Professional Documents

Culture Documents

B-84567-SB-MM1-DSR-ST-60-0021 - 1 - AOC - GTG Fuel Gas Heater PDF

Uploaded by

pragatheeskOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B-84567-SB-MM1-DSR-ST-60-0021 - 1 - AOC - GTG Fuel Gas Heater PDF

Uploaded by

pragatheeskCopyright:

Available Formats

Data Sheet

GTG Fuel Gas Heater (60HAP-302)

ConocoPhillips (Grissik) Ltd.

B-84567-SB-MM1-DSR-ST-60-0021 - Rev. 1

Page 2 of 7

Revision Sheet

ConocoPhillips (Grissik) Ltd.

REVISION

DATE

0A

25-Jun-15

0B

3-Jul-15

DESCRIPTION OF CHANGE

First Issuance

Issued for Approval

- Change bolt material

- Add indication light type

- Add Note 30 and Note 31

13-Jul-15

Issued for Use

- Update operating condition

- Update design pressure

- Add requirement pickling & passivation for SS

- Update PID no. for GTG heater

- Add Note 32

20-Aug-15

Re-Issued for Use

Additional Approvers (If Applicable)

Name

Designation

Signature

Date

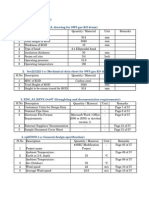

MECHANICAL DATA SHEET

DOC. NO

B-84567-SB-MM1-DSR-ST-60-0021

GTG Fuel Gas Heater (60HAP-302)

ConocoPhillips (Grissik) Ltd.

Proposal

Page :

Purchase

3 of 7

Applicable to

Location

Suban Gas Plant

Manufacturer

Equipment Name

Item No.

:

:

GTG Fuel Gas Heater

60HAP-302

Serial No.

No. of Unit

:

:

*

1 (One) x 100%

As Built

PERFORMANCE

Case 1 :

Normal

Case

HC Gas

Case 2 :

Normal

Case

HC Gas

Case 3 :

Maximum

Case

HC Gas

Case 4 :

Minimum

Case

HC Gas

lb/hr

5,328

5,334

5,046

3,517

MMscfd

2.53

2.53

2.53

1.67

19.18

19.20

18.16

19.18

lb/hr

Liquid Vaporized

lb/hr

Inlet Liquid Molecule Weight

lb/hr

10

Temperature Inlet

167.3

157.3

11

Temperature Outlet

181.0

181.0

12

Inlet Pressure (Operating)

psig

345

345

9.84

(Note 31)

52.7

(Note 31)

345

13

Max. Allowable pressure drop

psi

10

10

10

10

14

Heat Load

kW

11.79

20.14

34.24

7.82

15

Efficiency

16

Heater Capacity (Vendor to verify)

kW

17

Fluid properties

Operating Case

Fluid circulated

Total Fluid entering

Volume Flowrate

Inlet Gas Molecule Weight

Inlet Liquid Flowrate

F

F

Case 5

Case 6 :

Turndown

Case

167.3

181.0

345

See sheet 6 of 7

CONSTRUCTION OF CASING

18

19

Rev. 2

Design Pressure

psig

FV / 490

-20 / 225

20

Design Temperature (Min/Max)

21

Corrosion Allowance

F

inch

22

Electric Heater Connections, Size & Rating

inch

(*) /

23

Gas Connections, Size & Rating

In

inch

4 (*) / 300#

Out

inch

4 (*) / 300#

24

N/A

CASING DATA

25

26

Code

27

Dimension: - Inside Dia.

- T/F Line

28

Material Specifications

ASME Sec. VIII Div. 1 Latest Edition

:

inch

Shell

: SA 240 - 316L / SA 312 TP316L

ft

Head

: SA 240 - 316L / SA 403 Gr WP316L

Reinforcement Pad

: SA 240 - 316L

29

Orientation

Horizontal

30

Thickness: Shell

inch

Nozzle Neck

: SA 312 TP 316L

31

Head

inch

Nozzle Flange

: SA 182 F316L

32

Joint Efficiency

Heater Flange Cover

: SA 182 F316L

33

Radiography

Full

Gasket

: (Note 4)

34

PWHT

As Per Code

External Bolt / Nut

: SA 193 Gr. B7M / SA 194 Gr. 2HM (HDG)

35

No of Passes

Heating Element

: Incoloy 800 (*)

36

MAWP

Sheath / Tubes

: SA 213 TP 316L (*)

37

Hydrostatic Test Pressure

As Per Code [UG 99 (b)]

Tubesheet

: (*)

38

Wind Speed

80

Resistive Wire

: (*)

39

Seismic Zone

Segmental Baffle

: SA 240 TP 316L (*)

40

Type of Heads

2 : 1 Ellipsoidal & Flange

Tie Rods

: SS 316L

41

Support Type

Saddle

Fittings

: N/A

42

Baffle Cross Type

Impingement Plate

: N/A

43

Baffle Cut% (Dia. / Area)

External Attachment

: SA 240 - 316L

44

Baffle Spacing (C/C / Inlet / Outlet) :

Name plate

: SS 316

45

Element to Tube Sheet Connect

Anchor Bolts

: SA 307 Gr. C (HDG)

46

Insulation

Hot

Support / Pad

: SA 36 / SA 240 - 316L

47

Insulation clips

Yes

Insulator

: * (Note 14)

48

Painting

External

Lifting Lugs

: SA 240 - 316L

49

Pickling and Passivation for SS

Yes

Earthing Boss

: SS 316

Cable Gland

: *

Terminal Box

: *

psig

Km/hr

(Note 3)

(Note 14)

(Note 5)

Weight Data

50

Empty

lb

52

Operating

lb

53

Test

lb

51

Weight

MECHANICAL DATA SHEET

DOC. NO

B-84567-SB-MM1-DSR-ST-60-0021

GTG Fuel Gas Heater (60HAP-302)

ConocoPhillips (Grissik) Ltd.

3

3

4

5

6

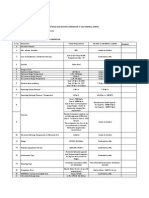

7

8

9

10

11

12

13

14

15

16

Cable Entry

Heater Power Terminal Box Type

No. of Stage of Heater Element

Type of Element

No. of Active Elements

No. of Spare Elements

Element Length

Element Active Length

Element Inactive Length

Element O.D.

Thickness

Heating Stage

Height of the Bottom Heating

Element from BOV

Assembly of Heating Elements

on Flange

: Bottom

: Ex"d", IIA, T3 or NEC equal

:

*

:

*

:

*

:

*

:

*

in

:

*

in

:

*

in

:

*

in

:

*

in

:

*

:

*

in

:

*

:

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

4 of 7

Rev. 2

ELECTRICAL DATA

1

2

Page :

Manufacturer

Control Arrangement

Hazardous Class.

Enclosure Rating

Material (Enclosure)

Location

Installation

Breather Drain

Cable Entry

Weight

:

:

:

:

:

:

:

:

:

:

Heat Flux

Sheath Temperature

Terminal Box Enclosure

Heater Bundle Diameter

Withdrawable Length

Element Protection

Voltage Rating

Hazardous Classification

Type of Control

Transmitter Type

CPT (Control Power

Transformer)

Anti Condensate Heater

Heater Bundle Weight

Total Surface Area

Certification

Heater Power (Duty)

ELECTRICAL CONTROL PANEL

*

*

Unclassified

NEMA 1 (c/w Gasket) / IP-42

Painted Sheet Metal

Indoor, Air Conditioned

Free Standing

Not Required

Top Entry

*

kg

:

:

:

:

:

:

:

:

:

:

:

* (Note 34)

Btu/hr.ft2

o

*

F

NEMA 7

*

in

*

in

RTD c/w Transmitter

400 VAC ; 50 Hz ; 3 phase ; 3 wire

Class 1 ; Div 2 ; Group D ; Temp. T3

Thyristor (*)

*

400 / 120 VAC; 50 Hz; 1 phase

:

:

:

:

:

Required, 230 V rated

*

*

*

*

(Note 17)

lb

in2

kW

Controller

: Thyristor (Note 33)

Control Volt. (CPT)

: 400 VAC / 120VAC ; 50 Hz

Breaker and Magnetic Starter : Required

Push Button

: Start & Stop

Indication Light

: Red, Amber & Green LED Type

Sequential Panel Required

: *

Anti Condensation Heater

: Required, 230 V rated

(Note 17)

Dimension (L x W x H)

: *

Color Paint

: Note 5

Thyristor Rated Power

(A) : *

Heat Loss

(W) : *

Radio Frequency Interference Suppression Circuit

:

Required

Control Relays (For Start - Stop)

:

Required

Fan for Panel Cooling (2 x 100%)

:

Required

Panel Accessories Such As Thermostat Controlled Space Heater and Lamp

:

Required

Harmonic Level Caused by Thyristor Control (VTHD Max : 5% & ITHD Max : 12%)

:

Required

Protection Equipment:

- Ultra Rapid Fuses for Overload Protection of Thyristors

:

Required

- A Core Balance Ground Fault Protection Relay

:

Required

- Heat Sink Over Temperature Trip

:

Required

Indication Control Unit (LED Type):

- Main Supply On (White)

: Required

- Thyristor Fuse Trip

: Required

- Heater On (Red)

: Required

- Unbalance Voltage Trip

: Required

- Heater Off (Amber)

: Required

- Heater control panel over-temperature

: Required

- Fault Indicator

: Required

- Earth fault

: Required

- Heater Element high-temperature

: Required

- Thyristor high-temperature

: Required

- Heater Element terminal box space heater ON : Required

- Emergency trip (from field emergency push button)

: Required

- Heater ON/OFF indication at local

: Required

- Local / Remote control

: Required

- Low Flow Stop

: Required

Minimum Requirement for Control and Protection Refer to Note 26

INSPECTION & TESTING (Note 8)

Observe

Witness Non Witness

MIGAS (PJIT) Inspection

Yes

No

Post Weld Heat Treatment

As Per Code & Spec.

Special Heat Treatment

Yes

No

Radiography

Full

Spot

Mechanical Test for Heating Bundle

Yes

No

Performance Test

Yes

No

Noise Level Test

Yes

No

Dis-assemble / Re-Assemble Test

Yes

No

Gas Leak Test

Yes

No

Functional Test for UCP

Yes

No

ASME U-Stamp

Yes

No

PMI (For SS & Alloy Material)

Yes

No

NACE Certificate

Yes

No

Impact Test

Radiography

Magnetic Particle

Dye Penetrant

Ultrasonic

Hydrostatic Test

MECHANICAL DATA SHEET

DOC. NO

B-84567-SB-MM1-DSR-ST-60-0021

GTG Fuel Gas Heater (60HAP-302)

ConocoPhillips (Grissik) Ltd.

Page :

5 of 7

Rev. 2

SKETCHES DRAWING

(*)

N1

N5

N4

N2

Lifting Lugs

H1

Earthing

Boss (2 ea)

N3

(*)

(*)

(*)

Sliding side

Fixed side

Note : Dimensions of Fuel / Seal Gas Heater are preliminary, it will be finalized by vendor during EPC stage.

NOZZLE SCHEDULE

PROJECTION

MARK

QTY

SIZE (in)

RATING

FACING

TYPE

(FROM OUTSIDE

SURFACE (in)

SERVICE

N1

4 (*)

300#

RF

WN

Gas Inlet

N2

4 (*)

300#

RF

WN

Gas Outlet

N3

300#

RF

WN

Drain Connection

N4

300#

RF

WN

Vent

N5

3 (*)

300#

RF

WN

PSV

H1

(*)

300#

RF

WN

(*)

Heater Flange

REMARKS

Hold (Note 30)

MECHANICAL DATA SHEET

ConocoPhillips (Grissik) Ltd.

DOC. NO

B-84567-SB-MM1-DSR-ST-60-0021

GTG Fuel Gas Heater (60HAP-302)

Page :

6 of 7

INLET GAS PROPERTIES

Operating Case

Case 1 :

Normal

Case

Case 2 :

Normal

Case

Case 3 :

Maximum

Case

Case 4 :

Minimum

Case

Fluid properties

Specific Heat

0.532

0.529

0.533

0.532

Btu/ft.h. F

0.0230

0.0230

0.017

0.023

lb/ft3

cP

1.066

1.087

1.436

1.066

0.0136

0.0134

0.0107

0.0136

cP

Btu/lb

0.0012

0.0012

0.0012

0.0012

Case 1 :

Normal

Case

Case 2 :

Normal

Case

Case 3 :

Maximum

Case

Case 4 :

Minimum

Case

0.00181

0.00181

0.00188

0.00181

15

Nitrogen

CO2

0.05731

0.05730

0.03484

0.05731

16

Methane

0.88196

0.88067

0.91146

0.88196

17

Ethane

0.03389

0.03390

0.03446

0.03389

18

Propane

0.00990

0.00994

0.00965

0.00990

19

i-Butane

0.00292

0.00295

0.00264

0.00292

20

n-Butane

0.00289

0.00293

0.00247

0.00289

21

i-Pentane

0.00158

0.00161

0.00110

0.00158

22

n-Pentane

0.00100

0.00103

0.00062

0.00100

23

n-Hexane

0.00153

0.00160

0.00048

0.00153

0.00016

0.00017

0.00004

0.00016

25

Mcyclohexane

Benzene

0.00055

0.00058

0.00013

0.00055

26

Cyclohexane

0.00015

0.00016

0.00003

0.00015

27

n-Heptane

0.00071

0.00074

0.00007

0.00071

28

Mcyclohexane

0.00019

0.00021

0.00002

0.00019

29

Toluene

0.00036

0.00039

0.00002

0.00036

30

n-Octane

0.00044

0.00045

0.00001

0.00044

31

m-Xylene

0.00007

0.00008

0.00000

0.00007

32

p-Xylene

0.00007

0.00008

0.00000

0.00007

33

o-Xylene

0.00003

0.00004

0.00000

0.00003

34

n-Nonane

0.00018

0.00017

0.00000

0.00018

35

124-MBenzene

0.00002

0.00002

0.00000

0.00002

36

n-Decane

0.00008

0.00007

0.00000

0.00008

37

n-C11

0.00003

0.00003

0.00000

0.00003

38

n-C12

0.00001

0.00001

0.00000

0.00001

39

n-C13

0.00000

0.00000

0.00000

0.00000

40

n-C14

0.00000

0.00000

0.00000

0.00000

41

n-C15

0.00000

0.00000

0.00000

0.00000

42

n-C16

0.00000

0.00000

0.00000

0.00000

43

n-C17

0.00000

0.00000

0.00000

0.00000

44

n-C18

0.00000

0.00000

0.00000

0.00000

45

n-C19

0.00000

0.00000

0.00000

0.00000

46

0.00000

0.00000

0.00000

0.00000

47

n-C20

H2O

0.00211

0.00303

0.00008

0.00210

48

H2S

40 ppm

40 ppm

Thermal Conductivity

Density

Vapor Viscosity

Liquid Viscosity (@ Temperature)

Latent Heat

10

Fouling Resistance (Note 15)

Btu/lb.oF

o

ft2.h.oF/Btu

Rev. 2

Case 5

Case 6 :

Case 5

Case 6 :

11

12

13

14

24

49

50

51

52

53

54

55

Inlet Gas Composition

Mercury

< 1 g/Nm3 < 1 g/Nm

3 - 4 ppm

3

< 1 g/Nm

40 ppm

3

< 1 g/Nm3

MECHANICAL DATA SHEET

DOC. NO

B-84567-SB-MM1-DSR-ST-60-0021

ConocoPhillips (Grissik) Ltd.

GTG Fuel Gas Heater (60HAP-302)

Page :

7 of 7

Rev. 2

NOTES

1. * = Vendor to specify and verify data.

2. Vendor shall responsible for detailed engineering of the electric heater. Vendor to confirm that fabrication, inspection and testing shall

follow the referenced Codes, Standards and Project Specifications.

3. Earthquake zone shall be : Zone 5 ( correspondence to zone 2 in ANSI A.58.1 with basic seismic coefficient 0.03).

4. Gasket shall be 0.175 thick, spiral wound, 316 SS Windings Flexible graphite filler SS inner & outer ASME B16.20.

5. Painting specification for steel shall refer to project specification ID-G-BU-DD3-STS-GN-98-0002, Coating Specification for Offshore and Onshore Facilities.

6. This data sheet shall be read together with P&ID B-84567-SB-PP0-PID-ST-60-0013 and Process data sheet B-84567-SB-PP0-DSR-ST-60-0020

7. Vendor to provide all required data for MIGAS certification.

8. Inspection and testing shall be refer to ID-G-BU-YA1-PRO-GN-00-0003, Inspection and Testing Requirements for Equipment and Material.

9. All metallic material shall be provided with inspection certificate in accordance with BS EN 10204 latest edition, pressure parts and non pressure part

shall be a minimum type 3.1 certificate.

10. Electric heater design as per standard manufactured and refer to Specification Electric Process Heater, B-84567-SB-EE1-SPC-ST-60-0002.

Vendor shall check and guarantee them on strength.

11. Electric element shall be removable flanged type.

12. Heating element tubesheet flange shall also be equipped with high temperature trip for overheating protection.

13. Vendor to confirm heater arrangement, nozzle orientation, size, control system, and safety devices. Heater Control System to be supplied by Vendor.

14. Vendor to advise hot insulation type and thickness to prevent heat loss not more than 5%. Insulation thickness and material shall refer to

specification for Vessel and piping insulation ID-N-BU-MM0-STS-GN-00-0002.

15. Design fouling resistance shall be verified by Vendor.

16. Vendor shall supply a detailed description of control system and brochure / catalogue information for the control panel during bid.

17. The Anti condensation heater shall be 230 Volts rated and operating at 120 Volt (form CPT). CPT (Control Power Transformer)

must be supplied in package.

18. Vendor shall provide high temperature trip (RTD) for element overheating protection (one pieces per phase per stage completed with Transmitter)

and for flange/tubesheet overheating protection (one RTD completed with Transmitter).

19. Vendor to provide the performance guarantee for the heater.

20. Deleted

21. Vendor shall propose with corrosion / erosion resistant tube, and meet process condition.

22. Vendor shall provide insulation clips and heater shall be c/w earthing lug and lifting lug.

23. Interconnecting cables between heater and Unit Control Panel (UCP) on the skid shall be provided by others.

24. Vendor shall inform heater control system design, completed with panel indicator and signal / alarm design.

25. Vendor shall provide spare gasket 300% for body flange of heater bundle, for SAT, commissioning & start-up.

26. Applicable Specification and Drawing :

1

B-84567-SB-EE1-SPC-ST-60-0002, Specification Electric Process Heater

B-84567-SB-JJ1-SPC-ST-87-0001, Specification of Instrument for Mechanical Package Equipment

B-84567-SB-LL0-SPC-ST-00-0001, Piping material Specification

B-84567-SB-LL0-SPC-ST-00-0002, Specification Pipe Stress Analysis.

B-84567-SB-MM2-SPC-ST-00-0301, Spec. Unfired Pressure Vessel

B-84567-SB-PP0-BOD-GN-00-0001, Project Design Basis

B-84567-SB-PP0-DSR-ST-60-0020, Process Data sheet GTG Fuel Gas Heater

B-84567-SB-PP0-PID-ST-60-0013, PID GTG Fuel Gas Filter Coalescer & GTG Heater

ID-G-BU-DD2-STS-GN-00-0001, Positive Material Identification (PMI)

10 ID-G-BU-DD3-STS-GN-98-0002, Coating Specification for Offshore and Onshore Facilities

11 ID-G-BU-GG0-AML-GN-00-0001 Standard Spec. COPI Approved Vendor List

12 ID-G-BU-JJ0-STS-GN-87-0001, Std Spec Instrument Design

13 ID-N-BU-LL2-STS-GN-00-0001, Standard Spec. Welding

14 ID-N-BU-CC0-STS-GN-00-0001, Std Spec. for General Civil and Structural Design

15 ID-N-BU-EE0-STS-GN-00-0001, Std Spec. General Electrical Design

16 ID-N-BU-EE1STS-GN-00-0001, Std Spec. Package Equipment Electrical

17 ID-N-BU-EE1-STS-GN-00-0008, Std Spec. Wire and Cable

18 ID-N-BU-MM0-STS-GN-00-0002, Std Spec. Vessel & Piping Insulation

27. Fuel Gas Heater is designed to get superheat condition (50oF above gas Dew Point Temperature) for gas supply to Gas Turbine Generator.

28. All external nozzles localized stress analysis to be performed by Vendor as per WRC 107, 297 & 537 Bulletin. The allowable nozzle load shall be as

per B-84567-SB-LLO-SPC-ST-00-0002, Specification Pipe Stress Analysis.

29. Vendor shall inform and verify actual weight, shear & moment data information based on verified calculation.

30. PSV size nozzle will be finalized during EPC Stage.

31. The low operating temperature is taken with assumption the Fuel / Seal Gas Heater (60HAP-301) is not operated yet. This case is addressed to

anticipate worst operating temperature. However, it will be recommended in operating procedure the Fuel/Seal Gas Heater (60HAP-301) shall be

operated first prior to sending gas to GTG Fuel Gas Filter Coalescer (60NAD-304) to avoid low temperature and hydrate formation.

32. All Pressure parts and parts directly exposed to the fluid shall comply with NACE MR0175.

33. The controller logic shall be PLC based ((Allen Bradley Control Logix with 10 HMI Color) ) with Ethernet communication interface.

34. Fuel Gas Heater shall be designed to meet minimal 20 years design life time.

You might also like

- Fuel Gas Superheater 195-E-301 A/B: Mechanical - Data SheetDocument3 pagesFuel Gas Superheater 195-E-301 A/B: Mechanical - Data SheetZulfikar N JoelNo ratings yet

- B 84567 SB MM2 DSR ST 60 0013 2 AOC Seal Gas Filter CoalescerDocument11 pagesB 84567 SB MM2 DSR ST 60 0013 2 AOC Seal Gas Filter CoalescerpragatheeskNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Inputs From Client: 1. bfp132401 1 0 (G.A. Drawing For SWS Gas KO Drum)Document3 pagesInputs From Client: 1. bfp132401 1 0 (G.A. Drawing For SWS Gas KO Drum)SIVANo ratings yet

- Typical Flare PackageDocument5 pagesTypical Flare PackageRahmat RiskiNo ratings yet

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationFrom EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo ratings yet

- Datasheet of Equipment - ANNAMDocument8 pagesDatasheet of Equipment - ANNAMhuyly34No ratings yet

- BB.G VSP Pve Ed 20 Me Das 004 - 0Document9 pagesBB.G VSP Pve Ed 20 Me Das 004 - 0Luong AnhNo ratings yet

- SRK HDDocument14 pagesSRK HDАнастасия ДоморацкаяNo ratings yet

- Si 83 - ENDocument52 pagesSi 83 - ENBabis PapadopoulosNo ratings yet

- Chemtrol Samil - Instrument D/SDocument48 pagesChemtrol Samil - Instrument D/SAnonymous OFP2ygPIdNo ratings yet

- NCR - SampleDocument7 pagesNCR - SamplecamycaxNo ratings yet

- CAT C175-16 2.5eMW Tier 4i QuoteDocument13 pagesCAT C175-16 2.5eMW Tier 4i Quoteraybugler100% (1)

- APNEA-J-DSH-0002 Rev. 1Document3 pagesAPNEA-J-DSH-0002 Rev. 1Michelle MartinezNo ratings yet

- Technical Comparison Format - Process Gas Reciprocating CompressorDocument11 pagesTechnical Comparison Format - Process Gas Reciprocating CompressorAlvin Smith100% (1)

- Quick Reference GuideDocument2 pagesQuick Reference Guideapi-279886039No ratings yet

- Datasheet Fuel Gas Scrubber (FGS-01)Document4 pagesDatasheet Fuel Gas Scrubber (FGS-01)Andika PratamaNo ratings yet

- B 84567 SB MM1 SPC ST 00 0301 - 1 - AOC - Seal Gas Mercury Guard BedDocument7 pagesB 84567 SB MM1 SPC ST 00 0301 - 1 - AOC - Seal Gas Mercury Guard BedpragatheeskNo ratings yet

- 145B9973 - Off Base Piping List of Lines PDFDocument4 pages145B9973 - Off Base Piping List of Lines PDFHumayun NawazNo ratings yet

- HSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterDocument2 pagesHSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterThanh Phuc Nguyen100% (1)

- 010-PREWPS FOR SS304 (2.5 - 11 MM) PDFDocument7 pages010-PREWPS FOR SS304 (2.5 - 11 MM) PDFKöksal PatanNo ratings yet

- Data Sheet: LPG Filling Pump P-001/002/003/004/005/006Document5 pagesData Sheet: LPG Filling Pump P-001/002/003/004/005/006Denstar Ricardo Silalahi100% (1)

- B 84567 SB Mm2 DSR ST 60 0020 - 1 - Aoc - GTG Fuel Gas Filter CoalescerDocument11 pagesB 84567 SB Mm2 DSR ST 60 0020 - 1 - Aoc - GTG Fuel Gas Filter CoalescerpragatheeskNo ratings yet

- Fire Water Make Up PumpDocument7 pagesFire Water Make Up PumpAlvin SmithNo ratings yet

- York Rooftops EngDocument14 pagesYork Rooftops EngBulclimaNo ratings yet

- Carrier Air Con 38QRR ManualDocument30 pagesCarrier Air Con 38QRR ManualYorkistNo ratings yet

- Service: ManualDocument54 pagesService: ManualElseven AkifNo ratings yet

- 22 1739 04 - 02012010XXDocument16 pages22 1739 04 - 02012010XXMartinez MarNo ratings yet

- 008364-001-DS-I001 Dehydration Switching Valves Datasheet - Rev BDocument17 pages008364-001-DS-I001 Dehydration Switching Valves Datasheet - Rev BNaveen KumarNo ratings yet

- SM Rav SM SP 560 800 XT E - enDocument187 pagesSM Rav SM SP 560 800 XT E - enVahida KozicNo ratings yet

- Ducted Split Air Conditioner: Service ManualDocument19 pagesDucted Split Air Conditioner: Service ManualLuis Ernesto Cabrera MartinezNo ratings yet

- 011-PREWPS FOR SS304 (6.3 - 18.7 MM) PDFDocument9 pages011-PREWPS FOR SS304 (6.3 - 18.7 MM) PDFKöksal PatanNo ratings yet

- Datasheet AcDocument9 pagesDatasheet AcMohan VarkeyNo ratings yet

- Ip Pressure Transmitter Data SheetDocument2 pagesIp Pressure Transmitter Data Sheetneurolepsia3790No ratings yet

- LG Therma V MonoblocDocument47 pagesLG Therma V MonoblocMuhidin KozicaNo ratings yet

- Welding Procedure Specification SampleDocument5 pagesWelding Procedure Specification SampleAdiNo ratings yet

- Datasheet Phe OnwjDocument1 pageDatasheet Phe OnwjMamank Ira Sudrajat100% (1)

- WPSDocument1 pageWPSNidhinkorothNo ratings yet

- TBDP A M DS 0007 2Document7 pagesTBDP A M DS 0007 2Bùi Văn HợpNo ratings yet

- Min1244a12 - Tag 130-Pu-029Document7 pagesMin1244a12 - Tag 130-Pu-029Monty MathewsNo ratings yet

- Chiller Tonillo Daikin WGS190A - Technical Data SheetDocument2 pagesChiller Tonillo Daikin WGS190A - Technical Data SheetMatthew OlsenNo ratings yet

- Data Sheet For Power TransformerDocument3 pagesData Sheet For Power TransformerNakkolopNo ratings yet

- AHU CLCP Dimension DrawingsDocument92 pagesAHU CLCP Dimension DrawingsPhạm ĐạtNo ratings yet

- Reaction Tank Design For WWTPDocument9 pagesReaction Tank Design For WWTPDavid LambertNo ratings yet

- FAHU SubmittalDocument62 pagesFAHU SubmittalEngr.MmosaadNo ratings yet

- LG - LBUM7280BL Exploded ViewDocument55 pagesLG - LBUM7280BL Exploded ViewGuillermo HernandezNo ratings yet

- Quotation Cold Room An NAM Group - 17 Aug 2010Document12 pagesQuotation Cold Room An NAM Group - 17 Aug 2010huyly34No ratings yet

- Bosch - Rexroth - Marine Technic - 2002Document291 pagesBosch - Rexroth - Marine Technic - 2002nguyenvanhai19031981No ratings yet

- Data Sheet For Absorber Reflux Drum (GTPT-V-250-003)Document4 pagesData Sheet For Absorber Reflux Drum (GTPT-V-250-003)Mohamed hamza souissiNo ratings yet

- WPS SiloDocument1 pageWPS SiloNidhinkorothNo ratings yet

- Digital Zone 2 Technical Comparison: Air Cooled Chilled Water Package-280 TR - (Normal Operation)Document4 pagesDigital Zone 2 Technical Comparison: Air Cooled Chilled Water Package-280 TR - (Normal Operation)thinkpad x1No ratings yet

- Sp-210-E-103 Rev 0Document7 pagesSp-210-E-103 Rev 0Natarajan RavisankarNo ratings yet

- J P Mukherji & Associates PVT LTD ParametersDocument8 pagesJ P Mukherji & Associates PVT LTD ParametersAnonymous 7ZYHilDNo ratings yet

- KR - MV IDU - R410A - 5060Hz - MFL61741606 - 0CVP0-03A (110503)Document388 pagesKR - MV IDU - R410A - 5060Hz - MFL61741606 - 0CVP0-03A (110503)eselcosacNo ratings yet

- Sov - 1Document1 pageSov - 1biswasdipankar05No ratings yet

- DS-21-J-0026 - 2 TPCDR Approved PDFDocument40 pagesDS-21-J-0026 - 2 TPCDR Approved PDFsumant.c.singh1694No ratings yet

- Data Sheet - Overhead TravellingDocument4 pagesData Sheet - Overhead TravellingSugiarto SaptomoNo ratings yet

- LabDocument12 pagesLabpragatheeskNo ratings yet

- Product Leaflet Seawater ElectrochlorinationDocument1 pageProduct Leaflet Seawater ElectrochlorinationpragatheeskNo ratings yet

- RFQ For Pumps-UpdatedDocument3 pagesRFQ For Pumps-UpdatedpragatheeskNo ratings yet

- List of Preferred BrandDocument8 pagesList of Preferred BrandpragatheeskNo ratings yet

- ComparisonDocument10 pagesComparisonpragatheeskNo ratings yet

- Kubota-Mbr Technical PDFDocument13 pagesKubota-Mbr Technical PDFpragatheeskNo ratings yet

- Equipment: Respond To This Bidding DocumentDocument1 pageEquipment: Respond To This Bidding DocumentpragatheeskNo ratings yet

- Equalisation GuideDocument16 pagesEqualisation GuidepragatheeskNo ratings yet

- MBR System Evaluation Overview: A C E H F MBR TDocument9 pagesMBR System Evaluation Overview: A C E H F MBR TpragatheeskNo ratings yet

- Design of Oxidation DitchDocument23 pagesDesign of Oxidation Ditchartiraha100% (1)

- Anoxic TankDocument12 pagesAnoxic TankpragatheeskNo ratings yet

- MBR DesignDocument52 pagesMBR Designpragatheesk100% (2)