Professional Documents

Culture Documents

Us 4738206

Uploaded by

KrozeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us 4738206

Uploaded by

KrozeCopyright:

Available Formats

United States Patent [19]

[11] Patent Number:

4,738,206

Noland

[45] Date of Patent:

Apr. 19, 1988

[54] APPARATUS AND METHOD FOR LOW

TEMPERATURE THERMAL STRIPPING OF

WOLATILE ORGANIC COMPOUNDS FROM

SOIL

[75] Inventor: John W. Noland, West Chester, Pa.

[56]

References Cited .

U.S. PATENT DOCUMENTS

3,751,267 8/1973 Sachnik .........

.... 432/13

4,098,200 7/1978 Dauvergne ...

. 110/228

4,167,909 9/1979 Dauvergne ......................... 110/228

4,504,222 3/1985 Christian ............................. 110/228

4,544,374 10/1985 Mallek et al. ....................... 110/226

[73] Assignee: Roy F. Weston, Inc., West Chester,

Pa.

[21] Appl. No.: 907,961

-

[22] Filed:

Sep. 16, 1986

[51] Int. Cl* ................................................ F23G 5/02

[52] U.S. Cl. .... 110/346; 432/13;

432/139; 110/226; 110/228

[58] Field of Search ................... 432/72, 139, 106, 13;

110/223, 224, 226, 227, 228, 346

4,628,828 12/1986 Holtham et al. .................... 110/228

Primary ExaminerHenry C. Yuen

Attorney, Agent, or FirmAustin R. Miller

[57]

ABSTRACT

Apparatus and method for removing volatile and semi

volatile organic contaminants from natural soil contain

ing moisture by sealing the soil in a stripping conveyor

against contact with air and vapor stripping the contam

inants at a temperature below the boiling temperatures

of the contaminants.

27 Claims, 3 Drawing Sheets

U.S. Patent

Apr. 19, 1988

Sheet 1 of 3

4,738,206

U.S. Patent

Apr. 19, 1988

Sheet 2 of 3

4,738,206

IT!),

U.S. Patent

Apr. 19, 1988

Sheet 3 of 3

4,738,206

4,738,206

2

organic contaminants are removed with safety and may

be discharged without environmental pollution.

Other objects and advantages of this invention, in

cluding the simplicity and economy of the same and the

ease with which it may be applied to a variety of soils

APPARATUS AND METHOD FOR LOW

TEMPERATURE THERMAL STRIPPING OF

WOLATILE ORGANIC COMPOUNDS FROM SOIL

The Government has rights in this invention pursuant

to Contract No. DAAK11-82-C-0017 awarded by the

U.S. Army Armament, Munitions, and Chemical Com

mand. The invention described herein may be manufac

tured, used and licensed by or for the Government for

governmental purposes without the payment to me of

any royalty thereon.

This invention relates to an apparatus and method of

removing volatile and semi-volatile hazardous organic

and combinations of contaminants contained in the soils

will further become apparent hereinafter in the draw

ings whereof:

10

contaminants from natural soil. The invention more 15

particularly relates to the treatment of soil containing

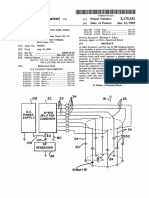

FIG. 1 represents a schematic diagram showing one

preferred form according to which the invention may

be practiced.

FIG. 2 shows a front elevational end view of a mobile

form of apparatus in accordance with the present inven

tion.

FIG. 3 depicts a top plan view of mobile apparatus

utilized in accordance with the present invention.

FIG. 3A represents an exploded view of twin screw

processing apparatus taken generally from the phantom

such hazardous organic contaminants whereby the con

taminants are removed and the soil may be returned to

the earth without pollution to the environment. The circle as shown in FIG. 3.

invention further relates to the removal from the earth 20 FIG. 4 is a side elevational view of mobile soil pro

of soil already polluted by the presence of hazardous cessing apparatus of the present invention.

organic contaminants, the treatment of such soil for

FIG. 5 represents a schematic cross sectional view of

removal of the contaminants, and the return of the soil apparatus utilized in accordance with the present inven

to the earth.

tion.

In recent years it has been an important objective to 25 FIG. 6 is a schematic slide view of a portion of mobile

treat soils contaminated as a result of industrial opera soil processing apparatus of the present invention.

tions, waste, accidents or the like, and many difficulties

FIG. 7 shows a front elevational end view of mobile

have been experienced because of problems encoun soil processing apparatus manifesting other aspects of

tered in materials handling, high operational costs, and the invention.

difficulty in achieving high levels of contaminant re 30 Although specific terms will be used for the sake of

moval.

clarity in hereafter describing the particular form of the

Contamination of soils involving volatile organic invention selected for illustration in the drawings, it will

compounds has become one of the predominant envi be realized that this description is not intended to limit

ronmental concerns. Trichloroethylene is perhaps the the scope of the invention or to exclude the use of a

most frequently found contaminant; however, other 35 wide variety of modifications.

volatile organic compounds such as dichloroethylene,

Turning now to the drawings in general and FIGS. 1

tetrachloroethylene and xylene have also been found. If and 2 in particular, the number 10 designates a feed

allowed to remain in the soil, these compounds can hopper for the contaminated soil S, which may be re

migrate to contaminate underlying ground waters and moved from the earth by conventional earth removing

can lead to other hazardous conditions as well.

40 means 18 and stored in the hopper 10, here shown as

Although thermal stripping of dry soil has been at having a bottom discharge pipe 11. The number 12

tempted, high stripping temperatures are necessary to designates an inclined conveyor, which may be a screw

assure release and removal of the higher boiling organic conveyor or a continuous belt conveyor, for example,

contaminants, with serious operating and cost disadvan having a sealed connection 13 to the bottom of the

tages.

45 bottom discharge pipe 11.

In an entirely different field, in conjunction with off

At its upper end, the inclined conveyor 12 discharges

shore and inland drilling barges and rigs, drill cuttings in sealed relationship into a feed device, such as a pug

have been treated to transform them from a wet oily mill 14, which in turn is connected sealingly to the inlet

condition to a clean substantially oil-free condition, by of a twin screw, indirectly heated processor 15. The

feeding them to a heating chamber having a non-oxida 50 processor 15 may be of the Holo-Flite type as dis

tive environment, thereby vaporizing the hyrocarbon closed in U.S. Pat. Nos. 2,731,241 and 2,753,159, pro

residue and discharging the product to the atmosphere. vided with hollow flights having internally arranged

The patent to Sample, Jr. No. 4,139,462 discloses the passageways for conducting a heat transfer fluid such as

use of a twin screw Holo-Flite heating vessel which is hot oil, steam or the like (see FIG. 3A). Means are

an indirect heat exchanger and screw conveyor that 55 provided for supplying heat transfer fluids such as hot

continuously heats the oil well drilling mud as the mate oil to the twin screw processor, comprising a hot trans

rial is continuously moved through it. Problems are fer fluid or oil heater 16 having an outlet pipe 17 con

encountered, however, when such a drilling mud pro nected to the twin screw processor 15 to supply hot oil

cess is attempted to be applied to contaminated natural for indirect heating of the soil processed therein. The

soils.

60 exit pipe 20 for hot oil is arranged to return the oil to the

It is accordingly an object of this invention to provide inlet 21 of the oil heater 16. The oil heater 16 produces

an apparatus and method of removing volatile and semi combustion gas which exits through the flue pipe 22 and

volatile hazardous organic contaminants from natural to the atmosphere. A branch pipe 23, provided with a

soil, to produce substantially complete removal of the damper 24, extends from the flue pipe 22 to the upper

contaminants, all at a relatively low temperature well 65 space within the twin screw processor 15, above the

below the vaporization temperature of the higher boil screw flights contained therein. It is an important and

ing organic contaminants. Another object of this inven advantageous feature of this invention that the branch

tion is to provide such a method wherein the hazardous pipe 23 is connected at the earth exit end of the twin

4,738,206

3

screw processor, for reasons which will become appar

ent hereinafter.

Located approximately at a middle portion of twin

screw processor 15 is an exhaust duct 25 provided with

a flow meter 26 and a temperature sensor 27. A damper

30 is provided in the exhaust duct 25, which also in

cludes an induced draft blower 31 having its outlet

connected to exhaust gas treatment chamber 32 the

outlet of which communicates with the atmosphere. 10

As shown in FIG. 2, it will now be appreciated that,

in operation, the soil Sis conducted in a sealing relation

ship through the seal 13 into the inclined conveyor 12

and then, still in a sealed relationship, through the pug

mill 14 into the sealed twin screw processor 15, where 15

it is processed in intimate contact with the intermeshing

worm flights which are indirectly heated through inter

nal passageways with the hot oil introduced through

the line 17 from the oil heater 16. Processed soil exits

processor 15 by way of earth transporter 19 as shown in 20

FIG. 5.

Referring to FIGS. 3 and 4, combustion gases from

the oil heater 16 flow through the branch pipe 23 and

the damper 24 into the earth exit end of the twin screw

processor 15 and are then caused to flow above the 25

rotating screw flights in a countercurrent manner with

respect to the flow of the earth being processed. The

combustion gases flow out of the twin screw processor

15 through the exhaust duct 25, past the flow meter 26

and temperature sensor 27, into the inlet of the induced 30

draft blower 31 and then out through the exhaust gas

treatment 32 to the atmosphere. Exhaust gas treatment

32 may consist of removing dust, wet scrubbing for

removal of acid gases, burning organics, burning organ

cient moisture to perform the vapor stripping operation

throughout the length of the twin screw processor 15.

It is also an important and advantageous feature of

this invention that the induced draft blower 31, operat

ing under the control and in response to the determina

tions of the flow meter 26 and the temperature sensor

27, provides a negative pressure within the twin screw

processor 15, preventing fugitive emissions of the haz

ardous organic constituents. This feature combined

with the utilization of the sealed system as heretofore

described provides highly advantageous vapor strip

ping and safety as well.

It will be appreciated that the settings of the dampers

24 and 30 are regulated automatically in response to the

determinations of flow meter 26 and temperature sensor

27, all in a manner known in the art per se and not

shown in the drawing in order to avoid unnnecessary

complications.

It will also be observed that a suction line 33 extends

from the sealed inclined conveyor 12 to the exhaust

duct 25. This applies negative pressure to the inclined

conveyor 12, preventing fugitive emissions of hazard

ous organic constituents which may be released from

the soil in the inclined conveyor 12.

It will accordingly be appreciated that, in accordance

with this invention, soil containing volatile and

semivolatile hazardous organic contaminants is treated

by removing the soil from the earth by conventional

earth moving means such as a front end loader or an

excavator 18 as shown in FIG. 2, and placing it in a soil

container such as the feed hopper 10, sealing the soil

against substantial contact with the air and conveying

the soil in sealed condition to a stripping conveyor

provided with heated flights, heating the moisture con

ics followed by wet scrubbing, adsorbing a portion of 35 tained in the soil by intimate contact with the heated

the hazardous constituents on activated carbon, recov surfaces in the stripping conveyor 15, vapor stripping

ery of hazardous constituents by condensation or recov the hazardous organic contaminants from the soil in the

ery by condensation followed by adsorption on acti twin screw processor 15 at a temperature below the

vated carbon.

boiling temperatures of the soil contaminants with non

Alternatively the exhaust gas may be conducted oxidizing combustion gases which are conducted coun

through duct 34 to combustion air inlet duct 35 and tercurrently over the soil subjected to vapor stripping in

recycled to oil heater 16 by blower 36 (See FIGS. 1 and the stripping conveyor, and controlling the temperature

3). This is advantageous in utilizing the combustion and flow rate of the countercurrent sweep to maintain

process in oil heater 16 for disposal (or use as an energy moisture continuously present at the surface of the soil

source) of the organic contaminants from the soil.

45 as and after the soil enters the stripping conveyor. It

It has been discovered that it is important to maintain will further be appreciated that the provision of a nega

a moisture content in the soil and that this moisture

tive pressure over the soil in the sealed conveyor, when

performs a vapor stripping operation which allows even non-oxidizing sweep gases are countercurrently con

the higher boiling organic contaminants to be removed ducted with respect to the direction of movement of the

at temperatures far below their boiling points. Moisture 50 soil, not only provides a negative pressure in a manner

is retained in the soil by virtue of the sealing relationship to prevent fugitive emissions of the hazardous organic

at 13 and 14 in the drawing, assuring that the soil fed

into the twin screw processor 15 contains sufficient

moisture to serve the aforesaid vapor stripping opera

tion.

It is an important advantageous feature of this inven

tion that the combustion gas from the oil heater 16 is a

non-oxidizing gas, namely, that it is either slightly re

ducing or inert, and that it is introduced for countercur

rent flow in the twin screw processor 15, with respect

to the flow of the soil being processed. In this manner

the non-oxidizing combustion gas at its highest tempera

ture contacts the process soil when such soil is also at its

highest temperature. By contrast, the non-oxidizing

combustion gas is at its coolest temperature when it

contacts the incoming soil, which is also at its coolest

temperature. This avoids excessive removal of moisture

from the incoming soil and assures the presence of suffi

constituents but also enhances release of moisture from

55

the soil and enhances the vapor stripping effect of the

moisture in accomplishing removal of higher boiling

organic contaminants at a temperature far below the

boiling points of these contaminants. It has been found

that the soil to be processed should reside within the

processor for between about 3090 minutes with a resi

dence time of about between 4560 minutes being pre

ferred. The temperature of the exiting processed soil

should be between about 120450 F. with a tempera

ture of about between 140220 F. being preferred.

It has been determined that removal of as much as

65

99.99% of all organic contaminants has been continu

ously achieved at a production rate reaching a practical

level for treatment of natural soil.

Although this invention has been described with

reference to a specific form selected for illustration in

4,738,206

the drawings, it will be appreciated that many modifica

tions may be made, that certain steps may be performed

independently of other steps, and that a wide variety of

equivalent forms of apparatus may be utilized, all with

out departing from the spirit and scope of this invention, 5

which is defined in the appended claims.

I claim:

1. In a method of removing volatile and semi-volatile

hazardous organic contaminants from natural soil con

taining moisture and such contaminants the steps which 10

comprise:

(a) removing the soil from the earth and placing it in

a soil container;

(b) sealing the soil against substantial contact with air

and conveying the soil in sealed condition to a

15

stripping conveyor with heated flights,

(c) vapor stripping said hazardous organic contami

nants from said soil in said conveyor at a tempera

ture below the boiling temperatures of said con

taminants by driving said moisture out of said soil

20

by volatilization of said moisture;

(d) separately by combustion of fuel firing a heater

6

15. The method defined in claim 1, wherein the step

of heating the moisture contained in the soil comprises

burning a fuel with combustion air, and wherein coun

tercurrent sweep gases are returned to said burning step

along with said combustion.

16. Apparatus for removing volatile and semi-volatile

hazardous organic contaminants from natural soil con

taining moisture and such contaminants, comprising:

(a) a soil container for the earth;

(b) sealing means for sealing the soil against substan

tial contact with air;

(c) a stripping conveyor comprising a screw con

veyor with internally heated intermeshing flights;

(d) means for conveying soil in sealed condition,

including a sealed soil conveyor provided to trans

port soil from the soil container to the stripping

conveyor;

(e) means for applying a negative pressure over soil in

said sealed conveyor in a manner to prevent fugi

tive emissions of the hazardous organic constitu

ents;

(f) means for heating the moisture contained in the

for heating said stripping conveyor and thereby

soil by intimate contact with heated surfaces in said

generating non-oxidizing combustion gases;

stripping conveyor, thereby vapor stripping said

(e) sweeping said combustion gases countercurrently

hazardous organic contaminants from said soil in

said conveyor;

over the soil subjected to vapor stripping in said 25

stripping conveyor; and

(g) a fuel burner connected for heating said stripping

conveyor and thereby generating non-oxidizing

(f) controlling the temperature and flow rate of said

combustion gases;

countercurrent sweep to maintain moisture contin

uously present at the surface of the soil as and after

(h) means for conveying said combustion gases coun

said soil enters said stripping conveyor.

tercurrently over the soil subjected to vapor strip

30

ping in said stripping conveyor; and

2. The method defined in claim 1, further omprising

intermixing portions of said soil within said stripping

(i) control means connected for controlling the tem

conveyor with a twin screw conveyor with internally

perature and flow rate of said countercurrent

heated intermeshing flights.

sweep to maintain moisture continuously present at

the surface of the soil as and after said soil enters

3. The method defined in claim 1, further comprising

applying a negative pressure to a sealed soil conveyor 35

said stripping conveyor.

provided to transport the soil from the soil container to

17. The apparatus defined in claim 16, wherein said

the stripping conveyor, in a manner to prevent fugitive negative pressure is applied from the exhaust from said

stripping conveyor to said soil conveyor.

emissions of the hazardous organic constituents.

4. The method defined in claim 3, further comprising

18. The apparatus defined in claim 16, further includ

applying said negative pressure to said soil conveyor ing means for maintaining the countercurrently flowing

sweep gases at less than atmospheric pressure in said

from the exhaust from said stripping conveyor.

5. The method defined in claim 1, further including stripping conveyor.

the step of maintaining the countercurrently flowing

19. The apparatus defined in claim 16, further includ

sweep gases at less than atmospheric pressure in said ing means for removing and purifying the countercur

stripping conveyor.

.

45 rent sweep gases and discharging them to the atmo

6. The method defined in claim 1, further including sphere.

the steps of removing and purifying the countercurrent

20. The apparatus defined in claim 19, wherein the

sweep gases and discharging them to the atmosphere.

removing and purifying means comprises means for

7. The method defined in claim 6, wherein the purify removing dust.

ing step comprises removing dust.

21. The apparatus defined in claim 19, wherein the

50

8. The method defined in claim 6, wherein the purify purifying means comprises a wet scrubber for removal

ing step comprises wet scrubbing for removal of acid of acid gases from said gases.

gases from said gases.

22. The apparatus defined in claim 19, wherein the

9. The method defined in claim 6, wherein the purify purifying means comprises a burner for burning organ

ing step comprises burning organics contained in said 55 ics contained in said gases.

gases.

23. The apparatus defined in claim 22, comprising a

10. The method defined in claim 9, followed by the wet scrubber downstream of said burner.

step of wet scrubbing said gases.

24. The apparatus defined in claim 19, wherein the

11. The method defined in claim 6, wherein the puri purifying means comprises means for adsorbing at least

fying step comprises adsorbing at least some of the 60 some of the hazardous constituents on activated carbon.

hazardous constituents on activated carbon.

25. The apparatus defined in claim 19, further includ

12. The method defined in claim 6, including the ing means for recovering at least one of the hazardous

further step of recovering at least one of the hazardous constituents by condensation.

constituents by condensation.

26. The apparatus defined in claim 25, further includ

13. The method defined in claim 12, followed by the ing means for adsorption on activated carbon.

65

further step of adsorption on activated carbon.

27. The apparatus defined in claim 16, further includ

14. The method defined in claim 1, further including ing conveyor means for returning the purified natural

the step of returning the purified natural soil to the soil to the earth. :: # # 3% ::

earth.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2022 Army Climate Strategy Implementation Plan FY23-FY27Document50 pages2022 Army Climate Strategy Implementation Plan FY23-FY27Jim Hoft100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Global Citizenship EducationDocument20 pagesGlobal Citizenship EducationKeith O'brien95% (19)

- RE-REFINING OF USED LUBRICATING OILSDocument23 pagesRE-REFINING OF USED LUBRICATING OILSJaydeep TayadeNo ratings yet

- United States Patent (19) : (45) Date of Patent: Oct. 12, 1999Document17 pagesUnited States Patent (19) : (45) Date of Patent: Oct. 12, 1999KrozeNo ratings yet

- Rock Classification and Formation ProcessesDocument6 pagesRock Classification and Formation ProcessesYogendra PatilNo ratings yet

- Pearson Ib Chemistry Text Book AnswersDocument99 pagesPearson Ib Chemistry Text Book Answersmohammad abdurehmanNo ratings yet

- Us8608097 PDFDocument10 pagesUs8608097 PDFKrozeNo ratings yet

- Us 3616264Document4 pagesUs 3616264KrozeNo ratings yet

- Us 6250486Document14 pagesUs 6250486KrozeNo ratings yet

- Us 5818319Document30 pagesUs 5818319KrozeNo ratings yet

- Us 7006327Document11 pagesUs 7006327KrozeNo ratings yet

- Aug. 5, 1969 ?. R. ???.?.?.? 3,459,957: Woltage Regulator CircuitDocument6 pagesAug. 5, 1969 ?. R. ???.?.?.? 3,459,957: Woltage Regulator CircuitKrozeNo ratings yet

- Variable capacity staged cooling DX geothermal heat pumpDocument44 pagesVariable capacity staged cooling DX geothermal heat pumpKrozeNo ratings yet

- United States Patent: (21) Appl. N0.: 13/226,109 (Continued)Document17 pagesUnited States Patent: (21) Appl. N0.: 13/226,109 (Continued)KrozeNo ratings yet

- Us 6633161Document21 pagesUs 6633161KrozeNo ratings yet

- Dec. 12, 1967 F. Grossoehme 3,358,210: Filed June 25, 1964Document4 pagesDec. 12, 1967 F. Grossoehme 3,358,210: Filed June 25, 1964KrozeNo ratings yet

- United States Patent (19) (11) Patent Number: 5,179,332Document14 pagesUnited States Patent (19) (11) Patent Number: 5,179,332KrozeNo ratings yet

- Us 3376803Document26 pagesUs 3376803KrozeNo ratings yet

- Us 3195038Document10 pagesUs 3195038KrozeNo ratings yet

- Low inductance high energy inductive ignition systemDocument18 pagesLow inductance high energy inductive ignition systemKrozeNo ratings yet

- Low inductance high energy inductive ignition systemDocument18 pagesLow inductance high energy inductive ignition systemKrozeNo ratings yet

- Patent for Moving Coil Linear Actuator with Interleaved Magnetic CircuitsDocument11 pagesPatent for Moving Coil Linear Actuator with Interleaved Magnetic CircuitsKrozeNo ratings yet

- United States Patent (19) (11) Patent Number: 6,130,863: Wang Et Al. (45) Date of Patent: Oct. 10, 2000Document18 pagesUnited States Patent (19) (11) Patent Number: 6,130,863: Wang Et Al. (45) Date of Patent: Oct. 10, 2000KrozeNo ratings yet

- Us 6577888Document12 pagesUs 6577888KrozeNo ratings yet

- Us 4774914Document25 pagesUs 4774914KrozeNo ratings yet

- United States PatentDocument14 pagesUnited States PatentKrozeNo ratings yet

- Coil Array Design Enhances Resolution and Depth of Investigation for Induction Logging ToolsDocument21 pagesCoil Array Design Enhances Resolution and Depth of Investigation for Induction Logging ToolsKrozeNo ratings yet

- Patent for Moving Coil Linear Actuator with Interleaved Magnetic CircuitsDocument11 pagesPatent for Moving Coil Linear Actuator with Interleaved Magnetic CircuitsKrozeNo ratings yet

- United States PatentDocument25 pagesUnited States PatentKrozeNo ratings yet

- Us 5379832Document16 pagesUs 5379832KrozeNo ratings yet

- United States PatentDocument15 pagesUnited States PatentKrozeNo ratings yet

- United States PatentDocument15 pagesUnited States PatentKrozeNo ratings yet

- Us 4866424Document14 pagesUs 4866424KrozeNo ratings yet

- United States Patent (19) (11) Patent Number: 5,207,074Document18 pagesUnited States Patent (19) (11) Patent Number: 5,207,074KrozeNo ratings yet

- United States Patent (19) : 16 VoltageDocument12 pagesUnited States Patent (19) : 16 VoltageKrozeNo ratings yet

- Physics: Class: Xi Target Jee 2022 DateDocument7 pagesPhysics: Class: Xi Target Jee 2022 DateBhushanNo ratings yet

- Final Annotated BibiliographyDocument4 pagesFinal Annotated Bibiliographyapi-491166748No ratings yet

- English exam with multiple choice questions and answersDocument7 pagesEnglish exam with multiple choice questions and answersDương Đặng Ngọc KhánhNo ratings yet

- First Semester Examination Class: VII Geography Marks: 40 / Pgs. 3 Date: 06.10.2021 Time: 1 HRDocument3 pagesFirst Semester Examination Class: VII Geography Marks: 40 / Pgs. 3 Date: 06.10.2021 Time: 1 HRश्रवण कुमारNo ratings yet

- Grade 4 ScienceDocument1 pageGrade 4 ScienceXernick M. FelipeNo ratings yet

- Consumerism and Waste Products PDFDocument4 pagesConsumerism and Waste Products PDFEDCELL sjce100% (4)

- Mapping of Significant Natural Resources: Category: Bodies of WaterDocument3 pagesMapping of Significant Natural Resources: Category: Bodies of WaterDei HernandezNo ratings yet

- SCES1094 Tutorial 2Document21 pagesSCES1094 Tutorial 2SN2-0622 NURUL ADLYNA BINTI LOKMANNo ratings yet

- Bahasa Inggris Kelas XI IPA/ XI IPS: Name: Class: DateDocument7 pagesBahasa Inggris Kelas XI IPA/ XI IPS: Name: Class: DateChristevanNo ratings yet

- TIDAL AND HYDEL ENERGY - by MAHIMADocument22 pagesTIDAL AND HYDEL ENERGY - by MAHIMAMahima KamraNo ratings yet

- 9202Document80 pages9202leninks_1979No ratings yet

- Thermodynamics Exam Questions Focus on Cycles, Processes, and Efficiency CalculationsDocument26 pagesThermodynamics Exam Questions Focus on Cycles, Processes, and Efficiency CalculationsSuhas G MNo ratings yet

- Chapter 2 Review of LiteratureDocument13 pagesChapter 2 Review of LiteratureReeya PatelNo ratings yet

- Biology Project on Transpiration in PlantsDocument29 pagesBiology Project on Transpiration in PlantsDhanush PSNo ratings yet

- Module 4 - Environmental Protection 3Document95 pagesModule 4 - Environmental Protection 3Matthew JordanNo ratings yet

- PerformanceDocument2 pagesPerformanceTenny SupNo ratings yet

- Bess For Containerized R2Document1 pageBess For Containerized R2risqi rotbiNo ratings yet

- Pure Substances and Physical Mixtures ExplainedDocument7 pagesPure Substances and Physical Mixtures ExplainedaiynaNo ratings yet

- ResumeDocument5 pagesResumeAllright ShitNo ratings yet

- Design and Analysis of Electric Power Production Unit For Low Enthalpy Geothermal Reservoir ApplicationsDocument7 pagesDesign and Analysis of Electric Power Production Unit For Low Enthalpy Geothermal Reservoir Applicationsyousufali56No ratings yet

- Wilting PointDocument7 pagesWilting Pointbunaladi.jhonNo ratings yet

- 10 - Hazardous Wastes PDFDocument30 pages10 - Hazardous Wastes PDFEruvin Ike SumisuNo ratings yet

- Power Plant Engineering Question Bank For EEEDocument7 pagesPower Plant Engineering Question Bank For EEEJOHN PAUL V100% (1)

- Types of Geological Formations of GroundwaterDocument7 pagesTypes of Geological Formations of Groundwatertoegyi2527No ratings yet

- Jumaidin 2019Document33 pagesJumaidin 2019Aldi WijayantoNo ratings yet