Professional Documents

Culture Documents

STRUCTURAL DESIGN OF HAND RAIL TITLE

Uploaded by

msiddiq1Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STRUCTURAL DESIGN OF HAND RAIL TITLE

Uploaded by

msiddiq1Copyright:

Available Formats

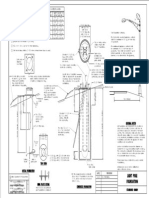

STRUCTUAL DESIGN OF HAND RAIL

I.

General

1. Design Philosophy - PREAMBLE

The purpose of this calculation is to verify the thickness of tube and

its supporting structure for its integrity, strength and stability

verification. The result of this conclusion is that the structure

considered adequate in meeting the required of design criteria.

2. Unit of Measurement

Unit of measurement in design shall be in Metric system.

II.

Design Calculations

1. Design Code and reference:

BS 5950: Steel Structural use of steel work in building

2. Materials

Bracket Connection

The modulus of elasticity of Steel E = 210000 MPa

Ultimate Bending stress Po - = 275 MPa = 275 N/mm2

Ultimate Shear Stress Pv = 0.4X Po = 0.4X275 = 110 MPa = 110

N/mm2

All bolts used shall be of high yield.

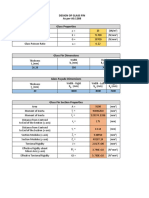

3. Loading

Dead Load Self weight is considered

The Forces acting on the Handrails apart from self weight

are as follows which is complying with the Structural

Performance of Handrails and Railings ASTM E 985:

Handrail shall be designed to resist a load of 50 plf (0.73 kN/m)

applied in any direction at the top and to transfer this load through

the supports to the structure.

Handrail shall be able to resist a single concentrated load of 200

pounds (0.89 kN), applied in any direction at any point along the

top, and have attachment devices and supporting structure to

transfer this loading to appropriate structural elements of the

building.

Horizontal Load is considered as 89 Kgs.

Maximum Moment developed by the above forces from the bottom

surface i.e. at an average distance of 0.10m.

Mx1 = (89) X 0.10

Mx1 = 8.90 kgm

Mx1 = 89 Nm = 0.089KNm

Maximum Moment developed due to horizontal concentrated load is

0.089KNm, this moment has to be resisted by the 16mm SS Rod.

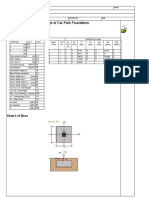

Bottom Connection details:

The SS Rod is connected with the steel base plate that is anchored with

bolts embedded into the concrete 120mm deep to resist shear force or

reaction and moments from the above forces.

The maximum reaction is equal to 0.89 KN that has to be resisted by

the connection.

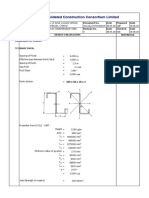

Check for Shear:

Shear Stress = Shear Force / Cross-sectional area

A=

(16)2

A = 804 mm2

Shear Stress = 890 / 804

Shear Stress = 1.10 N/mm2 which is less than the allowable Shear

Stress

Allowable Shear Stress = 110 N/mm2

Hence, the above section is safe against Shear.

Moment Developed by Tube Section:

The area in contact with the concrete surface shall develop moment

that will resist the moment from the above calculations.

Flexural Strength of the member = Sectional Modulus X Flexural

stresses

Flexural stresses for Steel = 275 N/mm2

The Sectional Modulus is calculated as mentioned below:

Zxx =

(D)3 /32

Zxx =

(16)3 / 32 = 402.12 mm3

Sectional Modulus = 402.12 mm3

MR = Zxx X Fy

MR = 402.12 X 275

MR = 0.1106KNm

Hence, the moment of resistance is more than the required.

Design of Bolt M8 X 100mm:

The shear resistance of screws should resist the maximum shear force

acting on the window profile.

Maximum Shear force Vmax = 890 N

Shear Capacity of the Bolt = 0.4 X 0.785 X 64 X 275/1000 = 5.52 KN

Tensile capacity of the Bolt = 0.6 X 0.785 X 64 X 275/1000 = 8.29 KN

Hence, the bolts size mentioned above is safe against shear and

tension.

Conclusion:

All sections used are structurally sufficient and meet its intended

purpose.

You might also like

- Design Calculations For Aluminium Profile-13794Document14 pagesDesign Calculations For Aluminium Profile-13794msiddiq175% (4)

- Handrail CalculationDocument8 pagesHandrail Calculationsuresh_viki100% (1)

- Handrail DesignDocument5 pagesHandrail DesignMuhamadGustiMuharamaNo ratings yet

- Structural Calculation For Balcony Handrail - R1 PDFDocument4 pagesStructural Calculation For Balcony Handrail - R1 PDFArdrick Bosco100% (2)

- Sample and Reference Calculations for Guardrail DesignDocument24 pagesSample and Reference Calculations for Guardrail DesignRommel Angelo KirongNo ratings yet

- LIGHT POLE FOUNDATION STANDARDSDocument1 pageLIGHT POLE FOUNDATION STANDARDSMalik Imran Shakir100% (2)

- Sample Railing Calculation To Euro CodeDocument4 pagesSample Railing Calculation To Euro CodeEric Ng S L100% (5)

- Design of Grating For PlatformDocument5 pagesDesign of Grating For Platformvj8584100% (2)

- Design of Glass Fin for Glass FaçadeDocument4 pagesDesign of Glass Fin for Glass FaçadeZaido Al HalabiNo ratings yet

- Stainless Steel Handrail Structural CalculationDocument31 pagesStainless Steel Handrail Structural CalculationZaido Al Halabi100% (4)

- Railing DesignDocument2 pagesRailing DesignSutha100% (1)

- Design of Monorail BeamDocument6 pagesDesign of Monorail BeamMahata Priyabrata100% (2)

- Car Park Shed Structural Design Basis ReportDocument23 pagesCar Park Shed Structural Design Basis ReportMdShahbazAhmed0% (1)

- Handrail Code AnalysisDocument1 pageHandrail Code AnalysisSivadol VongmongkolNo ratings yet

- DESIGN CALCULATION Report PDFDocument61 pagesDESIGN CALCULATION Report PDFShaikh Muhammad Ateeq100% (1)

- Structural Glass Design-UBCDocument6 pagesStructural Glass Design-UBCmsiddiq1100% (1)

- Plinth Beam Design CalculationDocument4 pagesPlinth Beam Design CalculationVinod NairNo ratings yet

- Z PurlinDocument3 pagesZ PurlinSaravana NNo ratings yet

- Crane Girder DesignDocument6 pagesCrane Girder DesignAya Montes100% (3)

- Desing Calculation PDFDocument49 pagesDesing Calculation PDFChan Nov100% (1)

- Glass Balustrade Design EN 16612Document2 pagesGlass Balustrade Design EN 16612Ciprian POPANo ratings yet

- Steel Staircase DesignDocument4 pagesSteel Staircase DesignSenthooran MahendranNo ratings yet

- Stair Hand Rail Connection Design Calculation-WPCDocument12 pagesStair Hand Rail Connection Design Calculation-WPCUmesh ChamaraNo ratings yet

- Glass BalustradeDocument7 pagesGlass BalustradeARYANo ratings yet

- Design of Steel Shelter FinalDocument63 pagesDesign of Steel Shelter Finalalaa4altaie100% (2)

- Wind load calculations for steel canopy fabricDocument11 pagesWind load calculations for steel canopy fabricamitkukna100% (3)

- Structural Calculation of Link Bridge Curtain Wall 20160930Document94 pagesStructural Calculation of Link Bridge Curtain Wall 20160930Ronald RoblesNo ratings yet

- How Do You Calculate Chequered Plate WeightDocument2 pagesHow Do You Calculate Chequered Plate Weightssr11700% (1)

- Design of Light Pole FoundationDocument2 pagesDesign of Light Pole Foundationabhinav100% (2)

- Grating DesignDocument19 pagesGrating DesignAmanpreet SinghNo ratings yet

- Warehouse Roof Design and AnalysisDocument51 pagesWarehouse Roof Design and AnalysisAnonymous q0irDXlWAm100% (2)

- Anchor Bolt Calculation For Sign PostDocument5 pagesAnchor Bolt Calculation For Sign PostaselabambarandageNo ratings yet

- Design Calculation Steel Structure Power PlantDocument58 pagesDesign Calculation Steel Structure Power Plantrajeshdebnath100% (2)

- Stainless Steel Ladder DesignDocument71 pagesStainless Steel Ladder DesignDonald Hamilton100% (4)

- The Dubai Chamber of Commerce and Industry Building ExtensionDocument22 pagesThe Dubai Chamber of Commerce and Industry Building ExtensionAhammad KabeerNo ratings yet

- Geometry and loading details for steel roof structureDocument31 pagesGeometry and loading details for steel roof structureSharyn PolleyNo ratings yet

- Typical Anchor BoltsDocument33 pagesTypical Anchor BoltslucianduNo ratings yet

- Steel Bracket DesignDocument3 pagesSteel Bracket Designrandy_pabilona50% (4)

- Structural analysis of a high-rise building curtain wallDocument9 pagesStructural analysis of a high-rise building curtain walleromax1No ratings yet

- 9m Pole FDN Design 18.2.2015Document2 pages9m Pole FDN Design 18.2.2015faizankhan23No ratings yet

- Design of Base Plate For BS5950Document2 pagesDesign of Base Plate For BS5950dantevarias89% (19)

- Skylight Structure Design CalculationsDocument5 pagesSkylight Structure Design Calculationsmsiddiq150% (4)

- Design of ACP PanelDocument27 pagesDesign of ACP PanelSibiSam100% (1)

- GLASS BALUSTRADE DESIGN CALCULATIONSDocument8 pagesGLASS BALUSTRADE DESIGN CALCULATIONSmsiddiq1100% (2)

- Design to BS 5950 Part 1: Limit State Design of Tubular StructuresDocument55 pagesDesign to BS 5950 Part 1: Limit State Design of Tubular StructuresTingluhelen90% (10)

- DESIGN CALCULATIONS - GL-03 2509 - 4.0mDocument17 pagesDESIGN CALCULATIONS - GL-03 2509 - 4.0mmsiddiq1No ratings yet

- Design of CHQRD PlateDocument20 pagesDesign of CHQRD PlateRagavanNo ratings yet

- Chequered Plate 1250mm-cDocument28 pagesChequered Plate 1250mm-casvenk309100% (3)

- Monorail Beam Design 07Document5 pagesMonorail Beam Design 07bakellyNo ratings yet

- 9m x 3.1m shed designDocument36 pages9m x 3.1m shed designPrathamesh PrathameshNo ratings yet

- Design Calculations For Light MastDocument24 pagesDesign Calculations For Light Mastjobees7850100% (17)

- Jib Crane Design SellDocument13 pagesJib Crane Design Selljafary100% (3)

- Design Calculation-Skylight StructureDocument7 pagesDesign Calculation-Skylight Structuremsiddiq1No ratings yet

- Toaz - Info Design Calculation Skylight Structure PRDocument7 pagesToaz - Info Design Calculation Skylight Structure PRAbdul khaliquNo ratings yet

- Structural design calculations bulkhead supportDocument8 pagesStructural design calculations bulkhead supportmsiddiq1No ratings yet

- STRUCTURAL GLASS DESIGN OF HAND RAIL BALCONYDocument5 pagesSTRUCTURAL GLASS DESIGN OF HAND RAIL BALCONYmsiddiq1No ratings yet

- Design Calculations For Aluminium Profile 13794Document14 pagesDesign Calculations For Aluminium Profile 13794Wilson PesantezNo ratings yet

- Analysis of Simple StressesDocument39 pagesAnalysis of Simple StressesEduCartNo ratings yet

- Load Calculations For Steel StructureDocument4 pagesLoad Calculations For Steel Structuremsiddiq1100% (1)

- E22: RCC DesignDocument9 pagesE22: RCC DesignAmolsingh100No ratings yet

- Spreadsheet Slope Stability CalculatorDocument37 pagesSpreadsheet Slope Stability Calculatorali jamiilNo ratings yet

- Detailed Design: General Notes TABLE '1' Structural SteelworkDocument1 pageDetailed Design: General Notes TABLE '1' Structural Steelworkmsiddiq1No ratings yet

- DESIGN CALCULATIONS - GL-03 13940 - 4.0m-R2Document16 pagesDESIGN CALCULATIONS - GL-03 13940 - 4.0m-R2msiddiq1No ratings yet

- Structural Calculation Curtain WallDocument93 pagesStructural Calculation Curtain Wallashaswamy100% (1)

- Column ReportDocument24 pagesColumn Reportmsiddiq1No ratings yet

- Aluminium Design Manual 2010 - The Aluminium AssociationDocument440 pagesAluminium Design Manual 2010 - The Aluminium AssociationQuang Hoành Lê100% (15)

- 1.0 Design Calculation For Louver 1Document6 pages1.0 Design Calculation For Louver 1msiddiq1No ratings yet

- Bridge ReportDocument33 pagesBridge Reportmsiddiq1No ratings yet

- Report Roof StructureDocument44 pagesReport Roof Structuremsiddiq1No ratings yet

- DESIGN CALCULATIONS - GL-03 2509 - 4.0mDocument17 pagesDESIGN CALCULATIONS - GL-03 2509 - 4.0mmsiddiq1No ratings yet

- Job Information: Job No Sheet No RevDocument9 pagesJob Information: Job No Sheet No Revmsiddiq1No ratings yet

- Footing DesignDocument7 pagesFooting Designmsiddiq1No ratings yet

- Tank Mat Foundation DesignDocument1 pageTank Mat Foundation Designdantevarias100% (1)

- Facade NotesDocument303 pagesFacade NotesKho C Ahl100% (2)

- DesignDocument of G+22 Roof Canopy R5-02 OCT2016 PDFDocument188 pagesDesignDocument of G+22 Roof Canopy R5-02 OCT2016 PDFmsiddiq1No ratings yet

- Carbon Steel GradesDocument4 pagesCarbon Steel GradesKiky IchanafiNo ratings yet

- Wausau HP Wall Guide SpecificationDocument6 pagesWausau HP Wall Guide Specificationmsiddiq1No ratings yet

- Wrana 2015 4 PDFDocument11 pagesWrana 2015 4 PDFarslanpasaNo ratings yet

- Truss Design PDFDocument131 pagesTruss Design PDFmsiddiq1No ratings yet

- GRC Outdoor PanelDocument6 pagesGRC Outdoor PanelYuki GitaraNo ratings yet

- UppieDocument117 pagesUppiemuhammed_bulanNo ratings yet

- Cessm 3Document81 pagesCessm 3msiddiq1No ratings yet

- Weld Design StrengthDocument9 pagesWeld Design Strengthmsiddiq1No ratings yet

- Cessm 1Document75 pagesCessm 1msiddiq1No ratings yet

- Fasteners - Concrete and Steel PDFDocument10 pagesFasteners - Concrete and Steel PDFmsiddiq1No ratings yet

- Eccentric Footing Design PDFDocument9 pagesEccentric Footing Design PDFmsiddiq1No ratings yet

- SBE SS4-secure PDFDocument135 pagesSBE SS4-secure PDFMyron OikonomakisNo ratings yet

- Fasteners - Concrete and Steel PDFDocument10 pagesFasteners - Concrete and Steel PDFmsiddiq1No ratings yet

- WindDocument93 pagesWindOsama EL HakimNo ratings yet

- BS5950 BOLT AND WELD CAPACITIESDocument1 pageBS5950 BOLT AND WELD CAPACITIESHelena DomičićNo ratings yet

- Rab Venturi Wet Scrubber 00Document2 pagesRab Venturi Wet Scrubber 00rudiawanNo ratings yet

- Design and Construction of BreakwatersDocument24 pagesDesign and Construction of Breakwatersshakirhamid6687100% (2)

- National Building Code ReviewerDocument16 pagesNational Building Code ReviewerZoeNo ratings yet

- Stainless steel penthouse railing detailsDocument1 pageStainless steel penthouse railing detailsRenz ChuaNo ratings yet

- VbeDocument2 pagesVbeAniket PatilNo ratings yet

- Design of Deep BeamDocument29 pagesDesign of Deep BeamHuzaifa zafer100% (1)

- Scully U31766uDocument2 pagesScully U31766unumonveNo ratings yet

- 15570Document6 pages15570JhoNo ratings yet

- Repair Procedure For High Temperature Boiler PipingDocument14 pagesRepair Procedure For High Temperature Boiler PipingEzhil Vendhan PalanisamyNo ratings yet

- CCTV Headquarters - Structural Case StudyDocument16 pagesCCTV Headquarters - Structural Case StudyRamiz AkhtharNo ratings yet

- Norma 60.2Document4 pagesNorma 60.2EstebanCórdobaNo ratings yet

- HDPE Tender DocumentDocument4 pagesHDPE Tender Documentabhijithaval100% (1)

- Site Readiness Checksheet R1Document3 pagesSite Readiness Checksheet R1Rahil TasawarNo ratings yet

- Review of Specifications and Plan DetailsDocument35 pagesReview of Specifications and Plan DetailsBondoc, Miles Jerome Z.No ratings yet

- Linear and Nonlinear Static Analysis For Assessment of Progressive Collapse Potential of Multi Storied BuildingDocument12 pagesLinear and Nonlinear Static Analysis For Assessment of Progressive Collapse Potential of Multi Storied BuildingNoble Obeng-AnkamahNo ratings yet

- Precast Concrete Solutions HumesDocument89 pagesPrecast Concrete Solutions HumesAdhitya DwijayanthoNo ratings yet

- CHPB - Prospectus 2021Document35 pagesCHPB - Prospectus 2021Madusanka WeebeddaNo ratings yet

- Luminaire Schedule-Exterior Facade Rev.02Document2 pagesLuminaire Schedule-Exterior Facade Rev.02NATHANNo ratings yet

- A I R P O R T S Construction Program Management 56Document56 pagesA I R P O R T S Construction Program Management 56Carl WilliamsNo ratings yet

- APCO Air Valve 613Document4 pagesAPCO Air Valve 613jones0055No ratings yet

- Construction of Tunnels, by New Austrian Tunnelling Method (NATM) and by Tunnel Boring Machine (TBM) PDFDocument12 pagesConstruction of Tunnels, by New Austrian Tunnelling Method (NATM) and by Tunnel Boring Machine (TBM) PDFChin Thau WuiNo ratings yet

- Economics of Cable-Stayed BridgesDocument2 pagesEconomics of Cable-Stayed Bridgesdebjyoti_das_6No ratings yet

- Standard dimensions and data for steel and stainless steel pipe sizesDocument7 pagesStandard dimensions and data for steel and stainless steel pipe sizesRSGatesNo ratings yet

- Holding Down Bolts BS 7419 (Square Square) : Grade 4.6 & 8.8Document2 pagesHolding Down Bolts BS 7419 (Square Square) : Grade 4.6 & 8.8Thilan SenarathneNo ratings yet

- Full Thesis PDFDocument215 pagesFull Thesis PDFArzath SajeerNo ratings yet

- 3.3 Foundation - General - Information - Tubular - Towers - Generic - XXHZ - EN - r01 Traduzido PDFDocument76 pages3.3 Foundation - General - Information - Tubular - Towers - Generic - XXHZ - EN - r01 Traduzido PDFJoão Batista Medeiros GonçalvesNo ratings yet

- Earthing Structures SystemsDocument72 pagesEarthing Structures SystemsIsaac AppiagyeiNo ratings yet

- Muhammad Rehan Khalil: Summary of CareerDocument3 pagesMuhammad Rehan Khalil: Summary of CareerRehAn KhAlil100% (1)

- Valuation Report ExampleDocument25 pagesValuation Report ExampleKenan TemboNo ratings yet

- What Is The Column Kicker - Its Formworks, Application and AdvantagesDocument2 pagesWhat Is The Column Kicker - Its Formworks, Application and AdvantagesNaveen BansalNo ratings yet