Professional Documents

Culture Documents

AISI 1045 Medium Carbon Steel - AZoM

Uploaded by

Luis NunesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AISI 1045 Medium Carbon Steel - AZoM

Uploaded by

Luis NunesCopyright:

Available Formats

AISI 1045 Medium Carbon Steel

AISI 1045 Medium Carbon Steel

Written by AZoM

Jul 2 2012

Topics Covered

Introduction

Chemical Composition

Physical Properties

Mechanical Properties

Machining

Welding

Heat Treatment

Forging

Annealing

Normalizing

Stress Relieving

Hardening

Tempering

Applications

Introduction

AISI 1045 steel is a medium tensile steel supplied in the black hot rolled or normalized

condition. It has a tensile strength of 570 - 700 MPa and Brinell hardness ranging

between 170 and 210.

AISI 1045 steel is characterized by good weldability, good machinability, and high

strength and impact properties in either the normalized or hot rolled condition.

AISI 1045 steel has a low through-hardening capability with only sections of size

around 60 mm being recommended as suitable for tempering and through-hardening.

However, it can be efficiently flame or induction hardened in the normalized or hot

rolled condition to obtain surface hardnesses in the range of Rc 54 - Rc 60 based on

factors such as section size, type of set up, quenching medium used etc.

AISI 1045 steel lacks suitable alloying elements and hence does not respond to the

nitriding process.

Saved from URL: http://www.azom.com/article.aspx?ArticleID=6130

/4

AISI 1045 Medium Carbon Steel

Chemical Composition

Element

Content

Carbon, C

0.420 - 0.50 %

Iron, Fe

98.51 - 98.98 %

Manganese, Mn

0.60 - 0.90 %

Phosphorous, P

0.040 %

Sulfur, S

0.050 %

Physical Properties

Physical Properties

Density

Metric

Imperial

7.87 g/cc

0.284 lb/in3

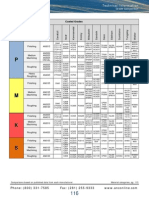

Mechanical Properties

Mechanical Properties

Metric

Imperial

Hardness, Brinell

163

163

Hardness, Knoop (Converted from Brinell hardness)

184

184

Hardness, Rockwell B (Converted from Brinell hardness)

84

84

Hardness, Vickers (Converted from Brinell hardness)

170

170

Tensile Strength, Ultimate

565 MPa 81900 psi

Tensile Strength, Yield

310 MPa 45000 psi

Elongation at Break (in 50 mm)

16.0 %

16.0 %

Reduction of Area

40.0 %

40.0 %

Modulus of Elasticity (Typical for steel)

200 GPa 29000 ksi

Bulk Modulus (Typical for steel)

140 GPa 20300 ksi

Poissons Ratio (Typical For Steel)

0.290

0.290

Shear Modulus (Typical for steel)

80 GPa

11600 ksi

Machining

AISI 1045 steel has good machinability in normalized as well as the hot rolled

condition. Based on the recommendations given by the machine manufacturers,

operations like tapping, milling, broaching, drilling, turning and sawing etc. can be

carried out on AISI 1045 steel using suitable feeds, tool type and speeds.

Welding

Certain facts about welding of AISI 1045 steel are:

Saved from URL: http://www.azom.com/article.aspx?ArticleID=6130

/4

AISI 1045 Medium Carbon Steel

AISI 1045 steel is readily welded when correct procedure is followed.

Welding AISI 1045 steel in through-hardened, tempered and flame or induction

hardened condition is not recommended.

Low hydrogen electrodes are preferred for welding AISI 1045 steel.

The workpiece is

Pre-heated at 200C300C (392F - 572F)

Maintained at the same temperature during welding

Cooled slowly using sand, ashes etc and

Stress relieved at 550C - 660C (1022F - 1220F).

Heat Treatment

AISI 1045 is subjected to the following processes:

Forging

Annealing

Normalizing

Stress relieving

Hardening

Tempering

Forging

Heat to 850C - 1250C (1562F - 2282F)

Hold until the temperature is uniform

Cool in furnace

Annealing

Heat to 800C - 850C (1472F - 1562F)

Hold until the temperature is uniform

Cool in furnace.

Normalizing

Heat to 870C - 920C (1598F-1688F)

Hold until the temperature is uniform

Soak for 10 - 15 minutes

Cool in still air

Stress Relieving

Saved from URL: http://www.azom.com/article.aspx?ArticleID=6130

/4

AISI 1045 Medium Carbon Steel

Heat to 550C - 660C (1022F - 1220F)

Hold until the temperature is uniform

Soak for 1 hour per 25mm of section

Cool in still air

Hardening

Heat to 820C - 850C (1508F - 1562F)

Hold until the temperature is uniform

Soak for 10 - 15 minutes per 25mm of section

Quench in water or brine

Tempering

Re-heat to 400C - 650C (752F - 1202F ) as required

Hold until the temperature is uniform

Soak for 1 hour per 25mm of section

Cool in still air

Applications

AISI 1045 is widely used for all industrial applications requiring more wear resistance

and strength. Typical applications of AISI 1045 are as follows:

Gears

Pins

Rams

Shafts

Rolls

Sockets

Axles

Spindles

Worms

Bolts

Ratchets

Light gears

Studs

Crankshafts

Guide rods

Connecting rods

Torsion bars

Hydraulic clamps

Saved from URL: http://www.azom.com/article.aspx?ArticleID=6130

/4

You might also like

- 3 Crazy Excel Formulas That Do Amazing Things - Advanced Excel Tips & TricksDocument9 pages3 Crazy Excel Formulas That Do Amazing Things - Advanced Excel Tips & TricksLuis NunesNo ratings yet

- Hawking-Brief History of TimeDocument336 pagesHawking-Brief History of TimeAlbert Kristian0% (1)

- HVOF Hardfacing AlloyDocument12 pagesHVOF Hardfacing AlloyLincoln ChauNo ratings yet

- 5.back StopDocument44 pages5.back Stopaiyubi20% (1)

- Sae j429 Vs Astm A354 BDDocument2 pagesSae j429 Vs Astm A354 BDAdam GordonNo ratings yet

- Stainless Steel Grade Composition ChartDocument8 pagesStainless Steel Grade Composition Chart23OtterNo ratings yet

- Stainless Steel Grade Composition ChartDocument8 pagesStainless Steel Grade Composition Chart23OtterNo ratings yet

- Cause and Effect DiagramDocument23 pagesCause and Effect DiagramSham Kadoli100% (3)

- BRP 768847 - Riggingcatalog PDFDocument229 pagesBRP 768847 - Riggingcatalog PDFAlex VdbusscheNo ratings yet

- GLT Id Valves CatalogDocument80 pagesGLT Id Valves Catalogdjoko witjaksonoNo ratings yet

- Abrasive Blast Nozzle Catalog: Bringing Ceramic Technology To Industry Boride P Roduct SDocument46 pagesAbrasive Blast Nozzle Catalog: Bringing Ceramic Technology To Industry Boride P Roduct SSamsu SamsNo ratings yet

- Training Matrix For TM IDocument14 pagesTraining Matrix For TM IApril NavaretteNo ratings yet

- Welder Qualification Record: CODE: AS/NZS 1554.5-2014 WMS-WPS-30Document2 pagesWelder Qualification Record: CODE: AS/NZS 1554.5-2014 WMS-WPS-30Ali TalebiNo ratings yet

- Astm A-194-NutsDocument3 pagesAstm A-194-NutsDavid Luna MolinaNo ratings yet

- Welding Handbook Maritime UnitorDocument552 pagesWelding Handbook Maritime UnitorPeter BournelisNo ratings yet

- Grades of Steel ChartDocument3 pagesGrades of Steel ChartKimNo ratings yet

- Pressure Vessel Inspection ProcedureDocument16 pagesPressure Vessel Inspection Procedurejabir ahmad anarwalaNo ratings yet

- WPS - 2Document3 pagesWPS - 2aleventNo ratings yet

- SDH TechnologyDocument26 pagesSDH TechnologyJayesh SinghalNo ratings yet

- Singer Basic Tote Bag: Shopping ListDocument5 pagesSinger Basic Tote Bag: Shopping ListsacralNo ratings yet

- Kirloskar Valves Technical Specification CatalogueDocument24 pagesKirloskar Valves Technical Specification CatalogueAbhinay SuratkarNo ratings yet

- ANSYS ACT Developers GuideDocument506 pagesANSYS ACT Developers GuideEDIZONNo ratings yet

- Curtis CatalogDocument9 pagesCurtis CatalogtharngalNo ratings yet

- Aisi 4140 En8 En19Document1 pageAisi 4140 En8 En19Jose KurianNo ratings yet

- Human Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveFrom EverandHuman Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveNo ratings yet

- Lincoln Submerged ArcDocument54 pagesLincoln Submerged ArcjdNo ratings yet

- Aisi 4140Document3 pagesAisi 4140BayuPrasetyaPutraNo ratings yet

- Paint Specification SheetDocument1 pagePaint Specification Sheetheru firmansyahNo ratings yet

- Properties s45cDocument3 pagesProperties s45ctomas duranNo ratings yet

- Machine Tool Shanks (Tapers)Document22 pagesMachine Tool Shanks (Tapers)michaelguzziNo ratings yet

- Stainless Steel, cf8, cf3, cf8m, cf3m, Ca15, Ca40, 17 - 4, 15 - 5, cd4m 1a, cg8mDocument2 pagesStainless Steel, cf8, cf3, cf8m, cf3m, Ca15, Ca40, 17 - 4, 15 - 5, cd4m 1a, cg8mDewandanuNo ratings yet

- API 650 tank construction sequenceDocument3 pagesAPI 650 tank construction sequenceSunket Patel100% (1)

- Hydrostatic Test 3.1Document1 pageHydrostatic Test 3.1yogitatanavadeNo ratings yet

- VTI Ball Valve IOM PDFDocument16 pagesVTI Ball Valve IOM PDFSandra Viviana Esquivel BenavidesNo ratings yet

- Metal Tapered Tube Plugs: Tube Plug Sizing ChartDocument1 pageMetal Tapered Tube Plugs: Tube Plug Sizing ChartRaghavanNo ratings yet

- Instrumentation Pipe & Weld Fittings: 6000psig, 10000psig and Standard RatingDocument5 pagesInstrumentation Pipe & Weld Fittings: 6000psig, 10000psig and Standard Ratinggohjh80No ratings yet

- API 5CT P110 7Document2 pagesAPI 5CT P110 7rageshmv100% (1)

- Model 7600: NDIR Infrared Gas AnalyzerDocument126 pagesModel 7600: NDIR Infrared Gas Analyzerzulfiqar aliNo ratings yet

- TorqueDocument2 pagesTorquestaedtlerpNo ratings yet

- ASTM A536 Ductile Iron Castings Tensile RequirementsDocument1 pageASTM A536 Ductile Iron Castings Tensile RequirementsTheOne Yasir100% (1)

- Advantage & Disadv of Bellow & Slip JointDocument2 pagesAdvantage & Disadv of Bellow & Slip JointSharun Suresh0% (1)

- Almen Strip Holders: Meets SAE J442Document2 pagesAlmen Strip Holders: Meets SAE J442donhan91No ratings yet

- Design and Analysis of Disc Plate in Hot Blast Valve #DN1800Document8 pagesDesign and Analysis of Disc Plate in Hot Blast Valve #DN1800MounicaRasagyaPallaNo ratings yet

- Is-4696-1 2004Document7 pagesIs-4696-1 2004ofajNo ratings yet

- Electrode/Flux Stabilizing Oven GuideDocument2 pagesElectrode/Flux Stabilizing Oven GuideSun SunNo ratings yet

- ASME-B31-3-2014 Table 331.1.3 PDFDocument2 pagesASME-B31-3-2014 Table 331.1.3 PDFImane KhammouriNo ratings yet

- Data Table For Grades Tool Die Steels SKD-11Document3 pagesData Table For Grades Tool Die Steels SKD-11Adhi candra irawanNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationMark Jason M. BrualNo ratings yet

- 8008 ControlSwitches EK00 III enDocument8 pages8008 ControlSwitches EK00 III enLaurence Malanum100% (1)

- Equivalencia AceroDocument30 pagesEquivalencia AceroJose VelosaNo ratings yet

- Manual for Induction Motors and Generators Alignment GuideDocument2 pagesManual for Induction Motors and Generators Alignment GuideMuhammed SulfeekNo ratings yet

- Hydro Aluminium - AlSi7Mg0.6Document2 pagesHydro Aluminium - AlSi7Mg0.6Raj PrasanthNo ratings yet

- Krautkramer Thickness Gauge Probes and Accessories Price ListDocument7 pagesKrautkramer Thickness Gauge Probes and Accessories Price List7043578600No ratings yet

- Tecnoplast SRL - Product ListDocument44 pagesTecnoplast SRL - Product Listbarino1966No ratings yet

- Asme 1417 WordDocument12 pagesAsme 1417 WordERIKA RUBIONo ratings yet

- Manual Técnico de Parafusos - BOSSARDDocument85 pagesManual Técnico de Parafusos - BOSSARDRenato Caldas100% (1)

- Technical Information: Grade Comparison ChartDocument2 pagesTechnical Information: Grade Comparison ChartsansagithNo ratings yet

- Tosaca Catalogue PDFDocument16 pagesTosaca Catalogue PDFgabNo ratings yet

- Catalogo de Conectores Hidraulicos PARKER PDFDocument86 pagesCatalogo de Conectores Hidraulicos PARKER PDFgbobadillaNo ratings yet

- Knife Gate Valve - AVKCMSDocument2 pagesKnife Gate Valve - AVKCMSjuantamad02No ratings yet

- Interview Type Question Manufacturing PDFDocument4 pagesInterview Type Question Manufacturing PDFSourav KayalNo ratings yet

- Ficha Tecnica Astm 514Document1 pageFicha Tecnica Astm 514Ruben Dario Mamani ArellanoNo ratings yet

- Dimensions of Spiral Wound Gaskets ASME B16Document3 pagesDimensions of Spiral Wound Gaskets ASME B16Almir PendekNo ratings yet

- 5'' 19.5 - G105 NC50 6.625-3.25Document1 page5'' 19.5 - G105 NC50 6.625-3.25Hamza LahbibenNo ratings yet

- Shell Joint SpecificationsDocument37 pagesShell Joint SpecificationsKiran NikateNo ratings yet

- Virgo Trunnion Ball ValveDocument16 pagesVirgo Trunnion Ball ValveKamalNo ratings yet

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNo ratings yet

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesFrom EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- AISI 1045 Medium Carbon SteelDocument4 pagesAISI 1045 Medium Carbon Steelsenthil4you100% (1)

- 1045 Medium Tensile Carbon Steel Bar - Interlloy EngineeringDocument3 pages1045 Medium Tensile Carbon Steel Bar - Interlloy EngineeringLuis NunesNo ratings yet

- Excavator Pre Use Inspection SUP 134 e en 16 077Document1 pageExcavator Pre Use Inspection SUP 134 e en 16 077acarisimovicNo ratings yet

- AISI 1045 Carbon Steel - MakeItFromDocument4 pagesAISI 1045 Carbon Steel - MakeItFromLuis NunesNo ratings yet

- Medium Tensile Steel A Is I 1045Document2 pagesMedium Tensile Steel A Is I 1045Madhav RajpurohitNo ratings yet

- Lecture 3 - FMEADocument55 pagesLecture 3 - FMEALuis NunesNo ratings yet

- Safe Work Procedure - Grapple Skidder: Company NameDocument3 pagesSafe Work Procedure - Grapple Skidder: Company NameLuis NunesNo ratings yet

- Atlas 1045Document4 pagesAtlas 1045teddy18No ratings yet

- S&T Stainless Steel Product RangeDocument7 pagesS&T Stainless Steel Product RangeLuis NunesNo ratings yet

- Analysis of Stress & Strain PDFDocument2 pagesAnalysis of Stress & Strain PDFLuis NunesNo ratings yet

- S&T Engineering Steels RangeDocument4 pagesS&T Engineering Steels RangeLuis NunesNo ratings yet

- Atlas 1045Document4 pagesAtlas 1045teddy18No ratings yet

- 1045 Medium Tensile Carbon Steel Bar DatasheetDocument3 pages1045 Medium Tensile Carbon Steel Bar DatasheetSamuel FreitasNo ratings yet

- Carbon Steel Pipe Pressure RatingsDocument4 pagesCarbon Steel Pipe Pressure RatingsAllison MoraisNo ratings yet

- Product SpecDocument4 pagesProduct Specpandy1604No ratings yet

- Atlas Technical Handbook of SS Rev Aug 2013Document49 pagesAtlas Technical Handbook of SS Rev Aug 2013timparker01No ratings yet

- Stainless Steel Grade Selection PDFDocument11 pagesStainless Steel Grade Selection PDFLuis NunesNo ratings yet

- 1045 Medium Tensile Carbon Steel Bar DatasheetDocument3 pages1045 Medium Tensile Carbon Steel Bar DatasheetSamuel FreitasNo ratings yet

- Stainless Steel in Architecture - OverviewDocument2 pagesStainless Steel in Architecture - OverviewLuis NunesNo ratings yet

- Atlas Aluminium Datasheet 5083Document3 pagesAtlas Aluminium Datasheet 5083Luis NunesNo ratings yet

- Pressure Rating A269 (Tubing)Document2 pagesPressure Rating A269 (Tubing)Michel LupienNo ratings yet

- Stainless Steel Grade Selection PDFDocument11 pagesStainless Steel Grade Selection PDFLuis NunesNo ratings yet

- Atlas Product Summary GuideDocument4 pagesAtlas Product Summary GuideLuis NunesNo ratings yet

- Atlas Aluminium Datasheet 5083Document3 pagesAtlas Aluminium Datasheet 5083Luis NunesNo ratings yet

- Atlas Aluminium Datasheet 6063 PDFDocument2 pagesAtlas Aluminium Datasheet 6063 PDFLuis NunesNo ratings yet

- Indian Standards List As On Jan2009Document216 pagesIndian Standards List As On Jan2009Vasudeva Pavan VemuriNo ratings yet

- Meeting 5: Data Warehouses and SQL Query OptimizationDocument4 pagesMeeting 5: Data Warehouses and SQL Query Optimizationzvipev1050% (2)

- QAF10A200S TheTimkenCompany 2DSalesDrawing 03 06 2023Document1 pageQAF10A200S TheTimkenCompany 2DSalesDrawing 03 06 2023LeroyNo ratings yet

- Solvent based printing inks applicationsDocument34 pagesSolvent based printing inks applicationsAmna liaquatNo ratings yet

- Reliability EngineeringDocument9 pagesReliability Engineeringnvaradharajan1971No ratings yet

- Technical Data: Pump NameDocument6 pagesTechnical Data: Pump Nameسمير البسيونىNo ratings yet

- DasibiOzoneMonitorManual 1008Document183 pagesDasibiOzoneMonitorManual 1008api-26966403100% (2)

- Geophysical Report Megnatic SurveyDocument29 pagesGeophysical Report Megnatic SurveyShahzad KhanNo ratings yet

- 2N3866 Datasheet Rev BDocument5 pages2N3866 Datasheet Rev Bardier34No ratings yet

- 2017 Yr 9 Linear Relations Test A SolutionsDocument13 pages2017 Yr 9 Linear Relations Test A SolutionsSam JeffreyNo ratings yet

- Bash 101 Hacks PDFDocument5 pagesBash 101 Hacks PDFAmira A MarreiNo ratings yet

- Self Report QuestionnaireDocument6 pagesSelf Report QuestionnaireMustafa AL ShlashNo ratings yet

- Blowfish Encryption AlgorithmDocument3 pagesBlowfish Encryption AlgorithmParkerAllisonNo ratings yet

- Austenitic Stainless SteelsDocument10 pagesAustenitic Stainless SteelsbramNo ratings yet

- e-GP System User Manual - Tender Evaluation Committee UserDocument82 pagese-GP System User Manual - Tender Evaluation Committee UserMd. Jakaria ApuNo ratings yet

- 8086 Instruction SetDocument66 pages8086 Instruction SetRaj KumarNo ratings yet

- Bab 8Document29 pagesBab 8Nurul AmirahNo ratings yet

- Records of Intervention On The Findings of Test Results and Other Forms of AssessmentDocument10 pagesRecords of Intervention On The Findings of Test Results and Other Forms of AssessmentLea May MagnoNo ratings yet

- Introduction To Curve FittingDocument10 pagesIntroduction To Curve FittingscjofyWFawlroa2r06YFVabfbajNo ratings yet

- SubNetting Practice LabDocument3 pagesSubNetting Practice LabOdoch HerbertNo ratings yet

- CI SetDocument18 pagesCI Setতন্ময় ঢালি Tanmay DhaliNo ratings yet

- Lab Manual MCSE 101Document35 pagesLab Manual MCSE 101Juan JacksonNo ratings yet

- 1/2" Cellflex Superflexible Foam-Dielectric Coaxial Cable: SCF12-50JDocument2 pages1/2" Cellflex Superflexible Foam-Dielectric Coaxial Cable: SCF12-50JpeguigonsoNo ratings yet