Professional Documents

Culture Documents

2848-Types of Bearings

Uploaded by

syllavethyjim0 ratings0% found this document useful (0 votes)

22 views1 pageGeometer Tips

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentGeometer Tips

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views1 page2848-Types of Bearings

Uploaded by

syllavethyjimGeometer Tips

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

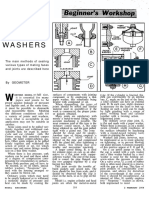

Preventing nuts unscrewing

GEOMETER explains some of the better-known processes

for preventing nuts becoming loose on their bolts and studs

HE PROBLEM OF preventing nuts

and threads slackening from

vibration or other movement

has been solved in various ways

according to the requirements of

assemblies, and, as usual, there

are. the dos and donts.

Where rotation is in a particular

direction, threads can be right or

left-hand so there is a tendency for

them to tighten. Spindles of cycle

pedals, wheel hub nuts. of cars and

on occasion the actual wheel nuts of

lorries are examples of this methoda n d there are numerous other applications.

Naturally care must be

taken in dismantling to turn in the

required direction.

Split pins are perhaps the most

common locking devices for nuts,

whether on studs or bolts, and require

the nuts to be either slotted or castle

types, A and B. The slotted nut A

needs less room where space is

lacking,_ but is not so strong as the

castle nut B with its circular portion

on top incorporating the s l o t s . Con..

sequently, slotted nuts must not be

substituted for castle cuts in important

fittings.

Split pins should fit the holes

reasonably tightly, their heads be

tapped into slots, then the legs

opened round the ends of the bolts.

Where there is continuous vibration

(car big-end bearings), loose split pins

will eventually wear so the legs break

off and the pins fall out.

The lock-nut

Another common device is the

lock-nut C on U-bolts of car springs.

Usually, the thin nut is on the end or

outside, though in this position some

engineers declare it takes the load on

the bolt, owing to slight slackness in

the threads of the thicker standard nut.

Plain washers do not prevent unscrewing, but they are used in preference to others where firm pressure

is required and it is desired to avoid

scoring a metal surface by the underside of nuts. There are two types of

tab washer, however, to provide

security-the single type D and the

the multiple type fitting on two or

more bolts or studs, with a tab at

each position to turn up on the nut.

In final tightening of nuts, care is

required on multiple tab washers not

to twist them, and on single tabs not

to turn them into a wrong attitude

for locking.

Spring washer types

In general use, three types of spring

washer provide security: single coil E,

double coil (similar) and the serrated

type with bore or outside cut. Spring

washers should not be used where

loads are heavy, or the undersurface

can be scored from dismantling.

Under pressure, a single coil washer

will often break or splay; a double

coil, splay, and a serrated type break.

Coarse, sharp single coil washers can

be much improved by slightly straightening-in the vice, using pliers.

Unless assembly is permanent, studs

or bolts should not be burred. However, the centre punch dot F is often

used on aircraft sub-assemblies. For

removal, the displaced portion is

chiselled or filed off.

5 JANUARY 1956

11

The multiple-tab washer G is used

with keyed or splined shafts (car hub

nuts). For unscrewing, the outside

tabs must be fully released or the

inner one will be sheared.

Nuts fitted with a fibre insert H

provide security against unscrewing

for two or three removals-after which

they are not so secure. They should

not be used where heat can dry or

burn the fibre.

All steel nuts Z have an undersize

piece at the end which grips the thread

on the bolt or stud. These are a

modem alternative for castle nuts on

car big-end bolts. They avoid the

difficulty of the split pin holes not

being in line when. the nuts are fully

tight-to overcome which, castle nuts

have to be removed and filed on the

bottom. In many fittings, a normal

nut can be held by a small screw

against a flat J-motorcycle crankpins.

Studs can be fitted and removed by

means of two nuts locked firmly

together K-turning on the top one

for fitting, on the bottom one for

removing. Immovable nuts may be

split L with a sharp chisel down one

of -the flats, or a small drill down one

of the comers M-then a chisel used

for splitting. Alternatively, a chisel and

support block can be used as N. q

MODEL ENGINEER

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- IMP Workshop ManualDocument336 pagesIMP Workshop Manualsyllavethyjim67% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- 2888-Oblique Drilling PDFDocument1 page2888-Oblique Drilling PDFsyllavethyjimNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 2886-Stud Fitting & Removal PDFDocument1 page2886-Stud Fitting & Removal PDFsyllavethyjimNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 2884-Panel Beating PDFDocument1 page2884-Panel Beating PDFsyllavethyjim100% (1)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Contours 1: Hile It CannotDocument1 pageContours 1: Hile It CannotsyllavethyjimNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 2878-Chains & Sprockets PDFDocument1 page2878-Chains & Sprockets PDFsyllavethyjimNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 2873-Cotters & Wedges PDFDocument1 page2873-Cotters & Wedges PDFsyllavethyjimNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- 2853-Simple Drilling JigsDocument1 page2853-Simple Drilling JigssyllavethyjimNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 2864-Poppet Valves & Seating PDFDocument1 page2864-Poppet Valves & Seating PDFsyllavethyjimNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- 2877-Roller Chain & Sprockets PDFDocument1 page2877-Roller Chain & Sprockets PDFsyllavethyjimNo ratings yet

- 2847-Keys & Driving PinsDocument1 page2847-Keys & Driving PinssyllavethyjimNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- 2852-Polishing Metal SurfacesDocument1 page2852-Polishing Metal SurfacessyllavethyjimNo ratings yet

- 2858-How To Use Scrapers PDFDocument1 page2858-How To Use Scrapers PDFsyllavethyjimNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Tws 600 S Pump Flyer - 0910Document2 pagesTws 600 S Pump Flyer - 0910santanuaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 3029tf120 PDFDocument2 pages3029tf120 PDFfranklin albarranNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- 2 Maintenance Schdule Blow Room, Carding DecDocument15 pages2 Maintenance Schdule Blow Room, Carding DecBHASKAR MITRANo ratings yet

- 08 GRP01 All EnginesDocument24 pages08 GRP01 All Enginescianurel2184No ratings yet

- Pulling Out Manual TransmissionDocument66 pagesPulling Out Manual TransmissionTesda Ptc Malilipot100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- D39EX-23 D39PX-23: Tier 4 Interim EngineDocument16 pagesD39EX-23 D39PX-23: Tier 4 Interim EngineElena Uriña100% (1)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- RCP-7.5 Drilling fluid agitator RCP-7.5 搅拌器: Parts List 9-D)Document6 pagesRCP-7.5 Drilling fluid agitator RCP-7.5 搅拌器: Parts List 9-D)waleedNo ratings yet

- Aeb725 PDFDocument5 pagesAeb725 PDFSilviu PircanNo ratings yet

- Monitoring Backlog 16 Desember 2021 InfrastrukturDocument2 pagesMonitoring Backlog 16 Desember 2021 InfrastrukturKhairullahNo ratings yet

- Lovejoy Jaw Type CouplingsDocument26 pagesLovejoy Jaw Type CouplingsJohn Alexander Bonilla AngelNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Industrial Cylinder Products: Hydraulic and Pneumatic CylindersDocument161 pagesIndustrial Cylinder Products: Hydraulic and Pneumatic CylindersplantuserNo ratings yet

- Catalogo Perma-CoolDocument24 pagesCatalogo Perma-CoolrotnegerNo ratings yet

- M 10ia SeriesDocument2 pagesM 10ia Seriessenior_cor73zNo ratings yet

- 2T75H Parts Catalog (For Toyota)Document63 pages2T75H Parts Catalog (For Toyota)Галина КарташоваNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- 36 - TopicsDocument14 pages36 - TopicsMohamad MagdyNo ratings yet

- Catalogo Transmision CardanDocument251 pagesCatalogo Transmision CardanGabriel Garcia MassanetNo ratings yet

- 220089enb Generator DesignDocument58 pages220089enb Generator DesignMahmoud ElboraeNo ratings yet

- DM30 Series: Atlas Copco Blasthole DrillsDocument4 pagesDM30 Series: Atlas Copco Blasthole Drillscristian garciaNo ratings yet

- TEC-2000671-WC INSTALACIONES-Almacen Pasto-750gpm@150PSI-DIESEL-HOR-ES-Rev0Document15 pagesTEC-2000671-WC INSTALACIONES-Almacen Pasto-750gpm@150PSI-DIESEL-HOR-ES-Rev0Carlos YepezNo ratings yet

- MPD-1000 Bug-ODocument59 pagesMPD-1000 Bug-OROMERJOSENo ratings yet

- Centrifugal PumpDocument36 pagesCentrifugal PumpshubhamNo ratings yet

- Liebherr 200 DR PDFDocument2 pagesLiebherr 200 DR PDFereresrdfNo ratings yet

- Ethiopian Engine Shop PDFDocument28 pagesEthiopian Engine Shop PDFslam12125No ratings yet

- ICE Lab ReportDocument34 pagesICE Lab ReportUmair Ali RajputNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Spark-Plug Faces: 2009 - 2010 Bosch Automotive AftermarketDocument1 pageSpark-Plug Faces: 2009 - 2010 Bosch Automotive AftermarketZamriNo ratings yet

- Solving The Failure of High Speed (3000 RPM) SEAL AIR FANDocument5 pagesSolving The Failure of High Speed (3000 RPM) SEAL AIR FANTaraknath MukherjeeNo ratings yet

- BMW EGR RecallDocument7 pagesBMW EGR RecallPhilNo ratings yet

- Spare Parts Gatalogue Getman Parte 1Document310 pagesSpare Parts Gatalogue Getman Parte 1EFREN SANCHEZ ROBLESNo ratings yet

- Crawler Crane 70 Ton (Zoomlion QUY70)Document18 pagesCrawler Crane 70 Ton (Zoomlion QUY70)peckonet100% (1)

- Service Manual: Split TypeDocument132 pagesService Manual: Split TypeRodrigo VictorNo ratings yet