Professional Documents

Culture Documents

Blasteel Ziliplate

Uploaded by

Karthimeena MeenaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blasteel Ziliplate

Uploaded by

Karthimeena MeenaCopyright:

Available Formats

DATA SHEET NO.

2006-002

BLASTEEL ZILIPLATE

A self curing inorganic Zinc Ethyl Silicate shop primer for the protection of steel during fabrication

and assembly. It renders long term weathering protection combining with good cutting and welding

performance. It is compatible with a wide range of topcoats.

PRODUCT INFORMATION

Colour

Green

Finish

Matt

Flash Point

Above 23o C

Mixing Ratio

Base : Accelerator

1 : 1 (by volume)

Volume Solids

24 % approximately

Recommended

dry film

thickness

20 microns per coat

Corresponding

wet film

thickness

83 microns

Theoretical

Spreading Rate

12.0 Sq.metre per litre

per coat

Drying time

Interval before

Overcoating

Storage life

Dry Heat

Resistance

Precaution

SURFACE PREPARATION

STEEL SURFACES:

Degrease and blast clean to Sa 2 grade

minimum of Swedish specification SIS - 05 5900 - 1967. No other mode of surface

preparation is acceptable. Surface profile not

to exceed 75 microns. Surface should be

perfectly clean and dry before applying

Blasteel Ziliplate.

Painting over weathered Zinc primer:

On weathering a white deposit of zinc salt may

appear on the surface. These are to be

removed by water scrubbing, sand / grit

sweeping etc. before overcoating.

APPLICATION DETAILS

Method of application:

Conventional / Airless Spray.

Touch dry

Mixed paint to be kept stirred during

Within

15

minutes application to avoid any pigment settlement

depending upon ambient and should be strained through 80 - 100 mesh

temperature

and sieve before application to avoid clogging of

ventilation.

spray nozzle. Use plastic container for mixing

base and acceelerator.

Full cure- 7 days

Notes on Airless Spray:

Minimum - 24 hours

Tip Range - 18 - 24 thou.

Maximum - Indefinite

Total output fluid pressure

- 1000 2000 psi.

Upto 6 months so long as

(70 - 140 kg/sq.cm.)

the material is stored in Pot life

3 - 4 hours.

sealed containers under Thinner

Thinner 6761

standard

warehouse

storage condition. Avoid

USES

contamination

of

moisture during storage.

Shop Primer / Preconstruction Primer in high

performance coating system which protects

Upto 200o C (Intermittent) surfaces in: Hydro - electric units, Fertilizer

units, Oil refineries, Gas plants, Mining and

Machinery units.

For

curing

relative

humidity should not be

lower than 40 %.

Pg 1

DATA SHEET NO. 2006-002

BLASTEEL ZILIPLATE

SYSTEM SELECTION GUIDE

1st COAT

2nd COAT

3rd COAT

4th COAT

Steel

Blasteel

Ziliplate

Epigard 4 Zinc

Phosphate Primer

/ Epigard HB MIO

Epigard 4 Finish /

Shalithane Finish /

Epithane HB Finish

Epigard 4 Finish /

Shalithane Finish

/ Epithane HB

Finish

- do -

- do -

Epigard XL HB

533 / TL HB 533

Finish

Epigard XL HB 533

/ TL HB 533 Finish

- do -

- do -

Bipigard CTE XL

Black / Brown

Bipigard CTE XL

Black / Brown

- do -

- do -

Chlorokote HB

MIO

Chlorokote Finish /

Chlorokote HB

Finish

SURFACE

Chlorokote Finish

/ Chlorokote HB

Finish

CHEMICAL RESISTANCE GUIDE (With suitable top coat)

EXPOSURE

SPLASH &

SPILLAGE

FUMES & OUTDOOR

EXPOSURE

Acids

Good

Excellent

Alkalis

Good

Excellent

Solvents

Excellent

Excellent

Salt

Excellent

Excellent

Water

Excellent

Excellent

NOTES

1. This cancels all previous literature on this product and is subject to revision without notice.

2. Use off mixed paint within stipulated pot life period.

3. The Primer must be fully cured and free from residual solvents before overcoating, which

normally takes 24 hours but time may be extended if relative humidity is below 80%. While

overcoating a mist coat should first be applied to avoid bubbling problem, which appears

due to air entrapment.

4. Zinc Ethyl Silicate Coatings cure by reaction with moisture and may be applied at high

humidity provided the surface itself is free from condensation.

5. Use of thinners other than supplied or approved by Shalimar may adversely affect product

performance and void product warranty whether express or implied.

6. Ensure weld seams, flux and spatters are removed / ground down and primed to avoid

corrosion.

HEALTH AND SAFETY

Please refer to the separate safety data sheet available with detailed information.

>> DISCLAIMER <<

The information in this leaflet is given in good faith. The company will not be

liable for loss or damage howsoever caused including liability for negligence,

which may be suffered by the user of the data contained therein. It is the user's

responsibility to conduct all necessary tests to confirm the suitability of any

product or system for their intended use. No guarantee of result is extended

since conditions of use are beyond our control.

Head Office:

5th Floor, C Wing, Oberoi Garden Estate

Chandivali Farm Road, Chandivali

Andheri (E), Mumbai - 400072

Phone: 022-28574043 / 6147

Fax: 022-28573725

Email: indl@shalimarpaints.com

Nov 2006

Pg 2

You might also like

- Carboguard 703 GFDocument2 pagesCarboguard 703 GFlhanx2100% (2)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 8810Document2 pages8810Sikander Aleem100% (1)

- Agitator DesignDocument130 pagesAgitator DesignAdrales Kristine75% (4)

- Metric Dimensions and Weights of Seamless and Welded Steel Pipe PDFDocument1 pageMetric Dimensions and Weights of Seamless and Welded Steel Pipe PDFAnonymous xcFcOgMiNo ratings yet

- DATA SHEET NO. 2006-013 Epigard High Build Mio Brown / GreyDocument2 pagesDATA SHEET NO. 2006-013 Epigard High Build Mio Brown / Greyvijayakumar_samyNo ratings yet

- DATA SHEET NO. 2006-013 Epigard High Build Mio Brown / GreyDocument2 pagesDATA SHEET NO. 2006-013 Epigard High Build Mio Brown / Greyvijayakumar_samyNo ratings yet

- Epiplus 556Document2 pagesEpiplus 556hareesh13h100% (1)

- Epigard Rich Primer - 2006-005 PDFDocument2 pagesEpigard Rich Primer - 2006-005 PDFabdulyunus_amirNo ratings yet

- Epigard Zinc Rich Primer PDFDocument2 pagesEpigard Zinc Rich Primer PDFKarthimeena MeenaNo ratings yet

- Shalimar Aluminium PaintDocument2 pagesShalimar Aluminium PaintDeepak Tantuway100% (1)

- Xylar Data SheetDocument3 pagesXylar Data Sheetsarath6725No ratings yet

- TDS - Resist 78 - English (Uk) - Issued.02.04.2010Document4 pagesTDS - Resist 78 - English (Uk) - Issued.02.04.2010PaulSwinbankNo ratings yet

- Aliphatic Acrylic Polyurethane Finish CoatDocument4 pagesAliphatic Acrylic Polyurethane Finish CoatDexter R. RoqueNo ratings yet

- DS 161 Synthetic ROZC Primer 12744Document2 pagesDS 161 Synthetic ROZC Primer 12744mahotkatNo ratings yet

- TDS - Resist 86Document4 pagesTDS - Resist 86EricNo ratings yet

- Interprime 198 PDFDocument4 pagesInterprime 198 PDFandreaju2013No ratings yet

- Resist GTI - English (Uk) - Issued.06.12.2007Document4 pagesResist GTI - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- DATA SHEET NO. 2006-008 Epigard HB Zinc Phosphate Primer Grey / RedDocument2 pagesDATA SHEET NO. 2006-008 Epigard HB Zinc Phosphate Primer Grey / Redvijayakumar_samyNo ratings yet

- 2006-008 (NXPowerLite)Document2 pages2006-008 (NXPowerLite)vijayakumar_samyNo ratings yet

- Berger MIO Coating Brown.253140503Document2 pagesBerger MIO Coating Brown.253140503Gaurav TripathiNo ratings yet

- Muki Z 2001 - TDSDocument4 pagesMuki Z 2001 - TDSshameelNo ratings yet

- Amercoat 370Document3 pagesAmercoat 370Victor Hugo Bustos Beltran100% (1)

- 21-5 PDS AiDocument3 pages21-5 PDS Aiuocmogiandi_aNo ratings yet

- Jotazinc PDFDocument4 pagesJotazinc PDFAnonymous YtgIj2A9nWNo ratings yet

- TDS - Muki Z 2008 - English (Uk) - Issued.26.11.2010Document4 pagesTDS - Muki Z 2008 - English (Uk) - Issued.26.11.2010Keith ChooNo ratings yet

- Interline 1012+ds+engDocument4 pagesInterline 1012+ds+engSUBHOMOYNo ratings yet

- Zinc Anode 304 MZ Ds 099 02Document2 pagesZinc Anode 304 MZ Ds 099 02Power PowerNo ratings yet

- Barrier 80Document5 pagesBarrier 80adeoye_okunoyeNo ratings yet

- DS 164 02 ZincAnode304 MZSDocument2 pagesDS 164 02 ZincAnode304 MZSPower PowerNo ratings yet

- Xylan 80-510-G3196 Pfa BeDocument2 pagesXylan 80-510-G3196 Pfa BeSYED MAZHARNo ratings yet

- 97 145Document2 pages97 145anon_251242493No ratings yet

- PDS en-GB 1736g19840Document2 pagesPDS en-GB 1736g19840nihad_mNo ratings yet

- Phenoline 1205 PDS 9-06 PDFDocument2 pagesPhenoline 1205 PDS 9-06 PDFttr_1947No ratings yet

- Tuffkote Protective CoatingsDocument2 pagesTuffkote Protective CoatingsioginevraNo ratings yet

- 058 - Guard Coal Tar EpoxyDocument3 pages058 - Guard Coal Tar EpoxyhemajsuryaNo ratings yet

- Interzone 101Document0 pagesInterzone 101hennawijayaNo ratings yet

- 3 in ONEprofessionalAnti SeizeCopperGreaseDocument1 page3 in ONEprofessionalAnti SeizeCopperGreaseRandima GajanayakaNo ratings yet

- Jet Mastic 800Document3 pagesJet Mastic 800jopersa9No ratings yet

- Tar ProductsDocument14 pagesTar ProductsShaival JhaNo ratings yet

- Interseal 547 PaintDocument4 pagesInterseal 547 PaintSUBHOMOYNo ratings yet

- 15780Document7 pages15780khalid764No ratings yet

- Bitumastic 300MDocument2 pagesBitumastic 300Mtharman749781No ratings yet

- SikaTop Seal-109 MY 2012-08 - 1Document3 pagesSikaTop Seal-109 MY 2012-08 - 1Mashithah AhmadNo ratings yet

- 0009 d9 SB Zinc Silicate Pds March 08Document2 pages0009 d9 SB Zinc Silicate Pds March 08Prashant MalveNo ratings yet

- 05500Document6 pages05500khalid764No ratings yet

- TDS - CHEMFLAKE CV - English (Uk) - Issued.13.04.200Document4 pagesTDS - CHEMFLAKE CV - English (Uk) - Issued.13.04.200wey5316No ratings yet

- Penguard Primer Datasheet " Azadjotun"Document3 pagesPenguard Primer Datasheet " Azadjotun"AzadAhmadNo ratings yet

- MegayachtDocument6 pagesMegayachtvolme20No ratings yet

- Carboguard 888 PDSDocument3 pagesCarboguard 888 PDSsalamrefighNo ratings yet

- Intergard 251 Tech Data SheetDocument0 pagesIntergard 251 Tech Data SheetL Mahender ReddyNo ratings yet

- Plasite 7159 PDS 1-07 PDFDocument2 pagesPlasite 7159 PDS 1-07 PDFFabricio Jiménez TNo ratings yet

- Megayacht Imperial Antifouling DataDocument3 pagesMegayacht Imperial Antifouling DatakormatekNo ratings yet

- Epirez 733Document3 pagesEpirez 733Andy AcousticNo ratings yet

- Data SF3300Document2 pagesData SF3300Ingrid Johhana BalbinNo ratings yet

- Protectosil CIT TDSDocument2 pagesProtectosil CIT TDSjaga67No ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- 75th Conference on Glass Problems: A Collection of Papers Presented at the 75th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 3-6, 2014From Everand75th Conference on Glass Problems: A Collection of Papers Presented at the 75th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 3-6, 2014S. K. SundaramNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- 77th Conference on Glass Problems: A Collection of Papers Presented at the 77th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, OH, November 7-9, 2016From Everand77th Conference on Glass Problems: A Collection of Papers Presented at the 77th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, OH, November 7-9, 2016S. K. SundaramNo ratings yet

- (P0) R C Columns-Rectangular-Biaxial Bending-Section design-IS456Document25 pages(P0) R C Columns-Rectangular-Biaxial Bending-Section design-IS456KhanthavelNo ratings yet

- Agitators GBDocument2 pagesAgitators GBKarthimeena MeenaNo ratings yet

- RCC52 Column Chart GenerationDocument6 pagesRCC52 Column Chart GenerationKarthimeena MeenaNo ratings yet

- First Col DSN Fina RCC-Biaxial-BendingDocument7 pagesFirst Col DSN Fina RCC-Biaxial-BendingmukhleshNo ratings yet

- Acoples Rigidos LIGHTNINDocument48 pagesAcoples Rigidos LIGHTNINDIEGO SANCHEZNo ratings yet

- WIND GIRDER-Bill of Material: ProfileDocument3 pagesWIND GIRDER-Bill of Material: ProfileKarthimeena MeenaNo ratings yet

- Model 20 HT and GT AgitatorsDocument12 pagesModel 20 HT and GT AgitatorsKarthimeena MeenaNo ratings yet

- Preventing Dust FormationDocument12 pagesPreventing Dust FormationKarthimeena MeenaNo ratings yet

- Worksheet in Roof Structure - Up4Document8 pagesWorksheet in Roof Structure - Up4Karthimeena MeenaNo ratings yet

- Bottom and Shell Bom - Up12Document27 pagesBottom and Shell Bom - Up12Karthimeena MeenaNo ratings yet

- Shed For Rock Unloading & Screening Area - Greenstar: STD Weig HT Unit Weight Sub Qty Sub WeightDocument13 pagesShed For Rock Unloading & Screening Area - Greenstar: STD Weig HT Unit Weight Sub Qty Sub WeightKarthimeena MeenaNo ratings yet

- Performance LogDocument1 pagePerformance LogsstuparusNo ratings yet

- BOX TANK-Static 1-1Document7 pagesBOX TANK-Static 1-1Karthimeena MeenaNo ratings yet

- Foundation BoltDocument2 pagesFoundation BoltKarthimeena MeenaNo ratings yet

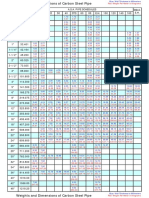

- Seamless Pipe - SCHDocument1 pageSeamless Pipe - SCHKarthimeena MeenaNo ratings yet

- HR AluminiumDocument1 pageHR AluminiumKarthimeena MeenaNo ratings yet

- EPF Form No 10 CDocument4 pagesEPF Form No 10 Capi-370495693% (14)

- Thiraviam Engineering PVT Limited: Approval For Work EstimateDocument2 pagesThiraviam Engineering PVT Limited: Approval For Work EstimateKarthimeena MeenaNo ratings yet

- Material ProcurmentDocument1 pageMaterial ProcurmentKarthimeena MeenaNo ratings yet

- Construction of ESP - Rev1ADocument23 pagesConstruction of ESP - Rev1AKarthimeena MeenaNo ratings yet

- Drum FilterDocument1 pageDrum FilterKarthimeena MeenaNo ratings yet

- SS Conical Tank - HWPDocument1 pageSS Conical Tank - HWPKarthimeena MeenaNo ratings yet

- Incentive Scheme Eligible Amount Against Fabrication: in RsDocument1 pageIncentive Scheme Eligible Amount Against Fabrication: in RsKarthimeena MeenaNo ratings yet

- Manpower Rate Calcutn 1Document2 pagesManpower Rate Calcutn 1Karthimeena MeenaNo ratings yet

- Abi Feed Water Inlet Nozzle No:1 Material CostDocument1 pageAbi Feed Water Inlet Nozzle No:1 Material CostKarthimeena MeenaNo ratings yet

- Bavai 06.01.17 Modal - 2Document37 pagesBavai 06.01.17 Modal - 2Karthimeena MeenaNo ratings yet

- Hayek - Planning, Science, and Freedom (1941)Document5 pagesHayek - Planning, Science, and Freedom (1941)Robert Wenzel100% (1)

- IPHPDocument4 pagesIPHPAliah CasilangNo ratings yet

- Workplace Risk Assessment PDFDocument14 pagesWorkplace Risk Assessment PDFSyarul NizamzNo ratings yet

- EE360 - Magnetic CircuitsDocument48 pagesEE360 - Magnetic Circuitsبدون اسمNo ratings yet

- Lab Final SolutionDocument18 pagesLab Final SolutionZeeNo ratings yet

- Concrete Lab ManualDocument20 pagesConcrete Lab ManualkelmazodroNo ratings yet

- Excel Crash Course PDFDocument2 pagesExcel Crash Course PDFmanoj_yadav735No ratings yet

- Lesson 2 (Probability of An Event)Document4 pagesLesson 2 (Probability of An Event)MarlNo ratings yet

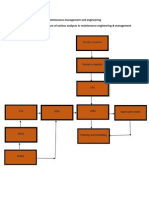

- Overview of MEMDocument5 pagesOverview of MEMTudor Costin100% (1)

- Operations and Service ManualDocument311 pagesOperations and Service ManualELARD GUILLENNo ratings yet

- Excavation Trench Permit Ex 1 F0206Document5 pagesExcavation Trench Permit Ex 1 F0206emeka2012No ratings yet

- Zoom g2 1nu Manual Do Utilizador PDFDocument56 pagesZoom g2 1nu Manual Do Utilizador PDFEliude Gonçalves FerreiraNo ratings yet

- Thesis StoryboardDocument5 pagesThesis StoryboardJill Brown100% (2)

- GARCH (1,1) Models: Ruprecht-Karls-Universit at HeidelbergDocument42 pagesGARCH (1,1) Models: Ruprecht-Karls-Universit at HeidelbergRanjan KumarNo ratings yet

- TMS320C67x Reference GuideDocument465 pagesTMS320C67x Reference Guideclenx0% (1)

- Package-Related Thermal Resistance of Leds: Application NoteDocument9 pagesPackage-Related Thermal Resistance of Leds: Application Notesalih dağdurNo ratings yet

- Anth 09 3 247 07 386 Yadav V S TTDocument3 pagesAnth 09 3 247 07 386 Yadav V S TTShishir NigamNo ratings yet

- Plane TrigonometryDocument545 pagesPlane Trigonometrygnavya680No ratings yet

- Certified Vendors As of 9 24 21Document19 pagesCertified Vendors As of 9 24 21Micheal StormNo ratings yet

- Practical Research 2.9Document22 pagesPractical Research 2.9Michael GabertanNo ratings yet

- Curriculum Improvement v2Document47 pagesCurriculum Improvement v2Nica Lagrimas100% (1)

- Bug Life Cycle in Software TestingDocument2 pagesBug Life Cycle in Software TestingDhirajNo ratings yet

- Jarir IT Flyer Qatar1Document4 pagesJarir IT Flyer Qatar1sebincherianNo ratings yet

- 4.1 Hydrostatic Force On Curved Surfaces - CE 309-CE22S2 - Fluid MechanicsDocument4 pages4.1 Hydrostatic Force On Curved Surfaces - CE 309-CE22S2 - Fluid MechanicsRUSSELNo ratings yet

- Module 2 DIPDocument33 pagesModule 2 DIPdigital loveNo ratings yet

- Tools of Persuasion StudentsDocument4 pagesTools of Persuasion StudentsBelén Revilla GonzálesNo ratings yet

- LITERARY THEORY BY TERRY EAGLETON NotesDocument6 pagesLITERARY THEORY BY TERRY EAGLETON NotesPrachi SharmaNo ratings yet

- Class I Water Well: DescriptionDocument10 pagesClass I Water Well: DescriptionJavier Andrés Acevedo GarcíaNo ratings yet

- Swanand 2009Document3 pagesSwanand 2009maverick2929No ratings yet

- Electromechani Cal System: Chapter 2: Motor Control ComponentsDocument35 pagesElectromechani Cal System: Chapter 2: Motor Control ComponentsReynalene PanaliganNo ratings yet