Professional Documents

Culture Documents

Copiar de ReinforcementArea

Uploaded by

lavascudoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Copiar de ReinforcementArea

Uploaded by

lavascudoCopyright:

Available Formats

file spec.

'file:///var/www/apps/conversion/tmp/scratch_5/335826962.xls'#$reinforcingpad -- printed 2016.11.4/9:28

Doc No

Branch Calculation table

Client

Project

Job No.

Location

Sheet

xxx

Rev.

Date

Made

Check

Appr

xxx

Description

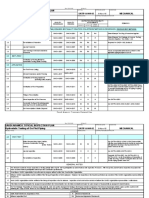

Branch Reinforcement calculation to EN 13480-3:1999 - branches reinforced by Pad

Branch calculation performed in acccordance with EN 13480-3:2002.

For each combination of Branch and header size is calculated:

Max pressure of unreinforced branch

Required od of reinforcing pad if it is possible to sufficiently reinforce the

branch by pad.

SIZE

DN10

DN15

DN20

DN25

DN32

DN40

DN50

DN65

DN80

DN100

DN150

DN200

DN250

DN300

DN350

DN400

DN500

DN600

OD

17.2

21.3

26.9

33.7

42.4

48.3

60.3

76.1

88.9

114.3

168.3

219.1

273.0

323.9

355.6

406.4

508.0

610.0

tnominal

1.60

1.60

1.60

2.00

2.00

2.00

2.00

2.60

2.60

2.60

3.00

2.90

3.00

3.00

3.00

3.00

3.00

3.00

ODanalysis

18.00

22.10

27.70

34.50

43.20

49.10

61.10

76.90

89.70

115.10

169.90

220.70

274.60

325.50

357.20

408.00

509.60

611.60

1.40

1.40

1.40

1.75

1.75

1.75

1.75

2.28

2.28

2.28

2.63

tanalysis

Pmax

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

Tolerances

NPS

OD

tnominal

OD+

ID+

t-

ODanalysis

tanalysis

2.54

2.63

2.63

2.63

2.63

2.63

2.63

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

Branch

Pmax

o

DN10

DN15

17.20

21.30

1.60

1.60

0.80

0.80

0.80

0.80

12.5%

12.5%

18.0

22.1

1.40

1.40

#VALUE!

#VALUE!

How it works

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

Calculates Required size of reinforcing Pad

Thickness to be same size as header

Input

DN20

26.90

1.60

0.80

0.80

12.5%

27.7

1.40

#VALUE!

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

Piping Class

Pressure (N/mm2)

Design Stress (N/mm2) *)

Corrosion Allowance (mm)

Weld joint quality factor

DN25

33.70

2.00

0.80

0.80

12.5%

34.5

1.75

#VALUE!

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

DN32

42.40

2.00

0.80

0.80

12.5%

43.2

1.75

#VALUE!

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

Output

Place curser to print calc.

Max pressure of unreinf. branch

Reinforcing Pad OD/ID (mm)

Pad required? (color)

DN40

48.30

2.00

0.80

0.80

12.5%

49.1

1.75

#VALUE!

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

DN50

60.30

2.00

0.80

0.80

12.5%

61.1

1.75

#VALUE!

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

DN65

76.10

2.60

0.80

0.80

12.5%

76.9

2.28

#VALUE!

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

DN80

88.90

2.60

0.80

0.80

12.5%

89.7

2.28

#VALUE!

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

Header

S03

1.60

150

0.0

1.0

2.75

o

1.05

270

o

0.85

Note 1

No

Yes

N.A.

Note 1: Branch cannot be sufficiently reinforced with pad

Try thicker pipe

*) Design Stress:

Refer EN 13480-3, section 5.2 for determination of design stresses

DN100

114.30

2.60

0.80

0.80

12.5%

115.1

2.28

#VALUE!

DN150

168.30

3.00

1.60

1.60

12.5%

169.9

2.63

#VALUE!

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

DN200

219.10

2.90

1.60

1.60

12.5%

220.7

2.54

#VALUE!

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

DN250

273.00

3.00

1.60

1.60

12.5%

274.6

2.63

#VALUE!

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

DN300

323.90

3.00

1.60

1.60

12.5%

325.5

2.63

#VALUE!

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

DN350

355.60

3.00

1.60

1.60

12.5%

357.2

2.63

#VALUE!

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

DN400

406.40

3.00

1.60

1.60

12.5%

408.0

2.63

#VALUE!

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

DN500

508.00

3.00

1.60

1.60

12.5%

509.6

2.63

#VALUE!

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

#VALUE!

#VALUE!

o

DN600

610.00

3.00

1.60

1.60

12.5%

611.6

2.63

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

#VALUE!

30

30

30

30

50

50

50

50

50

50

50

50

50

50

50

50

50

Minimum width of reinforcement pad ring

50

file spec.:

'file:///var/www/apps/conversion/tmp/scratch_5/335826962.xls'#$reinforcingpadsingle -- printed 2016.11.4/9:28

Doc No

Branch Calculation Sheet

Sheet

xxx

xxx

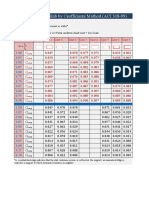

Branch Reinforcement calculation to prEN 13480-3:1999

Openings un-reinforced or reinforced by Pad

Piping Class

Branch Pipe

Size DN300

S03

DN65

DOB

eas

ls

AfB

DOS

eapl

Ap

AfS

Header Pipe (Shell)

Branch Outside diameter (max)

Branch thickness (Nominal)

Header Outside diameter (max)

Header thickness (Nominal)

Reinforcing Pad min Width

Reinforcing Pad thickness

Design Pressure

Design Stress

Corrosion Allowance

Mill Tolerance

Input Values

76.9

2.6

325.5

3

180.0

3.0

1.6

150

0.0

12.5

Calculation of max thickness ratio

Dib/Dis=(Dob-2*eab)/(Dos-2*eas)=

0.2

###

#VALUE!

or eab=

Afpl

lb

eas

lpl

2.28

Calculation Values

Dob

76.9

eab

2.28

Dos

325.5

eas

2.625

Dopl

440

eapl

2.625

pc

1.6

f

150

mm

mm

mm

mm

mm

mm

N/mm2

N/mm2

mm

%

=> max eab/eas= ###

whichever is smallest

#VALUE!

Calculation of pressure area

Lb=((Dob-eab)*eab)^0.5=

Ls=((Dos-eas)*eas)^0.5=

#VALUE!

29.1

Ap=(lb+Dos/2)*(Dob/2-eab)+(ls+eab)*(Dos/2-eas) =

#VALUE!

Calculation for un-reinforced branch

Af=lb*eab+eab*eas+ls*eas =

(f-pc/2)*Af

=

#VALUE!

>

[fig 8.3.1-1]

[8.4.3-1]

[8.4.1-2]

#VALUE!

#VALUE!

[8.4.3-3]

whichever is smallest

29.1

[8.4.3-4]

whichever is smallest

2.6

[8.4.3-5]

pc*Ap

###

Calculation for reinforced branch

Lpl=(Dopl-Dob)/2=

181.6

or Lpl=Ls=

eapl=

or eapl=eas=

29.1

2.625

2.6

Af=lb*eab+eab*eas+ls*eas+lpl*eapl =

(f-pc/2)*Af

=

#VALUE!

>

pc*Ap

#VALUE!

#VALUE!

###

Max pressure for unreinforced branch or tee

pmax = f * Af / (Ap + Af / 2)

Reinforced

### N/mm2

Unreinforced

#VALUE! N/mm2

mm

mm

mm

mm

mm

mm

N/mm2

N/mm2

file spec.:

'file:///var/www/apps/conversion/tmp/scratch_5/335826962.xls'#$reinforcednozzlesingle -- printed 2016.11.4/9:28

Doc No

Branch Calculation Sheet

Sheet

A2

Branch Reinforcement calculation to prEN 13480-3:1999

Opening reinforced by reinforced nozzle (o-let type)

Branch Pipe

DOB

eas

ls

AfS

lb

eas

AfB

DOB

DOS

Ap

Header Pipe (Shell)

Branch Outside diameter

Branch thickness

Header Outside diameter

Header thickness

Design Pressure

Design Stress

Corrosion Allowance

Mill Tolerance

Input Values

220

11

273

6

3

130

0

12.5

Calculation Values

Dob

220

eab

9.63

Dos

273

eas

5.25

pc

3

f

130

mm

mm

mm

mm

N/mm2

N/mm2

mm

%

Calculations

Lb=((Dob-eab)*eab)^0.5=

45.0

Ls=((Dos-eas)*eas)^0.5=

37.5

Ap=(lb+Dos/2)*(Dob/2-eab)+(ls+eab)*(Dos/2-eas) =

Af=lb*eab+eab*eas+ls*eas =

(f-pc/2)*Af

87,441

24,402.1

680.5

>

=> Reinforcement Not required

pc*Ap

73,206

mm

mm

mm

mm

N/mm2

N/mm2

You might also like

- Saddle AnalysisDocument17 pagesSaddle AnalysisPEJU0007No ratings yet

- PSV Reaction Forces and DirectionDocument29 pagesPSV Reaction Forces and Directionpvmsson100% (1)

- CAU2016 Tank PDFDocument21 pagesCAU2016 Tank PDFJagankumar100% (1)

- Piping Stress Critical Lines - Basis For Piping Critical Line List PDFDocument3 pagesPiping Stress Critical Lines - Basis For Piping Critical Line List PDFanup15balagarhNo ratings yet

- Nozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)Document17 pagesNozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)SingoNo ratings yet

- Calculating Stresses PDFDocument55 pagesCalculating Stresses PDFpilotte7No ratings yet

- Pipe Thickness & RF Pad Calculations As Per Asme b313Document3 pagesPipe Thickness & RF Pad Calculations As Per Asme b313Gaurav BhendeNo ratings yet

- Shell and Tube Heat Exchanger Design PreparedDocument6 pagesShell and Tube Heat Exchanger Design PreparedEmebu SamuelNo ratings yet

- CAESAR II Flange CalcDocument8 pagesCAESAR II Flange CalcDavid Fonseca100% (1)

- Structural TrunnionDocument4 pagesStructural TrunnionecsalomNo ratings yet

- Ancor Flanges Asme ViiiDocument3 pagesAncor Flanges Asme ViiiAnjani PrabhakarNo ratings yet

- Mech. Design CalculationDocument182 pagesMech. Design CalculationSajad AbdulNo ratings yet

- Pipe Is Under Clamping ForceDocument7 pagesPipe Is Under Clamping Forcejosediaz141No ratings yet

- Nozzle Loads - Part 1 - Piping-EngineeringDocument5 pagesNozzle Loads - Part 1 - Piping-EngineeringShaikh AftabNo ratings yet

- 7-12-0013 Rev. 6 Nozzle Reinforcement & ProjectionDocument2 pages7-12-0013 Rev. 6 Nozzle Reinforcement & ProjectionJitender Kumar GuptaNo ratings yet

- Coupling Calculations and Ug-32 Unstayed Head CalculationsDocument9 pagesCoupling Calculations and Ug-32 Unstayed Head CalculationsLcm TnlNo ratings yet

- CAESAR II Training Overview PDFDocument5 pagesCAESAR II Training Overview PDFJesus MaestreNo ratings yet

- Flange Asmeviii Div.1 App.2 Rev0Document10 pagesFlange Asmeviii Div.1 App.2 Rev0lk700615100% (1)

- Nozzle Calculation - Primary Reformer Stack-R0Document22 pagesNozzle Calculation - Primary Reformer Stack-R0Aditya Jain100% (1)

- The Basics of Pipe Thermal ExpansionDocument7 pagesThe Basics of Pipe Thermal Expansionmohdnazir100% (1)

- Piping Engineering - Tank Nozzle Loads 1Document1 pagePiping Engineering - Tank Nozzle Loads 1Nasrul AdliNo ratings yet

- Vortex Shedding Load On PipingDocument1 pageVortex Shedding Load On Pipingananyo_sengupta100% (1)

- Storage Tank Piping Stress Analysis As Per API 650 Using Caesar IIDocument4 pagesStorage Tank Piping Stress Analysis As Per API 650 Using Caesar IIaap183% (6)

- Trunnion Check - Node 710Document13 pagesTrunnion Check - Node 710Prashant ChauhanNo ratings yet

- Calculation and Fabricated Branch Connection 24 X 24: Prepared By: Review By: Approved By: Project: 10/6/2014Document5 pagesCalculation and Fabricated Branch Connection 24 X 24: Prepared By: Review By: Approved By: Project: 10/6/2014Henry SaenzNo ratings yet

- Modeling An API 661 Air Cooler - Intergraph CADWorx & AnalysisDocument2 pagesModeling An API 661 Air Cooler - Intergraph CADWorx & AnalysisdhurjatibhuteshNo ratings yet

- Data Sheet For Allowable Nozzle Load - SP1-110-9850-00-PI-DTDocument8 pagesData Sheet For Allowable Nozzle Load - SP1-110-9850-00-PI-DTbabak mirNo ratings yet

- WRC 537 Cige Noz B Op 1Document1 pageWRC 537 Cige Noz B Op 1metroroadNo ratings yet

- 15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Document4 pages15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Umair A. KhanNo ratings yet

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Mo ZeroNo ratings yet

- NozzleDocument11 pagesNozzleharyfadlyNo ratings yet

- C-00-1360-001 Piping Flexibility Stress Calculation (Sample)Document25 pagesC-00-1360-001 Piping Flexibility Stress Calculation (Sample)mengelito almonteNo ratings yet

- 7-12-0005 Rev6 (Skirt Opening Details)Document2 pages7-12-0005 Rev6 (Skirt Opening Details)sumit kumarNo ratings yet

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- PV Elite App 1-7Document2 pagesPV Elite App 1-7Pugel YeremiasNo ratings yet

- Pipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressDocument75 pagesPipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressMarius GhitaNo ratings yet

- Reinforcement Pad CalculationDocument4 pagesReinforcement Pad CalculationMohammad AbdullahNo ratings yet

- Dennis R Moss 4th EditionDocument5 pagesDennis R Moss 4th Editionsenthil kumarNo ratings yet

- WRC Check List CriteriaDocument1 pageWRC Check List CriteriaAlvin Smith100% (1)

- Trunnion Calculation SheetDocument2 pagesTrunnion Calculation SheetIshu Vohra0% (1)

- Dummy Leg JacobsDocument1 pageDummy Leg Jacobsananyo_sengupta0% (1)

- Calculations For: Calculations No. Asme Viii Div 1 Ed 2019Document21 pagesCalculations For: Calculations No. Asme Viii Div 1 Ed 2019David Vanegas100% (1)

- Equivalent PressureDocument1 pageEquivalent PressureSarfaraz KhanNo ratings yet

- Coupling UW16.2 KL Ver 1.1Document4 pagesCoupling UW16.2 KL Ver 1.1gopaltryNo ratings yet

- TrunnionDocument20 pagesTrunnionGowtham JayaprakashNo ratings yet

- Air Cooler Piping Stress Analysis Using Caesar IIDocument5 pagesAir Cooler Piping Stress Analysis Using Caesar IIsemin prsesNo ratings yet

- PDIL-Stress Analysis Design Basis PDFDocument13 pagesPDIL-Stress Analysis Design Basis PDFDarshan Panchal100% (1)

- Nozzle CheckDocument11 pagesNozzle CheckincaurcoNo ratings yet

- New Standard For FRP PipingDocument37 pagesNew Standard For FRP PipingKamatchi NathanNo ratings yet

- Saddle LoadsDocument11 pagesSaddle LoadsAnthony Dudley0% (1)

- M0237 01 RBP PD RP 3013Document159 pagesM0237 01 RBP PD RP 3013harishNo ratings yet

- Nozzle Design CalculationDocument1 pageNozzle Design CalculationSachin55860% (1)

- Cau 2014Document25 pagesCau 2014vinay1999No ratings yet

- External Loads On Nozzles and Piping Intersections Paulin Webinar Part 2 W044Rev1Document41 pagesExternal Loads On Nozzles and Piping Intersections Paulin Webinar Part 2 W044Rev1Nabil Al-Khirdaji100% (1)

- Offcon DNV Zorro SkidDocument7 pagesOffcon DNV Zorro SkidRAMSINGH CHAUHANNo ratings yet

- REBARS (318-05) (Engineersdaily - Com)Document8 pagesREBARS (318-05) (Engineersdaily - Com)sawahNo ratings yet

- WC3210 3220Document37 pagesWC3210 3220Vasile ValiNo ratings yet

- ProkonDocument7 pagesProkonmark7301158No ratings yet

- Memoria Acero Nave Kyung-LearDocument38 pagesMemoria Acero Nave Kyung-LearPaco MHNo ratings yet

- Vessel CalculationDocument106 pagesVessel CalculationBhadresh PatelNo ratings yet

- Slurry Pump CalculationsDocument46 pagesSlurry Pump Calculationslavascudo100% (2)

- Copiar de Vessel - Weld - EfficiencyDocument4 pagesCopiar de Vessel - Weld - EfficiencylavascudoNo ratings yet

- Pump. Slurry Selection - Typical - WarmanDocument58 pagesPump. Slurry Selection - Typical - Warmanlavascudo100% (1)

- Slurry Pump Calculations Com MacroDocument50 pagesSlurry Pump Calculations Com Macrolavascudo100% (1)

- Copiar de Nozzle - Design - ToolDocument2 pagesCopiar de Nozzle - Design - ToollavascudoNo ratings yet

- Copiar de Nozzle - Repad - Design - ToolDocument2 pagesCopiar de Nozzle - Repad - Design - ToollavascudoNo ratings yet

- A Guide To Refinery ProcessDocument35 pagesA Guide To Refinery ProcessBalamurugan100% (3)

- Guideline - Pump - System - Designers (Pump Fundamentals) PDFDocument16 pagesGuideline - Pump - System - Designers (Pump Fundamentals) PDFyyukin1100% (1)

- Slurry Pump Calculations Com MacroDocument50 pagesSlurry Pump Calculations Com MacrolavascudoNo ratings yet

- Rectangular Tank SizingDocument66 pagesRectangular Tank SizinglavascudoNo ratings yet

- Fans & Blowers-Calculation of PowerDocument20 pagesFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- Slurry Pump Calculations Com MacroDocument50 pagesSlurry Pump Calculations Com Macrolavascudo100% (1)

- Pipe and Fittings Data ChartsDocument20 pagesPipe and Fittings Data ChartskavNo ratings yet

- Victaulic General Catalog G-103Document248 pagesVictaulic General Catalog G-103Muhsen Khan100% (1)

- Viking Pumps PDFDocument11 pagesViking Pumps PDFlavascudoNo ratings yet

- Victaulic General Catalog G-103Document248 pagesVictaulic General Catalog G-103Muhsen Khan100% (1)

- DuctDocument60 pagesDuctdenizkund100% (5)

- Steel Grades Properties Global StandardsDocument20 pagesSteel Grades Properties Global StandardsJonald PoquizNo ratings yet

- Guideline - Pump - System - Designers (Pump Fundamentals) PDFDocument16 pagesGuideline - Pump - System - Designers (Pump Fundamentals) PDFyyukin1100% (1)

- Topej 8 117Document9 pagesTopej 8 117Karem Jeanette Saenz BernalNo ratings yet

- Commissioning: 7.1 Mechanical and Electrical Commissioning 7.1.1 GeneralDocument5 pagesCommissioning: 7.1 Mechanical and Electrical Commissioning 7.1.1 GenerallavascudoNo ratings yet

- Guideline - Pump - System - Designers (Pump Fundamentals) PDFDocument16 pagesGuideline - Pump - System - Designers (Pump Fundamentals) PDFyyukin1100% (1)

- Commissioning: 7.1 Mechanical and Electrical Commissioning 7.1.1 GeneralDocument5 pagesCommissioning: 7.1 Mechanical and Electrical Commissioning 7.1.1 GenerallavascudoNo ratings yet

- Getting Started With AutoCAD® Structural Detailing, Steel ModuleDocument49 pagesGetting Started With AutoCAD® Structural Detailing, Steel ModuleAllan David100% (1)

- Flygt Slurry HandbookDocument48 pagesFlygt Slurry Handbookrodolfocv92359100% (2)

- Indicador de Nivel de BoiaDocument2 pagesIndicador de Nivel de BoialavascudoNo ratings yet

- Victaulic General Catalog G-103Document248 pagesVictaulic General Catalog G-103Muhsen Khan100% (1)

- 804-Rectangular Steel TanksDocument24 pages804-Rectangular Steel Tanksjun005100% (4)

- Advanced Water Distribution ModelingDocument800 pagesAdvanced Water Distribution ModelingBriantonoRaharjo0% (1)

- Concise Beam DemoDocument33 pagesConcise Beam Demozaeem_sidd5291100% (1)

- Contract TerminologyDocument20 pagesContract TerminologyMital DamaniNo ratings yet

- KKT KrausDocument24 pagesKKT KrausDaniel TibreaNo ratings yet

- Tension Stiffening and Crack Formation in Reinforced Concrete Members With Fiber-Reinforced Polymer SheetsDocument8 pagesTension Stiffening and Crack Formation in Reinforced Concrete Members With Fiber-Reinforced Polymer SheetsMuhammad Fajrul FalahNo ratings yet

- PMO801N0615398Document2 pagesPMO801N0615398Jose ExtremeraNo ratings yet

- Tigges Catalogue PDFDocument119 pagesTigges Catalogue PDFwal1547No ratings yet

- Standard Pitch Diameter ChartDocument5 pagesStandard Pitch Diameter ChartDibya DeyNo ratings yet

- Papercrete4 PDFDocument9 pagesPapercrete4 PDFPrasad TekadeNo ratings yet

- New AVME EXPORT-20220530 - 090509Document4,936 pagesNew AVME EXPORT-20220530 - 090509Muthukumaran TNo ratings yet

- Saudi Aramco Typical Inspection Plan Hydrostatic Testing of On-Plot PipingDocument10 pagesSaudi Aramco Typical Inspection Plan Hydrostatic Testing of On-Plot PipingAhdal NoushadNo ratings yet

- Capitol Steel Corporation-RSB PDFDocument1 pageCapitol Steel Corporation-RSB PDFeg choloNo ratings yet

- Rubber BellowDocument20 pagesRubber BellowPrateek100% (1)

- ESP Installation and Records G81 Rev CDocument23 pagesESP Installation and Records G81 Rev Cradulescuandrei100No ratings yet

- Uet LahoreDocument43 pagesUet LahoreMunawwar KhanNo ratings yet

- UM-min PDFDocument44 pagesUM-min PDFIsidro Ochotorena BeunzaNo ratings yet

- Ale Building Technology and MaterialsDocument2 pagesAle Building Technology and MaterialsiloilocityNo ratings yet

- Roof Ponding and Sprinkled Roof: Bs-IiiDocument8 pagesRoof Ponding and Sprinkled Roof: Bs-IiiPriya UdamaleNo ratings yet

- Assignment 10 PDFDocument2 pagesAssignment 10 PDFarchies iescaNo ratings yet

- History of Rigid Frame BridgesDocument36 pagesHistory of Rigid Frame BridgesTamaduianu IoanNo ratings yet

- Mineral Wool Compressive PropertiesDocument10 pagesMineral Wool Compressive Propertiespturner890No ratings yet

- Affa Tiles BookletDocument41 pagesAffa Tiles BookletAnonymous iTzCnMNo ratings yet

- Coefficients Slab For ACI Code 318Document14 pagesCoefficients Slab For ACI Code 318relu59No ratings yet

- Fixotec Technical CatalogueDocument71 pagesFixotec Technical CatalogueSaqib AliNo ratings yet

- Calculation Sheet Boiler Control BuildingDocument35 pagesCalculation Sheet Boiler Control BuildingKhamal Rachmanda AdamNo ratings yet

- DME-Cotter and Knuckle JointDocument91 pagesDME-Cotter and Knuckle JointAnjanKumarMishraNo ratings yet

- SlopeDesignGuidelines JKRDocument37 pagesSlopeDesignGuidelines JKRtanchuanngan100% (9)

- Structural Design PDFDocument683 pagesStructural Design PDFKanenus B Finfinnee100% (1)

- 1605 HOBAS Jacking Pipes WebDocument16 pages1605 HOBAS Jacking Pipes Weballouche_abdNo ratings yet

- Technical ProposalDocument54 pagesTechnical ProposalNone None NoneNo ratings yet

- Wa0040.Document14 pagesWa0040.robert nick eusebio teheranNo ratings yet