Professional Documents

Culture Documents

Tds - Emaco r303

Uploaded by

Venkata RaoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tds - Emaco r303

Uploaded by

Venkata RaoCopyright:

Available Formats

EMACO R303

Single component polymer modified

fairing coat cosmetic mortar for concrete

surfaces

Description

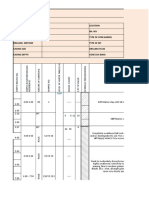

Typical properties*

EMACO R303 is a single component acrylic polymer

modified repair mortar for use as a "fairing coat" or cosmetic

mortar. When mixed with water, as directed, a fine grey

trowellable mortar results which can readily be applied to fill

in pores, blowholes and blemishes on a concrete surface.

Plastic density:

Compressive strength at 28 days

EMACO R303 can be used as a 'skim' coat prior to the

application of protective coatings.

EMACO R303 should be applied to the complete area with

the minimum of trowelling. Leave for a short period before

final trowelling. Finishing may be aided by flicking a small

amount of water onto the surface, using a paint brush before

final trowelling.

EMACO R303 is specially formulated to produce a

shrinkage compensating mortar with no cracking when

applied in a thin section. Adhesion to concrete and flexibility

are excellent.

Primary uses

As a fairing or skim coat to cover and make good

blemishes in concrete surfaces such as slight

honeycombing, blowholes, defects caused by 'sand

runs', patch repairs, shutter movement and grout loss.

Preparatory treatment to concrete to receive a thin film

protective coating.

To produce a uniform surface over repaired areas.

Advantages

Precision made, consistent results.

Requires only the addition of mixing water.

Shrinkage compensating.

Excellent adhesion to concrete.

Flexible.

Smooth, easily produced finish.

Low permeability

Excellent resistance to freeze / thaw action and

carbonation

Ingress of water borne salts, such as chloride and

atmospheric / chemical attack.

Subsequent paint coats can be applied with greater

economy.

Packaging

EMACO R303 is supplied in 25kg bags.

1700kg/m

27N/mm

Application

When used as a "scrape coat" EMACO R303 can be applied

with a brush or roller and then the excess scraped off with

the edge of a steel float. In this way blow holes and minor

blemishes in an otherwise fair faced concrete can be hidden.

Curing:

Good curing practice is essential even though EMACO

R303 is specially formulated to prevent shrinkage and

cracking. Particular care is required in hot and windy

conditions.

Cure with a single coat of MASTERKURE 181 which is

compatible with most subsequent protective coatings, or by

covering the work with a properly secured plastic sheeting.

Preparation:

It is essential that the surfaces to be bonded are sound,

clean and uncontaminated. All loose powdering material

must be removed.

Concrete surfaces should be thoroughly soaked prior to

application of EMACO R303, to ensure a saturated, but

surface dry condition.

Void filling:

Deeper voids should be filled prior to the application of a

cosmetic coating by reducing the amount of water added

when mixing to produce a trowellable putty like mortar.

Mixing:

EMACO R303 is formulated to give an easily mixed

material. For full bag quantities, it is preferable to mix the

material in a Creteangle or similar forced action mixer.

Alternatively, a slow speed, hand held electric mixer with a

suitable paddle can be used. Over mixing should be

avoided. The powder should be placed in the mixing vessel

and mixing commenced. Clean water should be slowly

added up to the recommended maximum or until the

required consistency is achieved. No more than 4.75 litres of

water per 25kg of EMACO R303 should be added.

Coverage

One 25kg bag of EMACO R303 will typically yield 16 litres of

mortar and will cover approximately 6.3m at 2.5mm

thickness.

Quality and care

All products originating from Degussas Dubai, UAE facility

are manufactured under a management system

independently certified to conform to the requirements of the

quality, environmental and occupational health & safety

standards ISO 9001, ISO 14001 and OHSAS 18001.

12/94 Degussa-UAE revised 11/2004

Equipment care

* Properties listed are only for guidance and are not a guarantee of

performance.

Tools should be washed with water immediately after use.

Specification clause

Surface finishing:

All slight surface imperfections should be made good by the

application of EMACO R303 as manufactured by Degussa.

Applications should be strictly in accordance with the

manufacturer's instructions.

Storage

Store out of direct sunlight, clear of the ground on pallets

protected from rainfall. Avoid excessive compaction.

Failure to comply with the recommended storage conditions

may result in premature deterioration of the product or

packaging. For specific storage advice consult Degussa's

Technical Services Department.

Safety precautions

As with all chemical products, care should be taken during

use and storage to avoid contact with eyes, mouth, skin and

foodstuffs. Treat splashes to eyes and skin immediately. If

accidentally ingested, seek medical attention. Reseal

containers after use. Use in well ventilated areas and avoid

inhalation. For further information refer to the material

safety data sheet.

Note

Field service, where provided, does not constitute

supervisory responsibility. For additional information contact

your local Degussa representative.

Degussa reserves the right to have the true cause of any

difficulty determined by accepted test methods.

Degussa Construction Chemicals UAE LLC

P.O. Box 37127, Dubai, UAE

Tel: +971 4 8851000

Fax: +971 4 8851002

www.degussa-cc.ae

e-mail: marketingcc.mideast@degussa.com

Whilst any information contained herein is true, accurate and

represents our best knowledge and experience, no warranty is given or

implied with any recommendations made by us, our representatives or

distributors, as the conditions of use and the competence of any labour

involved in the application are beyond our control.

Certificate No.

963680

As all Degussa technical datasheets are updated on a regular basis it is the user's responsibility to obtain the most recent issue.

Certificate No.

945787

Certificate No.

772556

You might also like

- Tds - Emaco r307Document2 pagesTds - Emaco r307Venkata RaoNo ratings yet

- Emaco R303: Single Component Polymer Modified Fairing Coat / Cosmetic Mortar For Concrete SurfacesDocument3 pagesEmaco R303: Single Component Polymer Modified Fairing Coat / Cosmetic Mortar For Concrete SurfacesFrancois-No ratings yet

- 13 - TDS - Emaco S43 NTDocument3 pages13 - TDS - Emaco S43 NTaahtagoNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- MasterEmaco N 303 Formerly Emaco - R303M - EGDocument2 pagesMasterEmaco N 303 Formerly Emaco - R303M - EGMohiuddin Muhin100% (1)

- Tds - Emaco r301Document2 pagesTds - Emaco r301Venkata Rao0% (1)

- TDS - Mastertop 300Document3 pagesTDS - Mastertop 300Venkata RaoNo ratings yet

- TDS - Masterseal 381Document2 pagesTDS - Masterseal 381Venkata RaoNo ratings yet

- Masteremaco S 348Document2 pagesMasteremaco S 348shahzadNo ratings yet

- Masteremaco S 348: Dual Shrinkage Compensated, Trowelable Fibre Reinforced Thixotropic Repair MortarDocument2 pagesMasteremaco S 348: Dual Shrinkage Compensated, Trowelable Fibre Reinforced Thixotropic Repair MortardepakmunirajNo ratings yet

- Master EmacoDocument3 pagesMaster EmacoSmookers HeavenNo ratings yet

- Weatherproofing Water StructuresDocument4 pagesWeatherproofing Water StructuresAkhilNo ratings yet

- TDS - Mastertop 200Document2 pagesTDS - Mastertop 200Venkata RaoNo ratings yet

- Masteremaco N 303 TdsDocument2 pagesMasteremaco N 303 TdsBijaya RaulaNo ratings yet

- Cemtop 400SD: Cement Based, Self Levelling, Industrial Floor Surfacing System - 6mm To 12mmDocument4 pagesCemtop 400SD: Cement Based, Self Levelling, Industrial Floor Surfacing System - 6mm To 12mmBalasubramanian AnanthNo ratings yet

- MasterEmaco - S 348 v2Document2 pagesMasterEmaco - S 348 v2Umeshchandra PatilNo ratings yet

- Masteremaco - S 348 v2Document2 pagesMasteremaco - S 348 v2shahzadNo ratings yet

- Rheomix 157 Pds Asean 311209Document2 pagesRheomix 157 Pds Asean 311209Gabriel LimNo ratings yet

- High Strength Epoxy Mortar for Manhole RehabilitationDocument1 pageHigh Strength Epoxy Mortar for Manhole Rehabilitationpravi3434No ratings yet

- Basf Masteremaco S 488 TdsDocument3 pagesBasf Masteremaco S 488 TdsArindamBhattacharjee100% (2)

- TDS - Emaco S88 PlusDocument2 pagesTDS - Emaco S88 PlusVenkata RaoNo ratings yet

- TDS - Emaco R907 PlusDocument2 pagesTDS - Emaco R907 PlusVenkata RaoNo ratings yet

- Basf Masteremaco S 488 v1 TdsDocument2 pagesBasf Masteremaco S 488 v1 Tdsraahul_nNo ratings yet

- 13 - Tds - Emaco s43 NTDocument3 pages13 - Tds - Emaco s43 NTmanil_5No ratings yet

- Master Emaco S5400Document2 pagesMaster Emaco S5400WahyudiBlueghostNo ratings yet

- High-strength structural repair mortarDocument4 pagesHigh-strength structural repair mortarBhanuka SamarakoonNo ratings yet

- TDS - Emaco S68 PlusDocument3 pagesTDS - Emaco S68 PlusVenkata RaoNo ratings yet

- 05 - TDS - Mastertop 300Document4 pages05 - TDS - Mastertop 300Vimal KakNo ratings yet

- Basf MasterEmaco S 488Document3 pagesBasf MasterEmaco S 488abdul majeedNo ratings yet

- MasterProtect 300Document3 pagesMasterProtect 300Gavriel NgNo ratings yet

- TDS - Emaco S66 TDocument2 pagesTDS - Emaco S66 TVenkata RaoNo ratings yet

- MasterEmaco N 301-190315Document2 pagesMasterEmaco N 301-190315Irshad Ali DurraniNo ratings yet

- Masteremaco N 303 TdsDocument2 pagesMasteremaco N 303 TdsChaitanya MehtaNo ratings yet

- TDS - Masterseal 300HDocument3 pagesTDS - Masterseal 300HVenkata RaoNo ratings yet

- Brush BondDocument4 pagesBrush BondVenkata RaoNo ratings yet

- Masteremaco S 488: Dual Shrinkage Compensated, Trowelable Fibre Reinforced Thixotropic Repair MortarDocument2 pagesMasteremaco S 488: Dual Shrinkage Compensated, Trowelable Fibre Reinforced Thixotropic Repair MortarAvinash PrajapatiNo ratings yet

- Tds - Emaco s88c TDocument2 pagesTds - Emaco s88c TVenkata RaoNo ratings yet

- TDS - Masterkure 161Document2 pagesTDS - Masterkure 161Venkata Rao0% (1)

- Tds - Emaco s66 CPDocument2 pagesTds - Emaco s66 CPVenkata RaoNo ratings yet

- TDs - Emaco R101Document3 pagesTDs - Emaco R101Venkata RaoNo ratings yet

- sHOTPATCH 10 v3 PDFDocument2 pagessHOTPATCH 10 v3 PDFAnkita Baban GavadeNo ratings yet

- MasterEmaco - S 348 v1Document2 pagesMasterEmaco - S 348 v1vahab_shaik0% (1)

- Abrasion-Resistant Epoxy Lining MortarDocument4 pagesAbrasion-Resistant Epoxy Lining MortarBalasubramanian AnanthNo ratings yet

- Masteremaco S 346 v1Document2 pagesMasteremaco S 346 v1Bijaya RaulaNo ratings yet

- TDS - Mastertop 1740Document3 pagesTDS - Mastertop 1740Venkata RaoNo ratings yet

- Masteremaco S 488: Structural Repair MortarDocument3 pagesMasteremaco S 488: Structural Repair MortarKhan ShahzebNo ratings yet

- TDS - Mastertop 1710Document2 pagesTDS - Mastertop 1710Venkata RaoNo ratings yet

- BASF MasterEmaco S488Document2 pagesBASF MasterEmaco S488HJNo ratings yet

- Repair Concrete StructuresDocument3 pagesRepair Concrete StructuresSindhe SwethaNo ratings yet

- 2.MasterEmaco N 301 - KSADocument2 pages2.MasterEmaco N 301 - KSAIRFAN NAZIRNo ratings yet

- Mastertop 1330m 12-04Document3 pagesMastertop 1330m 12-04djrote4No ratings yet

- MasterEmaco - S650 v1 PDFDocument2 pagesMasterEmaco - S650 v1 PDFPuneet AggarwalNo ratings yet

- tHORO STRUCTURITE PRIMER - v3Document2 pagestHORO STRUCTURITE PRIMER - v3Ankita Baban GavadeNo ratings yet

- ucrete-pfs-tdsDocument2 pagesucrete-pfs-tdsAbdul YaskarNo ratings yet

- Betakril: Decorative Water-Based Exterior Product GroupDocument2 pagesBetakril: Decorative Water-Based Exterior Product Groupmaga2292No ratings yet

- Smartsil 38 ErDocument3 pagesSmartsil 38 ErAnkita Baban GavadeNo ratings yet

- High-Strength Epoxy Grout Data SheetDocument2 pagesHigh-Strength Epoxy Grout Data SheetAtulNo ratings yet

- Appendix B - To Form of TenderDocument7 pagesAppendix B - To Form of TenderVenkata RaoNo ratings yet

- Volume 1 - Instruction To Tenderers & CoCDocument105 pagesVolume 1 - Instruction To Tenderers & CoCVenkata RaoNo ratings yet

- TRA Telecommunications Infra Deployment 2008Document101 pagesTRA Telecommunications Infra Deployment 2008Venkata RaoNo ratings yet

- 875 4 PDFDocument10 pages875 4 PDFVenkata RaoNo ratings yet

- Nass King Abdulla Medical City 1Document10 pagesNass King Abdulla Medical City 1Venkata RaoNo ratings yet

- Plasterroc MPRDocument2 pagesPlasterroc MPRVenkata RaoNo ratings yet

- Soil InvestigationDocument6 pagesSoil InvestigationVenkata RaoNo ratings yet

- CIOB - Construction Claims in The UAEDocument24 pagesCIOB - Construction Claims in The UAEVenkata Rao100% (1)

- APC Pathways and Competencies Forthcoming Changes in 2018Document3 pagesAPC Pathways and Competencies Forthcoming Changes in 2018Venkata RaoNo ratings yet

- Testing & InspectionDocument2 pagesTesting & InspectionVenkata RaoNo ratings yet

- Plasterroc MPRDocument2 pagesPlasterroc MPRVenkata RaoNo ratings yet

- Pe IeiDocument3 pagesPe IeiVenkata RaoNo ratings yet

- TDS - Shotpatch 10Document2 pagesTDS - Shotpatch 10Venkata RaoNo ratings yet

- Standard DrawingsDocument134 pagesStandard DrawingsVenkata RaoNo ratings yet

- TDS - Mastertop 1210 PlusDocument2 pagesTDS - Mastertop 1210 PlusVenkata RaoNo ratings yet

- TDS - Sonoshield ParkcoatDocument2 pagesTDS - Sonoshield ParkcoatVenkata RaoNo ratings yet

- TDS - Masterseal 300HDocument3 pagesTDS - Masterseal 300HVenkata RaoNo ratings yet

- TDS - Masterseal Blow Hole FillerDocument1 pageTDS - Masterseal Blow Hole FillerVenkata RaoNo ratings yet

- Recommended Application Procedures: CoatingsDocument1 pageRecommended Application Procedures: CoatingsVenkata RaoNo ratings yet

- TDS - Concresive ERLDocument2 pagesTDS - Concresive ERLVenkata RaoNo ratings yet

- Tds - Emaco Cp10h - Emaco Cp10vDocument3 pagesTds - Emaco Cp10h - Emaco Cp10vVenkata RaoNo ratings yet

- TDS - Emaco CP 30Document3 pagesTDS - Emaco CP 30Venkata RaoNo ratings yet

- Tds - Emaco s66 CPDocument2 pagesTds - Emaco s66 CPVenkata RaoNo ratings yet

- TDS - Emaco CP 60Document3 pagesTDS - Emaco CP 60Venkata RaoNo ratings yet

- Fast Setting Grout for Embedding Discrete AnodesDocument2 pagesFast Setting Grout for Embedding Discrete AnodesVenkata RaoNo ratings yet

- TDS - Masterseal SP120Document2 pagesTDS - Masterseal SP120Venkata RaoNo ratings yet

- Tds - Emaco Cp10h - Emaco Cp10vDocument3 pagesTds - Emaco Cp10h - Emaco Cp10vVenkata RaoNo ratings yet

- Tds - Emaco Cp20Document3 pagesTds - Emaco Cp20Venkata RaoNo ratings yet

- TDS - Masterseal 180Document2 pagesTDS - Masterseal 180Venkata RaoNo ratings yet

- Surface Applied Corrosion Inhibitor for ConcreteDocument2 pagesSurface Applied Corrosion Inhibitor for ConcreteVenkata RaoNo ratings yet

- Mapping India DEFDocument74 pagesMapping India DEFAlaina LongNo ratings yet

- Assignment-10 CE39 NOC20Document7 pagesAssignment-10 CE39 NOC20jayadeep ksNo ratings yet

- BuchananandGardner2019 Metal3Dprintinginconstruction AreviewDocument37 pagesBuchananandGardner2019 Metal3Dprintinginconstruction AreviewJoão PraganaNo ratings yet

- Building Energy Efficiency Technical Guideline For Passive Design PDFDocument196 pagesBuilding Energy Efficiency Technical Guideline For Passive Design PDFFirrdhaus Sahabuddin100% (1)

- 2 NDDocument3 pages2 NDAgnes AsilNo ratings yet

- Prueba y Ajuste Sistema HidraulicoDocument55 pagesPrueba y Ajuste Sistema HidraulicoIginio Malaver VargasNo ratings yet

- 1.03 - High-Rise Buildings PDFDocument19 pages1.03 - High-Rise Buildings PDFNicolas De NadaiNo ratings yet

- City of Redwood City Supervising Civil EngineerDocument3 pagesCity of Redwood City Supervising Civil EngineerhamadaNo ratings yet

- MasterFlow - 400 v1 - 2Document2 pagesMasterFlow - 400 v1 - 2Vivek GaurNo ratings yet

- SD05wi1 Structural Inspection WorkpackDocument22 pagesSD05wi1 Structural Inspection WorkpackidrisNo ratings yet

- Earth Pressure CalculationsDocument35 pagesEarth Pressure Calculationskeddy lamarNo ratings yet

- Luminaire Schedule-Exterior Facade Rev.02Document2 pagesLuminaire Schedule-Exterior Facade Rev.02NATHANNo ratings yet

- Afa Sebf9066-00Document95 pagesAfa Sebf9066-00Edwarth MazaNo ratings yet

- PT Concrete Slabs: Types and AdvantagesDocument18 pagesPT Concrete Slabs: Types and AdvantagesAakash MohanNo ratings yet

- Foundation Force TransmissionDocument8 pagesFoundation Force Transmissiondeepakram04No ratings yet

- GC Guy Wire (US) Catalog Sheet FinalDocument1 pageGC Guy Wire (US) Catalog Sheet FinalAde 'aiyie' SasmitaNo ratings yet

- Salberg A4 Catalogue RevisedDocument28 pagesSalberg A4 Catalogue RevisedSinenhlanhlaNo ratings yet

- The World's First RPC Road Bridge at Shepherds Gully Creek, NSWDocument12 pagesThe World's First RPC Road Bridge at Shepherds Gully Creek, NSWtiagojosesantosNo ratings yet

- Bore LogDocument4 pagesBore LogVardhanNo ratings yet

- Machine Design IgnouDocument181 pagesMachine Design IgnouAnup ChoudharyNo ratings yet

- Pile Design CalculationDocument69 pagesPile Design Calculationhessian123No ratings yet

- Raft Modeling in Etabs - Foundation Design - Structural Engineering Forum of Pakistan PDFDocument1 pageRaft Modeling in Etabs - Foundation Design - Structural Engineering Forum of Pakistan PDFKenny Manuel Vettoor100% (1)

- GP (6) Central Market KLDocument12 pagesGP (6) Central Market KLAmirul Hakim SabriNo ratings yet

- ProkonDocument7 pagesProkonTravel DiariesNo ratings yet

- STRENGTH OF MATERIALS REFRESHER SETDocument4 pagesSTRENGTH OF MATERIALS REFRESHER SETGracielle Nebres67% (3)

- Never-Seez® India Call +91-891-6666482Document2 pagesNever-Seez® India Call +91-891-6666482Project Sales CorpNo ratings yet

- Fxsq100-125a Dim 3d094917a enDocument1 pageFxsq100-125a Dim 3d094917a enDragos PicuNo ratings yet

- Ruukki Load Bearing Profiled Sheet Installation InstructionsDocument20 pagesRuukki Load Bearing Profiled Sheet Installation InstructionsEmanuel PopaNo ratings yet

- Assignment-2 Shear StrengthDocument3 pagesAssignment-2 Shear StrengthRabindraSubediNo ratings yet

- Concrete Batch Plant Control Plan PDFDocument42 pagesConcrete Batch Plant Control Plan PDFkatfy1No ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Guidelines for Siting and Layout of FacilitiesFrom EverandGuidelines for Siting and Layout of FacilitiesNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsFrom EverandGuidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsNo ratings yet

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisFrom EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisNo ratings yet

- An Applied Guide to Water and Effluent Treatment Plant DesignFrom EverandAn Applied Guide to Water and Effluent Treatment Plant DesignRating: 5 out of 5 stars5/5 (4)

- Robotics: Designing the Mechanisms for Automated MachineryFrom EverandRobotics: Designing the Mechanisms for Automated MachineryRating: 4.5 out of 5 stars4.5/5 (8)

- Guidelines for Developing Quantitative Safety Risk CriteriaFrom EverandGuidelines for Developing Quantitative Safety Risk CriteriaNo ratings yet

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- Perfume Engineering: Design, Performance and ClassificationFrom EverandPerfume Engineering: Design, Performance and ClassificationRating: 4 out of 5 stars4/5 (5)

- Temperature-Responsive Polymers: Chemistry, Properties, and ApplicationsFrom EverandTemperature-Responsive Polymers: Chemistry, Properties, and ApplicationsNo ratings yet

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesFrom EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo ratings yet

- Bow Ties in Risk Management: A Concept Book for Process SafetyFrom EverandBow Ties in Risk Management: A Concept Book for Process SafetyNo ratings yet