Professional Documents

Culture Documents

Mastertop 100 PDF

Uploaded by

Mohiuddin MuhinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mastertop 100 PDF

Uploaded by

Mohiuddin MuhinCopyright:

Available Formats

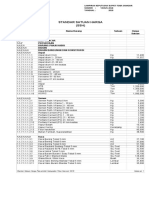

MASTERTOP 100

Natural aggregate surface hardener

DESCRIPTION

ESTIMATING DATA

DATA

Mastertop 100 is a pre-mixed, ready to use powder

designed to be applied as a dry shake over freshly floated

concrete floor or floor screed to obtain an aesthetically

pleasing, coloured floor with significant improvement in its

abrasion resistance. The products is based on selected

hard wearing mineral aggregates blended with certain

alkali and light fast colouring pigments and hydraulic

binders. Mastertop 100 is available in various standard

colours. A Light Reflective grade is available to order.

The rate of application will depend on the service

conditions that the floor will be exposed to and the

richness of colour required. The recommended rate is

5kg per m.

RECOMMENDED FOR

Mastertop 100 is recommended for treating floor areas

not exposed to serious chemical attack and where

uniform appearance and enhanced abrasion resistance

are desired. Applications include floor areas of:

Light Industrial and commercial buildings

Basement and cellars

Mechanical workshops

Storage rooms

Corridors, halls

Educational institutions

Parking areas

Loading platforms

FEATURES AND BENEFITS

Uniform and intense colourscolours attractive floors.

Pleasant working environment.

Light and alkalialkali-fast pigmentsigments durable, non-fading

colours.

Good abrasion resistanceresistance minimised maintenance of

floor surface.

Dense surfacesurface increased resistance to ingress of oil

and grease. Easy to clean.

PERFORMANCE DATA

DATA

Abrasion Resistance (ASTM C779)

0.65mm at 60 minutes

(33MPa concrete more than 1.4mm at 60 minutes)

Impact resistance (LA Rattler)

50% weight Loss

(33MPa concrete has 70% loss of weight)

(See Technical Sheet 22 for explanation of abrasion and

impact tests and how they relate to long-term durability of

the floor)

The performance data is typical and based upon

controlled laboratory conditions. Actual performance on

the job site may vary from these values based on actual

site conditions.

APPLICATION

For information about application, please obtain a copy of

the BASF Application Guide for Mastertop 100 from your

local representative.

Preparation of the Concrete

Concrete for single course monolithic floors should be

capable of achieving a 28 day compressive strength of

30MPa with a slump of 80mm or less, and with no more

than 3% air. Concrete should not contain calcium

chloride.

Mastertop 100 is applied as a dry shake over freshly

wooden bullfoated concrete.

COLOURS

Mastertop 100 is available in natural (concrete colour),

light reflective and a range of colours. Please consult your

local

BASF

Construction

Chemicals

technical

representative with regard to minimum order quantities

and lead times for coloured products.

FIELD SERVICE

BASF Construction Chemicals recommends that the user

request the free services of the local representative for a

pre-job conference to carefully place each step of the

installation.

PACKAGING

Mastertop 100 is packaged ready to use in 25kg bags.

No further measuring or mixing or ingredients is required

or permitted at the jobsite.

SHELF LIFE

LIFE

Mastertop 100 can be stored for 18 months.

PRECAUTIONS

Application is strongly recommended to be done after

roofing is completed. ONLY attempt modest size

slabs without a roof.

Do not apply over concrete containing added calcium

chloride.

Do not apply over concrete containing aggregate

contaminated with salt or salt water.

Do not apply over concrete containing more than 3%

entrained air**.

MASTERTOP 100

Use only admixtures in the concrete that are

approved by BASF Construction Chemicals.

Do not use water, burlap or polyethylene covering for

curing. Use only curing compounds approved by

BASF Construction Chemicals.

This product contains cement, which may cause

irritation. Avoid contact with eyes and prolonged

contact with skin.

For the full health and safety hazard information and how

to safely handle and use this product, please make sure

that you obtain a copy of the BASF Construction

Chemicals Material Safety Data Sheet (MSDS)

(MSDS from our

office or our website.

** Higher entrained air contents are often required for

concrete slabs exposed to water saturation and

freeze/thaw cycles. The high air content makes

proper application of dry shakes difficult or

impractical, depending on the dimensions of the

placement and ambient conditions.

STATEMENT OF

RESPONSIBILITY

SMt100/

Mt100/11/0310

/0310

The technical information and application advice given in this BASF Construction Chemicals publication are based on

the present state of our best scientific and practical knowledge. As the information herein is of a general nature, no

assumption can be made as to a product's suitability for a particular use or application and no warranty as to its

accuracy, reliability or completeness either expressed or implied is given other than those required by law. The user is

responsible for checking the suitability of products for their intended use. BASF Construction Chemicals data sheets

are updated on a regular basis and it is the users responsibility to obtain the most recent issue.

NOTE

Field service where provided does not constitute supervisory responsibility. Suggestions made by BASF either orally or

in writing may be followed, modified or rejected by the owner, engineer or contractor since they, and not BASF

Construction Chemicals,

Chemicals are responsible for carrying out procedures appropriate to a specific application.

BASF Construction Chemicals offices in ASEAN

Singapore

Tel: +65-6861-6766

Fax: +65-6861-3186

Malaysia

Tel: +60-3-5628-3888

Fax: +60-3-5628-3776

Website: www.ap.cc.basf.com

Indonesia

Tel: +62-21-526-2481

Fax: +62-21-526-2541

Thailand

Tel: +66-2-664-9222

Fax: +66-2-664-9267

Vietnam

Tel: +84-650-374-3100

Fax: +84-650-374-3200

Philippines

Tel: +63-2-811-8000

Fax: +63-2-838-1025

You might also like

- Lampiran 3. WPS of Pile JointDocument3 pagesLampiran 3. WPS of Pile JointDoni TriatmojoNo ratings yet

- U Cân BDE-2007Document49 pagesU Cân BDE-2007Awidhi KresnawanNo ratings yet

- Conplast CWPDocument2 pagesConplast CWPawliyaizzatiNo ratings yet

- Nitowrap FRC BaruDocument2 pagesNitowrap FRC BaruZax SantanaNo ratings yet

- Detai Rip Plate: Penerangan Jalan UmumDocument1 pageDetai Rip Plate: Penerangan Jalan UmumGo PeaksNo ratings yet

- Lokfix E75 TDS 8072020Document5 pagesLokfix E75 TDS 8072020KumarRamNo ratings yet

- Sika Bitumen® - WDocument3 pagesSika Bitumen® - WMohamed MamdohNo ratings yet

- Master Glenium SKY 8108: High Range Water Reducing AdmixtureDocument2 pagesMaster Glenium SKY 8108: High Range Water Reducing Admixturedana setiawanNo ratings yet

- Hot Rolled H-Beam Standard SizesDocument2 pagesHot Rolled H-Beam Standard SizesRenny RevildaNo ratings yet

- Construction Methods for Wharf StructuresDocument43 pagesConstruction Methods for Wharf Structuresruli100% (1)

- Cebex 100 Non-Shrink Grout AdmixtureDocument19 pagesCebex 100 Non-Shrink Grout AdmixturePutu Roby Adhitya Sapanca100% (1)

- Polifelt CatalogDocument28 pagesPolifelt CatalogCreanga CristinaNo ratings yet

- Datasheet Cofraplus 60Document2 pagesDatasheet Cofraplus 60Žarko JanjićNo ratings yet

- Facade & Fenestration Glass Embedding General GuidelinesDocument20 pagesFacade & Fenestration Glass Embedding General GuidelinesFrancisco BastidasNo ratings yet

- Tekcon - Spun Piles PropertiesDocument10 pagesTekcon - Spun Piles PropertiesChung Yiung YungNo ratings yet

- CMP0000599 - PC - Katalog Bevananda PDFDocument8 pagesCMP0000599 - PC - Katalog Bevananda PDFRieskeIswardhanyNo ratings yet

- Sika Backing RodDocument2 pagesSika Backing Rodthe pilotNo ratings yet

- Sikaflex Pro 3 WF Pds enDocument4 pagesSikaflex Pro 3 WF Pds enrydocNo ratings yet

- Daftar Peserta Skill Tes PT Pamapersada NusantaraDocument38 pagesDaftar Peserta Skill Tes PT Pamapersada NusantaraToupik JelaniNo ratings yet

- Fire Door Specification SheetDocument3 pagesFire Door Specification SheetBobby Underscore Tangger0% (1)

- 8.1 Fis em RebarDocument51 pages8.1 Fis em RebarJeyasingh GopalakrishnanNo ratings yet

- PU-300 Polyurethane Grouting Stops Water Leakage PermanentlyDocument2 pagesPU-300 Polyurethane Grouting Stops Water Leakage Permanentlymarklester100% (1)

- 17-1 Usage of Recycled Tyre MCRJ Volume 29, No.3, 2019 PDFDocument10 pages17-1 Usage of Recycled Tyre MCRJ Volume 29, No.3, 2019 PDFNor Intang Setyo HNo ratings yet

- Katalog Roman GranitDocument239 pagesKatalog Roman Granitadam tianziNo ratings yet

- Way Sekampung Regulating DAM Project: TunnelDocument1 pageWay Sekampung Regulating DAM Project: Tunnelardhyr ardhyrNo ratings yet

- Sika Viscocrete 3115Document2 pagesSika Viscocrete 3115Ronald MassoraNo ratings yet

- Sika Viscoflow®-3880 LV: Product Data SheetDocument3 pagesSika Viscoflow®-3880 LV: Product Data Sheetedars08100% (1)

- PC Spun PilesDocument2 pagesPC Spun PilesJoglo Solo100% (1)

- Calculation Report For PHC Pile: I. Input Data For Pile's Material I.1. Effective Presstress: ValueDocument3 pagesCalculation Report For PHC Pile: I. Input Data For Pile's Material I.1. Effective Presstress: ValuehuhumaluNo ratings yet

- COMPANY PROFILE PT. JAYA OBAYASHI Reduced - Compressed-CompressedDocument24 pagesCOMPANY PROFILE PT. JAYA OBAYASHI Reduced - Compressed-CompressedMUMU WarungNo ratings yet

- Fiber Carbon (New) - 2018 PDFDocument4 pagesFiber Carbon (New) - 2018 PDFDona Dwi SaputroNo ratings yet

- Aashto/Pci Standard Products: Appendix BDocument2 pagesAashto/Pci Standard Products: Appendix BJavier CaballeroNo ratings yet

- Tabel Baja ProfilDocument23 pagesTabel Baja ProfilChandra Eko PrasetyoNo ratings yet

- Kepmen 555 - EnglishDocument153 pagesKepmen 555 - Englishbqdianz100% (1)

- Jakarta Central Asia Steel Certificate QMS43581 20220714Document1 pageJakarta Central Asia Steel Certificate QMS43581 20220714Slamet Tri UsadhaNo ratings yet

- Geotechnical - Investigation - For Bilika PV - Hybrid - Power - PlantDocument20 pagesGeotechnical - Investigation - For Bilika PV - Hybrid - Power - Plantmessay100% (1)

- Company Profil PT. Sakura Matriks Utama RevisiDocument37 pagesCompany Profil PT. Sakura Matriks Utama Revisiyonathan haris tangdililingNo ratings yet

- Pengaruh Plstiment VZ Terhadap BetonDocument20 pagesPengaruh Plstiment VZ Terhadap BetonMalikNo ratings yet

- Main Sentences - Review Report On Existing Studies - Hasang HPP Project 130225 PDFDocument94 pagesMain Sentences - Review Report On Existing Studies - Hasang HPP Project 130225 PDFMuhammad TrayaNo ratings yet

- Harga Bahan Pemkab TOBASA 2019 OK PDFDocument406 pagesHarga Bahan Pemkab TOBASA 2019 OK PDFSyaifudin IsharNo ratings yet

- The Disadvantages of Fly AshDocument8 pagesThe Disadvantages of Fly AshShariar Masud TowhidNo ratings yet

- LOAD-TESTS-ON-PILESDocument48 pagesLOAD-TESTS-ON-PILESFajrin M. NatsirNo ratings yet

- Larssen Sheet Piles PalPile 341015478Document1 pageLarssen Sheet Piles PalPile 341015478Moataz M. M. RizkNo ratings yet

- Brosure Post Tension WBP 02 PDFDocument11 pagesBrosure Post Tension WBP 02 PDFikhsan fahroziNo ratings yet

- American Wide F Beam 6Document1 pageAmerican Wide F Beam 6bhaskarNo ratings yet

- PC Spun PilesDocument2 pagesPC Spun PilesFaridah Zahra100% (1)

- Glass Calculation ParametersDocument10 pagesGlass Calculation ParametersshoebNo ratings yet

- Specifications of Structural Steel and Sheet PileDocument8 pagesSpecifications of Structural Steel and Sheet PileAloysius Ferry Setiawan DaryantoNo ratings yet

- Pene Seal Pro Spec DataDocument2 pagesPene Seal Pro Spec DataAnonymous sF1BLz2PNo ratings yet

- Mutu Beton Standar EropaDocument1 pageMutu Beton Standar EropaDedy RachayuNo ratings yet

- Retaining Wall AhmadDocument1 pageRetaining Wall AhmadEngr Ahmad100% (1)

- MSDS 0008 Concrete Material Safety Data SheetDocument8 pagesMSDS 0008 Concrete Material Safety Data SheetGangsar Lukmanjaya100% (1)

- Dyna Bolt Technical DataDocument1 pageDyna Bolt Technical DataSulthan AriNo ratings yet

- Brochure Wika CLT - A5 - 280717 PDFDocument19 pagesBrochure Wika CLT - A5 - 280717 PDFHvbryNo ratings yet

- Mastertop 100 Asean 0310Document2 pagesMastertop 100 Asean 0310BamsiamNo ratings yet

- Mastertop 290: Iron Aggregate Hardener For Concrete FloorsDocument3 pagesMastertop 290: Iron Aggregate Hardener For Concrete FloorsFrancois-No ratings yet

- 05 - TDS - Mastertop 300Document4 pages05 - TDS - Mastertop 300Vimal KakNo ratings yet

- Macismo E210906 Cold AsphaltDocument3 pagesMacismo E210906 Cold AsphaltgkarakaxisNo ratings yet

- MasterSeal 550Document2 pagesMasterSeal 550Muhammad Abdul Wajid RaiNo ratings yet

- Mastertop 100: Dry-Shake Surface Hardener For Concrete Industrial FloorsDocument2 pagesMastertop 100: Dry-Shake Surface Hardener For Concrete Industrial FloorsFrancois-No ratings yet

- DR Fixit Samshield XL 1500 PDFDocument3 pagesDR Fixit Samshield XL 1500 PDFNational WaterproofingNo ratings yet

- DR Fixit Powercrete 77 1Document4 pagesDR Fixit Powercrete 77 1Karthikeyan PanchatcharamNo ratings yet

- 196 DR Fixit BitufixDocument3 pages196 DR Fixit BitufixMohiuddin MuhinNo ratings yet

- 101 DR Fixit Pidiproof LW+ PDFDocument2 pages101 DR Fixit Pidiproof LW+ PDFRishabh VijayNo ratings yet

- 35th BCS Final ResultDocument17 pages35th BCS Final ResultMohiuddin MuhinNo ratings yet

- 640 Dr. Fixit Raincoat 2 in 1Document3 pages640 Dr. Fixit Raincoat 2 in 1Rakib IslamNo ratings yet

- Dr. Fixit Fastflex: High Performance Polymer Modified Cementitious CoatingDocument3 pagesDr. Fixit Fastflex: High Performance Polymer Modified Cementitious CoatingDeep GandhiNo ratings yet

- 196 DR Fixit BitufixDocument3 pages196 DR Fixit BitufixMohiuddin MuhinNo ratings yet

- 101 DR Fixit Pidiproof LW+ PDFDocument2 pages101 DR Fixit Pidiproof LW+ PDFRishabh VijayNo ratings yet

- 103 DR Fixit Repellin WRDocument3 pages103 DR Fixit Repellin WRMohiuddin MuhinNo ratings yet

- Pidilite Speciality Chemicals (BD) Pvt. Ltd. (Maker of Fevicol)Document1 pagePidilite Speciality Chemicals (BD) Pvt. Ltd. (Maker of Fevicol)Mohiuddin MuhinNo ratings yet

- 103 DR Fixit Repellin WRDocument3 pages103 DR Fixit Repellin WRMohiuddin MuhinNo ratings yet

- MasterSeal 910Document2 pagesMasterSeal 910Mohiuddin MuhinNo ratings yet

- Masterflow 715: Non-Shrink, Cementitious Grout For Use in General Civil Engineering WorksDocument2 pagesMasterflow 715: Non-Shrink, Cementitious Grout For Use in General Civil Engineering WorksMohiuddin Muhin50% (2)

- Masteremaco P 130: Two Component Epoxy Based Zinc Rich Primer For SteelDocument2 pagesMasteremaco P 130: Two Component Epoxy Based Zinc Rich Primer For SteelMohiuddin MuhinNo ratings yet

- BASF MasterSeal M 800Document4 pagesBASF MasterSeal M 800Mohiuddin Muhin100% (2)

- MasterGlenium ACE 8761 v1Document3 pagesMasterGlenium ACE 8761 v1Mohiuddin MuhinNo ratings yet

- ProductivityDocument31 pagesProductivityMohiuddin MuhinNo ratings yet

- MasterEmaco P 168 v1Document2 pagesMasterEmaco P 168 v1Mohiuddin MuhinNo ratings yet

- MasterTop 1200 EngDocument3 pagesMasterTop 1200 EngMohiuddin MuhinNo ratings yet

- MASTERSEAL 550 v6Document2 pagesMASTERSEAL 550 v6Mohiuddin MuhinNo ratings yet

- Aci Rap-1Document7 pagesAci Rap-1Mauricio De Stefani100% (1)

- Masterseal NP 472 Tds UaeDocument2 pagesMasterseal NP 472 Tds UaeMohiuddin MuhinNo ratings yet

- Basf Masterbrace 1414 TdsDocument2 pagesBasf Masterbrace 1414 TdsMohiuddin MuhinNo ratings yet

- Ucrete MFDocument3 pagesUcrete MFMohiuddin MuhinNo ratings yet

- MasterEmaco N 303 Formerly Emaco - R303M - EGDocument2 pagesMasterEmaco N 303 Formerly Emaco - R303M - EGMohiuddin Muhin100% (1)

- Masterflow 870Document3 pagesMasterflow 870Mohiuddin MuhinNo ratings yet

- Basf Masterbrace 1414 TdsDocument2 pagesBasf Masterbrace 1414 TdsMohiuddin MuhinNo ratings yet

- Current Invoice Amount in BDT Previous Balance in BDT Amount Payable by 08-Aug-2015Document1 pageCurrent Invoice Amount in BDT Previous Balance in BDT Amount Payable by 08-Aug-2015Mohiuddin MuhinNo ratings yet

- Niosh SHO Exam Notes - Module 3 Question and Answer PDFDocument19 pagesNiosh SHO Exam Notes - Module 3 Question and Answer PDFExcellentdeals4all94% (51)

- VOC PlanDocument132 pagesVOC PlanBoris PetrovicNo ratings yet

- Carbonate Acidizing Design PDFDocument15 pagesCarbonate Acidizing Design PDFNelson PuentsNo ratings yet

- Applied Quantum Mechanics: DR Uzma KhaliqueDocument29 pagesApplied Quantum Mechanics: DR Uzma KhaliqueNaveed SultanNo ratings yet

- Extended Safety Data Sheet for Agidol-1Document24 pagesExtended Safety Data Sheet for Agidol-1Sekawan CosmeticsNo ratings yet

- Reanna DixonDocument10 pagesReanna DixonElvin BucknorNo ratings yet

- Air Carbon Arc GougingDocument3 pagesAir Carbon Arc GougingMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Rock Failure under Confined Brazilian TestDocument9 pagesRock Failure under Confined Brazilian TestMichel SartoNo ratings yet

- Lactobacillus Plantarum Strain (BAA-793) Via Solid State FermentationDocument7 pagesLactobacillus Plantarum Strain (BAA-793) Via Solid State FermentationChairun NisaNo ratings yet

- Mineral PropertiesDocument3 pagesMineral PropertiesAji SuhadiNo ratings yet

- MKS-112-TS-AZ7-RPT-03 - A - Design Report For Internal Corrosion Monitoring SystemDocument16 pagesMKS-112-TS-AZ7-RPT-03 - A - Design Report For Internal Corrosion Monitoring SystemĐiệnBiênNhâm100% (1)

- Maths Question of The DayDocument162 pagesMaths Question of The DayGaurav YadavNo ratings yet

- GSI SLV SFI Whitepaper EN PDFDocument9 pagesGSI SLV SFI Whitepaper EN PDFjayahasanNo ratings yet

- Bio Energiser Hair Boost Caffeine Power Tonic MSDS October 2016Document3 pagesBio Energiser Hair Boost Caffeine Power Tonic MSDS October 2016Alexander JefferyNo ratings yet

- 00 Gas Conversion ChartsDocument6 pages00 Gas Conversion Chartskarun agrawalNo ratings yet

- CR8047 Sulzer CompaX Short Report1Document20 pagesCR8047 Sulzer CompaX Short Report1DucVikingNo ratings yet

- Duplex and Superduplex Stainless Steel Fittings (Amendments/Supplements To Astm A 815)Document11 pagesDuplex and Superduplex Stainless Steel Fittings (Amendments/Supplements To Astm A 815)Mathew CherianNo ratings yet

- Typical Specification - Russian PCI Coal - KravaskyDocument1 pageTypical Specification - Russian PCI Coal - Kravaskynaresh adusumilliNo ratings yet

- Book of AbstractsDocument56 pagesBook of AbstractsCojocaru Bogdan EugenNo ratings yet

- Biochemical TestsDocument2 pagesBiochemical TestsJacqueline DavisNo ratings yet

- Earth System History 4th Edition Stanley Test BankDocument6 pagesEarth System History 4th Edition Stanley Test BankVernon Hilton100% (31)

- Experiment 1 Lab ReportDocument25 pagesExperiment 1 Lab ReportJasper Laurence SyNo ratings yet

- Kinematic Viscosity of Transparent and Opaque Liquids (And Calculation of Dynamic Viscosity)Document15 pagesKinematic Viscosity of Transparent and Opaque Liquids (And Calculation of Dynamic Viscosity)Luigi MazzuccoNo ratings yet

- DNAfractalantenna 1Document8 pagesDNAfractalantenna 1Guilherme UnityNo ratings yet

- Hombright S-Id (WD)Document6 pagesHombright S-Id (WD)何恭彥No ratings yet

- Cleaning AC Coils ArticleDocument5 pagesCleaning AC Coils ArticleTauseefAhmadNo ratings yet

- Test Bank For Essentials of Genetics 8th Edition by KlugDocument9 pagesTest Bank For Essentials of Genetics 8th Edition by Klugminhkhoit8cua3No ratings yet

- Summary of Scigress Commands Practical 1: Task Scigress Command Shortcut Comments/notesDocument4 pagesSummary of Scigress Commands Practical 1: Task Scigress Command Shortcut Comments/notesnoorNo ratings yet

- 6 A5 Amiya Kumar SahuDocument7 pages6 A5 Amiya Kumar SahuChandan KumarNo ratings yet

- RMS 6th 2019Document14 pagesRMS 6th 2019angelgupta2303No ratings yet