Professional Documents

Culture Documents

Carberry 1960

Uploaded by

maiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carberry 1960

Uploaded by

maiCopyright:

Available Formats

A

Boundary-Layer Model of

Fluid-Particle Mass Transfer in Fixed Beds

JAMES J. CARBERRY

E. 1. du Pont de Nemours 8 CO., Inc., Wilmington, Delaware

The process of fluid-particle mass transfer in fixed beds a t Reynolds numbers less than 1,OOO

is viewed in terms of transient molecular diffusion within a boundary layer which is developed

and destroyed repeatedly as the fluid journeys through the bed. Literature data support the

j factor derived from the premises of the model. The theory predicts a Schmidt number ex1.

ponent of 2/3 for Ns. 2 1; however this exponent should approach 1/2 for Na,

<

While numerous empirical correlations exist which permit the determination of mass transfer coefficients for

fluid-particle exchange in fixed beds

(10, 11, 15, 22, 3 0 ) , it is nevertheless

of some interest to explore these events

from a theoretical point of view. To

date the most interesting rationalization of fixed bed mass transfer is found

in the recent work of Thoenes and

Kramers (28) who interpreted their

data in terms of mass transfer from a

particle into a fluid network composed

of laminar, turbulent, and stagnant

regimes. The present work attempts to

establigh a rationale in terms of a simplified boundary-layer theory. Although

this study is confined to mass transfer,

the model 'may well be extended to

heat transfer in fixed beds.

Higbie (14) made one of the earliest

attempts to relate the average mass

transfer coefficient to the species diffusivity and the average time of fluid

element exposure to sink or source by

contribution by applying the HigbieDanckwerts penetration model to predict the experimental concentrationprofile data found in the mass transfer

studies of Lin, Moulton, and Putnam

(19). Since the data treated were obtained in the region of turbulent flow,

it is apparent that the exchange involved transfer from the source to

eddies, and therefore the velocity

gradient in the fluid has no influence

upon the diffusive process. In a comparable circumstance Johnson and Huang

(16) found evidence to support the

penetration model in their study of

solids dissolution in an agitated vessel.

It should be emphasized that an independent evaluation of e is not possible

in exchange events between eddies and

a sink or source, and evidence for support of Higbie theory or the Danckwerts modification thereof rests upon

finding a 1/2 power dependence of the

transfer rate upon the Schmidt number.

DIFFUSION WITHIN A DEVELOPING

BOUNDARY LAYER

Higbie's model follows via solution

Higbies' theory has been verified in

investigations in which the boundary

conditions inherent in the model have

been satisfied experimentally (7, 21,

26). One of the key and limiting assumptions in this model is that specifying the absence of a velocity gradient

at the transfer interface. Transfer processes between a solid and flowing fluid

obviously occur across a boundary at

which a velocity gradient must exist;

consequently the influence of velocity

upon the diffusive process must be assessed. In the case of simple geometries

the transfer processes may be readily

predicted for an assumed velocity distribution. Heat transfer literature reveals well-known examples such as the

solution of Leveque (18) for heat

transfer between a laminar fluid and a

pipe wall. Kramers (17) applied an

analogous model to mass transfer from

a wall to a laminar falling film.

In the instance of turbulent exchange

Hanratty ( 1 3 ) has made a significant

Page 460

of

[ ( b + l)K]lI(a+2)(a+2)o/(a+Z)D(o+l)/(a+Z)

[ 1/ (a+2) ] ( x / u , )(b+l)/(e+2)

b/(a+z)

(5)

It will be recognized that the fluid

velocity component in the y direction,

perpendicular to flow, has been ignored

in formulating the basic differential

equation. The author has assumed

that the term u dc/dy is negligible relative to u aclay. A consideration of the

perpendicular component alters the coefficient of the derived relationship

[Equation (14)] by about 20%, but

in no way is the indicated functionality

changed ( 2 4 ) .

Equation (5) reduces readily to a

number of interesting cases corresponding to various value of a and b:

a = b = 0,Higbie's model.

k= 2

a

1, b

F

- where 0

?re

= X/u, (6)

= 0, Leveque

approximation

K DZ 118

k = 0.808

(-)

(7)

X/U"

Equation (7) is identical to that derived by Kramers ( 1 7 ) for solid dissolution into a falling film.

The instance of diffusion within a

developing boundary layer is approximated by a = 1 and b = M; that is

__

u / u , = Ky/

where the fluid velocity is invarient in

x and y. It will prove fruitful however

to express u as a function of these distance variables as

u/u. = ( K Y ) " / ( ~ ) ~

u.3

(3)

Thus Equation (3) becomes

dC

If the velocity at the boundary-layer

edge, u,, is expressed in terms of the

average as u, = 2u,, Equation (9)

reduces to

(4)

0.815 y/

d -,u

v x -

Mixon and Carberry (24) have obtained a solution to Equation (4),

expressing the average mass transfer

For a = 1 and b

coefficient in terms of the exponents

(5) becomes

a and b:

k=

(a+2)

[ (a+2)-(b+l)

A.1.Ch.E. Journal

(8)

Boundary-layer theory ( 2 7 ) teaches

that the linear velocity approximation

is

U/U, =

dE

a,

k=

.K

= 0.815

(10)

= y2

Equation

1.15 D'/'

(x/u,)'J2

Y'16

(11)

September, 1960

data of Gaffney and Drew for N,, =

10,500. These authors noted however

that natural-convection effects were

evident in that: system at low flow

rates. The data of Baddour and Gilliland (1) for dilute solution ion exchange are shown in the i factor form

as recalculated and presented by Moison and OHern ( 2 5 ) .

Obviously not all of the literature

data were considered in testing the

theory. Ergun (9) has made a critical

examination of fixed-bed mass transfer

data, and the literature utilized in the

present instance was chosen from those

studies which evidenced reproducibility and absence of axial mixing effects

as noted by Ergun. The latter problem

was found to be a prominent one (9)

and has been discussed previously ( 3 ,

8, 2 0 ) .

I00

10

(Ion Exchange)

4%

I

0.I

0.01

0.1

10

opvo

1000

I00

I0,ooO

DISCUSSION

NRe,.

Fig.

I . Fixed bed mass transfer in terms of boundary-layer theory.

APPLICATION TO FIXED BED

TRANSFER PROCESSES

The precise characterization of flowing fluid behavior in a fixed bed is

hardly possible at this time. It is perhaps equally difficult to define the

geometry of the fixed phase as it is

seen by the flowing fluid. Nevertheless

if the fixed bed is viewed as a series of

discrete surfaces separated at points

by void cells, it might be argued that

in the flow regime below fully developed turbulence the fluid, in its journey through the bed, must experience

a succession of boundary-layer developments and destructions. During a given

boundary-layer development over a

distance x diffusion or penetration of a

species will occur between fluid and

the fixed surface. If it is assumed that

the velocity within the developing

boundary layer at the transfer boundary

can be approximated by Equation

( l o ) , then the specification of % by

Equation (11) is possible if x can be

defined for a fixed bed.

A specification of x is possible in the

light of recently acquired axial-dispersion data for fixed beds which suggest

that, for gases, mixing of a perfect

nature occurs about once every particle diameter ( 2 3 ) . Liquid-dispersion

data present a more complex problem

( 4 , 6 ) ; however if a model suggesting

imperfect fluid mixing in each void cell

is tolerable ( 5 ) , then in terms of the

developing boundary-layer notion it

can be argued that the boundary layer

ought to suffer destruction at the mixing points. In other words the boundary

layer develops and collapses over a

Vol. 6, No. 3

distance approximately equal to one

particle diameter.

and recalling the definition of the

Schmidt number, N,, = v / D , one can

reduce Equation (11) to

-

1.15 U , NRe-lJa

Ns c-2/s

(13)

In terms of a boundary layer i factor,

bed void fraction, and the average

superficial velocity based upon tube

cross-sectional area

-

i.,,

k

-

NsC2" = 1.15 NRs?

(14)

U"

A comparison of the theoretical relation with empirical correlations indicates that the literature i factors are

usually based upon superficial velocity.

Thus the derived equation can be

tested against experimental data by

correcting the published i factors with

the void fraction encountered in the

experiments and plotting the resulting

i values against the Reynolds number

based upon average velocity in the

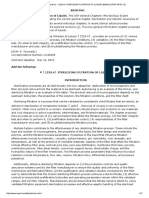

bed. Figure 1 displays the comparison

of literature data with Equation (14).

A Schmidt number variation of from

0.6 to 10,500 is represented by the

data for such diverse transfer processes

as vaporization, solids dissolution, dilute solution ion exchange, and chromatography. The agreement between

data and theory is quite good with the

exception of the low Reynolds number

A.1.Ch.E. Journal

The limits of applicability of the

derived equation deserve comment. In

view of the model invoked Equation

(14) should be applicable until the

flow rate approaches the value corresponding to turbulent boundary-layer

development. The precise value of the

Reynolds number at which the transition occurs in a packed bed is difficult

to specify. If the character of the

packed-bed friction factor-Reynolds

number functionality as well as axial

dispersion-flow rate relationships ( 4 )

permit an inference, then fully developed turbulent flow and therefore turbulent boundary-layer development

takes place in the Reynolds number

region of about several hundred. The

data shown in Figure 1 would suggest

that the model is valid to about NRe of

1,000.

The lower flow regime limit of applicability is difficult to define in view

of the natural-convection effects on one

hand and the specification of x on the

other. It is not inconceivable that at

very low rates of flow, boundary-layer

development may occur over a distance greater than one particle diameter. Thus x itself becomes a function

of flow rate; that is x 00 l/NRa at Nle

<< 1. Such a circumstance would lead

to a decrease in i with decreasing

values of NRe, a result verified recently

by the data of Bar-Ilan and Resnick

(2) and more recently by Hamilton

(12).

TRANSFER RATES AT THE WALL

The recent work of Yagi ( 3 2 ) on

heat and mass transfer at the wall of

the packed bed might be interpreted

in the light of the boundary-layer

notion developed here. Data for mass

transfer between water and the coatedtube wall of a packed bed were correlated by Yagi with the equation

Page 461

boundary layer. However systems characterized by high diffusivity, Ns,<l,

present an interesting circumstance in

(15) which the concentration boundary

When one assumes an average void layer becomes larger than the hydrofraction of 0.4, the above relationship dynamic one. In other words the hydromay be written on the basis of the dynamic boundary layer tends, by

average fluid velocity within the bed: reason of rapid diffusion, to become

saturated in the case of transfer from

the surface to the fluid. Under these

circumstances the transfer rate will no

longer be governed by the velocity

gradient at the surface but dictated by

While this functionality is identical the velocity gradient at a point closer

to that derived above [Equation (14) 1, to the hydrodynamic boundary-layer

the j relations differ by a constant edge. To the extent that the velocity

factor of about 3. In terms of the profile is nonlinear at this point, the

model suggested in this work the wall power upon the Schmidt number will

transfer data would tempt one to be less than 2/3. Therefore at Schmidt

speculate that the boundary layer at numbers less than unity a power delow flow rates along the wall of a pendency approaching 1/4! should be in

packed bed develops over a distance evidence. Data for Schmidt numbers of

equivalent to several particle diam- about unity or less (for example 0.6

eters. Thus Equation (14) is perhaps for air-water vapor) hardly provide a

best written for both transfer at the valid test; however Lynch and Wilke

tube wall and fluid-particle transfer at ( 2 0 ) recently presented data characterized by a Schmidt number of 0.24.

low values of N,. as

Their careful analysis of these data rej B L = 1.15 (niVRe)-I1' (17) vealed that the Schmidt exponent is

An alternative model of wall-fluid close to 1/2. Indeed this fact was interheat transfer has been presented by preted by Wilke ( 3 1 ) as perhaps being due to a concentration boundaryHanratty ( 1 3 a ) .

The anomalies at low Reynolds layer effect.

With respect to gas-liquid systems

numbers and the transfer events at

(for

example absorption of a gas by a

the wall of a packed bed present opliquid

flowing through a packed colportunities for further experimentation

umn)

it

might be expected that the

designed in a manner which will confirm or deny mechanistic speculations. Schmidt number exponent be 2/3 for

A quantitative specification of n and the gas film, where a velocity gradient

its dependence upon velocity near the exists, and 1/2 for the liquid film, where

wall is required to clarify the rate for slight penetration the velocity

process at that point, while the rela- gradient in the liquid film adjacent to

tionship between n and the Reynolds the gas is probably negligible ( 7 ) .

The foregoing remarks do not apply

number must be determined to rato

transfer processes in turbulent flow,

tionalize particle-fluid exchange data at

very low flow rates. Studies of wall- a topic which has been treated by Toor

fluid transfer rates in which the inner and Marchello (29).

surface of the packed tube is corm- CONCLUSIONS

gated or coated with pellets identical

The concept of diffusion within a

to the packing should reveal the extent

boundary

layer which is repeatedly

to which presence of a smooth exchange surface extends the boundary- developed and destroyed over a dislayer life and thereby reduces the tance equal to one particle diameter is

apparently supported by literature

average exchange rate at the wall.

data for particle-fluid exchange in fixed

beds. Additional research efforts are

SCHMIDT NUMBER FUNCTIONALITY

needed to provide data and interpretaEquation ( 5 ) states that the expo- tion at very low Reynolds numbers.

nent upon the Schmidt number is Further studies are required in systems

governed by the value of the term (a+ where the Schmidt number is signifil ) / ( a + 2 ) . Hence the exponent must cantly less than 1 to provide additional

always lie between 1/2 and 2/3 as the support for the contention that saturavelocity at the transfer boundary is tion of the hydrodynamic boundary

either a linear or less than linear func- layer results in a Schmidt exponent

tion of distance ( 1 2 ~ 2 0 )The

.

reason- approaching y2.

It is possible that transfer rates in

ing which follows may clarify this

other systems, for example fluidized

point.

Where the diffusivity of the species beds, might be interpreted in terms, of

is low (high Schmidt number), the an appropriately modified version of

region of transfer resistance most .cer- the boundary-layer model suggested

tainly lies within the hydrodynamic here.

U, (Nsc)'"= 0.60 NR.*-"';

Page 462

NRer

ACKNOWLEDGMENT

<40

A.1.Ch.E. Journal

The criticisms, insights, and suggestions

of Professor T. J. Hanratty were invaluable aids to the development of this work.

NOTATION

a, b

c

D,

iD

jsL

K

-

2,

exponents in velocity-distribution relation, Equation

(3)

= concentration of

diffusing

species

= molecular diffusivity

= particle diameter

= mass transfer j factor

= i factor defined by Equation

(14)

= coefficient defined by Equations (3) and (10)

= average mass transfer coefficient

= number of particle diameters

of length, Equation (17)

= Reynolds number, D,,u,/vQ

= Reynolds number, D,u./v

= Schmidt number

= fluid velocity

= superficial velocity

= average velocity in a packed

bed, u. = u./e

= velocity at boundary-layer

edge

= fluid-velocity component

= distance in direction of flow

= distance

perpendicular to

flow

=

Greek Letters

E

0

37

fractional void volume

kinematic viscosity

= time

= 3.1416

= gamma function

=

=

LITERATURE CITED

1. Baddour, R. F., and E. R. GilLiland,

Ind. Eng. Chem., 45, 330 (1953).

2. Bar-Ilan, M., and William Resnick,

ibid., 49, 313 (1957).

3. Carberry, J. J., Can. J . Chem. Eng.,

36, 207 ( 1958).

4. , and R. H. Bretton, A.l.Ch.E.

Journal, 4, 367 ( 1958).

5. Carberry, J. J., ibid., 4, 13M (1958).

6. Ebach, Earl, and R. R. White, ibid., 4,

161 (1958).

7. Emmert, R. E., and R. L. Pigford,

Chem. Eng. Progr., 50, 87 (1954).

8. Epstein, Norman, Can. J . Chem. Eng.,

36, 210 (1958).

9. Ergun, Sabri, Chem. Eng. Progr., 48,

227 (1952).

10. Gaffney, B. W., and T. B. Drew, Ind.

Eng. Chem., 42, 1120 (1950).

11. Gamson, B. N., George Thodos, and

0. A. Hougen, Trans. Am. Inst.

Chem. Engrs., 39, 1 (1943).

12. Hamilton, P. B., Alfred I. du Pont Institute, Private Communication ( 1959).

13. Hanratty, T. J., A.1.Ch.E. Journal, 2,

359 (1956).

13~.

, Chem. Eng. Sci., 3, 209

( 1954).

September, 1960

14. Higbie, Ralph, Trans. Am. Inst. Chem.

E n rs., 31, 365 ( 1935).

15. Ho son, Merk, and George Thodos,

Chem. Eng. Progr., 47, 370 (1951).

16. Johnson, A. I., and Chen-Jung Huang,

A.1.Ch.E. Journal, 2, 412 (1956).

17. Kramers, H., and P. J. Kreyger, Chem.

Eng. Sci., 6, 42 (1956).

18. Leveque, J., Ann. Mines, 13, 283

(1928).

19. Lin, C. S., R. W. Moulton, and G. L.

Putnam, Id.Eng. Chem., 45, 636

(1953).

20. Lynch, E. J., and C. R. Wilke, to be

published, A.l.Ch.E. Journal.

21. Lynn, Scott, J. R. Straatemeier, and

22.

23.

24.

25.

26.

27.

H. Kramers, Chem. Eng. Sci., 4, 58

1955).

McCune, L. K., and R. H. Wilhelm,

I d . Eng. Chem., 41, 1124 (1949).

McHenry, K. W., and R. H. Wilhelm,

A.I.Ch.E. Journal, 3, 83 (1957).

Mixon, F. O., and J. J. Carberry, to

be published, Chem. Eng. Sci.

Moison, R. L., and H. A. OHem,

Chem. Eng. Progr. Symposium Series

No. 24, 55,. 71 ( 1959).

Raimondi, Pietro, and H . L. Toor,

A.1.Ch.E. Journul, 5, 86 (1959)

Schlichting, Hermann, Boundary

Layer Theory, Pergamon Press, New

York, ( 1955).

28. Thoenes, D., and H. Kramers, Chem.

Eng. Sci., 8, 271 (1958).

29. Toor, H. L., and J. M. Marchello,

A.I.Ch.E. J O U T ~ ,4, 97 (1958).

30. Wilke, C. R., and 0. A. Hougen,

Trans. Am. Inst. Chem. Engrs., 41,

445 (1945).

31. Wilke, C. R., Remarks at St. Paul,

Minn., A.1.Ch.E. Meeting (Sept.,

1959).

32. Yagi, Sakae, and Noriaki Wakao,

A.l.Ch.E. Journal, 5, 79 (1959).

Manuscript received Au ust 3 1959. revisfon

received December 28 19$: paGer acc&ted December 28, 1959. P a & r presented at A.I.Ch.E.

St. Paul meeting.

Entrainment and Pressure Drop in

Concurrent G a s

I. Air

Water in

Flow:

Horizontal Flow

Liquid

MOYE WICKS, 111, and A. E. DUKLER

University of Houston, Houston, Texas

Experimental equipment and data are reported for entrainment and energy loss in annular,

two-phase flow of water and air. Measurements were made with a sample withdrawal technique

in 1- and 3-in. horizontal tubes. A knowledge of entrainment is necessary to an understanding

of various mass transfer, heat transfer, and separation problems in two-phase flow. A preliminary correlation is presented.

Research in two-phase gas-liquid

flow has increased steadily over the

past ten years, In addition to a longstanding need for a better theoretical

understanding of this type of flow the

demands of a group of important industrial problems have accelerated this

work.

Several investigators (8, 17) have

demonstrated that when two phases

flow together in a tube the liquid and

gas streams can assume several different shapes. At high gas rates a predominant pattern is annular flow with

the liquid at the wall and the gas moving in the core. This type of flow is

thought to be accompanied by a dispersion or entrainment of part of the

liquid in the gas phase. Entrainment is

of considerable importance to an understanding of mass transfer, heat

transfer, separation processes, and

energy loss. This paper reports the first

phase of a program to study entrainment. Equipment designed for direct

measurement of entrainment and entrainment distribution is described.

Vol. 6, No. 3

Experimental data on the air-water

system is presented and preliminary

correlation is proposed.

PREVIOUS STUDIES

Experimental data on entrainment

or entrainment-measuring techniques

in moving gas streams are very limited

in the literature. Several studies of

drop distribution from nozzles, spray

chambers* and

disks ( I 6 ) can

be found* However in each Of these

cases the amount of liquid dispersed

can be predetermined by the experimenter and the problems restricted to

a study of drop-size distribution, spray

areas, etc. In two-phase flow the entrainment is generated by the action

AIR CONTROL

PROSE DETAILS

Fig. 1. Experimental equipment.

A.1.Ch.E. Journal

Page 463

You might also like

- Ion Association in Proton Transfer Reactions: Use of ESR for the Quantitative Determination of Gas Phase Atom and Radical ConcentrationsFrom EverandIon Association in Proton Transfer Reactions: Use of ESR for the Quantitative Determination of Gas Phase Atom and Radical ConcentrationsNo ratings yet

- Samsung LN26A330J1D Chasis N45A PDFDocument173 pagesSamsung LN26A330J1D Chasis N45A PDFMiguel Arcangel Mejias MarreroNo ratings yet

- Convective Mass TransferDocument13 pagesConvective Mass TransferAriadne ChuaNo ratings yet

- Convective Mass Transfer PDFDocument14 pagesConvective Mass Transfer PDFAnonymous 4XZYsImTW5100% (1)

- Iv PDFDocument41 pagesIv PDFEd Gar YundaNo ratings yet

- Mills Heat TransferDocument3 pagesMills Heat TransferNatrix20% (1)

- AIChE Journal Volume 2 Issue 4 1956 (Doi 10.1002 - Aic.690020410) W. A. Selke Y. Bard A. D. Pasternak S. K. Aditya - Mass Transfer Rates in Ion ExchangeDocument3 pagesAIChE Journal Volume 2 Issue 4 1956 (Doi 10.1002 - Aic.690020410) W. A. Selke Y. Bard A. D. Pasternak S. K. Aditya - Mass Transfer Rates in Ion Exchangetakkar1392No ratings yet

- Diffusion and Flow of Gases in Porous SolidsDocument12 pagesDiffusion and Flow of Gases in Porous SolidsSal HashemifardNo ratings yet

- Progress in The Development of A Reynolds-Stress Turbulence ClosureDocument30 pagesProgress in The Development of A Reynolds-Stress Turbulence ClosureMutiaRezaNo ratings yet

- Mass Transfer Coefficient ExplainedDocument37 pagesMass Transfer Coefficient ExplainednivedhithaNo ratings yet

- Effect of Chemical Reaction On Mass Transfer Over A Stretching Surface Embedded in A Porous MediumDocument9 pagesEffect of Chemical Reaction On Mass Transfer Over A Stretching Surface Embedded in A Porous MediumInternational Journal of computational Engineering research (IJCER)No ratings yet

- Application of Ergun Equation To Computation of Criticalication of Ergun Equation To Computation of CriticalDocument21 pagesApplication of Ergun Equation To Computation of Criticalication of Ergun Equation To Computation of CriticalNovianto J. SunarnoNo ratings yet

- Paper13 PhysRevLett 98 155702Document4 pagesPaper13 PhysRevLett 98 155702ivandornicNo ratings yet

- Thin Films and Moving Contact Lines: The Mathematics of Fourth-Order Degenerate DiffusionDocument9 pagesThin Films and Moving Contact Lines: The Mathematics of Fourth-Order Degenerate DiffusionVetPhoenix StkNo ratings yet

- Flow of Fluids through Fixed BedsDocument39 pagesFlow of Fluids through Fixed BedsHasbi AsshidiqiNo ratings yet

- Mass Transfer in Fixed BedsDocument4 pagesMass Transfer in Fixed BedsGustavo Gabriel JimenezNo ratings yet

- Commun Nonlinear Sci Numer Simulat: Sung-Ik SohnDocument6 pagesCommun Nonlinear Sci Numer Simulat: Sung-Ik SohnRebecca ClarkNo ratings yet

- Jce-1983-393 - Modernization of The Van Deemter EquationDocument6 pagesJce-1983-393 - Modernization of The Van Deemter EquationSolomon EricksonNo ratings yet

- Application of Ergun Equation To Computation of Criticalication oDocument21 pagesApplication of Ergun Equation To Computation of Criticalication oAbdallah abdellaouiNo ratings yet

- Modeling Fouling of Rough Surfaces by Colloidal Particles in Turbulent FlowsDocument8 pagesModeling Fouling of Rough Surfaces by Colloidal Particles in Turbulent FlowsmaycvcNo ratings yet

- MOLECULAR DIFFUSIONDocument10 pagesMOLECULAR DIFFUSIONchitreauNo ratings yet

- CFD Simulations of Lid Driven Cavity Flow at Moderate Reynolds NumberDocument14 pagesCFD Simulations of Lid Driven Cavity Flow at Moderate Reynolds NumberVivek JoshiNo ratings yet

- SzymkiewiczDocument20 pagesSzymkiewiczAbdoulaye PouyeNo ratings yet

- The Molecular-Kinetic Theory of WettingDocument3 pagesThe Molecular-Kinetic Theory of WettingMahdi koolivandNo ratings yet

- Topological Aspect of Disclinations in Two-Dimensional MeltingDocument6 pagesTopological Aspect of Disclinations in Two-Dimensional MeltingBayer MitrovicNo ratings yet

- A E E C C S V S S: Nian-Sheng ChengDocument25 pagesA E E C C S V S S: Nian-Sheng ChengqgfreireNo ratings yet

- Colloquium FLUID DYNAMICS 2013 Institute of Thermomechanics AS CR, V.v.i., Prague, October 23 - 25, 2013 1Document5 pagesColloquium FLUID DYNAMICS 2013 Institute of Thermomechanics AS CR, V.v.i., Prague, October 23 - 25, 2013 1SangeethaVairavanNo ratings yet

- Janzen Et Al 2010 Estimation of Mass Transfer VelocityDocument13 pagesJanzen Et Al 2010 Estimation of Mass Transfer VelocityFrancisco OppsNo ratings yet

- Distribution Eddy Viscosity Length: Mixing inDocument6 pagesDistribution Eddy Viscosity Length: Mixing inGustavo Gabriel JimenezNo ratings yet

- Comparing transport-limited and ξ-q models for sediment transportDocument39 pagesComparing transport-limited and ξ-q models for sediment transportSimoNo ratings yet

- Galilean Invariant Fluid-Solid Interfacial Dynamics in Lattice Boltzmann SimulationsDocument22 pagesGalilean Invariant Fluid-Solid Interfacial Dynamics in Lattice Boltzmann SimulationsMücahitYıldızNo ratings yet

- Progress in The Development of A Reynolds Stress TDocument31 pagesProgress in The Development of A Reynolds Stress TSmith Diaz VasquezNo ratings yet

- Flow and Heat Transfer of A Power-Law Fluid Over A Permeable Shrinking SheetDocument6 pagesFlow and Heat Transfer of A Power-Law Fluid Over A Permeable Shrinking SheetHendarNo ratings yet

- A4........ ACoupled Vibration of A Cantilever Micro-Beam SubmergedDocument10 pagesA4........ ACoupled Vibration of A Cantilever Micro-Beam SubmergedyohannesNo ratings yet

- Sinking of A Horizontal Cylinder: Dominic VellaDocument3 pagesSinking of A Horizontal Cylinder: Dominic VellaJuan Manuel ScarpettaNo ratings yet

- Modelling Sedimentation in Activated Sludge ProcessDocument18 pagesModelling Sedimentation in Activated Sludge ProcessDenis TanNo ratings yet

- Comparison of the Effects of k-, k-ω, and Zero Equation Models on Characterization of Turbulent Permeability of Porous MediaDocument8 pagesComparison of the Effects of k-, k-ω, and Zero Equation Models on Characterization of Turbulent Permeability of Porous MediaGanesh GPNo ratings yet

- Modelling evaporation from a capillaryDocument36 pagesModelling evaporation from a capillaryDiego JesusNo ratings yet

- Non-Newtonian Flow in Annuli: of ofDocument6 pagesNon-Newtonian Flow in Annuli: of ofJames GarciaNo ratings yet

- France (1974)Document18 pagesFrance (1974)julianaNo ratings yet

- Boundary Conditions High-Shear Grain Flows: by Hui, Haff, J. E. UngarDocument11 pagesBoundary Conditions High-Shear Grain Flows: by Hui, Haff, J. E. UngarKhalid EL ABBAOUINo ratings yet

- Two-Dimensional Turbulence Dispersion in A Closed Domain: Influence of Confinement and GeometryDocument12 pagesTwo-Dimensional Turbulence Dispersion in A Closed Domain: Influence of Confinement and GeometryLetyNo ratings yet

- Classification of The Group Invariant Solutions For Contaminant Transport in Saturated Soils Under Radial Uniform Water OwsDocument21 pagesClassification of The Group Invariant Solutions For Contaminant Transport in Saturated Soils Under Radial Uniform Water OwsLuis Alberto FuentesNo ratings yet

- Assessment of A New Fluent Model For Particle Dispersion in Turbulent FlowsDocument18 pagesAssessment of A New Fluent Model For Particle Dispersion in Turbulent FlowsgarridolopezNo ratings yet

- Mathematical Proceedings of the Cambridge Philosophical Society Volume 69 issue 3 1971 [doi 10.1017_s0305004100046880] Packham_ B. A._ Shall_ R. -- Stratified laminar flow of two immiscible fluids.pdfDocument6 pagesMathematical Proceedings of the Cambridge Philosophical Society Volume 69 issue 3 1971 [doi 10.1017_s0305004100046880] Packham_ B. A._ Shall_ R. -- Stratified laminar flow of two immiscible fluids.pdfSrinivas JangiliNo ratings yet

- H.K. Moffatt - Some Remarks On Topological Fluid MechanicsDocument8 pagesH.K. Moffatt - Some Remarks On Topological Fluid MechanicsVortices3443No ratings yet

- Draft ASMEDocument21 pagesDraft ASMEManoj TripathiNo ratings yet

- Numerical modeling of drying shrinkageDocument72 pagesNumerical modeling of drying shrinkageAnonymous q8HhQ4wNo ratings yet

- Hydrodynamics of Highly Viscous Flow Past A Compound Particle: Analytical SolutionDocument15 pagesHydrodynamics of Highly Viscous Flow Past A Compound Particle: Analytical SolutionMojeime Igor NowakNo ratings yet

- A Similarity Solution For The Gulf Stream: Technical Report No. 30 (WB-E55A Series)Document30 pagesA Similarity Solution For The Gulf Stream: Technical Report No. 30 (WB-E55A Series)Yazid Al ShehriNo ratings yet

- Heat Transfer in Rotating Porous MediaDocument8 pagesHeat Transfer in Rotating Porous MediaRicardo SilvaNo ratings yet

- Solute Transport in Hetro Porous MediaDocument46 pagesSolute Transport in Hetro Porous MediaRupali SatavalekarNo ratings yet

- Weiss Enstrophy TransferDocument22 pagesWeiss Enstrophy Transfersamik4uNo ratings yet

- ModelefewxDocument8 pagesModelefewxAndres PalchucanNo ratings yet

- Calculation of Axially Symmetric Cavities and Jets: P. R. GarabedianDocument74 pagesCalculation of Axially Symmetric Cavities and Jets: P. R. GarabedianNguyen QueNo ratings yet

- Transport Phenomena (CHE-345) : Interphase Transport and Transfer Coefficients Ismail TosunDocument21 pagesTransport Phenomena (CHE-345) : Interphase Transport and Transfer Coefficients Ismail Tosunmuhammad shahadat awanNo ratings yet

- PETSOC 08-03-55 Model WorkDocument7 pagesPETSOC 08-03-55 Model WorkMejbahul SarkerNo ratings yet

- Capillary Correction To Buckley LeverettDocument19 pagesCapillary Correction To Buckley LeverettChun YanNo ratings yet

- FLATModel para Flujo de Detritos y Deslizamento de Tierra Casos de EjemplosDocument12 pagesFLATModel para Flujo de Detritos y Deslizamento de Tierra Casos de EjemplosAaron Arango AyalaNo ratings yet

- On The Dispersion of A Solute in A Fluid Flowing Through A TubeDocument11 pagesOn The Dispersion of A Solute in A Fluid Flowing Through A TubeCoraKiriNo ratings yet

- Emergency Response Plan LayoutDocument2 pagesEmergency Response Plan LayoutmaiNo ratings yet

- Boundary Layer Theory ExplainedDocument51 pagesBoundary Layer Theory ExplainedMohamed Sayed SolimanNo ratings yet

- Boundary Layer Theory ExplainedDocument51 pagesBoundary Layer Theory ExplainedMohamed Sayed SolimanNo ratings yet

- Prandtl S Boundary Layer TheoryDocument7 pagesPrandtl S Boundary Layer TheoryGibran GarnicaNo ratings yet

- Packed Amine Absorber Simulation Tracks Plant PerformanceDocument14 pagesPacked Amine Absorber Simulation Tracks Plant Performancematrix69No ratings yet

- Finding a feasible fugacity approachDocument6 pagesFinding a feasible fugacity approachMatias Herrera CornejoNo ratings yet

- Unit 1 Concept and TheoryDocument57 pagesUnit 1 Concept and TheoryRahaf HammadNo ratings yet

- Heat and Mass Transfer 2mark QuestionsDocument12 pagesHeat and Mass Transfer 2mark QuestionsRohit KalyanNo ratings yet

- Drug Release Kinetics ModelsDocument7 pagesDrug Release Kinetics ModelsSajid Khan SadozaiNo ratings yet

- NMR Properties of Reservoir FluidsDocument13 pagesNMR Properties of Reservoir FluidsLorena Pastana MartinsNo ratings yet

- Phosgene Micro Reactor A I CheDocument9 pagesPhosgene Micro Reactor A I CheJorge RamirezNo ratings yet

- Diffusion-Controlled Deposition On Fibers and SurfacesDocument8 pagesDiffusion-Controlled Deposition On Fibers and Surfacescwellard1No ratings yet

- Lecture Notes 03 Mass and Heat Transfer in Steady State 1276989501 Phpapp01Document51 pagesLecture Notes 03 Mass and Heat Transfer in Steady State 1276989501 Phpapp01rejie magnayeNo ratings yet

- Combustion Fundamental PDFDocument33 pagesCombustion Fundamental PDFmahreza189No ratings yet

- Computer Simulation of Sugar Crystallization in Confectionery Products PDFDocument8 pagesComputer Simulation of Sugar Crystallization in Confectionery Products PDFFelipe RiveraNo ratings yet

- Christian Hansen - Bactoferm Meat Manual Vol. 3 - 2013Document34 pagesChristian Hansen - Bactoferm Meat Manual Vol. 3 - 2013МихаилNo ratings yet

- Take A Deep BreathDocument5 pagesTake A Deep BreathMelanie DeivenNo ratings yet

- One-Family House Acoustic ModelDocument16 pagesOne-Family House Acoustic Modelaurora borealissNo ratings yet

- Report 2Document17 pagesReport 2Nisha FareenaNo ratings yet

- Sterilizing Filtration Process OverviewDocument11 pagesSterilizing Filtration Process OverviewRangga120890No ratings yet

- Scheme For Trial STPM Biology Term 1 2022 Set 2Document7 pagesScheme For Trial STPM Biology Term 1 2022 Set 2RuoQi LeeNo ratings yet

- Heat and Mass Transfer in Packed Beds-Iii.Document9 pagesHeat and Mass Transfer in Packed Beds-Iii.Jesús Miguel Jacinto NavaNo ratings yet

- Mass Transfer I Online Education 1. Week DuzelDocument20 pagesMass Transfer I Online Education 1. Week DuzeljormungandNo ratings yet

- V. Kulish Human Respiration Anatomy and Physiology - Mathematical Modeling - Numerical Simulation and Applications Advances in Bioengineering 2006Document243 pagesV. Kulish Human Respiration Anatomy and Physiology - Mathematical Modeling - Numerical Simulation and Applications Advances in Bioengineering 2006Sofiah QotrunadaNo ratings yet

- Field Scale Simulation of Cyclic Solvent Injection (CSI) 2Document15 pagesField Scale Simulation of Cyclic Solvent Injection (CSI) 2Jhon Alex PabonNo ratings yet

- IGCSE Chemistry Revision Notes on Particulate Nature of MatterDocument3 pagesIGCSE Chemistry Revision Notes on Particulate Nature of MatterNikhil YadavNo ratings yet

- Corrosion of Ceramic and Composite MaterialsDocument407 pagesCorrosion of Ceramic and Composite MaterialsKhin Aung ShweNo ratings yet

- Fogler - ECRE - CDROM - Book Page 830 Wednesday, September 17, 2008 5:01 PMDocument8 pagesFogler - ECRE - CDROM - Book Page 830 Wednesday, September 17, 2008 5:01 PMCurieNo ratings yet

- International Journal of Heat and Mass Transfer: Kai Yang, Fangjun Hong, Ping ChengDocument12 pagesInternational Journal of Heat and Mass Transfer: Kai Yang, Fangjun Hong, Ping ChengHassan AbdelmoamenNo ratings yet

- JNTU Old Question Papers 2007Document7 pagesJNTU Old Question Papers 2007Srinivasa Rao G100% (1)

- Oxidation Kinetics of Molten Copper SulphideDocument244 pagesOxidation Kinetics of Molten Copper Sulphidemariu_rdsiNo ratings yet

- Morphological Evolution Thick Wax Deposits During Aging: Mechanics and Transport PhenomenaDocument13 pagesMorphological Evolution Thick Wax Deposits During Aging: Mechanics and Transport PhenomenaAbhay Pratap SinghNo ratings yet

- Cambridge - Igcse.biology - Mapped.against - Edexcel.ig FinalDocument86 pagesCambridge - Igcse.biology - Mapped.against - Edexcel.ig FinalBenish RehanNo ratings yet

- BHRAMANKAR - BiopharmaceuticsDocument410 pagesBHRAMANKAR - Biopharmaceuticsbhargav42787% (293)

![Mathematical Proceedings of the Cambridge Philosophical Society Volume 69 issue 3 1971 [doi 10.1017_s0305004100046880] Packham_ B. A._ Shall_ R. -- Stratified laminar flow of two immiscible fluids.pdf](https://imgv2-1-f.scribdassets.com/img/document/369976502/149x198/e221873304/1516893704?v=1)