Professional Documents

Culture Documents

481 Lecture 11

Uploaded by

KuldeepMalikCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

481 Lecture 11

Uploaded by

KuldeepMalikCopyright:

Available Formats

Whites, EE 481/581

Lecture 11

Page 1 of 8

Lecture 11: Dispersion. Stripline and

Other Planar Waveguides.

Perhaps the biggest reason the TEM mode is preferred over TE

or TM modes for propagating communication signals is that

ideally it is not dispersive. That is, the phase velocity of a TEM

wave is not a function of frequency [ v p g ( ) ] provided the

material properties of the waveguide are not functions of

frequency.

To see this, recall for a TEM wave that LC . Therefore,

1

vp

LC

which is not a function of frequency, as conjectured, provided

neither L nor C are functions of frequency.

However, for either TE or TM modes, v p is a function of

frequency regardless of the material properties of the

waveguide.

Take the rectangular waveguide as an example. In the last

lecture, we found that with e j z propagation

2

2

m

mn k 2 kc2,mn and kc2,mn

b

where m, n 0,1,2, m n 0 for TE modes, while

m, n 1,2, for TM modes.

2015 Keith W. Whites

Whites, EE 481/581

Lecture 11

Page 2 of 8

For a CW signal carried by one of these modes, the phase

velocity is

v p ,mn

2 kc2,mn

which is clearly a function of frequency. Consequently, we have

confirmed that TE and TM modes in a rectangular waveguide

are dispersive.

One special case is m n 0 . Since kc ,00 0 , then v p g ( f )

which means this is not a dispersive mode. However, the

m n 0 mode is the TEM mode, which cannot exist in a

hollow conductor waveguide.

The problem with (temporally) dispersive modes is that they can

severely distort signals that have been modulated onto them as

the carrier. As the signal propagates down the waveguide:

In communications, such distortion is often unacceptable.

Therefore, the TEM mode is the one commonly used in

microwave engineering. (For high power applications, hollow

waveguides made be required; hence, one would need to

somehow work around the distortion.)

Whites, EE 481/581

Lecture 11

Page 3 of 8

Since we prefer to work with the TEM mode of wave

propagation, it is important that we use waveguides in our

microwave circuits that will support TEM or quasi-TEM

modes. Examples of such structures are:

Microstrip and covered microstrip

Stripline

Slotline

Coplanar waveguide.

In this course, we will work primarily with microstrip. Actually,

in the lab we will exclusively use microstrip.

Before delving into microstrip, however, lets quickly overview

some of these other TEM waveguides, beginning with stripline.

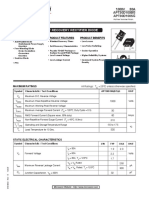

Stripline

Stripline is a popular, planar geometry for microwave circuits.

As shown in Fig. 3.22:

Metal planes

r

W

Whites, EE 481/581

Lecture 11

Page 4 of 8

Stripline has one or more interior strip conductors immersed in a

dielectric with ground planes above and below.

Stripline can support the TEM mode exclusively provided that

b 4 where 0 r . At higher frequencies, TE and TM

modes may also propagate, which leads to signal distortion and

other undesirable effects. This is called an over-moded

waveguide.

Well assume that the (carrier) frequency is low enough that

b 4 and only the TEM mode propagates. As with any TEM

mode, in a stripline with 0 :

c

1

vp

0

(3.176),(1)

LC

r

Z0

vp

k0 r

(3.177),(2)

L

LC

1

C

C

v pC

(3.178),(3)

Once r is known, we can straightaway determine v p , , and

Z 0 since none of these quantities depend on frequency for a

TEM mode.

Whites, EE 481/581

Lecture 11

Page 5 of 8

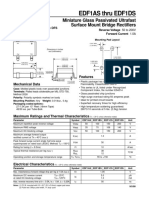

Forward Stripline Design

We will need to design stripline with a specific Z 0 . How do we

determine C (the p.u.l. capacitance) required in (3) to

accomplish this? Unfortunately, there is no simple, exact

analytical solution for stripline (or microstrip, for that matter).

Other the other hand, extremely accurate numerical solutions

can be found using a number of techniques including the method

of moments and the finite element method, among others.

By curve fitting to these numerical solutions, it can be shown

that for a stripline:

30

b

[

(3.179a),(4)

Z0

r We 0.441b

where We is called an effective strip width given by

W

0

0.35

b

We W

(3.179b),(5)

2

b

b

W W

0.35

0.35

b

b

Equation (4) is quite accurate, to 1% or so.

As an example, if we stack two Rogers RO4003C laminates,

then b 2 0.032" 1.626 mm and r 3.38 . Using (4):

Whites, EE 481/581

Lecture 11

Page 6 of 8

Z0 W

50

40

30

20

10

10

W b

Notice that as W b increases, Z 0 decreases.

With b 1.626 mm, then to obtain Z 0 50 W b 0.58

from this plot. Therefore, W 0.58 b 0.943 mm.

Reverse Stripline Design

One can also determine the inverse of (4) so that W b can be

determined once r and the required Z 0 are specified:

Z 0 r 120

W x

(3.180),(5)

b 0.85 0.6 x

Z 0 r 120

30

where x

0.441.

Z0 r

For example, with r 3.38 and Z 0 50 , 50 3.38 91.92 .

From the upper solution in (5) we find that

Whites, EE 481/581

Lecture 11

Page 7 of 8

W

30

0.441 0.5843

b 50 3.38

This is very close to the graphical solution we just obtained.

The text describes an approximate electrostatic solution for Z 0

on pp. 144-147. Surprisingly, that numerical solution is

presumably less accurate than (4), so we will not discuss it. [It

assumes a constant charge density on the strip conductor as in

(3.188), which cannot be true because of the so called edge

effect, as well see in Lecture 13.]

Other Planar Waveguides

Besides stripline and microstrip, there are a few other popular

planar waveguides:

1. Slotline Fig 3.33,

2. Coplanar waveguide Fig 3.34,

3. Covered microstrip Fig 3.35,

4. Suspended stripline:

Metal enclosure

Dielectric substrate

Whites, EE 481/581

Lecture 11

Page 8 of 8

A nice comparison of the electromagnetic and physical

characteristics of coaxial cable, hollow waveguides, stripline,

and microstrip is given in Table 3.6.

You might also like

- Microstrip Line EquationsDocument14 pagesMicrostrip Line EquationscftrutaNo ratings yet

- Predict Resonances of Shielded PCBsDocument8 pagesPredict Resonances of Shielded PCBskhanafzaal2576No ratings yet

- Band Stop Filter TodayDocument4 pagesBand Stop Filter TodayrehanNo ratings yet

- Greve 2005Document12 pagesGreve 2005Emotional V.I.PNo ratings yet

- W - C L T: Aveguide Oaxial INE RansitionsDocument12 pagesW - C L T: Aveguide Oaxial INE RansitionssandhraNo ratings yet

- Razavi PLL TutorialDocument39 pagesRazavi PLL TutorialbsrathorNo ratings yet

- AE AE?: Hubbard ModelsDocument1 pageAE AE?: Hubbard ModelsSupriyaNo ratings yet

- Micros Trip Slo Tline Transitions Modeling and Experimental InvestigationDocument11 pagesMicros Trip Slo Tline Transitions Modeling and Experimental InvestigationPablo Andres CartesNo ratings yet

- Razavi Monolithic Phase-Locked Loops and Clock Recovery CircuitsDocument39 pagesRazavi Monolithic Phase-Locked Loops and Clock Recovery CircuitsAhmedEssa89No ratings yet

- Barov 2001 0120Document3 pagesBarov 2001 0120Particle Beam Physics LabNo ratings yet

- Switching Time in Junction Diodes and Junction TransistorsDocument6 pagesSwitching Time in Junction Diodes and Junction TransistorsHu JackNo ratings yet

- Pulses in Cables: ReferencesDocument5 pagesPulses in Cables: ReferencesPaul DumitruNo ratings yet

- Enhanced Pml-Like Abcs For Layered Media Transmission Line TerminationDocument4 pagesEnhanced Pml-Like Abcs For Layered Media Transmission Line TerminationRadmilo MandaricNo ratings yet

- Ring Osc Phase NoiseDocument4 pagesRing Osc Phase NoiseHosein ZadeNo ratings yet

- Frequency Response of Basic BJT and MOSFET Amplifiers: (Review Materials in Appendices III and V)Document42 pagesFrequency Response of Basic BJT and MOSFET Amplifiers: (Review Materials in Appendices III and V)Jawath BinaNo ratings yet

- AVE Uides: Eneral Olutions For Rbitrary WaveguideDocument16 pagesAVE Uides: Eneral Olutions For Rbitrary WaveguideDush AkilaNo ratings yet

- List of Contents: S/No. Subject Page NumberDocument24 pagesList of Contents: S/No. Subject Page NumberAbdelrahman DaakirNo ratings yet

- Frequency Multiplication TechniquesDocument3 pagesFrequency Multiplication TechniquesoguzhanNo ratings yet

- EELE44515 Lab7Document5 pagesEELE44515 Lab7Onat ŞenelNo ratings yet

- WWW - Stanford.edu Jbarral Downloads JoelleBarral CoilDesignDocument9 pagesWWW - Stanford.edu Jbarral Downloads JoelleBarral CoilDesignSachin_AnchanNo ratings yet

- Mode MatchingDocument6 pagesMode MatchingaxNo ratings yet

- High-Field Laser Physics: ETH Zürich Spring Semester 2010 H. R. ReissDocument34 pagesHigh-Field Laser Physics: ETH Zürich Spring Semester 2010 H. R. ReissjasmonNo ratings yet

- Lecture 09Document7 pagesLecture 09Dr. Rami HalloushNo ratings yet

- Investigation of Signal Characteristics Using The Continuous Wavelet TransformDocument12 pagesInvestigation of Signal Characteristics Using The Continuous Wavelet Transformforscribd1981No ratings yet

- Knotes Chapter-2 Amplitude ModulationDocument66 pagesKnotes Chapter-2 Amplitude ModulationGp Bhupinder100% (1)

- Transmission LineDocument152 pagesTransmission Linemsharma22No ratings yet

- Circular WaveguidesDocument35 pagesCircular WaveguidesAlas Mallari DonatoNo ratings yet

- Nu ) ) (Z J,: R' (0 RW P' and G' (0 : 2 GFT™ 'Document2 pagesNu ) ) (Z J,: R' (0 RW P' and G' (0 : 2 GFT™ 'shirtquittersNo ratings yet

- Semiclassical Four-Level Single-Atom LaserDocument4 pagesSemiclassical Four-Level Single-Atom LaserAnanta KusumaNo ratings yet

- Nov Dec 2016Document16 pagesNov Dec 2016ShanilDayalanNo ratings yet

- EE533 Lec 15 17 1Document22 pagesEE533 Lec 15 17 1DiDo Mohammed AbdullaNo ratings yet

- ECE 461: Digital Communication Lecture 8b: Pulse Shaping and SamplingDocument9 pagesECE 461: Digital Communication Lecture 8b: Pulse Shaping and SamplingShounak DasguptaNo ratings yet

- Chapter 4: Circuit CharacterizationDocument9 pagesChapter 4: Circuit Characterizationbikash routNo ratings yet

- A Broad-Band TL Model For A Rectangular Microstrip AntennaDocument10 pagesA Broad-Band TL Model For A Rectangular Microstrip AntennathgnguyenNo ratings yet

- Surge Propagation in Electrical SystemsDocument5 pagesSurge Propagation in Electrical SystemssamiNo ratings yet

- Microwave Engineering Assignment 1 To 5Document6 pagesMicrowave Engineering Assignment 1 To 5Anonymous 4bUl7jzGqNo ratings yet

- MCQ On Unit 4 EC20Document9 pagesMCQ On Unit 4 EC20zohaibNo ratings yet

- Handout 5Document7 pagesHandout 5Samama ZafarNo ratings yet

- Hollow Waveguide TapersDocument6 pagesHollow Waveguide Tapersgeodinger9316No ratings yet

- L. Bilbao Et Al - D-T Ignition in A Z-Pinch Compressed by Imploding LinerDocument5 pagesL. Bilbao Et Al - D-T Ignition in A Z-Pinch Compressed by Imploding LinerCola7890No ratings yet

- Exact Ray Calculations in A Quasi .. Parabolic Ionosphere With No Magnetic FieldDocument6 pagesExact Ray Calculations in A Quasi .. Parabolic Ionosphere With No Magnetic FieldASM AAS ASSASNo ratings yet

- SLT-A QuestionsDocument5 pagesSLT-A QuestionsrhythmNo ratings yet

- Microwave Circuits: Stripline & MicrostripDocument29 pagesMicrowave Circuits: Stripline & MicrostripRocky BobNo ratings yet

- N Carrier Modulatio: Version 2 ECE IIT, KharagpurDocument10 pagesN Carrier Modulatio: Version 2 ECE IIT, KharagpurAayush RajvanshiNo ratings yet

- Hollow Rectangular WaveguideDocument6 pagesHollow Rectangular Waveguidemoluewli100% (1)

- Ee3104 Lecture1 PDFDocument38 pagesEe3104 Lecture1 PDFAbdul Hafiz AnuarNo ratings yet

- LPF Simulation and MOSFET CharacteristicsDocument10 pagesLPF Simulation and MOSFET CharacteristicsAhmad Kamal100% (1)

- Transmission Line Characteristics (Coaxial Cable) : ObjectiveDocument4 pagesTransmission Line Characteristics (Coaxial Cable) : Objectivetareq omarNo ratings yet

- Analyze Transmission Lines With Almost No MathDocument5 pagesAnalyze Transmission Lines With Almost No MathCARROUCHO62No ratings yet

- Performance Very Low Frequency Filters: Design Considerations For HighDocument4 pagesPerformance Very Low Frequency Filters: Design Considerations For Highmvmuthukumar88No ratings yet

- Design High Performance Pulse Transformers in Easy StageDocument18 pagesDesign High Performance Pulse Transformers in Easy StagefagundesbrNo ratings yet

- Prof. Hossam Shalaby Paper 5Document4 pagesProf. Hossam Shalaby Paper 5drhammoudaNo ratings yet

- Distortion and Coupling Analysis of Short Electric Pulses On Lossy, Coupled Microstrip LinesDocument6 pagesDistortion and Coupling Analysis of Short Electric Pulses On Lossy, Coupled Microstrip LinesjrosouzaNo ratings yet

- Mechanical Systems and Signal Processing: Yuh-Tay SheenDocument10 pagesMechanical Systems and Signal Processing: Yuh-Tay Sheendado djanatiNo ratings yet

- E193004 Micro Wave Lab 03Document4 pagesE193004 Micro Wave Lab 03Md FahimNo ratings yet

- Direct RF Sampling Mixer With Recursive Filtering in Charge DomainDocument4 pagesDirect RF Sampling Mixer With Recursive Filtering in Charge DomainBinod AdhikariNo ratings yet

- Unit5 PDFDocument181 pagesUnit5 PDFSandhya VijayaparvathyNo ratings yet

- Analysis and Design of Multicell DC/DC Converters Using Vectorized ModelsFrom EverandAnalysis and Design of Multicell DC/DC Converters Using Vectorized ModelsNo ratings yet

- Feynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterFrom EverandFeynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterNo ratings yet

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Rating: 4.5 out of 5 stars4.5/5 (5)

- 481 Lecture 17Document7 pages481 Lecture 17KuldeepMalikNo ratings yet

- 481 Lecture 19Document6 pages481 Lecture 19KuldeepMalikNo ratings yet

- Lecture 18: Vector Network AnalyzerDocument17 pagesLecture 18: Vector Network AnalyzerKuldeepMalikNo ratings yet

- VNA FMR AgilentDocument15 pagesVNA FMR AgilentErickOmarBurgosParraNo ratings yet

- 481 Lecture 14Document8 pages481 Lecture 14Ismael Ochoa JimenezNo ratings yet

- LectureDocument19 pagesLectureFirdaus SinagapertolaNo ratings yet

- 481 Lecture 7Document19 pages481 Lecture 7KuldeepMalikNo ratings yet

- Lecture 15: S Parameters and The Scattering MatrixDocument7 pagesLecture 15: S Parameters and The Scattering MatrixDinda NurhayatiNo ratings yet

- 481 Lecture 6Document15 pages481 Lecture 6KuldeepMalikNo ratings yet

- 481 Lecture 13Document14 pages481 Lecture 13KuldeepMalikNo ratings yet

- Lecture 9: Quarter-Wave-Transformer Matching.: R JZ L Z Z Z JR LDocument13 pagesLecture 9: Quarter-Wave-Transformer Matching.: R JZ L Z Z Z JR LKuldeepMalikNo ratings yet

- 481 Lecture 0Document2 pages481 Lecture 0Neetirajsinh ChhasatiaNo ratings yet

- 481 Lecture 8Document8 pages481 Lecture 8KuldeepMalikNo ratings yet

- 481lecture16 T Section S ParameterDocument10 pages481lecture16 T Section S ParameterRuben BellNo ratings yet

- 481 Lecture 2Document13 pages481 Lecture 2Muhammad RamzyNo ratings yet

- TE TM Mode PDFDocument10 pagesTE TM Mode PDFYudistira Adi NNo ratings yet

- 481 Lecture 5Document9 pages481 Lecture 5KuldeepMalikNo ratings yet

- 481 Lecture 3Document9 pages481 Lecture 3KuldeepMalikNo ratings yet

- 481 Lecture 4Document12 pages481 Lecture 4KuldeepMalikNo ratings yet

- 481 Lecture 2Document13 pages481 Lecture 2Muhammad RamzyNo ratings yet

- Ultrafast Soft Recovery Rectifier Diode: Product Benefits Product Features Product ApplicationsDocument4 pagesUltrafast Soft Recovery Rectifier Diode: Product Benefits Product Features Product ApplicationsEDER RIBEIRONo ratings yet

- CHAPTER VII Direct Current CircuitsDocument28 pagesCHAPTER VII Direct Current CircuitsNandya GuvitaNo ratings yet

- C6140-0060 - Control Cabinet Industrial PC: VariantsDocument2 pagesC6140-0060 - Control Cabinet Industrial PC: Variantsdarinel88No ratings yet

- Profibus-Dp: Installation ManualDocument38 pagesProfibus-Dp: Installation ManualLeandroNo ratings yet

- Keller: P T T S 21 RDocument2 pagesKeller: P T T S 21 RAmal AntonyNo ratings yet

- Temperature Error of 2-Wire, 3-Wire & 4-Wire RTD Instrumentation ToolsDocument3 pagesTemperature Error of 2-Wire, 3-Wire & 4-Wire RTD Instrumentation Toolskali bangonNo ratings yet

- Make Poweful A Green RailgunDocument8 pagesMake Poweful A Green RailgunjumpupdnbdjNo ratings yet

- Ti21 TC NotesDocument157 pagesTi21 TC NotesVikas JainNo ratings yet

- By: Mr.L.Kumaraswamy M.E. (Iisc), Associate Professor, Mce, HassanDocument6 pagesBy: Mr.L.Kumaraswamy M.E. (Iisc), Associate Professor, Mce, Hassansarala20021990No ratings yet

- E7125v1 0Document135 pagesE7125v1 0uti12345No ratings yet

- IMP REF Design and Characterization of Ferroelectric Negative CapacitanceDocument126 pagesIMP REF Design and Characterization of Ferroelectric Negative Capacitancesai prashanthNo ratings yet

- m1 2006Document4 pagesm1 2006spoof183No ratings yet

- M54HC75 M74HC75: 4 Bit D Type LatchDocument9 pagesM54HC75 M74HC75: 4 Bit D Type LatchnooorNo ratings yet

- Synchronous Machines3Document103 pagesSynchronous Machines3Daniela CastroNo ratings yet

- CapacitorDocument5 pagesCapacitorAina shivhareNo ratings yet

- Retroreflective Sensor (Glass) OBG5000-R100-2EP-IO-V31: FunctionDocument6 pagesRetroreflective Sensor (Glass) OBG5000-R100-2EP-IO-V31: FunctionRodrigo LimaNo ratings yet

- Daewoo DLX32D1SMSB Manual de Servicio LCDDocument40 pagesDaewoo DLX32D1SMSB Manual de Servicio LCDAlexis ColmenaresNo ratings yet

- Cable Modelling: List of Inputs RequiredDocument5 pagesCable Modelling: List of Inputs RequiredarunmozhiNo ratings yet

- DX20VC: High-Efficiency, Communicating, Variable-Speed, Inverter Drive Split System Air Conditioner Up To 24.5 SEERDocument20 pagesDX20VC: High-Efficiency, Communicating, Variable-Speed, Inverter Drive Split System Air Conditioner Up To 24.5 SEERJohn AristaNo ratings yet

- Smart Home Automation Based On Iot Using Arduino Mega: Abstract-In The Advancement of TechnologiesDocument4 pagesSmart Home Automation Based On Iot Using Arduino Mega: Abstract-In The Advancement of TechnologiesUdupiSri groupNo ratings yet

- Analysis and Implementation of Fuzzy Logic Controller Based MPPT To Enhance Power Quality in PV SystemDocument10 pagesAnalysis and Implementation of Fuzzy Logic Controller Based MPPT To Enhance Power Quality in PV SystemEditor IJTSRDNo ratings yet

- SGP Question BankDocument3 pagesSGP Question BankSanjay AgrawalNo ratings yet

- ML Maximum Power Point Tracking (MPPT) Series Ml4860: User ManualDocument13 pagesML Maximum Power Point Tracking (MPPT) Series Ml4860: User ManualReymark EmbateNo ratings yet

- Checking Data, I-CANDocument3 pagesChecking Data, I-CANWaldek KozlowskiNo ratings yet

- Troubleshooting The Syringe PumpDocument2 pagesTroubleshooting The Syringe PumpbleaurosenNo ratings yet

- Huawei BTS3900A Installation Guide V1.0Document29 pagesHuawei BTS3900A Installation Guide V1.0Ganidu Rochana100% (2)

- Project Report (Vending Machine)Document9 pagesProject Report (Vending Machine)Muhammad HamzaNo ratings yet

- 013 - SAS Operating Work Station (OWS)Document3 pages013 - SAS Operating Work Station (OWS)Ahmed KhankyNo ratings yet

- EDF1AS Thru EDF1DS: Miniature Glass Passivated Ultrafast Surface Mount Bridge RectifiersDocument2 pagesEDF1AS Thru EDF1DS: Miniature Glass Passivated Ultrafast Surface Mount Bridge RectifiersCarlosNo ratings yet

- Universal Receiver: Wireless AccelerometerDocument2 pagesUniversal Receiver: Wireless AccelerometerMarco SotoNo ratings yet