for

production and delivery of products and services, with a performance

orientation. The objective is (i) to create a clear understanding of various

business processes, (ii) identify potential improvements (iii) learn existing tools

and techniques for performance enhancement and (iv) design a framework to

implement the process improvement strategies.

Content of the Course

Concepts like Factory Physics, Product Process Matrix, Theory of cumulative

capabilities and the Theory of performance frontiers will be used to create a

greater understanding of inherent nature of operating processes. Various case

studies from manufacturing and service operations will be used to further the

understanding and scope for improvement. Benchmarking tools like Balanced

Score Card, Pareto analysis, statistical process control and quality

improvement tools like TQM, TPS, Lean Manufacturing and Six Sigma will be

studied to analyze, evaluate and improve processes. Usefulness and challenges

faced by IT enabled advanced manufacturing technologies like CAD, CAM, CIM

and Flexible Manufacturing Systems (FMS) in improving business processes will

be explored with the help of case studies of organizations that embraced these

technologies across the globe.

Learning from this course will enable a

systematic method of asking questions, collecting data, and analyzing that data

to learn how processes work, how to improve them and how to sustain the

improvements in the longer run.

Session Plan

Session

Date

TOPICS

Module I: Business Process Fundamentals

Topic: A Dynamic approach to Operations Management

14.12.09

15.12.09

21.12.09

Readings:

1. Frances X Frei, Breaking the Trade-Off Between Efficiency

and Service HBR, November 2006.

2. Roger W. Schmenner, Morgan L. Swink, (1998) On theory in

operations

management,

Journal

of

Operations

Management, 17, 97113.

3. Jaikumar and Bohn A Dynamic approach to Operations

Management: An alternative to Static optimisation

International Journal of Production Economics. 1992, 27, pp:

265-272.

4. Gray A E and Leonard J Process Fundamentals

Case: Sologen: Process Improvement in the Manufacture of

Gelatine at Kodak

Reading: Michael Hammer, Deep Change How Operational

Innovation Can Transform Your Company. HBR, April 2004.

Case: Stermon Mills Incorporated

Reading: David M Upton, The Management of Manufacturing

Flexibility, California Management Review. 1994, 36(2).

Module II: Process Performance measures & Benchmarking

22.12.09

29.12.09

Topic: Need for Metrics and measurement techniques The

Balanced Scorecard

Readings:

1. Robert S Kaplan and David P Norton The Balanced

Scorecard: Measures That Drive Performance HBR Classic,

July 2005

2. Kaplan and Norton Operations Management Processes

3. Raymond E. Kordupleski, Roland T Rust and Anthony J

Zahorik, Why Improving Quality Doesnt Improve Quality

California Management Review, 1993, 35(3).

Case: Integron Incorporated: The Integrated Components Division

(ICD)

04.01.10

Case: The Cummins engine company: Starting Up B Crankshaft

Manufacturing at the San Luis Potosi Plant

Module III: Process Improvement methodologies

05.01.10

Topic: Role of Quality in process improvement

Case: Hank Kolb, Director of Quality Assurance

Readings:

1. David A Garvin, A Note on Quality: The views of Deming,

Juran and Crosby HBR, February 1990.

2. Michael Hammer, Reengineering Work: Dont Automate,

Obliterate, HBR July August, 1990.

28.12.09

Topic: Statistical Process Control

Case: Deutsche Allgemeinversicherung

12.01.09

Case: Six Sigma Quality at Flyrock Tires

Reading: Michael Hammer, Process Management and the Future of

Six Sigma MIT Sloan Management Review, Winter 2002, Vol. 43(2).

13.01.09

Case: Johnson Controls, Automotive Systems Group: The

Georgetown Kentucky Plant

Reading: Steven Spear and Kent Bowen, Decoding the DNA of the

Toyota Production System, HBR, September October, 1999.

Reading: James P. Womack and Daniel T. Jones Beyond Toyota:

How to Root Out Waste and Pursue Perfection, HBR, September

October, 1996.

19.01.09

Case: Lean at Wipro Technologies

Topic: Lean Thinking and Value Stream Mapping

Reading: Michael Hammer, The Super Efficient Company, HBR,

September 2001.

10

11

12

20.01.09

Topic: Business Process Improvement in practice Guest

Lecture

Module IV Designing and implementing operations improvement strategies

13

27.01.09

Topic: Framework for implementation of process improvement

strategies

Readings: Michael Hammer, The Process Audit, HBR, April 2007.

14

31.01.09

Case: John Crane UK Limited: The CAD-CAM Link

15

02.02.09

Case: ABC Transport Equipment Ltd. By Prof. B Mahadevan

Reading: Robert Kaplan, Must CIM be Justified by Faith Alone?

HBR, 1986.

Case: Corning Glass Works: The Z-Glass Project

Reading: Michael Hammer and Steven Stanton, How Process

Enterprises Really work? HBR November- December, 1999.

16

03.02.09

17

09.02.09

18

09.02.10

19

15.02.10

Project Presentations

20

16.02.10

Project Presentations

Case: Micom Caribe (A)

Reading: Harold Sirkin and George Stalk, Jr. Fix the Process, Not

the Problem HBR, July August 1990

Topic: Course review

Readings:

1. Robert Hayes and Gary Pisano, Beyond World Class: The

New Manufacturing Strategy, HBR, January February

1994.

2. Nelson P. Repenning and John D. Stermon, Nobody Ever

Gets Credit for Fixing Problems that Never Happened:

Creating and Sustaining Process Improvement, CMR, 2001,

43(4).

Course material

The students will be provided with handouts/links covering all parts of the course

contents.

Pedagogy

The course predominantly is case-based. The students have to form groups of size

four each (group size may change based on the class size). Each group has to submit

three case analyses. The groups have to turn-in the case analyses (both hard copy

and soft copy) before the respective class begins. Also each group has to take up a

project for the term, submit the report and make a presentation at the end of the

term.

Instructions regarding timelines for group formation and project work

It is required to form groups of four and inform by e-mail by 19 th December 5:00 pm

sharp. The schedule of case submissions by the groups would then be announced. All

the groups are required to decide and submit their project proposal by 15 th January,

which will be taken up for discussion in the subsequent week. The final project

reports and presentations (hard copy and soft copy) have to be submitted latest by

13th February, 1p.m.

Evaluation:

Case Analyses (2)

30%

Assignment

10%

Project

25%

End Term Examination

35%

You might also like

- STWS Business Model ArchetypesDocument1 pageSTWS Business Model ArchetypesManjit SinghNo ratings yet

- Entrepreneurship Development A4Document44 pagesEntrepreneurship Development A4paroothiNo ratings yet

- MOS PGPM Individual Assignment 2Document1 pageMOS PGPM Individual Assignment 2Sukanta JanaNo ratings yet

- Designing A Business Process Architecture 2Document11 pagesDesigning A Business Process Architecture 2codru_greenNo ratings yet

- The Need For Skeptical' Accountants in The Era of Big Data PDFDocument18 pagesThe Need For Skeptical' Accountants in The Era of Big Data PDFDeanne ColeenNo ratings yet

- Intorduction To Business - AnalyticsDocument40 pagesIntorduction To Business - AnalyticsAbhimanyu ParmarNo ratings yet

- Evolution of DatabaseDocument15 pagesEvolution of DatabaseKristel Jen E. RosalesNo ratings yet

- International Business RESIT Summative Assessment BriefDocument12 pagesInternational Business RESIT Summative Assessment BriefSahibzada Abu Bakar GhayyurNo ratings yet

- BPRDocument34 pagesBPRAndrew WamaeNo ratings yet

- Modeling Enterprise Activities with BPMN NotationDocument10 pagesModeling Enterprise Activities with BPMN Notationvu TinhNo ratings yet

- Semester: 3 Course Name: Marketing Analytics Course Code: 18JBS315 Number of Credits: 3 Number of Hours: 30Document4 pagesSemester: 3 Course Name: Marketing Analytics Course Code: 18JBS315 Number of Credits: 3 Number of Hours: 30Lipson ThomasNo ratings yet

- Building The Business Case:: Identifying Criteria To Measure ROI For Additive ManufacturingDocument11 pagesBuilding The Business Case:: Identifying Criteria To Measure ROI For Additive ManufacturingRushabh ZambadNo ratings yet

- World Big Data Market Opportunities 2013-2018Document19 pagesWorld Big Data Market Opportunities 2013-2018VisiongainGlobalNo ratings yet

- Managing Brand Equity in The Digital Age: Croma's Omni-Channel RetailingDocument1 pageManaging Brand Equity in The Digital Age: Croma's Omni-Channel RetailingETCASESNo ratings yet

- Using Business Intelligence: The Strategic Use of Analytics in GovernmentDocument6 pagesUsing Business Intelligence: The Strategic Use of Analytics in GovernmentIBMGovernmentNo ratings yet

- SyscoDocument6 pagesSyscoRohit Meena100% (1)

- Big Data Not Right Data YesDocument8 pagesBig Data Not Right Data YesRitaMoreNo ratings yet

- Ramco Cement Limited: Insight Into Their Marketing AnalyticsDocument15 pagesRamco Cement Limited: Insight Into Their Marketing Analyticsnishant1984No ratings yet

- A. Company OverviewDocument12 pagesA. Company Overviewsauvik ghoshNo ratings yet

- Machine Learning Techniques For Anomaly Detection: An OverviewDocument9 pagesMachine Learning Techniques For Anomaly Detection: An OverviewLeandro SouzaNo ratings yet

- 1) Explain The Various Stages of NPD: New Product Development StagesDocument33 pages1) Explain The Various Stages of NPD: New Product Development StagesROHITNo ratings yet

- BIM5 History and Background Update 2014 v2.4Document18 pagesBIM5 History and Background Update 2014 v2.4Shannon MaxwellNo ratings yet

- Simulation Modeling for System AnalysisDocument25 pagesSimulation Modeling for System AnalysisBalaji Ganesh100% (1)

- LJ 5Document6 pagesLJ 5Kotwal Mohit KotwalNo ratings yet

- Unit II-Database Design, Archiitecture - ModelDocument23 pagesUnit II-Database Design, Archiitecture - ModelAditya ThakurNo ratings yet

- What Business Analyst Skills Are Important For A New BADocument6 pagesWhat Business Analyst Skills Are Important For A New BAManivannancNo ratings yet

- Ameritas SwotDocument18 pagesAmeritas Swotapi-383702107No ratings yet

- DATA MiningDocument55 pagesDATA MiningAwadhesh YadavNo ratings yet

- Analysis of Tesla Inc. 1Document12 pagesAnalysis of Tesla Inc. 1nick2020No ratings yet

- Bcg Matrix - Google 搜尋Document8 pagesBcg Matrix - Google 搜尋Mike Shufflebottom50% (2)

- CCW331 Business Analytics Material Unit I Type2Document43 pagesCCW331 Business Analytics Material Unit I Type2ultra BNo ratings yet

- Erp Functional ArchitectureDocument12 pagesErp Functional ArchitectureKarthika SasikumarNo ratings yet

- Implications of Predictive AnalyticsDocument9 pagesImplications of Predictive AnalyticsAMIT PANDEYNo ratings yet

- Big Data Analytics: A Literature Review Paper: Lecture Notes in Computer Science August 2014Document16 pagesBig Data Analytics: A Literature Review Paper: Lecture Notes in Computer Science August 2014ferbNo ratings yet

- Improving Exploration Decisions through Risk Analysis & Decision TreesDocument53 pagesImproving Exploration Decisions through Risk Analysis & Decision TreespanpanpanpanpanNo ratings yet

- Developing Financial InsightsDocument12 pagesDeveloping Financial InsightsDeepan BaalanNo ratings yet

- 5 Essential Elements of A Modern Knowledge BaseDocument19 pages5 Essential Elements of A Modern Knowledge BaseHamed TajabadiNo ratings yet

- AUDI's Big Data Analytics Strategy and ServicesDocument4 pagesAUDI's Big Data Analytics Strategy and ServicesRomeo BullequieNo ratings yet

- Tactical vs. Strategic Purchasing PDFDocument9 pagesTactical vs. Strategic Purchasing PDFmihai simionescuNo ratings yet

- Tata Business ModelDocument15 pagesTata Business ModelJoaquinNo ratings yet

- Emerging Trends in BPM Domain PoVDocument16 pagesEmerging Trends in BPM Domain PoVVenkatesh K100% (1)

- Annual Management Consulting Rankings - 2010/2011Document10 pagesAnnual Management Consulting Rankings - 2010/2011chocobanana123No ratings yet

- Question 8: P&G Has Developed A New Toothpaste That Provides Tooth and Gum Protection ForDocument3 pagesQuestion 8: P&G Has Developed A New Toothpaste That Provides Tooth and Gum Protection ForNgọc Thảo NguyễnNo ratings yet

- Week 1 Tutorial Exercise Introduction To Business Intelligence Task 1 Answer To Discussion QuestionDocument7 pagesWeek 1 Tutorial Exercise Introduction To Business Intelligence Task 1 Answer To Discussion QuestionSyed ZaidiNo ratings yet

- RecordPoint Records Management With SharePointDocument17 pagesRecordPoint Records Management With SharePointoptical420No ratings yet

- Malhotra 03 - Basic-2 Research DesignDocument25 pagesMalhotra 03 - Basic-2 Research DesignNkriswindari100% (1)

- Case Study The Morrison CompanyDocument4 pagesCase Study The Morrison CompanyAbhishek Prasad RoyNo ratings yet

- Unit VIII - Query Processing and SecurityDocument29 pagesUnit VIII - Query Processing and SecurityI SNo ratings yet

- Assignment 2: (Wikipedia - )Document3 pagesAssignment 2: (Wikipedia - )richardanelson000No ratings yet

- DSS Characteristics Data Warehouse OLAPDocument4 pagesDSS Characteristics Data Warehouse OLAPHiraNo ratings yet

- Enterprise E-Business SystemsDocument13 pagesEnterprise E-Business SystemsArtur100% (114)

- GartnerDocument4 pagesGartnersumeetpatnaikNo ratings yet

- Accenture AI Roadmap InfographicDocument1 pageAccenture AI Roadmap InfographicJason CHENNo ratings yet

- Agile Leadership Requires A Different Kind of Business CaseDocument13 pagesAgile Leadership Requires A Different Kind of Business CasePradip100% (1)

- MBAZ513 Assignment 1Document9 pagesMBAZ513 Assignment 1HaggaiNo ratings yet

- Art of Structured Thinking AnalyzingDocument1 pageArt of Structured Thinking AnalyzingCayo OliveiraNo ratings yet

- CIS 8011 Module 6 Digital Innovation AssessmentDocument15 pagesCIS 8011 Module 6 Digital Innovation AssessmentAbdulSamadNo ratings yet

- SBI Life Annual Report 2015-16Document301 pagesSBI Life Annual Report 2015-16Sukanta JanaNo ratings yet

- Service InnovationDocument8 pagesService InnovationSukanta JanaNo ratings yet

- Industry Analysis of The Stationary Sector in India A Market Acceptance Study PDFDocument11 pagesIndustry Analysis of The Stationary Sector in India A Market Acceptance Study PDFSukanta JanaNo ratings yet

- Sukanta Winner's Circle WiproDocument1 pageSukanta Winner's Circle WiproSukanta JanaNo ratings yet

- A Guide to Combining Products and ServicesDocument49 pagesA Guide to Combining Products and ServicesSukanta JanaNo ratings yet

- Lincpen Annual Report 2014 15Document104 pagesLincpen Annual Report 2014 15Sukanta JanaNo ratings yet

- Course Plan-SHRM - Prof A K SenDocument3 pagesCourse Plan-SHRM - Prof A K SenSukanta JanaNo ratings yet

- Final PlacementReport-2016 PDFDocument5 pagesFinal PlacementReport-2016 PDFSukanta JanaNo ratings yet

- Anu Kharwal: Profile SummaryDocument2 pagesAnu Kharwal: Profile SummarySukanta JanaNo ratings yet

- Anu Kharwal BADocument2 pagesAnu Kharwal BASukanta JanaNo ratings yet

- ITC e-Choupal Supply Chain AnalysisDocument39 pagesITC e-Choupal Supply Chain AnalysisSukanta JanaNo ratings yet

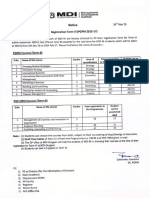

- Notice-Registration Term-VI (PGPM 2015-17) 24.11.16.Document1 pageNotice-Registration Term-VI (PGPM 2015-17) 24.11.16.Sukanta JanaNo ratings yet

- Ranjith CM Personal Details and ResumeDocument3 pagesRanjith CM Personal Details and ResumeAnand RajNo ratings yet

- Final Placement Report 2016ggggDocument7 pagesFinal Placement Report 2016ggggSukanta JanaNo ratings yet

- Termpaperflipkart 1Document29 pagesTermpaperflipkart 1Utkarsh Misra100% (1)

- Notice For Invites Applications For The Non-Teaching PostsDocument2 pagesNotice For Invites Applications For The Non-Teaching PostsSukanta JanaNo ratings yet

- Suman IT ManagementDocument2 pagesSuman IT ManagementSukanta JanaNo ratings yet

- BobDocument13 pagesBobSukanta JanaNo ratings yet

- Achint Arora - 28: Email: PH: +91 9930940943 LinkedinDocument1 pageAchint Arora - 28: Email: PH: +91 9930940943 LinkedinSukanta JanaNo ratings yet

- Zaraitfinal Edit1 120826055208 Phpapp01Document20 pagesZaraitfinal Edit1 120826055208 Phpapp01Anuj SharmaNo ratings yet

- Voice Recognition Tip SheetDocument2 pagesVoice Recognition Tip SheetABugraCetinNo ratings yet

- Winfieldpresentationfinal 130212133845 Phpapp02Document26 pagesWinfieldpresentationfinal 130212133845 Phpapp02Sukanta JanaNo ratings yet

- Subject CombinationsDocument1 pageSubject CombinationsSukanta JanaNo ratings yet

- IMT-Hyderabad Internship Report 2015-17Document3 pagesIMT-Hyderabad Internship Report 2015-17Sukanta JanaNo ratings yet

- Placement Report 2016Document6 pagesPlacement Report 2016Sukanta JanaNo ratings yet

- HulDocument9 pagesHulSukanta JanaNo ratings yet

- Designing and Managing Integrated Marketing CommunicationsDocument31 pagesDesigning and Managing Integrated Marketing CommunicationsSukanta JanaNo ratings yet

- Functions of Production Operation Management (POMDocument13 pagesFunctions of Production Operation Management (POMVanessa Houston0% (1)

- LTCC Tape System High FrequencyDocument2 pagesLTCC Tape System High FrequencyUnicorn54No ratings yet

- Aramco Electrical Safety HandbookDocument5 pagesAramco Electrical Safety HandbookFarhan M100% (1)

- Red Ocean Vs Blue OceanDocument8 pagesRed Ocean Vs Blue Oceanbadshahkhn110No ratings yet

- Chapter 3Document12 pagesChapter 3Adet the moralistaemNo ratings yet

- Non-isometric centrifugal fan blades reduce noiseDocument5 pagesNon-isometric centrifugal fan blades reduce noiseVitthal KhandagaleNo ratings yet

- CV Edin Fatic2Document2 pagesCV Edin Fatic2yousab creator2No ratings yet

- HC110110023 Link AggregationDocument12 pagesHC110110023 Link Aggregationmangla\No ratings yet

- Why Why Analysis Presentation-TPm-training-materialDocument43 pagesWhy Why Analysis Presentation-TPm-training-materialsaravanananusha67% (6)

- C - EWM - 90 - SAP Certified Application Associate - Extended Warehouse Management 9Document4 pagesC - EWM - 90 - SAP Certified Application Associate - Extended Warehouse Management 9Padma Raju0% (1)

- Candlescript IntroductionDocument26 pagesCandlescript IntroductionLucasLavoisierNo ratings yet

- D 2320 - 98 R03 RdizmjaDocument3 pagesD 2320 - 98 R03 RdizmjaEliKax!No ratings yet

- DP-10/DP-10T/DP-11/DP-15/DP-18 Digital Ultrasonic Diagnostic Imaging SystemDocument213 pagesDP-10/DP-10T/DP-11/DP-15/DP-18 Digital Ultrasonic Diagnostic Imaging SystemDaniel JuarezNo ratings yet

- w13 - CRM How It Works and Help BusinessDocument15 pagesw13 - CRM How It Works and Help BusinessYahya Vernanda RamadhaniNo ratings yet

- TemplateDocument148 pagesTemplateWahyu Tri JuniantoNo ratings yet

- Altitude Encoders SSD120Document3 pagesAltitude Encoders SSD12057722No ratings yet

- Fujitsu-General ASYG07-12 LLC 2014Document2 pagesFujitsu-General ASYG07-12 LLC 2014Euro-klima BitolaNo ratings yet

- GGGGGGGGGGGGGGG: FTF Is The Only One Standing OutDocument4 pagesGGGGGGGGGGGGGGG: FTF Is The Only One Standing OutsebastianNo ratings yet

- Cv-Sreenath (T&i)Document5 pagesCv-Sreenath (T&i)sreenaths100% (1)

- Pune University Simulation and Modeling Question PapersDocument2 pagesPune University Simulation and Modeling Question Paperspradeepkraj22No ratings yet

- Consistent Engineering Units in FEADocument6 pagesConsistent Engineering Units in FEAAntonis AlexiadisNo ratings yet

- Siemens Compressor PackageDocument8 pagesSiemens Compressor PackageMilos ObrenovicNo ratings yet

- Operations and Maintenance Manual MAN-10000946 Elmar Grease Injection Equipment AssemblyDocument56 pagesOperations and Maintenance Manual MAN-10000946 Elmar Grease Injection Equipment AssemblyAbhinav KumarNo ratings yet

- A5 Service Manual 2.8Document223 pagesA5 Service Manual 2.8Anahi Calle Velasco0% (1)

- Mastertop 1205: Three Component Solvent Free High Build Epoxy Floor CoatingDocument3 pagesMastertop 1205: Three Component Solvent Free High Build Epoxy Floor CoatingEngTamerNo ratings yet

- Programa Congreso CIDUPDocument2 pagesPrograma Congreso CIDUPGigi GallardoNo ratings yet

- 60-500 KV High Voltage-Gallery PDFDocument33 pages60-500 KV High Voltage-Gallery PDFuzakcilNo ratings yet

- SolverTable HelpDocument13 pagesSolverTable HelpM Ibnu Aji DwiyantoNo ratings yet

- Drawing Assignment Ii Ce 2211 - Civil Engineering MethodsDocument2 pagesDrawing Assignment Ii Ce 2211 - Civil Engineering MethodsFearless HeroNo ratings yet

- Data Visualization Nanodegree Program Syllabus PDFDocument4 pagesData Visualization Nanodegree Program Syllabus PDFsergio paredesNo ratings yet

- SNMP Tutorial PDFDocument24 pagesSNMP Tutorial PDFSrivignessh PssNo ratings yet