Professional Documents

Culture Documents

Recommended Testing Procedures For HDPE Pipe

Uploaded by

osto720 ratings0% found this document useful (0 votes)

127 views1 pageRecommended Testing Procedures For HDPE Pipe R-26

Original Title

Recommended Testing Procedures for HDPE Pipe

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRecommended Testing Procedures For HDPE Pipe R-26

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

127 views1 pageRecommended Testing Procedures For HDPE Pipe

Uploaded by

osto72Recommended Testing Procedures For HDPE Pipe R-26

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Engineering

& Technical

Data

R-26

Recommended

Testing

Procedures For

HDPE Pipe

Pressure Testing Outside The Trench:

If specified by the engineer, pressure testing may be conducted prior to pipe installation.

After the pipe has been joined, fill it with water, carefully bleed off any trapped air. Subject the pipe to a hydrostatic

test pressure that is 1.5 times the system design pressure for a maximum of 3 hours. During this time, add water periodically to maintain the test pressure; this compensates for the initial stretching of the pipe. The line pressure tightness

is determined by visual observation; therefore, it is not necessary to measure the make-up water. Examine every fused

joint; any leakage must be repaired and then retested.

NOTE: It shall be the responsibility of the contractor to ensure that appropriate safety precautions are observed during

hydrostatic testing above ground.

Testing In The Trench:

Fill the pipeline with water after it has been laid; bleed off any trapped air. Subject the lowest element in the system to a

test pressure that is 1.5 times the design pressure, and check for any leakage. When, in the opinion of the engineer, local

conditions require that the trenches be backfilled immediately after the pipe has been laid, apply the pressure test after

backfilling has been completed but not sooner than a time which will allow sufficient curing of any concrete that may have

been used. Typical minimum concrete curing times are 36 hours for early strengths and 7 days for normal strengths.

The test procedures consist of two steps; the initial expansion and the test phase. When test pressure is applied to a

water filled pipe, the pipe expands. During the initial expansion of the pipe under test, sufficient make-up water must

be added to the system at hourly intervals for 3 hours to maintain the test pressure. After about 4 hours, initial expansion should be complete and the actual test can start.

When the test is to begin, the pipe is full of water and is subjected to a constant test pressure of 1.5 times the system

design pressure. The test phase should not exceed 3 hours, after which time any water deficiency must be replaced and

measured. Add and measure the amount of make-up water required to return to the test pressure and compare this to

the maximum allowance in the table below.

An alternate leakage test consists of maintaining the test pressure (described above) over a period of 4 hours and then

dropping the pressure by 10 psi (0.69 MPa). If the pressure then remains within 5% of the target value for 1 hour, this

indicates there is no leakage in the system.

NOTES:

Under no circumstances shall the total time under test exceed 8 hours at 1.5 times the system pressure rating. If the test is

not complete within this time limit (due to leakage, equipment failure, etc.), the test section shall be permitted to relax

for 8 hours prior to the next test sequence.

Air testing is not recommended. Additional safety precautions may be required.

Above procedure taken from PPI Technical Report TR-31 by the Plastic Pipe Institute.

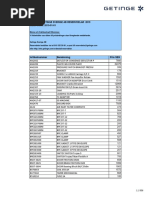

ALLOWANCE FOR EXPANSION UNDER TEST PRESSURE

nominal

PIPE SIZE(1)

2"

3"

4"

5"

6"

8"

10"

12"

14"

16"

18"

u.s. gals/100 ft. of pipe(2)

1 hour

2 hours

3 hours

0.08

0.12

0.15

0.10

0.15

0.25

0.13

0.25

0.40

0.21

0.41

0.63

0.30

0.60

0.90

0.50

1.00

1.50

0.75

1.30

2.10

1.10

2.30

3.40

1.40

2.80

4.20

1.70

3.30

5.00

2.20

4.30

6.50

nominal

PIPE SIZE(1)

20"

22"

24"

28"

30"

32"

36"

42"

48"

54"

u.s. gals/100 ft. of pipe(2)

1 hour

2 hours

3 hours

2.80

5.50

8.00

3.50

7.00

10.50

4.50

8.90

13.30

5.50

11.10

16.80

6.20

12.60

19.10

7.00

14.30

21.50

9.00

18.00

27.00

12.00

24.00

36.00

15.00

27.00

43.00

18.00

30.00

50.00

mm=0.03937, (2)multiply by 11.53 to convert to liters/100 meters of pipe.

(1)

R-26

Phone: 800-EJP-24HR (357-2447) Fax: 207-582-5637

You might also like

- Modified Hydrotest 6barDocument4 pagesModified Hydrotest 6barMohamed ElarabiNo ratings yet

- Upg Stream Pe100 HydrotestDocument4 pagesUpg Stream Pe100 HydrotestMoezNo ratings yet

- The Pressure Testing of DI CI and PVC Pipe - Upload - 27!10!16Document4 pagesThe Pressure Testing of DI CI and PVC Pipe - Upload - 27!10!16Rushan Lakdimuthu100% (1)

- Pipeline TestingDocument4 pagesPipeline Testingveljko2008100% (1)

- Bi-Di PigDocument1 pageBi-Di PigrobyharyudhaNo ratings yet

- uPVC & PVC Pipes Catalogue uPVC & PVC Pipes Catalogue: High Standard PipeDocument35 pagesuPVC & PVC Pipes Catalogue uPVC & PVC Pipes Catalogue: High Standard PipeFerryTimothyNo ratings yet

- Rubber Gasket (Full Face in Flat Face Flanges) Installation & TorqueDocument4 pagesRubber Gasket (Full Face in Flat Face Flanges) Installation & Torquecavillalobosb8167No ratings yet

- SleeveDocument16 pagesSleeveengsamerhozinNo ratings yet

- Pressure Testing of Pipeline Systems (Version 1.1.0, MAY 2013)Document46 pagesPressure Testing of Pipeline Systems (Version 1.1.0, MAY 2013)Amit SharmaNo ratings yet

- Smith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureDocument8 pagesSmith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureWong Chung MengNo ratings yet

- Hdpe Pressure Pipe ManualDocument62 pagesHdpe Pressure Pipe Manualmai huy tânNo ratings yet

- Pipe SupportDocument6 pagesPipe SupportEshant Rane RaneNo ratings yet

- Bolted Flanged Joints New Methods Practices ProceedingsDocument2 pagesBolted Flanged Joints New Methods Practices ProceedingsMladen ČorokaloNo ratings yet

- HDPE FittingsApril2012Document110 pagesHDPE FittingsApril2012Carlos GutierrezNo ratings yet

- Pressure VesselsDocument14 pagesPressure VesselsChevronelleNo ratings yet

- FRP Fabrication, Installation and Repair ProcedureDocument3 pagesFRP Fabrication, Installation and Repair Procedurearchalys4u100% (1)

- Hydrostatic TestingDocument18 pagesHydrostatic TestingRicardoNo ratings yet

- Water SoftenersDocument11 pagesWater Softenersadel rihanaNo ratings yet

- Hydrostatic Test Calculation FormulaDocument1 pageHydrostatic Test Calculation FormulaMajeed Rumani100% (1)

- Sluice Gate ValveDocument15 pagesSluice Gate ValveRinia DurrsakeNo ratings yet

- u-PVC InchDocument46 pagesu-PVC Inchegemen7404612No ratings yet

- Auger BoringDocument7 pagesAuger BoringMuhammad AmjadNo ratings yet

- Da and Dhda Datasheet Master - XLSM - Hpu-Dhda118-4.1 Rev1Document3 pagesDa and Dhda Datasheet Master - XLSM - Hpu-Dhda118-4.1 Rev1jujuroyaleNo ratings yet

- HOBAS Pressure Pipes SystemsDocument40 pagesHOBAS Pressure Pipes Systemsu_florinNo ratings yet

- HDPE Pipe and Fitting Materials Fusion Joining and Installation 1Document8 pagesHDPE Pipe and Fitting Materials Fusion Joining and Installation 1Mohamed ElsayedNo ratings yet

- Pipeline Acronyms and Classifications GuidelineDocument12 pagesPipeline Acronyms and Classifications GuidelinelsaishankarNo ratings yet

- Pipeline PigsDocument7 pagesPipeline PigsnadNo ratings yet

- INS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1Document7 pagesINS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1jayhuacat7743100% (4)

- Electrode Consumption PDFDocument1 pageElectrode Consumption PDFharold_bhieNo ratings yet

- 7hfkqlfdouhsruw Dvnhwvirusro/Hwk/Ohqh3 (SLSHFRQQHFWLRQV: A Technical Paper Presented by James Walker Australia Pty LTDDocument16 pages7hfkqlfdouhsruw Dvnhwvirusro/Hwk/Ohqh3 (SLSHFRQQHFWLRQV: A Technical Paper Presented by James Walker Australia Pty LTDthmaraishriNo ratings yet

- How To Calculate Surge Forces On Piping Systems - Intergraph CADWorx & AnalysisDocument4 pagesHow To Calculate Surge Forces On Piping Systems - Intergraph CADWorx & Analysissammar_10No ratings yet

- Welding enDocument54 pagesWelding enyohanes_ongNo ratings yet

- Sultanate's ultrasonic flowmeter standardsDocument3 pagesSultanate's ultrasonic flowmeter standardsaltipatlarNo ratings yet

- Pneumatic Testing Procedure For PipelinesDocument3 pagesPneumatic Testing Procedure For PipelinesKu Masayu Ku HusinNo ratings yet

- Pump Centrifugal Pre Commissioning ITPDocument10 pagesPump Centrifugal Pre Commissioning ITPMohamad IbrahimNo ratings yet

- Oil Cooler - Pre Design Data SheetDocument3 pagesOil Cooler - Pre Design Data SheetSakthi VelNo ratings yet

- 4.3 Basic Design Awwa D100 & Api 650Document7 pages4.3 Basic Design Awwa D100 & Api 650Miguel Martinez Guerrero100% (1)

- Commissioning Procedure APR10 GBDocument11 pagesCommissioning Procedure APR10 GBAleksanrd Mihailov100% (1)

- 0310-HPT Hydrostatic Pressure Test Procedure RADocument6 pages0310-HPT Hydrostatic Pressure Test Procedure RARamakrisnanMeenakshiSundaramRamaNo ratings yet

- Fundamentals of ValvesDocument28 pagesFundamentals of ValvesMohamed ModerNo ratings yet

- Pump Types Guide - Find the right pump for the jobDocument6 pagesPump Types Guide - Find the right pump for the jobEnvergyProjectsNo ratings yet

- Field Hydrotest Manual UndergroundDocument8 pagesField Hydrotest Manual UndergroundPhuoc PhuNo ratings yet

- Storage and HandlingDocument6 pagesStorage and HandlingalagurmNo ratings yet

- Hydrostatic Test of Pandi WaterDocument7 pagesHydrostatic Test of Pandi WaterOscar C. GabinayNo ratings yet

- Plumbing Design for a 4-Storey Mixed-Use BuildingDocument65 pagesPlumbing Design for a 4-Storey Mixed-Use BuildingCharles Kaven Dela Cruz100% (1)

- Welded Steel Pipe 10.10.07Document93 pagesWelded Steel Pipe 10.10.07Jose Alberto Patterson FelixNo ratings yet

- Pipeline Hydro Test Pressure Determination - Pipeline & Gas JournalDocument7 pagesPipeline Hydro Test Pressure Determination - Pipeline & Gas Journalmailmaverick8167100% (1)

- Europe's Longest Marine PE Pipe ProjectDocument8 pagesEurope's Longest Marine PE Pipe Projectmidhun1986No ratings yet

- How To Do A Tie-InDocument2 pagesHow To Do A Tie-Inrenjithv_4100% (1)

- How To Select A Heat Shrink SleeveDocument2 pagesHow To Select A Heat Shrink SleeveLava SatNo ratings yet

- R5000 IomDocument26 pagesR5000 Iomfuminori0% (1)

- Book 2: Chapter 4 - Fluid Flow: Application LimitationsDocument20 pagesBook 2: Chapter 4 - Fluid Flow: Application LimitationsVaniya GoelNo ratings yet

- Leak StopDocument18 pagesLeak StopAmrit SarkarNo ratings yet

- Above Ground Pipe Installation ManualDocument9 pagesAbove Ground Pipe Installation ManualPUSHKAR A JAINNo ratings yet

- Camx 2015 Vaidya UabDocument11 pagesCamx 2015 Vaidya UabJuNeng NigLtdNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Pressure Testing Outside The Trench:: Allowance For Expansion Under Test PressureDocument1 pagePressure Testing Outside The Trench:: Allowance For Expansion Under Test PressurembobterateraNo ratings yet

- Pressure Testing Piping SystemsDocument3 pagesPressure Testing Piping SystemsWeny Astuti100% (1)

- 330130Document7 pages330130Cool SharyNo ratings yet

- Annex1 - Technical Specifications PDFDocument64 pagesAnnex1 - Technical Specifications PDFabdelkader benabdallahNo ratings yet

- Acs 1208al 1216alDocument70 pagesAcs 1208al 1216alosto72No ratings yet

- LV Extension Box Dimentions, Depth 20cmDocument1 pageLV Extension Box Dimentions, Depth 20cmosto72No ratings yet

- Electrical Engineering Pocket Handbook - 09Document1 pageElectrical Engineering Pocket Handbook - 09osto72No ratings yet

- Electrical Engineering Pocket Handbook - 07Document1 pageElectrical Engineering Pocket Handbook - 07osto72No ratings yet

- Style, Comfort and Audio Quality.: Blackwire 3300 SeriesDocument2 pagesStyle, Comfort and Audio Quality.: Blackwire 3300 Seriesosto72No ratings yet

- NEMA NOMENCLATURE-6 LEADSDocument1 pageNEMA NOMENCLATURE-6 LEADSosto72No ratings yet

- Electrical Engineering Pocket Handbook - 01Document1 pageElectrical Engineering Pocket Handbook - 01osto72No ratings yet

- Electrical Engineering Pocket Handbook - 11Document1 pageElectrical Engineering Pocket Handbook - 11osto72No ratings yet

- Electrical Engineering Pocket Handbook - 08Document1 pageElectrical Engineering Pocket Handbook - 08osto72No ratings yet

- Electrical Engineering Pocket Handbook - 10Document1 pageElectrical Engineering Pocket Handbook - 10osto72No ratings yet

- Electrical Engineering Pocket Handbook - 04Document1 pageElectrical Engineering Pocket Handbook - 04osto72No ratings yet

- Blackwire 8225: User GuideDocument8 pagesBlackwire 8225: User Guideosto72No ratings yet

- Electrical Engineering Pocket Handbook - 06Document1 pageElectrical Engineering Pocket Handbook - 06osto72No ratings yet

- Electrical Engineering Pocket Handbook - 03Document1 pageElectrical Engineering Pocket Handbook - 03osto72No ratings yet

- Electrical Engineering Pocket Handbook - 05Document1 pageElectrical Engineering Pocket Handbook - 05osto72No ratings yet

- Wide. Wider. Widest.: Logitech Webcam C930eDocument3 pagesWide. Wider. Widest.: Logitech Webcam C930eraviezsoftNo ratings yet

- IEC 61439 Official ListDocument1 pageIEC 61439 Official Listosto72No ratings yet

- Voyager 6200 UC: Comfort. Versatility. PerformanceDocument2 pagesVoyager 6200 UC: Comfort. Versatility. Performanceosto72No ratings yet

- Ultra High Def For Ultra High Expectations.: Logitech BRIODocument3 pagesUltra High Def For Ultra High Expectations.: Logitech BRIOosto72No ratings yet

- Tia s7 1500 Programming 2 (Tia Pro2)Document2 pagesTia s7 1500 Programming 2 (Tia Pro2)osto720% (2)

- Product OverviewDocument4 pagesProduct Overviewmfarouk1No ratings yet

- Metal Enclosures - Al Fanar CatalogDocument20 pagesMetal Enclosures - Al Fanar CatalogAkhil MohanNo ratings yet

- Facom 75-10Document1 pageFacom 75-10osto72No ratings yet

- VW3A5207Document4 pagesVW3A5207osto72No ratings yet

- ASTM A-49 (2001) (Heat Treated Carbon Steel Joint Bars Microalloyed Joint Bars and Forged Carbon Steel Compromise Joint Bars)Document3 pagesASTM A-49 (2001) (Heat Treated Carbon Steel Joint Bars Microalloyed Joint Bars and Forged Carbon Steel Compromise Joint Bars)caballerolangNo ratings yet

- Brochure SXTab 7A EN1Document2 pagesBrochure SXTab 7A EN1osto72No ratings yet

- Al-Sayyed & Sons Trading CoDocument1 pageAl-Sayyed & Sons Trading Coosto72No ratings yet

- JFSC E102Document3 pagesJFSC E102osto72No ratings yet

- A2 PDFDocument3 pagesA2 PDFLelli KurniaNo ratings yet

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)jawadhussain1No ratings yet

- Aluform Work ChecklistDocument2 pagesAluform Work ChecklistVeera SenthilNo ratings yet

- Stralcio FIB 90Document7 pagesStralcio FIB 90Renzo DI VendraNo ratings yet

- Accelerated Bridge Construction PDFDocument347 pagesAccelerated Bridge Construction PDFဒုကၡ သစၥာNo ratings yet

- Precast Concrete Pile DesignDocument2 pagesPrecast Concrete Pile DesignSamishiNo ratings yet

- Building Services & Integration-1: KohinoorDocument5 pagesBuilding Services & Integration-1: KohinoorNithu NithiNo ratings yet

- Bilaga 3 ReservdelsprislistaDocument856 pagesBilaga 3 ReservdelsprislistaMarlon OliveiraNo ratings yet

- Tensile Structures: How They Work and Common TypesDocument10 pagesTensile Structures: How They Work and Common Typesaditya2053No ratings yet

- MC-Injekt 2700Document2 pagesMC-Injekt 2700Iker Astigarraga EpeldeNo ratings yet

- Jet PumpsDocument7 pagesJet PumpsNazeeh Abdulrhman AlbokaryNo ratings yet

- Lesson 2 Subsurface ExplorationDocument74 pagesLesson 2 Subsurface ExplorationJesser SollerNo ratings yet

- MEC103 Mechanics of Deformable Bodies Shearing StressDocument16 pagesMEC103 Mechanics of Deformable Bodies Shearing StressLorene Ropeta.No ratings yet

- Cat CPCA 06 SRV2017 03 PDFDocument48 pagesCat CPCA 06 SRV2017 03 PDFUmen AryanNo ratings yet

- Comprehensive Plumbing Legend and NotesDocument1 pageComprehensive Plumbing Legend and NotesJuanCarlosRodriguezVegaNo ratings yet

- GB1516 Sac 240 CV SP 0003 - ADocument31 pagesGB1516 Sac 240 CV SP 0003 - AkkkkNo ratings yet

- BILLING NO.2 - Daanlungsod-Calangahan DetailedDocument1 pageBILLING NO.2 - Daanlungsod-Calangahan Detailedanthony christian yangNo ratings yet

- Llb-Dissertation FinalDocument38 pagesLlb-Dissertation FinalRudy KameereddyNo ratings yet

- C.T. MCQ (Admixtures) 1 PDFDocument9 pagesC.T. MCQ (Admixtures) 1 PDFSameer KsNo ratings yet

- 201306190417510.technical Guide Uni 7000FDocument80 pages201306190417510.technical Guide Uni 7000Fdijana387No ratings yet

- Standard Reasons ListDocument4 pagesStandard Reasons List123444123No ratings yet

- Technical Manual For Constructing Ecosan Toilet: Environment & Public Health OrganizationDocument23 pagesTechnical Manual For Constructing Ecosan Toilet: Environment & Public Health OrganizationJonasbul Aluma JonasNo ratings yet

- BT 3 - Vernacular TermsDocument3 pagesBT 3 - Vernacular TermsJustin Ramos GollosoNo ratings yet

- Manual Fuji YidaDocument140 pagesManual Fuji Yidajeferson_camilo100% (1)

- Metal Siding Deflection LimitDocument1 pageMetal Siding Deflection Limitwaweng22No ratings yet

- Diaphragm Wall Construction SequenceDocument10 pagesDiaphragm Wall Construction Sequencedanzy89100% (2)

- Valtra S353Document610 pagesValtra S353Luis AndersonNo ratings yet

- NBC Code Etabs ReportDocument27 pagesNBC Code Etabs ReportAnish Neupane100% (3)

- Transmission and Distribution TechnologyDocument92 pagesTransmission and Distribution TechnologySing Yew LamNo ratings yet

- Joints: Types of Bolted or Riveted or Pinned JointsDocument11 pagesJoints: Types of Bolted or Riveted or Pinned JointsAhmad HamadehNo ratings yet

- ASME Stress CalcDocument96 pagesASME Stress CalclightsonsNo ratings yet

- Guide to Attaching Cables to NES PolesDocument29 pagesGuide to Attaching Cables to NES PolesDavid MarchandNo ratings yet