Professional Documents

Culture Documents

2014 139 - X-EGN - X-GHP - X-GN - DFTM - 2015 - Engpdf - Technical - Information - ASSET - DOC - 2597819 PDF

Uploaded by

Difa LiuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2014 139 - X-EGN - X-GHP - X-GN - DFTM - 2015 - Engpdf - Technical - Information - ASSET - DOC - 2597819 PDF

Uploaded by

Difa LiuCopyright:

Available Formats

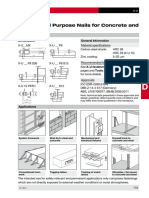

X-EGN, X-GHP, X-GN

X-EGN, X-GHP, X-GN: GX Fasteners

Product data

General information

X-EGN 14

Material specifications

o 6.8

Dimensions

1.8

o3

Carbon steel shank:

X-EGN

X-GHP

X-GN

Zinc coating:

213 m

14

15.8

HRC 58

HRC 58

HRC 53.5

o 6.8

X-GHP 16/18/20/24

1.8

Recommended fastening tools

o3

GX 120, GX 120-ME

GX 100, GX 100 E

Ls

L

See X-EGN, X-GHP, X-GN fastener program in the next pages and

Tools and equipment chapter for more details.

o 6.8

X-GN 20/27/32

1.9

Approvals

o3

ICC-ESR 1752 (USA):

Ls

L

IBMB

X-GN 39

o5

o 2.6

1.9

X-GN 20/27/32, X-EGN 14,

X-GHP 16/18/20/24

X-GHP, X-GN

Note: technical data presented in these approvals and design guidelines

reflect specific local conditions and may differ from those published in

this handbook.

39

40.9

Applications

Examples

Drywall tracks to concrete and steel

08 / 2014

Electrical applications

139

X-EGN, X-GHP, X-GN

Load data

Recommended loads

Vrec

Nrec

Design conditions:

Minimum 5 fastenings per fastened unit

All visible failures must be replaced

Vrec [kN]

hET [mm]

0.4

0.4

27

0.3

0.3

22

0.2

0.2

18

0.1

0.1

14

Steel

Nrec = Vrec = 0.4 kN

Application requirements

Thickness of base material

Concrete

Steel

70

tII

hmin

Concrete

Nrec [kN]

dnom

tll 4 mm

hmin = 60 mm

(dnom = 3.0 mm)

Thickness of fastened material

Wooden track:

Metal track:

140

tl 24 mm

tl 2 mm

08 / 2014

X-EGN, X-GHP, X-GN

Spacing and edge distances (mm)

Spacing along track

(as per U.S. Gypsum Handbook)

All track ends (cut-outs for doors),

secure with 2 nails

40

Distance to edge of concrete /

sandlime masonry

40

80

80

40

80

Fastener spacings on wood:

160-800

70

100

22

80

4.5 dnom = 14mm

Corrosion information

The intended use only comprises fastenings which are not directly exposed to external

weather conditions or moist atmospheres. For further detailed information on corrosion see

relevant chapter in Direct Fastening Principles and Technique section.

Application limits

Steel

20

18

Steel thickness, tII [mm]

16

14

12

10

S235Jxx

S235Jxx

S275Jxx

8

6

4

400

S355Jxx

450

500

550

600

650

Steel strength, Rm [N/mm2]

700

750

X-EGN 14

08 / 2014

141

X-EGN, X-GHP, X-GN

Fastener selection and system recommendation

Fastener selection

Fastening to concrete / sandlime masonry

Application

Base material

Wooden track (tI 24 mm) Concrete/sandlime masonry

X-GN 27MX

Metal track

Concrete/sandlime masonry

X-GN 20 MX

Metal track

Concrete/sandlime masonry

X-GHP_MX

Metal track

Concrete/sandlime masonry

Application

Base material

Metal track

Steel

increasing

strength

X-GN 39 MX

Fastening to steel

X-EGN 14

Fastener program

Item no.

Ls [mm]

L [mm]

dnom [mm]

X-EGN 14 MX

340231

14

15.8

3.0

X-GHP 16 MX

2071471

16

17.8

3.0

X-GHP 18 MX

340228

18

19.8

3.0

X-GHP 20 MX

285724

20

21.8

3.0

X-GHP 24 MX

438945

24

25.8

3.0

X-GN 20 MX

340232

19

20.9

3.0

X-GN 27 MX

340230

27

28.9

3.0

X-GN 32 MX

340233

32

33.9

3.0

X-GN 39 MX

340234

39

40.9

2.6

Tool and gas can

Designation

GX 120 / GX 120 ME

with gas can GC 20, GC 21 and GC 22

GX 100 / GX 100 E

with gas can GC 11 and GC 12 (for USA)

142

08 / 2014

X-EGN, X-GHP, X-GN

Fastening quality assurance

Fastening inspection

Fastening to steel

Fastening to concrete / sandlime masonry

hCS

hNVS

tI

tI

hNVS

tI

X-GN/GHP: hNVS = 25 mm

X-GN 39: hCS = 23 mm

X-EGN 14: hNVS = 47 mm

08 / 2014

143

You might also like

- 2013 201 - X-FCM Grating Fastening SystemDocument7 pages2013 201 - X-FCM Grating Fastening SystemDifa LiuNo ratings yet

- 2014 119 X-U - DFTM 2015 Engpdf Technical Information ASSET DOC 2597808Document9 pages2014 119 X-U - DFTM 2015 Engpdf Technical Information ASSET DOC 2597808Difa LiuNo ratings yet

- 2013 181 X-Em6h X-Ew6h X-Ef7h X-Em8h X-Em10h Ew10h - Threaded Studs For SteelDocument6 pages2013 181 X-Em6h X-Ew6h X-Ef7h X-Em8h X-Em10h Ew10h - Threaded Studs For SteelDifa LiuNo ratings yet

- 2014 195 X-CR M - DFTM 2015 Engpdf Technical Information ASSET DOC 2597844Document5 pages2014 195 X-CR M - DFTM 2015 Engpdf Technical Information ASSET DOC 2597844Difa LiuNo ratings yet

- 2013 157 - X-CR - Steel - DFTM - 2015 - Engpdf - Technical - Information - ASSET - DOC - 2597828 PDFDocument4 pages2013 157 - X-CR - Steel - DFTM - 2015 - Engpdf - Technical - Information - ASSET - DOC - 2597828 PDFDifa LiuNo ratings yet

- Hilti Direct Fastening SystemsDocument17 pagesHilti Direct Fastening Systemsbharathanin100% (1)

- 2014 237 X-HS X-CC - DFTM 2015 Engpdf Technical Information ASSET DOC 2597991Document6 pages2014 237 X-HS X-CC - DFTM 2015 Engpdf Technical Information ASSET DOC 2597991Difa LiuNo ratings yet

- 2013 87 - X-EnP Siding and Decking NailDocument8 pages2013 87 - X-EnP Siding and Decking NailDifa LiuNo ratings yet

- Hilti CatalogueDocument194 pagesHilti CatalogueFeleki AttilaNo ratings yet

- 111 1400 Simon Black Jaguar Land RoverDocument29 pages111 1400 Simon Black Jaguar Land RoverseehariNo ratings yet

- X BT Brochure en W3987Document68 pagesX BT Brochure en W3987Paul RobbinsNo ratings yet

- Base CHS X 10tDocument7 pagesBase CHS X 10tCollin NguNo ratings yet

- Hilti HST 1Document11 pagesHilti HST 1Mihnea-Bogdan NicolaescuNo ratings yet

- Api Plan 11Document6 pagesApi Plan 11johnsaballaNo ratings yet

- 736018Document2 pages736018Cao LanhNo ratings yet

- X-ECT MX, X-UCT MX and X-EKS MX fasteners and toolsDocument4 pagesX-ECT MX, X-UCT MX and X-EKS MX fasteners and toolsDifa LiuNo ratings yet

- Bypass - Damper Johnson ControlDocument6 pagesBypass - Damper Johnson Controlamirin_kingNo ratings yet

- X-C Nails For Concrete and Sand-lime-Masonry: General Information Dimensions Product DataDocument5 pagesX-C Nails For Concrete and Sand-lime-Masonry: General Information Dimensions Product DataDifa LiuNo ratings yet

- Trugrid Structural Final DraftDocument27 pagesTrugrid Structural Final DraftrogerngcyNo ratings yet

- Motor Ys11Document3 pagesMotor Ys11mspd2003No ratings yet

- Material Selection and NameDocument6 pagesMaterial Selection and NameHlaingm KyawNo ratings yet

- 734330Document2 pages734330Vladimir KoshmareNo ratings yet

- Hilti HIT-HY 150 MAX anchor systemDocument12 pagesHilti HIT-HY 150 MAX anchor systemMihnea-Bogdan NicolaescuNo ratings yet

- Multi-band Panel Dual Polarization Fixed Electrical DowntiltDocument2 pagesMulti-band Panel Dual Polarization Fixed Electrical DowntiltDenis LjNo ratings yet

- Type Code Pumps, Options and MaterialsDocument12 pagesType Code Pumps, Options and MaterialspablopinNo ratings yet

- Dual Polarized Flat Antenna 2 x 17.5 dBi - 65° GSM 1800 MHzDocument2 pagesDual Polarized Flat Antenna 2 x 17.5 dBi - 65° GSM 1800 MHzClaudio CalabreseNo ratings yet

- Valvula Borboleta Lug z411 ADocument6 pagesValvula Borboleta Lug z411 AWellington S. FrançaNo ratings yet

- General: Part Number: Status: Overview: DescriptionDocument2 pagesGeneral: Part Number: Status: Overview: DescriptionhkchingNo ratings yet

- 6.direct Fastening SystemsDocument4 pages6.direct Fastening SystemsincineratoriumNo ratings yet

- Data Sheet Tag 180-Pu-011eDocument8 pagesData Sheet Tag 180-Pu-011eSarah PerezNo ratings yet

- Worm Gear Sets enDocument30 pagesWorm Gear Sets enKarim FawziNo ratings yet

- PDFDocument20 pagesPDFsteve_fletch6225No ratings yet

- Corning PDFDocument0 pagesCorning PDFTфmmy WilmarkNo ratings yet

- For Harsh and Hazardous Locations: Exe EnclosuresDocument79 pagesFor Harsh and Hazardous Locations: Exe EnclosuresSimon LyonNo ratings yet

- 80010046v01 15 7 2013 10 19 5 331Document2 pages80010046v01 15 7 2013 10 19 5 331Ricardo LoureiroNo ratings yet

- ELGES Alloy Steel Rod Ends: Corrosion-ResistantDocument8 pagesELGES Alloy Steel Rod Ends: Corrosion-Resistantdunareanu_marian8668No ratings yet

- 2015 187 X-BT - DFTM 2015 Engpdf Technical Information ASSET DOC 2597837Document8 pages2015 187 X-BT - DFTM 2015 Engpdf Technical Information ASSET DOC 2597837Difa LiuNo ratings yet

- X ST GR Data Sheet Technical Information ASSET DOC 7304093Document5 pagesX ST GR Data Sheet Technical Information ASSET DOC 7304093Matt ThompsonNo ratings yet

- Data SheetDocument3 pagesData Sheetsydneyaus2005No ratings yet

- Bul SAE J2044 PDFDocument8 pagesBul SAE J2044 PDFhansegvNo ratings yet

- CB3033BS66,1MI4P LS71 0,09kW 365V 87HzDocument4 pagesCB3033BS66,1MI4P LS71 0,09kW 365V 87Hzmagda_biricaNo ratings yet

- Es LF289Document2 pagesEs LF289WattsNo ratings yet

- X ST GRDocument4 pagesX ST GRkerolcarrollNo ratings yet

- Dual Polarization Fixed Electrical Downtilt Panel AntennaDocument2 pagesDual Polarization Fixed Electrical Downtilt Panel AntennaAmani AthaNo ratings yet

- SOPORTERIADocument28 pagesSOPORTERIAWilliamsh1aNo ratings yet

- 736 623Document2 pages736 623slymnNo ratings yet

- Diablo 3 D TiledDocument25 pagesDiablo 3 D Tiledmam73No ratings yet

- 741989Document3 pages741989Indra AminudinNo ratings yet

- HSA Stud AnchorDocument12 pagesHSA Stud Anchorganesh_3No ratings yet

- KAT A 2410 PA ZETA Pneumatic Edition7!31!01 2013 enDocument3 pagesKAT A 2410 PA ZETA Pneumatic Edition7!31!01 2013 enGabriela AxinteNo ratings yet

- MASTIP-HOT RUNNER-SystemSelectionGuide - V2.07Document44 pagesMASTIP-HOT RUNNER-SystemSelectionGuide - V2.07Sree RajNo ratings yet

- Hilti ClipDocument6 pagesHilti ClipmandregomesNo ratings yet

- Three-point grippers optimize handling tasksDocument10 pagesThree-point grippers optimize handling tasksmohan raoNo ratings yet

- ARI StobuDocument2 pagesARI StobuMoonzeNo ratings yet

- Torqueo Pikotek PDFDocument4 pagesTorqueo Pikotek PDFjast111100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Fiche - Prod - TFC - UD - 75 - 350-ACI - en - V04 Version TempDocument2 pagesFiche - Prod - TFC - UD - 75 - 350-ACI - en - V04 Version TempDifa LiuNo ratings yet

- BUILDING - ForevaDocument3 pagesBUILDING - ForevaDifa LiuNo ratings yet

- BRIDGES - ForevaDocument4 pagesBRIDGES - ForevaDifa LiuNo ratings yet

- Circular Publication of The Fire Code 2018 EditionDocument3 pagesCircular Publication of The Fire Code 2018 EditionDifa LiuNo ratings yet

- SC Corrosion Book FinalDocument64 pagesSC Corrosion Book FinalDifa Liu100% (1)

- ICP Brochure Technical Specs January 2019 HR PDFDocument16 pagesICP Brochure Technical Specs January 2019 HR PDFLavanyanNo ratings yet

- THERMALDocument7 pagesTHERMALZabihullah SafiNo ratings yet

- R 181 Piles in Rock PDFDocument144 pagesR 181 Piles in Rock PDFDifa LiuNo ratings yet

- R 181 Piles in RockDocument42 pagesR 181 Piles in RockDifa LiuNo ratings yet

- BC1 Handbook Amd ADocument54 pagesBC1 Handbook Amd ACLEMENTNo ratings yet

- Aluminium AnalysisDocument38 pagesAluminium AnalysisDifa LiuNo ratings yet

- Eurocode example ex3.1.4 connection designDocument4 pagesEurocode example ex3.1.4 connection designРостислав Василев100% (2)

- Msds-Grout HGG 70spDocument2 pagesMsds-Grout HGG 70spDifa LiuNo ratings yet

- Design Guide For Structure & FoundationDocument50 pagesDesign Guide For Structure & FoundationDifa Liu100% (1)

- Bolt DesignDocument5 pagesBolt DesignDifa LiuNo ratings yet

- 2013 209 - X-GR-RU Grating Fastening SystemDocument4 pages2013 209 - X-GR-RU Grating Fastening SystemDifa LiuNo ratings yet

- 2nd Choice Steel Connection (All Type) DHAN Good MahfuzDocument19 pages2nd Choice Steel Connection (All Type) DHAN Good MahfuzDifa LiuNo ratings yet

- Grout Optiroc HGG 70spDocument2 pagesGrout Optiroc HGG 70spDifa LiuNo ratings yet

- 2014 257 X-FB - DFTM 2015 Engpdf Technical Information ASSET DOC 2598645Document4 pages2014 257 X-FB - DFTM 2015 Engpdf Technical Information ASSET DOC 2598645Difa LiuNo ratings yet

- Method of Statement For OPTIROC HGG 70SPDocument1 pageMethod of Statement For OPTIROC HGG 70SPDifa LiuNo ratings yet

- Hilti2015 Hi ResDocument674 pagesHilti2015 Hi ResDifa LiuNo ratings yet

- Msds-Grout HGG 70spDocument2 pagesMsds-Grout HGG 70spDifa LiuNo ratings yet

- 2013 265 - X-ET For Fastening Plastic Electrical Cable Trays and Junction Boxes PDFDocument4 pages2013 265 - X-ET For Fastening Plastic Electrical Cable Trays and Junction Boxes PDFDifa LiuNo ratings yet

- 2014 237 X-HS X-CC - DFTM 2015 Engpdf Technical Information ASSET DOC 2597991Document6 pages2014 237 X-HS X-CC - DFTM 2015 Engpdf Technical Information ASSET DOC 2597991Difa LiuNo ratings yet

- 2015 177 X-M6 X-W6 X-M8 M10 W10 - DFTM 2015 Engpdf Technical Information ASSET DOC 2597835Document4 pages2015 177 X-M6 X-W6 X-M8 M10 W10 - DFTM 2015 Engpdf Technical Information ASSET DOC 2597835Difa LiuNo ratings yet

- 2014 423 HT Metal Frame AnchorDocument4 pages2014 423 HT Metal Frame AnchorDifa LiuNo ratings yet

- Reciprocating Cryogenic Pumps & Pump Installations FinalDocument19 pagesReciprocating Cryogenic Pumps & Pump Installations Finaldaimon_pNo ratings yet

- Heating SystemDocument13 pagesHeating SystemFatima GonzalesNo ratings yet

- Radiator Selection GuideDocument36 pagesRadiator Selection GuideOwen PerrinNo ratings yet

- INDUSTRIAL & POWER PLANT DESIGN ELEMENTSDocument11 pagesINDUSTRIAL & POWER PLANT DESIGN ELEMENTSJohn Babe CapiliNo ratings yet

- Designing High-Lift Airfoils Using Inverse Potential FlowDocument25 pagesDesigning High-Lift Airfoils Using Inverse Potential Flowmarco_cj_orgNo ratings yet

- Electrode PDFDocument32 pagesElectrode PDFShrikant MojeNo ratings yet

- Creep Damage and Expected Creep LifeDocument9 pagesCreep Damage and Expected Creep LifeTrương Ngọc SơnNo ratings yet

- Heraeus Hoq 310Document6 pagesHeraeus Hoq 310Karthik GokulNo ratings yet

- 3900 Series Pilot Operated Safety Relief Valve Spec Data Gea20255Document72 pages3900 Series Pilot Operated Safety Relief Valve Spec Data Gea20255peng chaowenNo ratings yet

- Seismic Performance of Large RC Circular Hollow Columns: Giulio RANZO and M J N PriestleyDocument8 pagesSeismic Performance of Large RC Circular Hollow Columns: Giulio RANZO and M J N PriestleyAnonymous 66uWhphVNo ratings yet

- Roxtec UG Cable SealDocument4 pagesRoxtec UG Cable SealMarkNo ratings yet

- TRB 01 21 Rooftop Ductwork Round or RectangularDocument4 pagesTRB 01 21 Rooftop Ductwork Round or Rectangularagb71c2478No ratings yet

- BIWTA - Narayanganj - Estimates 2020.09.04Document1,056 pagesBIWTA - Narayanganj - Estimates 2020.09.04Anand PandeyNo ratings yet

- c19 Practical Electricity CompressedDocument11 pagesc19 Practical Electricity CompressedSherazNo ratings yet

- Designing CO2 Evaporators for Refrigeration SystemsDocument29 pagesDesigning CO2 Evaporators for Refrigeration SystemsgamunozdNo ratings yet

- Proposed Three-Storey Commercial Building (Autosaved)Document113 pagesProposed Three-Storey Commercial Building (Autosaved)Shōya IshidaNo ratings yet

- Farnsworth House SummaryDocument6 pagesFarnsworth House SummaryAshtonNo ratings yet

- rr321401 Principles of Machine DesignDocument8 pagesrr321401 Principles of Machine DesignSRINIVASA RAO GANTA100% (1)

- Solution Manual Heat and Mass Transfer A Practical Approach 2nd Edition Cengel CHDocument62 pagesSolution Manual Heat and Mass Transfer A Practical Approach 2nd Edition Cengel CHJohn A. CenizaNo ratings yet

- Sikagrout 215Document2 pagesSikagrout 215Riska Anshar PramonoNo ratings yet

- Non-Ferrous Alloys and Structure-Properties RelationshipsDocument12 pagesNon-Ferrous Alloys and Structure-Properties RelationshipstareasgratisNo ratings yet

- Condensing and Cooling Efficiently with Adiabatic SystemsDocument17 pagesCondensing and Cooling Efficiently with Adiabatic SystemsIon ZabetNo ratings yet

- 01 02 10 Reference StandardsDocument49 pages01 02 10 Reference StandardsKiran D AnvekarNo ratings yet

- 03 - Different Types of CorrosionDocument3 pages03 - Different Types of CorrosionAnushka SahuNo ratings yet

- IG Seismic Design HousesDocument36 pagesIG Seismic Design HousesmarkNo ratings yet

- Asahi Wafer Check ValveDocument1 pageAsahi Wafer Check ValveDuy Nguyen DucNo ratings yet

- 2 - Part RTVDocument2 pages2 - Part RTVCharles OlsenNo ratings yet

- Screw Pile Solar Mounting Structure for Mountain & Ground InstallationsDocument14 pagesScrew Pile Solar Mounting Structure for Mountain & Ground InstallationsAMIR100% (2)

- Nickel-Iron-Chromium-Silicon Alloy Welded Tube: Standard Specification ForDocument2 pagesNickel-Iron-Chromium-Silicon Alloy Welded Tube: Standard Specification ForEduardoNo ratings yet

- A Paper On Ground Improvement TechniquesDocument18 pagesA Paper On Ground Improvement TechniquesDhyanom GalaNo ratings yet