Professional Documents

Culture Documents

2839-Marking Off PDF

Uploaded by

syllavethyjimOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2839-Marking Off PDF

Uploaded by

syllavethyjimCopyright:

Available Formats

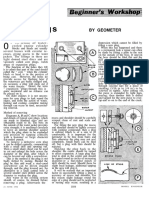

Marking off

BEGINNERS

GEOMETER explains the procedure for

marking work to make neat and accurate cuts

in various materials.

cut and fit material

neatly and position the centres

of holes accurately, the essential preliminary is proper markingoff. For most work, the tools

required are few, a steel rule for

measuring and to serve as a straightedge; a square for marking right

angles; a depth gauge for marking

from edges; dividers for describing

arcs, circles, and finding centres

(or a pencil compass for wood);

a centre punch and a hammer for

indenting centres, a scriber for

metal and a hard pencil for wood.

Wood will mark easily with a

pencil, metal needs a scriber if it is

slightly rusty or scaly but not hard.

If the metal is bright, scribed lines

will not show easily and a simple

remedy is to rub it with chalk.

N ORDER TO

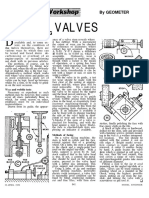

H in Fig. 2 on a piece of true material

can be obtained with the depth gauge

from the ends and sides, and the line

J-K scribed down the centre.

Position H being centre-punched,

dimensions H-J, H-K, are marked

with dividers, taking from a steel

rule, centring one leg at H, a n d

describing arcs at J and K.

When these positions have been

centre-punched, the dividers can be

closed to describe arc L from centre

J, and arc M from centre H. Using

the square at the intersections of

these arcs, centre N is obtained, the

mid-position. Centre 0 is obtained

similarly.

Using this centre and closing the

dividers, arc P can be described,

followed by arc Q from centre K and,

again using the square, the mid-posrtion is found between 0 and K.

Marking centre lines

To cut a piece of wood or metal

down the centre, or to position a line

of holes, a centre line is made using

the depth gauge (Fig. 1). The blade

is set to approximately half-distance

and a line A made. From the opposite

edge, another line B is made, then

the difference split to obtain the

line C.

Cross-checking from each edge,

the exact centre can be found and

the line continued full length, moving

depth gauge and scriber together.

Alternatively, not readjusting the

depth gauge, lines A and B can be

left for the width of the saw cut.

Dividing a line

When the number of holes does not

permit bisecting on this principle,

another method can be used to obtain

the setting for dividers for marking

off the centres-though it may be

necessary to use a piece. of waste

material.

Referring to Fig. 3, a line is marked

using the rule, and the overall dimension R-S marked. Another line R-T

is run at an angle, and the dividers

are used to step off positions U, V, W

-the last being joined to S. With the

dividers set to dimension W-S, and

using centre R, an arc X is made and

then joined by a straight line to S.

With the dividers reset to dimension

R-U, and beginning at S, dimensions

Z and Y are stepped off. Joining

U-Y, V-Z, centres AA and BB are

found. The dividers can be set to

dimensions R-AA, and this transferred to the work.

Fig. 3 shows a line divided into

three, but the principle is applicable

to any reasonable number of spaces.

Obtaining angles

A right angle (Fig. 4) can be marked

from a line CC-DD, using the principles

three, four and five. With dividers

set to three units, centre DD is marked

from CC, and from this position also,

dividers set to four units, an arc is

made at EE. Using centre DD, a n

arc of five units is made crossing at

EE. Thus, the intersection of arcs

at EE forms the right angle.

Straightness check

Dividing into 12 parts

Checking the working edge of

material for straightness, the blade of

the depth gauge can be set in for marking strips, or to bring the material

The square is used for

parallel.

marking ends or checking their truth.

On accurate material, the depth gauge

can be set in for marking lines D, E,

F, G at a uniform distance from the

edges to the position holes.

Engineers often work from centre

lines, taking dimensions or the positions of holes from such. The position

Using centres FF and GG diametrically opposite on the circumference of a circle (Fig. 5) arcs H H

and JJ can be made and when joined

will run a line at right angles. With

the dividers set at the radius of the

circle, and starting at FF or GC,

positions KK, LL, MM,, NN can be

stepped off round the crrcumference,

dividing the circle into six. Consequently, bisecting as required, a

circle can easily be divided into 2, 3,

4, 6, 8 or 12 parts.

q

20

OCTOBER 1955

The five methods of marking materials

explained in the text

555

MODEL ENGINEER

You might also like

- 2890-Nuts & Spanners PDFDocument1 page2890-Nuts & Spanners PDFsyllavethyjimNo ratings yet

- 2885-Dent & Bulge Removal PDFDocument1 page2885-Dent & Bulge Removal PDFsyllavethyjimNo ratings yet

- 2884-Panel Beating PDFDocument1 page2884-Panel Beating PDFsyllavethyjim100% (1)

- 2880-Supporting & Steadying PDFDocument1 page2880-Supporting & Steadying PDFsyllavethyjimNo ratings yet

- 2886-Stud Fitting & Removal PDFDocument1 page2886-Stud Fitting & Removal PDFsyllavethyjimNo ratings yet

- 2889-Further Drilling Methods PDFDocument1 page2889-Further Drilling Methods PDFsyllavethyjimNo ratings yet

- IMP Workshop ManualDocument336 pagesIMP Workshop Manualsyllavethyjim67% (3)

- 2881-Radii Functions and Checking PDFDocument1 page2881-Radii Functions and Checking PDFsyllavethyjimNo ratings yet

- Contours 1: Hile It CannotDocument1 pageContours 1: Hile It CannotsyllavethyjimNo ratings yet

- 2879-Clamping & Holding PDFDocument1 page2879-Clamping & Holding PDFsyllavethyjimNo ratings yet

- 2888-Oblique Drilling PDFDocument1 page2888-Oblique Drilling PDFsyllavethyjimNo ratings yet

- 2887-Broken Drills & Taps PDFDocument1 page2887-Broken Drills & Taps PDFsyllavethyjimNo ratings yet

- 2883-Metal Working PDFDocument1 page2883-Metal Working PDFsyllavethyjimNo ratings yet

- 2873-Cotters & Wedges PDFDocument1 page2873-Cotters & Wedges PDFsyllavethyjimNo ratings yet

- 2874-Fitting Core Plugs PDFDocument1 page2874-Fitting Core Plugs PDFsyllavethyjimNo ratings yet

- 2872-Circular Clips #2 PDFDocument1 page2872-Circular Clips #2 PDFsyllavethyjimNo ratings yet

- 2871-Circular Clips #1 PDFDocument1 page2871-Circular Clips #1 PDFsyllavethyjimNo ratings yet

- 2876-Belt Fasteners PDFDocument1 page2876-Belt Fasteners PDFsyllavethyjimNo ratings yet

- 2867 Case HardeningDocument1 page2867 Case HardeningEr Sukhwinder SinghNo ratings yet

- 2878-Chains & Sprockets PDFDocument1 page2878-Chains & Sprockets PDFsyllavethyjimNo ratings yet

- 2875-Belt Drives PDFDocument1 page2875-Belt Drives PDFsyllavethyjimNo ratings yet

- 2870-Simple Screw Assembly PDFDocument1 page2870-Simple Screw Assembly PDFsyllavethyjimNo ratings yet

- 2877-Roller Chain & Sprockets PDFDocument1 page2877-Roller Chain & Sprockets PDFsyllavethyjimNo ratings yet

- 2868-Glands & Pipe Fittings PDFDocument1 page2868-Glands & Pipe Fittings PDFsyllavethyjimNo ratings yet

- 2865-Testing & Facing Valves PDFDocument1 page2865-Testing & Facing Valves PDFsyllavethyjimNo ratings yet

- 2864-Poppet Valves & Seating PDFDocument1 page2864-Poppet Valves & Seating PDFsyllavethyjimNo ratings yet

- 2861-Wheel & Shaft PullersDocument1 page2861-Wheel & Shaft PullersSandra Barnett CrossanNo ratings yet

- 2869-Fitting & Joining Pipes PDFDocument1 page2869-Fitting & Joining Pipes PDFsyllavethyjimNo ratings yet

- 2866-Hardening & Tempering PDFDocument1 page2866-Hardening & Tempering PDFsyllavethyjimNo ratings yet

- 2863-Valve Seating Tools PDFDocument1 page2863-Valve Seating Tools PDFsyllavethyjimNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Tag-Lish Wattpad Stories: A Code-Switching AnalysisDocument9 pagesTag-Lish Wattpad Stories: A Code-Switching AnalysisDonna Joana A. SorianoNo ratings yet

- Mathematical Model To Design Rack and Pinion Ackerman Steering GeomteryDocument5 pagesMathematical Model To Design Rack and Pinion Ackerman Steering GeomteryIntiGowthamSai100% (1)

- Bbe Minutes Sem III, 2012Document8 pagesBbe Minutes Sem III, 2012Sdrt YdvNo ratings yet

- The African Novel As A Strategy For Decolonization in Ama Ata Aidoo's 'Our Sister Killjoy'Document9 pagesThe African Novel As A Strategy For Decolonization in Ama Ata Aidoo's 'Our Sister Killjoy'EmanNo ratings yet

- Education and Social ReproductionDocument14 pagesEducation and Social ReproductionArianne Kaye AlalinNo ratings yet

- CJR P. SpeakingDocument1 pageCJR P. SpeakingFedirman Hidayat Gulo100% (1)

- Cce Maths PPT Up-18.05.12Document31 pagesCce Maths PPT Up-18.05.12edwin_prakash75No ratings yet

- Apprentice Manual FinalDocument112 pagesApprentice Manual FinalshsnaNo ratings yet

- LORDocument3 pagesLORKuldeep SaxenaNo ratings yet

- Word of MouthDocument141 pagesWord of MouthMurali MuthusamyNo ratings yet

- Basic Audit Sampling Concepts: Jasmine V. Malabanan Kimberly Kaye O. FranciscoDocument35 pagesBasic Audit Sampling Concepts: Jasmine V. Malabanan Kimberly Kaye O. FranciscoKimberly Kaye Olarte FranciscoNo ratings yet

- IncoldbloodDocument5 pagesIncoldbloodapi-321434139No ratings yet

- 【Kwame Nkrumah】ConsciencismDocument65 pages【Kwame Nkrumah】ConsciencismAlainzhu100% (5)

- Academic Word List Generalizing/ Hedging Practice: Downloaded FromDocument2 pagesAcademic Word List Generalizing/ Hedging Practice: Downloaded FromLindsey CottleNo ratings yet

- Mormon Doctrine (Bruce R McConkie)Document304 pagesMormon Doctrine (Bruce R McConkie)Zuleica Oliveira83% (6)

- Thesis Format With SD (BSCS)Document4 pagesThesis Format With SD (BSCS)kathleencate0% (1)

- Stuvia 521677 Summary Strategy An International Perspective Bob de Wit 6th Edition PDFDocument86 pagesStuvia 521677 Summary Strategy An International Perspective Bob de Wit 6th Edition PDFRoman BurbakhNo ratings yet

- A Discussion On The Names and Attributes of AllahDocument3 pagesA Discussion On The Names and Attributes of AllahmaryamNo ratings yet

- Traditional Public Administration Versus The New Public Management: Accountability Versus Efficiency James P. PfiffnerDocument10 pagesTraditional Public Administration Versus The New Public Management: Accountability Versus Efficiency James P. PfiffnerChantal FoleriNo ratings yet

- Wolf, Werner and Bernhart, Walter (Ed.) - Description in Literature and Other MediaDocument352 pagesWolf, Werner and Bernhart, Walter (Ed.) - Description in Literature and Other MediaElNegroLiterario100% (3)

- Qualitative Characteristics of Accounting InformationDocument8 pagesQualitative Characteristics of Accounting InformationDiah Ayu KusumawardaniNo ratings yet

- Jack Canfield SuccessDocument49 pagesJack Canfield Successknfzed100% (1)

- Civic Welfare Training Service Program 2Document30 pagesCivic Welfare Training Service Program 2Glen Mangali100% (3)

- Indigenous Women and FeminismDocument27 pagesIndigenous Women and FeminismClaudia ArteagaNo ratings yet

- Gamit NG Wika Sa LipunanDocument5 pagesGamit NG Wika Sa LipunanRamcee Moreno Tolentino0% (1)

- InglesDocument2 pagesInglesCynthi PaisNo ratings yet

- What Is The Self by Michael D. Moga, S.J.Document2 pagesWhat Is The Self by Michael D. Moga, S.J.Rachelle Alexis Ingente100% (2)

- Sylvia Wynter's Theory of The Human: Counter-, Not Post-HumanistDocument19 pagesSylvia Wynter's Theory of The Human: Counter-, Not Post-HumanistFernández HernándezNo ratings yet

- The Whitsun Weddings: Chapter - IvDocument46 pagesThe Whitsun Weddings: Chapter - IvangryyetiNo ratings yet

- Explanatory NoteDocument3 pagesExplanatory NoteReyrhye RopaNo ratings yet