Professional Documents

Culture Documents

Indian Forging Industry

Uploaded by

arunkumar17Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Indian Forging Industry

Uploaded by

arunkumar17Copyright:

Available Formats

Indian Forging Industry

The Indian forging industry has emerged as a major contributor to the manufacturing sector of

the Indian Economy. It is a key element in the growth of the Indian automobile industry as well as

other industries such as general engineering, construction equipment, oil, gas and power. The

Indian forging industry is well recognised globally for its technical capabilities.

With an installed capacity of around 37.7 lakh MT, Indian forging industry has a capability to forge

variety of raw materials like carbon steel, alloy steel, stainless steel, super alloy, titanium,

aluminium, etc.

Based on their installed capacity, the forging units may be classified as very large (capacity

above 75,000 MT), large (capacity above 30,000 to 75,000 MT), medium (capacity above 12,500

to 30,000 MT), small (capacity above 5,000 to 12,500 MT) and very small (capacity up to 5,000

MT). Based on this classification it is seen that about 87% of the total number of units are small

and very small, while only about 5% can be classified as very large and large units; the balance

of about 8% constitute the medium sized units.

The Indian forging industry is concentrated around its end user customer locations. Therefore,

the major forging clusters are found to be in the states of Maharashtra, Punjab, Gujarat, Tamil

Nadu, Haryana, Delhi, Karnataka, Jharkhand, West Bengal and Andhra Pradesh. States such as

Maharashtra, Punjab, Tamil Nadu, Haryana, Jharkhand and Delhi.

The forging industry of India provides direct employment to about 95,000 people. The small and

very small units are mainly dependant on manual labour, however medium and large units are

more mechanized. Quality standards in the industry have improved significantly and the sector is

now well known globally for its high quality.

Current share of auto sector is about 61% of total forging production while the rest is with the

non-auto sector. Changes in Indian automobile industry directly impact Indian forging industry,

because the forging components form the backbone of the Indian automobile industry. Since the

automobile industry is the main customer for forgings the industrys continuous efforts in

upgrading technologies and diversifying product range has enabled it to expand its base of

customers to foreign markets.

The Indian forgings industry has made rapid strides and currently, not only meets almost all the

domestic demand, but has also emerged as a large exporter of forgings. The industry is

increasingly addressing opportunities arising out of the growing trend among global automotive

OEMs (Original Equipment Manufacturers) to outsource components from manufacturers in lowcost countries. As a result, the industry has been making significant contributions to countrys

growing exports.

In order to reduce the impact of cyclicality and dependence on auto sector, the industry plans to

diversify into non-automotive sectors.

PRODUCTION AND INSTALLED CAPACITY OF INDIAN FORGING INDUSTRY

Year

Installed

Capacity (Lakh

Tonnes)

Total

Production

(Lakh Tonnes)

Capacity

Utilization

(Percentage

)

2011-12

37.7

24.5

64.9

2012-13

37.7

21.1

55.9

2013-14

37.7

21.5

57.0

2014-15

37.7

23.0

61.0

2015-16

37.7

24.5

64.9

You might also like

- Auto Ancilary Macro ReportDocument88 pagesAuto Ancilary Macro ReportAdersh Ar Dahiya100% (1)

- Agri Implements IndustryDocument81 pagesAgri Implements IndustryNirav Joshi100% (1)

- Indian Construction Equipment IndustryDocument4 pagesIndian Construction Equipment Industryvenkat_MandaliNo ratings yet

- Indian Automotive Industry Report 250608Document28 pagesIndian Automotive Industry Report 250608workosaur100% (5)

- Liberalisation and Industrial PolicyDocument22 pagesLiberalisation and Industrial PolicyShivam GuptaNo ratings yet

- JamkashDocument69 pagesJamkashSahil Amla100% (2)

- White GoodsDocument20 pagesWhite GoodsSachi Bani PerharNo ratings yet

- Accelerating Innovation With Indian EngineeringDocument12 pagesAccelerating Innovation With Indian Engineeringrahulkanwar267856No ratings yet

- IBEF Auto Components 261112Document37 pagesIBEF Auto Components 261112asingh0001No ratings yet

- Tata Motors Suv Segment ProjectDocument57 pagesTata Motors Suv Segment ProjectmonikaNo ratings yet

- Construction IndustryDocument7 pagesConstruction IndustryVishal RastogiNo ratings yet

- Sintex Industries Companyanalysis92384293424Document16 pagesSintex Industries Companyanalysis92384293424Vijay Gohil100% (1)

- Material Handling India PDFDocument7 pagesMaterial Handling India PDFsangeeth_7No ratings yet

- Strategy Review - Tata SteelDocument20 pagesStrategy Review - Tata SteelKen SekharNo ratings yet

- CementDocument8 pagesCementppppNo ratings yet

- Impact of MNCs On Indian EconomyDocument36 pagesImpact of MNCs On Indian EconomyHimanshu RajaNo ratings yet

- Readymade GarmentsDocument19 pagesReadymade GarmentsAnonymous 1FrpCENo ratings yet

- KSFC ProjectDocument26 pagesKSFC ProjectsrinNo ratings yet

- Automotive Tyre Manufacturers' Association (ATMA)Document21 pagesAutomotive Tyre Manufacturers' Association (ATMA)flower87No ratings yet

- India Construction Equipment Market 2019-2029Document26 pagesIndia Construction Equipment Market 2019-2029nikoji9288No ratings yet

- Portfolio Analysis Commercial VehiclesDocument25 pagesPortfolio Analysis Commercial Vehiclesroguemba100% (1)

- Auto Parts Manufacturing in China: Ibisworld Industry ReportDocument33 pagesAuto Parts Manufacturing in China: Ibisworld Industry ReportSaira BanuNo ratings yet

- PaintDocument12 pagesPaintAmit SrivastavaNo ratings yet

- Role of Ssi in Economic DevelopmentDocument38 pagesRole of Ssi in Economic DevelopmentRaj K GahlotNo ratings yet

- Survey of Chemical IndustryDocument9 pagesSurvey of Chemical Industrymanu1920% (1)

- Raj Petro (Profile) PDFDocument5 pagesRaj Petro (Profile) PDFAbhinayKumarNo ratings yet

- Ashok LeylandDocument13 pagesAshok LeylandDiptiNo ratings yet

- Analysis of Tractor Industry in IndiaDocument29 pagesAnalysis of Tractor Industry in IndiaRaju Rawat100% (1)

- Industry AnalysisDocument9 pagesIndustry AnalysisNitesh Kr SinghNo ratings yet

- China Cutting Tools Market ReportDocument10 pagesChina Cutting Tools Market ReportAllChinaReports.comNo ratings yet

- Export Performance of NALCO 1987-1995Document24 pagesExport Performance of NALCO 1987-1995Mohammad Abubakar Siddiq100% (1)

- Team 1 - ROOTS INDUSTRIESDocument21 pagesTeam 1 - ROOTS INDUSTRIESChibi RajaNo ratings yet

- Automotive Sector MBA ISMDocument59 pagesAutomotive Sector MBA ISMAman AgarwalNo ratings yet

- Swot AnalysisDocument3 pagesSwot AnalysisAbhishek GuptaNo ratings yet

- Indian Cement IndustryDocument7 pagesIndian Cement IndustrymayankNo ratings yet

- Iron & Steel FinalDocument67 pagesIron & Steel FinalKartik Ravichander0% (1)

- Working Capital ReportDocument60 pagesWorking Capital ReportRavi JoshiNo ratings yet

- Team 1 - ROOTS INDUSTRIESDocument32 pagesTeam 1 - ROOTS INDUSTRIESChibi RajaNo ratings yet

- Leather IndustryDocument7 pagesLeather IndustrySumit ChandraNo ratings yet

- Vegi Sree Vijetha (1226113156)Document6 pagesVegi Sree Vijetha (1226113156)Pradeep ChintadaNo ratings yet

- Birla CementDocument76 pagesBirla CementRym Nath100% (1)

- Malabar Cements Internship Report Malabar Cements Internship ReportDocument79 pagesMalabar Cements Internship Report Malabar Cements Internship ReportrajeevreddyaNo ratings yet

- Edited Project Fulll - Docx - 1524468476442 PDFDocument70 pagesEdited Project Fulll - Docx - 1524468476442 PDFsai suvasNo ratings yet

- Chemical Sector of PakistanDocument4 pagesChemical Sector of Pakistanzapper766No ratings yet

- Oswal Pumps: The Legacy of Technology PerfectionDocument11 pagesOswal Pumps: The Legacy of Technology PerfectionKalyan ChNo ratings yet

- CastrolDocument11 pagesCastrolSaurabh AmbaselkarNo ratings yet

- Indian Edible Oil Market: Trends and Opportunities (2014-2019) - New Report by Daedal ResearchDocument13 pagesIndian Edible Oil Market: Trends and Opportunities (2014-2019) - New Report by Daedal ResearchDaedal ResearchNo ratings yet

- Kerala State DrugsDocument50 pagesKerala State Drugssanthoshchandu.santhoshmohan0% (1)

- SM Group5 SectionC BHEL PDFDocument23 pagesSM Group5 SectionC BHEL PDFroguemba100% (1)

- Atul AutoDocument62 pagesAtul AutoAkram Kaladia100% (2)

- SH Bearings A 1 August 2017Document8 pagesSH Bearings A 1 August 2017rohanNo ratings yet

- Int'l MKTG Case StudyDocument4 pagesInt'l MKTG Case Studyanon_71036931No ratings yet

- Industry Is The Segment of Economy Concerned With Production of Goods. Small Scale IndustryDocument43 pagesIndustry Is The Segment of Economy Concerned With Production of Goods. Small Scale IndustryMadhav AggarwalNo ratings yet

- Spicejet Strategy AssignmentDocument28 pagesSpicejet Strategy AssignmentsaurabhdrummerboyNo ratings yet

- B2B Project Report - Group9Document15 pagesB2B Project Report - Group9Vaibhav RajNo ratings yet

- JSW Steel Full 2010Document106 pagesJSW Steel Full 2010AMITKEKS50% (2)

- History and Development of Amul Indusries Pvt. Ltd.Document79 pagesHistory and Development of Amul Indusries Pvt. Ltd.asn8136No ratings yet

- Ji Ji Ji Ji Ji Ji JiDocument7 pagesJi Ji Ji Ji Ji Ji JiMonika WadhelNo ratings yet

- Aditya NewDocument72 pagesAditya NewShanthkumar Ramakrishnaiah100% (1)

- Bearing Industry in IndiaDocument3 pagesBearing Industry in Indiaumo14100% (1)

- Recommendation On Linkedin 5Document2 pagesRecommendation On Linkedin 5arunkumar17No ratings yet

- Recommendation On Linkedin 3Document1 pageRecommendation On Linkedin 3arunkumar17No ratings yet

- Electronics Industry Thailand 2005Document2 pagesElectronics Industry Thailand 2005arunkumar17No ratings yet

- Recommendation On Linkedin 2Document1 pageRecommendation On Linkedin 2arunkumar17No ratings yet

- Recommendation On Linkedin 4Document1 pageRecommendation On Linkedin 4arunkumar17No ratings yet

- Recommendation On Linkedin 7Document2 pagesRecommendation On Linkedin 7arunkumar17No ratings yet

- Recommendation On LinkedinDocument2 pagesRecommendation On Linkedinarunkumar17No ratings yet

- BRS Review2018 01 ShipbuildingDocument14 pagesBRS Review2018 01 Shipbuildingarunkumar17No ratings yet

- LFT - Technical Leaflet To 25 r05Document2 pagesLFT - Technical Leaflet To 25 r05arunkumar17No ratings yet

- Basic DesignDocument1 pageBasic Designarunkumar17No ratings yet

- Textile ContentsDocument1 pageTextile Contentsarunkumar17No ratings yet

- Power EPC 1. BGR Energy Systems 2. Energo India 3. Hindustan Power 4. EIL Gurgaon 5. Sterling WilsonDocument1 pagePower EPC 1. BGR Energy Systems 2. Energo India 3. Hindustan Power 4. EIL Gurgaon 5. Sterling Wilsonarunkumar17No ratings yet

- iEEMA 2012Document1 pageiEEMA 2012arunkumar17No ratings yet

- ParwanooDocument3 pagesParwanooarunkumar17No ratings yet

- Capacity AddictionDocument1 pageCapacity Addictionarunkumar17No ratings yet

- Electrical SubstationDocument1 pageElectrical Substationarunkumar17No ratings yet

- English News April 9-15, 2016Document11 pagesEnglish News April 9-15, 2016arunkumar17No ratings yet

- Trend December 2015Document11 pagesTrend December 2015arunkumar17No ratings yet

- Angel Broking Budget Special Sectoral Report Technical 010217Document24 pagesAngel Broking Budget Special Sectoral Report Technical 010217arunkumar17No ratings yet

- Please Find Following Food Package & Extra Item List With Rate (Or /) Per Pax 650Document1 pagePlease Find Following Food Package & Extra Item List With Rate (Or /) Per Pax 650arunkumar17No ratings yet

- Angel Broking Budget Special Sectoral Report Technical 010217Document24 pagesAngel Broking Budget Special Sectoral Report Technical 010217arunkumar17No ratings yet

- Grades Spec.Document2 pagesGrades Spec.arunkumar17No ratings yet

- © Feedback Consulting - 2015Document3 pages© Feedback Consulting - 2015arunkumar17No ratings yet

- IBEF Oil Gas-January 2017Document54 pagesIBEF Oil Gas-January 2017arunkumar17No ratings yet

- Team Building IdeasDocument23 pagesTeam Building Ideasarunkumar17No ratings yet

- BPSL Company ProfileDocument1 pageBPSL Company Profilearunkumar17No ratings yet

- Steel Techspec PDFDocument8 pagesSteel Techspec PDFarunkumar17No ratings yet

- Bearing SteelDocument2 pagesBearing Steelarunkumar17No ratings yet

- AME OF Unit S Address of Units Phon E No. Fax No. Produc TS Custome RSDocument1 pageAME OF Unit S Address of Units Phon E No. Fax No. Produc TS Custome RSarunkumar17No ratings yet

- Ahmed Madad Proposal NormalDocument29 pagesAhmed Madad Proposal NormalDhaabar Salaax100% (1)

- Week 2 Teradata Practice Exercises GuideDocument7 pagesWeek 2 Teradata Practice Exercises GuideFelicia Cristina Gune50% (2)

- NB-CPD SG02 03 002r2 - EN 934 series-FPC Cert - Admixtures For Concrete Mortar and Grout PDFDocument15 pagesNB-CPD SG02 03 002r2 - EN 934 series-FPC Cert - Admixtures For Concrete Mortar and Grout PDFAlban TabakuNo ratings yet

- FDA GMP GuidelinesDocument7 pagesFDA GMP Guidelinesm_ihab777629No ratings yet

- Websphere Business Modeler TutorialDocument46 pagesWebsphere Business Modeler TutorialIda MariaNo ratings yet

- PP (SCM) Consultant Certification Question BankDocument121 pagesPP (SCM) Consultant Certification Question BankSuraj Kamble100% (1)

- Mj19 Sample Apm QuestionsDocument9 pagesMj19 Sample Apm QuestionsAakash AadeezNo ratings yet

- Pipe SupportDocument224 pagesPipe SupportViswanath NeswaNo ratings yet

- Line History SheetDocument4 pagesLine History SheetBethel NdifonNo ratings yet

- Connectivity Options Between Honeywell® and DeltaV™ SystemsDocument17 pagesConnectivity Options Between Honeywell® and DeltaV™ SystemsRicardo VillalongaNo ratings yet

- Abap RicefwDocument2 pagesAbap RicefwSchatenz ZnetahcsNo ratings yet

- NJ Lemon LawDocument2 pagesNJ Lemon Lawscd9750No ratings yet

- E Wallet ReportDocument27 pagesE Wallet ReportGovindaram RajeshNo ratings yet

- Csic April 2013Document52 pagesCsic April 2013prof_ktNo ratings yet

- MahindraDocument83 pagesMahindraRajanikanth Reddy100% (1)

- Lean Think PDFDocument13 pagesLean Think PDFசரவணகுமார் மாரியப்பன்No ratings yet

- Clemson University Starbucks Coffee Company: Architects Project No. 0816.01Document35 pagesClemson University Starbucks Coffee Company: Architects Project No. 0816.01Machu SoPe100% (1)

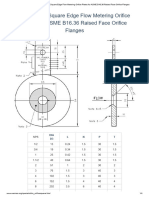

- Wermac - Dimensions of Square Edge Flow Metering Orifice Plates For ASME B16.36 Raised Face Orifice FlangesDocument4 pagesWermac - Dimensions of Square Edge Flow Metering Orifice Plates For ASME B16.36 Raised Face Orifice Flangestechnicalei sulfindoNo ratings yet

- Test Bank For Horngrens Financial Managerial Accounting 4e by Nobles 0133359840Document55 pagesTest Bank For Horngrens Financial Managerial Accounting 4e by Nobles 0133359840JonathanHicksnrmo100% (36)

- Freight Depot Layout - 0Document28 pagesFreight Depot Layout - 0Jaikanthan DasarathaNo ratings yet

- Virtual Reality From Operations Management Perspective - Mosad SaberDocument37 pagesVirtual Reality From Operations Management Perspective - Mosad SaberMosad SaberNo ratings yet

- Engine Technology International - September 2014Document108 pagesEngine Technology International - September 2014Guilherme PfeilstickerNo ratings yet

- Mian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and SoDocument17 pagesMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and Sons ProfiMian Munir and SoWaseem WaseemNo ratings yet

- Oertli - SculeDocument307 pagesOertli - SculeDore EmilNo ratings yet

- Internship Report On Hypoid Composite Knit Ltd.Document144 pagesInternship Report On Hypoid Composite Knit Ltd.Ashik Faisal100% (2)

- TOGU BrochureDocument4 pagesTOGU Brochureisaias_pm92No ratings yet

- Control Valve PresentationDocument61 pagesControl Valve PresentationDhanny Miharja100% (1)

- 31 32 13 Cement Stabilization PDFDocument7 pages31 32 13 Cement Stabilization PDFJUAN RULFONo ratings yet

- QFD PresentationDocument75 pagesQFD PresentationBhushan Verma100% (3)

- Two Marks Questions Unit I: Dr. N E Edwin Paul, GRTIETDocument4 pagesTwo Marks Questions Unit I: Dr. N E Edwin Paul, GRTIETashvanth kumarNo ratings yet