Professional Documents

Culture Documents

4 - PRO - Alpha 355 - EN

Uploaded by

Guillermo BetancourtOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4 - PRO - Alpha 355 - EN

Uploaded by

Guillermo BetancourtCopyright:

Available Formats

Alpha 355

High performance fully automatic crimping machine

THE WAY TO MAKE IT | EFFICIENT

Short setup and changeover times, integrated quality measurements, and top

performance are the three main features of the Alpha 355 fully automatic

crimping machines.

Area of application

The Komax Alpha 355 is designed for one and twosided crimping and seal loading. It even handles

double-crimp connections involving varying lengths

and the same wire types without any problem.

The ultra-precise dual-channel blade system allows

for a large range of wire sizes without blade changes.

Alpha 355 In action

Blade head Dual-channel blade system

Draw-in and wire selector

Guide tube changer automatic

Fast changeovers

In most machines, changeover times offer the biggest potential for optimization. With options like

the manual wire selector and/or the quick-change

system for crimping tools, materials and tools can

be prepared for the next job while the machine is

running.

Jobs can also be recorded and edited with TopWin

while the machine is running. The changeover time is

displayed, providing an easy method for optimizing

the workflow.

Maximum quality control

Crimp-height measurement and pull-out force measurement are integrated in the process sequence.

Optional material-change detection and the optional

barcode scanner help to prevent materials from

getting mixed up. The processes are constantly

checked against the specified values during production with functions that monitor crimp force, seals,

splices, end of wire supply, and length. Any cables

with processing defects are removed and an appropriate number of cables are post-processed automatically to replace them.

Quick-change system For crimping tools

Conductor detector sensor ACD

Miniaturization and new technologies are making the

quality requirements on cable processing tougher

all the time. To satisfy the current automobile crimping standard for solder-free electric connections,

Komax has developed the fully automatic conductor

detection (ACD). This product recognizes even the

slightest contacts between blades and conductor

strands in the course of production. ACD is based

on a capacitive measuring principle and integrated in

the blade holder. It uses the regular stripping blades.

The work range covers the entire spectrum of cross

sections, any conductor length and stripping with full

strip or partial strip. There are setup parameters to

set the limits of monitoring desired. Defective conductor ends are removed fully automatically during

production.

Conductor detector sensor ACD

Strip Quality Check SQC

The stripping quality check (SQC) entails visually

monitoring the stripping quality during the swivel movement. It measures the stripping length and checks

the wire for projecting or splayed wires. The use

of the SQC instead of the CPS option (cut pulled

strands) boosts the output by an average up to

10percent. The actual figure depends on conductor

length and quality.Defective products are automatically removed.

Strip Quality Check SQC

User friendly

The drive unit for the blade head is placed underneath, giving the machine a neat and ergonomic

layout. All processing stations have safety covers

that open vertically for optimum access, and

application-specific parts like applicators and

contact rolls can be changed without tools. Controls

are placed at decentralized positions, allowing the

necessary machine functions to be triggered during

setup. All setting and adjustment procedures can be

controlled from the TopWin graphical user interface in

the operators choice of over 20 different languages.

TopWin

Clearly arranged machine

layout

Your benefits

Short changeover times

Reliable process monitoring

High production output

Conductor detector sensor for highest quality

in cutting

Setup of next job while production of current

job

Networking possibility with WPCS

Application sample Alpha 355

Cutting

Double sheath / Coaxial

and triaxial cables

Half strip

Cut pulled strands /

Full strip

Precision cut

Intermediate strip /

Hot stamp marking

Intermediate slitting

Ink-Jet marking

Crimping

Seal insertion

Split cycle

for closed barrel

Double crimping

Options and Accessories

Feeding systems

Komax 106 | ads 117 | ads 119

Marking systems

Komax 26 hot stamp marking | Komax Inkjet marking system IMS | Laser marking on

request

Wire infeed

Belt drive

Processing modules

Crimping module mci 712 | Crimping module mci 722 (with programmed crimp heights) |

Seal loading module mci 765 C (with seal position monitoring SPM) |

Double gripper module

Quality control

Integrated crimp height measurement | Integrated pull-off force measurement |

Conductor detector sensor ACD | Strip Quality Check SQC |

Crimp force analyzer CFA/CFA+ | Material change detection | Material verification |

Wire length correction | Splice check | Spark tester | Seal monitoring SPM/SPA |

Terminal end detection

Deposit systems

Basic module 2m (78.7in.) or 4m (157.5in.) |

Extension module 2m (78.7in.) or 4m (157.5in.) | Deposit gripper

Accessories

Tool changer | Automatic guide tube changer | Barcodescanner |

Software: Networking WPCS | Data conversion TopConvert |

Production control center KomaxCAO

Made in Switzerland

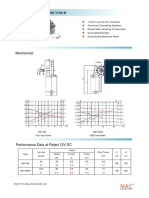

Machine layout Alpha 355

Height with cover closed:

Height with cover open:

0088141 Version 4

Subject to change /gu

1445mm (56.9in.)

4125mm (162.4in.)

1700 mm (70in.)

2154mm (84.8in.)

Reference values for piece output of Alpha 355

Pieces/h

4000

3000

2000

1000

0

0

500

1000

1500

2000

2500

3000

3500

4000

Conductor

FLRY 0.50mm2 (AWG20)

Pneumatic pressure

6bar (87psi)

Speed

12m/s (39ft/s)

Acceleration 60m/s2 (197ft/s2)

Crimping modules

mci 722

Seal loading module

mci 765 C

Crimp force analysis

active

Seal position monitoring

active

Wire length [mm]

Technical data

Length range

60mm65000mm (2.36in.213ft.)

Optionally from 30mm (1.18in.)

Length accuracy

Repeat accuracy: (0.2% +1.0mm (0.04in.))

Stripping lengths

0.1mm35mm (0.004in.1.38in.)

Stripping lengths with partial

strip

35mm1mm (1.38in.0.04in.)

Wire cross-sections*

0.22mm2 6mm2 (AWG24AWG10)

Optionally from 0.13mm2 (AWG26)

Wire infeed speed

max. 12m/s (39ft/s)

Noise level

<80dB (no crimping module)

Electrical connection

3208 480V / 50 60Hz 5kVA

Pneumatic system

5 8bar (73 116psi) | 9m3/h (318ft3/h)

Weight incl. crimp- und seal

modules

1300 kg (2866lb.)

Extremely hard and tough wires may not be able to be processed even if they are within the above cross section range.

If you are in doubt about your wires, we are happy to process samples of them.

THE WAY TO MAKE IT

More information about

our products:

www.komaxwire.com

Komax Wire is a division

of Komax Holding AG,

Switzerland.

CC. Alpha 355

5000

You might also like

- Ermaksan Epl-PlasmaDocument19 pagesErmaksan Epl-PlasmaMurat KayaNo ratings yet

- Komax Alpha 355 enDocument6 pagesKomax Alpha 355 enAttou Med100% (1)

- Gamma 333Document3 pagesGamma 333हिमांशु बिष्टNo ratings yet

- Zeta 633 / Zeta 633 L: Whole New Dimension of FlexibilityDocument6 pagesZeta 633 / Zeta 633 L: Whole New Dimension of FlexibilityOzanNo ratings yet

- Alpha 355 V2Document2 pagesAlpha 355 V2Daniel TH100% (2)

- Introduction To WiresDocument16 pagesIntroduction To WiresrangabhamNo ratings yet

- Manual Komax Kappa - 310 - 315 - 320 - ENDocument12 pagesManual Komax Kappa - 310 - 315 - 320 - ENGuilherme Sousa100% (1)

- SGM LEKTRA Pmag - T - ENDocument48 pagesSGM LEKTRA Pmag - T - ENEynar FrancoNo ratings yet

- Minic-III en PDFDocument2 pagesMinic-III en PDFmartinNo ratings yet

- The Way To Make IT The Way To Make ITDocument16 pagesThe Way To Make IT The Way To Make ITMnasri Rami0% (1)

- 20160316162112020Document2 pages20160316162112020ahmedNo ratings yet

- MV-20-PC Operation ManualDocument149 pagesMV-20-PC Operation ManualBogdan TabasNo ratings yet

- SIMATIC WinCC Professional V14Document1 pageSIMATIC WinCC Professional V14Pablo JaraNo ratings yet

- Fully automatic twisting machine offers high process security and stabilityDocument12 pagesFully automatic twisting machine offers high process security and stabilityayoub ramziNo ratings yet

- Spirax Sarco Sp500Document68 pagesSpirax Sarco Sp500Mário SantosNo ratings yet

- C Damper 009Document52 pagesC Damper 009Youssef EBNo ratings yet

- Photo Electric SensorDocument176 pagesPhoto Electric SensorAlfiansyah Dharma Setia Djaketra100% (1)

- Spatial transformations in MATLABDocument2 pagesSpatial transformations in MATLABAyman SalehNo ratings yet

- Wiper Motor - : MechanicalDocument8 pagesWiper Motor - : MechanicalAnonymous ytZsBOVNo ratings yet

- Elektro Manual ALPHA 477 488 D EDocument23 pagesElektro Manual ALPHA 477 488 D EIsakov IgorNo ratings yet

- 6210 H Data SheetDocument1 page6210 H Data SheetMgonzalez93No ratings yet

- Erca Formseal Training VinamilkDocument218 pagesErca Formseal Training Vinamilkphong viNo ratings yet

- Rievtech Micro PLC Brochure PDFDocument37 pagesRievtech Micro PLC Brochure PDFjuan c. condori ch.No ratings yet

- VJA 3330 3130 Lesson 2 System OverviewDocument72 pagesVJA 3330 3130 Lesson 2 System Overviewjohn smith100% (1)

- StipDocument22 pagesStipLatisha WalkerNo ratings yet

- Apresentacao en MailDocument19 pagesApresentacao en MailozanozerenNo ratings yet

- Kaschke PPYDocument23 pagesKaschke PPYSameer YadavNo ratings yet

- Simatic Wincc Professional: The SCADA System Inside TIA PortalDocument48 pagesSimatic Wincc Professional: The SCADA System Inside TIA PortalrogeliosigramaNo ratings yet

- FHPP Positioning Library TIADocument43 pagesFHPP Positioning Library TIAMartin Guzman100% (1)

- Example Tickets: Su MM AryDocument2 pagesExample Tickets: Su MM AryfasihaiderNo ratings yet

- Study of Evaluation & Selection of A New Seat Manufacturing Project Using Capital Budgeting Techniques at Lear Automotive India Pvt. LTDDocument22 pagesStudy of Evaluation & Selection of A New Seat Manufacturing Project Using Capital Budgeting Techniques at Lear Automotive India Pvt. LTDkrishna100% (1)

- McQuay MCW-C-H Technical Manual EngDocument20 pagesMcQuay MCW-C-H Technical Manual EngCarlos Can PootNo ratings yet

- Videojet Manual 3120-3320Document126 pagesVideojet Manual 3120-3320Felipe rdzNo ratings yet

- Arm Cortex-M3 Processor DatasheetDocument10 pagesArm Cortex-M3 Processor DatasheetthuhienktvNo ratings yet

- FP2000-1200 Inst Comm v8-1 (English)Document64 pagesFP2000-1200 Inst Comm v8-1 (English)Marius VasiloiuNo ratings yet

- Catalog Altivar Process ATV600 Variable Speed DrivesDocument136 pagesCatalog Altivar Process ATV600 Variable Speed DrivesBarney RossNo ratings yet

- Pac8000 Controllers Ds Gfa1831Document2 pagesPac8000 Controllers Ds Gfa1831mealysrNo ratings yet

- Toshiba Vfp7-4370pDocument250 pagesToshiba Vfp7-4370pLucas Lopes LemosNo ratings yet

- Infranor Variable Speed Drive Implementation: UserguideDocument24 pagesInfranor Variable Speed Drive Implementation: UserguideerasmoNo ratings yet

- Blowing Machine Sbo14 / 11081: NO. Sidel Code Item Disdreption Quntity Unit PicturesDocument6 pagesBlowing Machine Sbo14 / 11081: NO. Sidel Code Item Disdreption Quntity Unit Pictures潘兰平No ratings yet

- Technical Description: 4XP1640.00-K01/K02 & 4XP0000.00-K01Document30 pagesTechnical Description: 4XP1640.00-K01/K02 & 4XP0000.00-K01Justo Alberto Guerra Inca100% (1)

- S7-GRAPH - Mise en Route S7-GRAPH PDFDocument24 pagesS7-GRAPH - Mise en Route S7-GRAPH PDFRata IonNo ratings yet

- Ey Erformance Ndicators: 4wire KPI Dashboard K P IDocument4 pagesEy Erformance Ndicators: 4wire KPI Dashboard K P Ihiba elkremNo ratings yet

- Veichi sd700 Manual v1.0Document289 pagesVeichi sd700 Manual v1.0ronaldoNo ratings yet

- TD Systec Englisch PDFDocument52 pagesTD Systec Englisch PDFStefan MilojevicNo ratings yet

- Realized By:: Class: Internship PeriodDocument24 pagesRealized By:: Class: Internship Periodabir bzNo ratings yet

- 5 KEBA Standard ProtocolDocument50 pages5 KEBA Standard Protocoldedy250591No ratings yet

- AutoCAD 2013Document1 pageAutoCAD 2013Dreamtech PressNo ratings yet

- Leak Test 01CT3PEVLMB Spain+ Engleza + RomanaDocument5 pagesLeak Test 01CT3PEVLMB Spain+ Engleza + RomanaBoeroaia GeorgianNo ratings yet

- Lut400 Quick Start Guide PDFDocument422 pagesLut400 Quick Start Guide PDFJoni MoonNo ratings yet

- Instructions Lubrication System QLS401Document46 pagesInstructions Lubrication System QLS401amaurydesgayets100% (1)

- High-Productivity Inkjet Plotters for Apparel ProductionDocument3 pagesHigh-Productivity Inkjet Plotters for Apparel ProductionJinsu JangNo ratings yet

- CARPROG RNS_510 Navigator DecodeDocument2 pagesCARPROG RNS_510 Navigator Decodevictor hugoNo ratings yet

- s7 1500 CatalogueDocument54 pagess7 1500 CatalogueBenjamín Cares ZalazarNo ratings yet

- s7300 Cpu 31xc Technological Functions Operating Instructions en-US en-USDocument404 pagess7300 Cpu 31xc Technological Functions Operating Instructions en-US en-USNguyen Minh Thuong100% (1)

- Magnetic Particle Equipment Selection GuideDocument16 pagesMagnetic Particle Equipment Selection GuideWellington S. FrançaNo ratings yet

- Magnetic Particle Inspection EquipmentDocument16 pagesMagnetic Particle Inspection EquipmentSergio CalderonNo ratings yet

- Modprint 2020EC & Modprint 2020A Hot Stamp Printers for Insulated WireDocument2 pagesModprint 2020EC & Modprint 2020A Hot Stamp Printers for Insulated WireIlayaraja BoopathyNo ratings yet

- Komax Alpha 477 enDocument6 pagesKomax Alpha 477 ensamir abdellaouiNo ratings yet

- 9 PRO Alpha550 ENDocument12 pages9 PRO Alpha550 ENZayene KhmaisNo ratings yet

- DeltaOHM HD52.3D Manual ENGDocument44 pagesDeltaOHM HD52.3D Manual ENGGuillermo BetancourtNo ratings yet

- MMO Operator Manual OverviewDocument48 pagesMMO Operator Manual OverviewGuillermo BetancourtNo ratings yet

- Snapshots SIPROTEC 5Document7 pagesSnapshots SIPROTEC 5Guillermo BetancourtNo ratings yet

- SIP 5 - Hardware DescriptionDocument77 pagesSIP 5 - Hardware DescriptionGuillermo BetancourtNo ratings yet

- Neutral Earthing - SiemensDocument77 pagesNeutral Earthing - SiemensArnab BanerjeeNo ratings yet

- Sync Check CB1 Selection LogicDocument9 pagesSync Check CB1 Selection LogicGuillermo BetancourtNo ratings yet

- Test Suite Siprotec 5Document27 pagesTest Suite Siprotec 5Guillermo BetancourtNo ratings yet

- RAYMOND Manual PDFDocument240 pagesRAYMOND Manual PDFsugar4471% (7)

- RAYMOND Manual PDFDocument240 pagesRAYMOND Manual PDFsugar4471% (7)

- Testing and Maintenance of Steam TrapsDocument8 pagesTesting and Maintenance of Steam TrapsAjaypalsinh GohilNo ratings yet

- Gaspardo MAESTRA 2004-02 (19530520)Document78 pagesGaspardo MAESTRA 2004-02 (19530520)costelchelariuNo ratings yet

- Aerodrome Controller (ADC) ExamDocument5 pagesAerodrome Controller (ADC) ExamaxnpicturesNo ratings yet

- Tacloban Master Training Schedule (January-June 2012) For Web New FormatDocument5 pagesTacloban Master Training Schedule (January-June 2012) For Web New FormatFariq AdlawanNo ratings yet

- Meshing Methods (ANSYS Meshing) - Everyone Is Number OneDocument14 pagesMeshing Methods (ANSYS Meshing) - Everyone Is Number Oneicemage1991No ratings yet

- Operating Procedure ERLDCDocument154 pagesOperating Procedure ERLDCbramhanand vermaNo ratings yet

- Sustainable Transport Development in Nepal: Challenges and StrategiesDocument18 pagesSustainable Transport Development in Nepal: Challenges and StrategiesRamesh PokharelNo ratings yet

- Specification Substation AutomationDocument258 pagesSpecification Substation Automationmspd2003100% (1)

- DirectX 11 Practical ProjectsDocument64 pagesDirectX 11 Practical Projectszubair ansariNo ratings yet

- Grade CalculatorDocument1 pageGrade CalculatorKHENN ALDIANONo ratings yet

- Vapor Pressure Experiment Data AnalysisDocument3 pagesVapor Pressure Experiment Data AnalysisRanaNo ratings yet

- Standing Waves Worksheet SolutionsDocument6 pagesStanding Waves Worksheet SolutionsMaher TrabelsiNo ratings yet

- Transient Analysis of Electrical Circuits Using Runge-Kutta Method and Its ApplicationDocument5 pagesTransient Analysis of Electrical Circuits Using Runge-Kutta Method and Its ApplicationSwati kNo ratings yet

- Article ASI Magazine September 2014 Fumed Silica in Adhesives and Sealants FormulationsDocument4 pagesArticle ASI Magazine September 2014 Fumed Silica in Adhesives and Sealants FormulationsdombaraNo ratings yet

- Pfaff 360 Sewing Machine Instruction ManualDocument55 pagesPfaff 360 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Concept of Stress: DR Atul JAIN Mechanical Engineering Department Indian Institute of Technology KharagpurDocument57 pagesConcept of Stress: DR Atul JAIN Mechanical Engineering Department Indian Institute of Technology Kharagpursneha KumariNo ratings yet

- How To Build A Backyard PergolaDocument15 pagesHow To Build A Backyard PergolaMichael Wilkins100% (1)

- NPS-1 Piano Stand Lnstallation Guide: List of PartsDocument2 pagesNPS-1 Piano Stand Lnstallation Guide: List of PartsFian PanekenanNo ratings yet

- TMForumOpenAPIs EnablingAZeroIntergrationAPIeconomyDocument30 pagesTMForumOpenAPIs EnablingAZeroIntergrationAPIeconomyjdaoukNo ratings yet

- Queen Sala Celinda Del Rosario LECCION2 Actividad de Produccion 2.4Document4 pagesQueen Sala Celinda Del Rosario LECCION2 Actividad de Produccion 2.4Salustino AbreuNo ratings yet

- UML Modeling and Performance Evaluation of Multithreaded Programs On Dual Core ProcessorDocument10 pagesUML Modeling and Performance Evaluation of Multithreaded Programs On Dual Core ProcessorseravanakumarNo ratings yet

- Nonwoven Material StandardsDocument5 pagesNonwoven Material StandardsRajesh Dwivedi0% (1)

- Software Development Handbook Transforming For The Digital Age PDFDocument75 pagesSoftware Development Handbook Transforming For The Digital Age PDFdreamer4077No ratings yet

- AC 43-9-1 Amdt 0Document15 pagesAC 43-9-1 Amdt 0Harry NuryantoNo ratings yet

- Assist. Prof. DR - Thaar S. Al-Gasham, Wasit University, Eng. College 136Document49 pagesAssist. Prof. DR - Thaar S. Al-Gasham, Wasit University, Eng. College 136Hundee HundumaaNo ratings yet

- Brocade Ciscomds Cli ComparisonDocument17 pagesBrocade Ciscomds Cli ComparisonprocomphysNo ratings yet

- NOx Control of Kiln and Preheater Complete AnalysisDocument129 pagesNOx Control of Kiln and Preheater Complete AnalysisAnonymous sfY8T3q0100% (2)

- EMB 20100301 Mar 2010Document156 pagesEMB 20100301 Mar 2010agnithiumNo ratings yet

- Partition WallDocument24 pagesPartition WallSHRADDHA GHUGENo ratings yet

- Geberit Sanitary Catalogue 2017 2018Document348 pagesGeberit Sanitary Catalogue 2017 2018Po MoNo ratings yet