Professional Documents

Culture Documents

Welding Rod For c5 & f5 - Er 80s-b6

Uploaded by

SatyamEng0 ratings0% found this document useful (0 votes)

663 views1 pagewelding rod

Original Title

Welding Rod for c5 & f5 - Er 80s-b6 - Copy

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentwelding rod

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

663 views1 pageWelding Rod For c5 & f5 - Er 80s-b6

Uploaded by

SatyamEngwelding rod

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

U.S. ALLOY CO.

USA 80S-B6

Welding Wire and Rod

dba Washington Alloy

7010-G Reames Rd.

Charlotte, NC 28216

www.weldingwire.com

Quality Management System

in accordance with

ISO 9001:2000

Cert # 05-R0925

ALLOY DESCRIPTION AND APPLICATION;

80S-B6 is a low alloy Cr-Mo filler commonly used in the oil and chemical industries where

base metal such as 5% Cr, 1/2% Mo steels are found. Typical base metals found in this

group are ASTM grades: A182-F5/F5a, A336-F5/F5a, A199-T-5, A200-T5, A213-T5,

A335-P5, A369-FP5, A426-CP5, A217-C5, and A387-Gr5. Controlled preheat, interpass

and postheat treatment may be needed. 80S-B6 is similar to the previously classified

ER502 in AWS A5.9-93

(1)

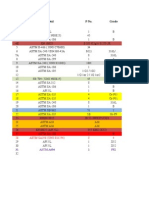

TYPICAL GMAW WELDING PROCEDURES; DCEP Short Circuit

98Ar/2% O2

Wire Diameter Wire Speed (ipm) Amps

Volts Travel speed (ipm) 75/25 CO2 (cfh)

0.023

80-350

30-85

14-19

10-15

20-25

0.030

110-340

40-130

15-20

12-24

20-25

0.035

100-520

60-235

16-25

11-40

20-30

0.045

70-270

90-290

18-23

12-22

25-35

(1)

Spray 0.035

320-600

160-300

23-26

11-22

25-35

(1)

0.045

170-550

170-375

23-29

12-21

25-35

(1)

1/16

175-350

275-475

25-31

9-19

25-35

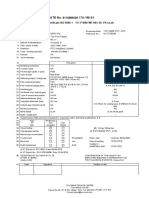

TYPICAL GTAW WELDING PROCEDURES; DCEN with EWTh-2 truncated conical tip

Filler Wire Size Tungsten Amps

Volts Gas Cup Size Argon (cfh) Base thickness

1/16

1/16

100-160

12

3/8

20

1/16-3/32

1/16-3/32

3/32

120-250

12

3/8

20

1/8- 3/16

1/8

1/8

150-300

12

1/2

25

1/4-1/2

Procedures may vary with change in position, base metals, filler metals, equipment and other changes.

WIRE CHEMISTRY (%) AND WELD METAL PROPERTIES;

Carbon

Manganese

Silicon

Phosphorus

Sulfur

Molybdenum

Chromium

AWS Spec.

0.10 max

0.40-0.70

0.50 max

0.025 max

0.025 max

0.45-0.65

4.50-6.00

Tensile Strength (psi)

Yield Strength (psi)

Elongation in 2

AWS Spec

80,000 min.

68,000 min.

17% min.

Nickel

Copper

0.60 max

0.35 max

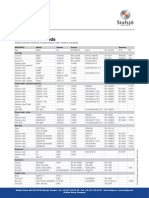

AVAILABLE SIZES: TC 502 = Spools and rods of .035, .045, 1/16,

TT 502 = Cut lengths of .035, .045, 1/16, 3/32, 1/8, 5/32

Other sizes available please inquire

SPECIFICATIONS; ANSI/AWS A5.28 ER 80S-B6

ASME SFA 5.28

ER 80S-B6 ; A-4, F-6

EAST COAST

GULF COAST

WEST COAST

8-2007 DC

7010-G Reames Rd

4855 Alpine Drive #190

8535 Utica Ave

Charlotte, NC 28216

Stafford, TX 77477

Rancho Cucamonga, CA 91730

Tel (888) 522-8296

Tel (877) 711-9274

Tel(800)830-9033

Fax (704)598-6673

Fax (281)313-6332

Fax (909)291-4586

Warehouse Distribution Center Dayton, Ohio

Head Office Puyallup, Washington

Washington Alloy Company believes that all information and data given is correct. Use this information to assist in making your

own evaluations or decisions and this information should not be mistaken as an expressed or implied warranty. U.S. ALLOY CO.

assumes no liability for results or damages incurred from the use of any information contained herein, in whole or in part.

You might also like

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNo ratings yet

- ASTM A36 DatasheetDocument4 pagesASTM A36 DatasheetRene D. ArrietaNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- Wps PQRDocument7 pagesWps PQRsobariNo ratings yet

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- BohlerThyssen PDFDocument386 pagesBohlerThyssen PDFElMacheteDelHuesoNo ratings yet

- Welding SAF2205 Tubes To CS TubesheetDocument2 pagesWelding SAF2205 Tubes To CS Tubesheetmasterdol1983No ratings yet

- Stainless Steel Alloys Comparsion ChartDocument3 pagesStainless Steel Alloys Comparsion Chartsengcyan100% (1)

- Nickel Alloy Based Filler MetalDocument1 pageNickel Alloy Based Filler MetaljoehodohNo ratings yet

- Tungsten ElectrodesDocument2 pagesTungsten ElectrodesSyed Furqan Rehmani0% (2)

- Data Sheet Material 2.4819Document3 pagesData Sheet Material 2.4819BoberNo ratings yet

- C43Document1 pageC43rudramansingh123No ratings yet

- W-55 PLATE ID CARDDocument6 pagesW-55 PLATE ID CARDKrishnan TnNo ratings yet

- Carbon Steel Pipes - Comparing AmericanDocument2 pagesCarbon Steel Pipes - Comparing AmericanKazi Anwarul Azim SohelNo ratings yet

- Test Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)Document1 pageTest Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)yskushwah16No ratings yet

- FCAW Electrode DesignationDocument3 pagesFCAW Electrode DesignationthedreampowerNo ratings yet

- Nip Material ComparsionDocument1 pageNip Material ComparsionRob WillestoneNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- IRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Document4 pagesIRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Mostafizur RahmanNo ratings yet

- A 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFDocument16 pagesA 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFshakeelahmadjsrNo ratings yet

- Mild Steel Welding ElectrodeDocument12 pagesMild Steel Welding ElectrodeVĩnh NguyễnNo ratings yet

- Thermanit 17-06 (Boehler)Document1 pageThermanit 17-06 (Boehler)queno1No ratings yet

- Graycor WPS 19 SampleDocument5 pagesGraycor WPS 19 SampleRaul SebastiamNo ratings yet

- Astm A36 Chapa Grossa Ate 19mm PDFDocument1 pageAstm A36 Chapa Grossa Ate 19mm PDFHugo RodriguezNo ratings yet

- Highlights On ASME Essential VariablesDocument8 pagesHighlights On ASME Essential VariableschowhkNo ratings yet

- 1 7335Document5 pages1 7335stamatsNo ratings yet

- Hydro Aluminium - AlSi7Mg0.6Document2 pagesHydro Aluminium - AlSi7Mg0.6Raj PrasanthNo ratings yet

- Spec Grade Number Symbol Number Symbol Asme (Astm) KS JISDocument50 pagesSpec Grade Number Symbol Number Symbol Asme (Astm) KS JISVinay TrivediNo ratings yet

- Hyundai Electrode CATALOG - 7thDocument134 pagesHyundai Electrode CATALOG - 7tharianaseri100% (1)

- Din 17100Document4 pagesDin 17100Sheby SandyNo ratings yet

- GMAWDocument12 pagesGMAWsushant47No ratings yet

- Material With Electrode SelectionDocument2 pagesMaterial With Electrode SelectionAhmadiBinAhmadNo ratings yet

- Astm A106 Ts EnglDocument4 pagesAstm A106 Ts EnglxaviereduardoNo ratings yet

- Welding BisplateDocument12 pagesWelding BisplateLim Senglin100% (1)

- Material Reference ListDocument7 pagesMaterial Reference ListionijhonnieNo ratings yet

- Material Datea 2.4602Document3 pagesMaterial Datea 2.4602Charwin XiaoNo ratings yet

- Duplex Stainless Steel - Part 2 - TWIDocument6 pagesDuplex Stainless Steel - Part 2 - TWItuanNo ratings yet

- Is 1570 1Document17 pagesIs 1570 1Raj K Sharma100% (1)

- Base Metal P No. Grade PQR No.: 28 ASTM SA358 (UNS S31254) 8 4Document3 pagesBase Metal P No. Grade PQR No.: 28 ASTM SA358 (UNS S31254) 8 4MAT-LIONNo ratings yet

- QCF312 WPQRDocument2 pagesQCF312 WPQRminhnnNo ratings yet

- ASTM A694 F60 - Heat Treatment and Mechanical Properties - ICRF 2012Document3 pagesASTM A694 F60 - Heat Treatment and Mechanical Properties - ICRF 2012Noushad Bin JamalNo ratings yet

- Impact AR500 PlateDocument2 pagesImpact AR500 PlateMario Diez100% (1)

- BHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelDocument2 pagesBHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelpradhankruhsnaNo ratings yet

- Chemical and Mechanical PropertiesDocument5 pagesChemical and Mechanical PropertiesAristotle MedinaNo ratings yet

- Asme Section Ii A-2 Sa-815 Sa-815mDocument10 pagesAsme Section Ii A-2 Sa-815 Sa-815mdavid perezNo ratings yet

- Materials Guide for Over 50 AlloysDocument8 pagesMaterials Guide for Over 50 AlloysMark RomeroNo ratings yet

- WPS List For Piping: (Asme Section Ix)Document2 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviNo ratings yet

- ST 35.8 (Germany / DIN) : Material PropertiesDocument3 pagesST 35.8 (Germany / DIN) : Material Propertiesmohammad zareiNo ratings yet

- WPS PQR-05Document10 pagesWPS PQR-05Ranjan KumarNo ratings yet

- Welding AISI 4130 PDFDocument5 pagesWelding AISI 4130 PDFDarioNo ratings yet

- Material Comparisons For Astm and JisDocument2 pagesMaterial Comparisons For Astm and JisNitesh GargNo ratings yet

- HeadDocument1 pageHeadabdulloh_99No ratings yet

- Welder Certificate ISO 9606-1 QualificationDocument1 pageWelder Certificate ISO 9606-1 QualificationDeepak Das100% (1)

- Aisi 4130Document2 pagesAisi 4130Marcos CarreroNo ratings yet

- 5183 Aluminum Welding WireDocument1 page5183 Aluminum Welding Wiresank79No ratings yet

- ER4043Document1 pageER4043Luis Fidel Ramírez LópezNo ratings yet

- Stainless Steel Grade Comparision System Diagram of Stainless Steel - Corrosion &heat Resistance Strength, Machinability WiseDocument1 pageStainless Steel Grade Comparision System Diagram of Stainless Steel - Corrosion &heat Resistance Strength, Machinability WiseSatyamEngNo ratings yet

- Material Selection GuideDocument0 pagesMaterial Selection GuidebbmokshNo ratings yet

- Conversion Factors, Pressure Conversion, Pressure Equivalents, Unit of Vaccum, Unit of FlowDocument3 pagesConversion Factors, Pressure Conversion, Pressure Equivalents, Unit of Vaccum, Unit of FlowSatyamEngNo ratings yet

- Asco Direct Acting Solenoid Valve - 320Document6 pagesAsco Direct Acting Solenoid Valve - 320SatyamEng100% (1)

- Equivalencia de MaterialesDocument1 pageEquivalencia de MaterialesHelden Jasmani100% (1)

- Parker O-Ring Material Guide-2008Document72 pagesParker O-Ring Material Guide-2008Ian Pillay50% (2)

- Tank Linings Resistance GuideDocument7 pagesTank Linings Resistance Guideenrico100% (1)

- Adjustable Floating ReamersDocument1 pageAdjustable Floating ReamersSatyamEngNo ratings yet

- TorcUP Rebirth Bolting IndustryDocument4 pagesTorcUP Rebirth Bolting IndustrySatyamEngNo ratings yet

- Fittech Brochure Companion Flanges and FittingsDocument16 pagesFittech Brochure Companion Flanges and FittingsSatyamEngNo ratings yet

- 3M Abrasives - Catalogue For AutoComponents PDFDocument48 pages3M Abrasives - Catalogue For AutoComponents PDFSatyamEngNo ratings yet

- Cast Iron Pressure Temperature RatingDocument1 pageCast Iron Pressure Temperature RatingSatyamEngNo ratings yet

- MechIndia Burnishing ToolsDocument4 pagesMechIndia Burnishing ToolsSatyamEngNo ratings yet

- Weartech Electrode Stellite Cobalt NickleDocument1 pageWeartech Electrode Stellite Cobalt NickleSatyamEngNo ratings yet

- Enerpac NC E324Document1 pageEnerpac NC E324SatyamEngNo ratings yet

- GEE ElectrodeDocument17 pagesGEE ElectrodeSatyamEngNo ratings yet

- Tank Linings Resistance GuideDocument7 pagesTank Linings Resistance Guideenrico100% (1)

- Surface Roughness Tester Page 1Document1 pageSurface Roughness Tester Page 1SatyamEngNo ratings yet

- Hindstan Nylons - Ptfe CatalogueDocument11 pagesHindstan Nylons - Ptfe CatalogueSatyamEngNo ratings yet

- Equivalent Materials Grade DIN ASTM BS GOSTDocument4 pagesEquivalent Materials Grade DIN ASTM BS GOSTSatyamEngNo ratings yet

- Enerpac HXD - E324Document2 pagesEnerpac HXD - E324SatyamEngNo ratings yet

- Material standards cross reference guideDocument2 pagesMaterial standards cross reference guideSatyamEng80% (5)

- Material Conversion TableDocument5 pagesMaterial Conversion TableMilin DesaiNo ratings yet

- ENERPAC 00682GB - LPwrenchDocument4 pagesENERPAC 00682GB - LPwrenchSatyamEngNo ratings yet

- TorcUP Rebirth Bolting IndustryDocument4 pagesTorcUP Rebirth Bolting IndustrySatyamEngNo ratings yet

- Enerpac NC E324Document1 pageEnerpac NC E324SatyamEngNo ratings yet

- Casting Grade Wise Welding Electrode Grade and MakeDocument1 pageCasting Grade Wise Welding Electrode Grade and MakeSatyamEngNo ratings yet

- Conversion Factors, Pressure Conversion, Pressure Equivalents, Unit of Vaccum, Unit of FlowDocument3 pagesConversion Factors, Pressure Conversion, Pressure Equivalents, Unit of Vaccum, Unit of FlowSatyamEngNo ratings yet